- DL manuals

- Daewoo

- Air Conditioner

- DMB-1822LH

- User Manual

Daewoo DMB-1822LH User Manual

CONTENTS

1. SPECIFICATIONS.....................................................................................................2

2. CONFIGURATION.....................................................................................................4

3. OUTLINE AND DIMENSIONS .................................................................................5

4. INSTALLATION SECTION......................................................................................10

5. OPERATION............................................................................................................26

6. WIRING DIAGRAM.................................................................................................41

7. REFRIGERANT CYCLE.........................................................................................45

8. CONTROL BLOCK DIAGRAM...............................................................................46

9. TROUBLE SHOOTING...........................................................................................48

10. PCB DRIVING DESCRIPTION............................................................................54

11. KEY COMPONENTS OF ELECTRONIC CIRCUIT ...........................................76

12. DISASSEMBLY INSTRUCTIONS........................................................................80

1) Indoor Unit ........................................................................................................80

2) Outdoor Unit .....................................................................................................83

3) Exploded Diagram (Indoor Unit)......................................................................84

4) Exploded Diagram (Outdoor Unit)...................................................................92

5) Control Box Assembly......................................................................................96

6) Control Panel Assembly.................................................................................102

Contents

Summary of DMB-1822LH

Page 1

Contents 1. Specifications.....................................................................................................2 2. Configuration.....................................................................................................4 3. Outline and dimensions .............................

Page 2: 1. Specifications

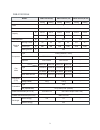

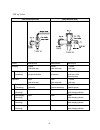

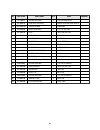

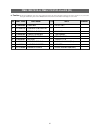

2 1. Specifications model dmb-1822/1832lh (9k) dmb-1822/1832lh (9k) dmb-1822/1832lh (9k+9k) function class t power ac 220-240v, 50hz capacity dehumidification 1.15 1.15 2.3 running current power input starting current 49 a type rotary (daewoo : china) model rbb095m011 capacitor 25uf/370vac 25uf/370v...

Page 3

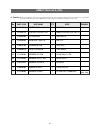

3 model dmb-2112/2122lh (9k) dmb-2112/2122lh (12k) dmb-2112/2122lh (9k+12k) function class t power ac 220-240v, 50hz capacity dehumidification 1.15 2.10 3.25 running current power input starting current 49 a type rotary (daewoo : china) model rcb120m001 capacitor 25uf/370vac 25uf/370vac type capacit...

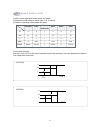

Page 4: 2. Configuration

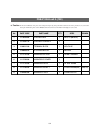

2. Configuration 4 * you should individually install and operate each a and b units in dmb-2112lh and dmb-2122lh. * you can exchangeably install and operate each a and b unit in dmb-1822lh and dmb-1832lh. Model dmb-1822lh dmb-1832lh dmb-2112lh dmb-2122lh indoor unit items unit capacity a 9000 btu/h ...

Page 5: 3. Outline And Dimensions

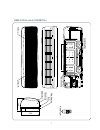

5 75 0 pla te m ou ntin g r em o c o n c on ne ctin g p ipe g rille in se rt 17 4 24 5 r em o te c o n tr o ll er fra m e g rille bo dy pla te m ou ntin g 3. Outline and dimensions 1 indoor unit dmb-1822lh unit a & b, dmb-2112lh unit b (9000 btu/h).

Page 6

6 75 0 75 0 pla te m ou ntin g r em o c o n c on ne ctin g p ipe g rille in se rt 17 4 24 5 r em o te c o n tr o ll er fra m e g rille bo dy pla te m ou ntin g dmb-1832lh unit a & b, dmb-2122lh unit b (9000 btu/h).

Page 7

Dmb-2112lh unit a (12000btu/h) 7 r em o c o n filte r - l filte r - r gril le in ser t fra me g rille bod y pla te m oun ting co nne ctin g p ipe pla te m oun ting 406 194 285 925 r em o te c o n tr o ll er.

Page 8

8 dmb-2122lh unit a (12000btu/h).

Page 9: Outdoor Unit

9 2 outdoor unit dmb-1822lh/1832lh/2112lh/2122lh inle t o utle t o utle t fo ot c us hio n 80 0 ca bin et f ron t se rvic e c ov er se rvic e v alv e ca bin et s ide pa nel top g uid e s up po rt fo ot 325.

Page 10: Basic Accessories

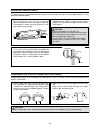

10 this installation section explains how and where to connect this new air conditioner. Please read make sure all acces- sories are included as shown below and read manual thoroughly. This installation section is provided to assist the per- son knowledgeable in air conditioner installation and shou...

Page 11: Optional Accessories

11 optional accessories 1 2 4 3 5 6 accessories not supplied with the unit: no. Description part no. Qty material size remark 1 drain hose extension 3103200400 2 id19.6 x 2m pvc pipe 2 tape 2tq1007502 2 pvc 75w x 0.1t x 25m 3 copper tubing extension 3104402600 2 1/4" copper tube x l5m wrapped with i...

Page 12: Installation Diagram

12 installation diagram below is an overview for the connection of the indoor unit to the outdoor unit. The pages following will give detailed instructions for full installation. Remember to read the complete installation section and follow all the safety instructions fully when installing the indoo...

Page 13: Installation

13 installation 1. Determine the type of wall (sheetrock, concrete, etc.) and make sure it is strong enough to hold indoor unit. Select an approximate position for the unit, taking the required distances away from walls/ac outlet into consideration. Indoor unit • do not install the unit in an area w...

Page 14

14 installing the ac connection wire to the indoor unit for ac power supply the ac connection wire is used to supply ac from the outdoor unit to the indoor units. To install ac connection wire, follow the procedures below. Note: • this appliance must be installed according to national power supply r...

Page 15

15 4. Connect the wires to the housing and terminals on the control board individually according to the outdoor uint connection. Indoor terminal connection cable connection cable not insert plug unit a l n indoor terminal unit b l n l1 n1 outdoor terminal outdoor l2 n2 unit a unit b brn y/g brn blu ...

Page 16

16 left tubing 2. Make sure the drain hose and copper tubing are wrapped with the rubber insulation. Using the tape, wrap the ac connection wire, copper tubing and drain hose together. Mounting (indoor unit) the indoor unit must be mounted before connecting the ac connection wire, drain hose and cop...

Page 17

17 1. Remove the flare nut stoppers from the inside unit. Determine the location of the copper tubing and where the bends will be. Gently bend the copper tub- ing, making sure to use big angles so no crimping will occur. Try to do this on the first try as repeated bend- ing may break or crimp the tu...

Page 18

18 1. Remove the screw holding on the connection cover. Remove the connection cover on the outdoor unit to access the connection area. 3. Connect the wires to the housing and terminals on the control board individually as the following. Installing the ac connection wire to the outdoor unit for ac po...

Page 19

19 4. To connect wires, loosen the screw in the terminal block and insert the correct wires like following figure. Connect the brown wire to the “l” connection, the yellow/green wire to the “ ” connection, the blue wire to the “n” connection. Dmb-1822/1832/2112/2122lh.

Page 20

20 connecting signal wires between indoor units and outdoor unit the signal wires are used to inter-communicate indoor and outdoor’s signal, and attached to the indoor unit at first. To install the signal wires to outdoor unit, follow the procedures below. Note: • make sure the indoor & outdoor unit...

Page 21

21 1. Tape the two copper tubes, drain hose (and the electrical wiring if local codes permit) together with the supplied tape. Make sure the electrical wiring does not come in direct contact with the copper tub- ing or drain hose. Approximately 1 foot outside the hole, let the drain hose out and sep...

Page 22

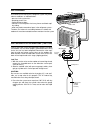

22 air purging air and moisture remaining in the refrigerant system may create adverse conditions as indicated below: • pressure in the system rises. • operating current rises. • cooling efficiency drops. • moisture in the refrigerant circuit may freeze and block capil - lary tubing. • water may lea...

Page 23

Evacuation 1. Attach the charge hose end described in the leak test area to a vacuum pump to evacuate the air remaining at the tubing and indoor unit. Confirm the ÒloÓ knob of the manifold valve is open. Then, run the vacuum pump. The operation time for evacuation varies with the tubing length and c...

Page 24

24 test run check that all tubing and wiring have been completed correctly. Check again that the wide and narrow tube service valves are fully opened. Turn on the power and run the system. Service valve construction • valve position closed the valve systems of both the wide and narrow tubes are turn...

Page 25

3-w ay v alve 3-way valve(liquid side) 3-way valve(gas side) works shaft position shaft position service port shipping closed closed closed (with valve cap) (with valve cap) (with cap) 1 air purging open closed open (installation) (counter-clockwise) (clockwise) (push-pin or with vacuum pump) operat...

Page 26: Indoor Unit

26 1 name and function of parts indoor unit 5. Opera tion 9000 btu/h class (dmb-1822lh unit a & b, dmb-2112lh unit b) electrostatic filter removes dust and particles from the air deodorizing filter removes bad smells from the air air inlet remote controller receiver signal wire remote controller f a...

Page 27

27 1 2 0 0 0 btu/ h cla ss (dm b-2 1 1 2 lh unit a ) lamp electrostatic filter removes dust and particles from the air deodorizing filter removes bad smells from the air air inlet remote controller receiver signal wire remote controller fan direction (up, down) air outlet antibacterial filter remove...

Page 28: Indoor Unit Display

28 indoor unit (dmb-2112lh unit a (12000btu/h)) ■ remote control signal receiver this place is the part to receive the signal if it receives the signal, you can hear the signal “beep”. ■ when the remote controller is lost or out- of-order, push the emergency button (emergency) to operate by hand. Op...

Page 29: Indoor Unit Display

29 ■ remote control signal receiver this place is the part to receive the signal if it receives the signal, you can hear the signal “beep”. ■ when the remote controller is lost or out- of-order, push the emergency button (emr.) to operate by hand. Open the front panel on emergency operating. Remocon...

Page 30: Indoor Unit Display

30 ■ remote control signal receiver this place is the part to receive the signal if it receives the signal, you can hear the signal “beep”. ■ when the remote controller is lost or out- of-order, push the emergency button (emr.) to operate by hand. Open the front panel on emergency operating. Remocon...

Page 31: Indoor Unit Display

31 ■ remote control signal receiver this place is the part to receive the signal if it receives the signal, you can hear the signal “beep”. ■ when the remote controller is lost or out- of-order, push the emergency button (emr.) to operate by hand. Open the front panel on emergency operating. Remocon...

Page 32: Outdoor Unit

32 a air in b air out connection cover remove cover to access the ac connection to the indoor unit. Service valves the indoor and outdoor units are connected by copper tubes which are connected here. Outdoor unit.

Page 33: Name of Each Button

33 name of each button 2 remote controller mode sleep on/off timer enter/ cancel fan speed turbo/mild display displays information pertaining to unit. Turbo/mild press to be colder the unit. Timer enter/cancel button press to enter a timer setting or to cancel timer setting timer on/off button press...

Page 34

34 repla cing ba tteries 3 r em o te co n tr o ller dis p la y open the cover after pressing the arrow direction and pulling out. Put the dry cell by +, - direction. Close the cover after pushing into arrow direction. 1 2 3 r em o te c o n tr o ll er + Ð + Ð r em o te c o n tr o ll er mode indicator...

Page 35: Off-Timer

35 if you set time in off-timer mode, the unit will stop at the set time. If you set time in on-timer mode, the unit will run at the set time. (1) range of setting temperature: 18~32°c (2) setting temperature: operating temperature of compressor if the indoor unit display receive the signal of remot...

Page 36

36 fa n speed (indoor unit) (1) motor speed (high speed, middle speed, low speed). (2) remote controller setting fan speed. (auto, l, m, h, natural) (3) relation of operating mode between fan speed. (4) automatic operation if the unit is set in 'auto' mode, the unit operates automatically according ...

Page 37: Sleep Mode

37 (1) when you are going to sleep, select sleep switch and the unit controls the room to the desired temperature. (the unit will not operate after 4 hour) (2) for changing the temperature. (3) to cancel sleep mode, press the sleep button again or press the mode button once.: the sleep indicator wil...

Page 38: Emergency Operation

38 (2) selecting operating mode again room temperature meets desired temperature and the compressor stops running over 30 minutes, then the unit selects operating mode again. 3 min. Time delay of compressor in normal operation, there is a time delay of three minutes between turn off and turning back...

Page 39: Dehumidification Mode

39 1) cooling mode when the room temperature is higher than 22 fan speed: super high speed air discharge direction: fixed set temperature: 18 (fixed) compressor and outdoor fan the air discharge direction procedure is below fixed up/down up/down fixed the option is left/right direction. 1) heating m...

Page 40: Self-Diagnostic Function

40 self-diagnostic function the control will contain diagnostic test to verify the integrity of the system. Led blink pattern case note room sensor open or short • continuously working to fix room temperature 18°c in heating mode. • continuously working to fix room temperature 32°c in cooling mode •...

Page 41

41 6. Wiring diag ram dm b-1 8 2 2 / 1 8 3 2 lh.

Page 42

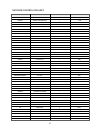

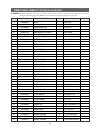

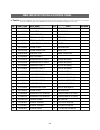

1 m a i n e le c tr i c p a r ts dm b-1 8 2 2 / 1 8 3 2 lh part name part code spec. Quantity remark fan motor 3108008700 ydk-8-4b 2 fan motor capacitor 3106900300 1.0uf 400vac 2 fuse 5fvlb3152l 250v 3.15a 2 stepping motor 3108003900 gsp-24sw-061 2 terminal block 3108914100 jxo-ch-3p 2 compressor 3r...

Page 43

43 dm b-2 1 1 2 / 2 1 2 2 lh.

Page 44

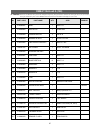

44 dm b-2 1 1 2 / 2 1 2 2 lh part name part code spec. Quantity remark fan motor 3108008700 ydk-8-4b 1 fan motor capacitor 3106900300 1.0uf 400vac 1 fuse 5fvlb3152l 250v 3.15a 1 stepping motor 3108003900 gsp-24sw-061 1 terminal block 3108914100 jxo-ch-3p 1 fan motor 3108008800 ydk-8-4b/a 1 fan motor...

Page 45

45 7. Refrig erant c yc le 1) dmb-1822/1832lh unit a&b, dmb-2112/2122lh unit b. 2) dmb-2112/2122lh unit a. Contents classes capillary tube charge quantity 9000 btu/h class id 1.6 x l1270 750 g 12000 btu/h class id 1.6 x l1000 1150 g.

Page 46

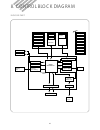

46 8. C o ntro l blo c k diag ram indoor fan motor communication o.D.U triac dc12v operating mode fan speed timer selection flap position unit on lamp room air temp. Indoor coil temp. Air clean lamp quick lamp remote emergency operation signal receiver timer lamp a/d converter lnitialization clock g...

Page 47

47 in door unit od sensor trans former micro controller a/d converter communication relay out put driver rl 1 comp(b) 4w(a) 4w(b) fan comp(a) rl 2 rl 3 rl 4 rl 5 dc power 12v, 5v dc 12v ac 220v out door part.

Page 48: 9. Trouble Shooting

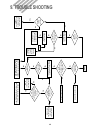

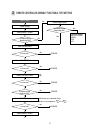

48 9. Trouble shooting o utd oo r u nit d oe s no t ru n? (n ote . 1 ) d oe s th e c om pre ss or ru n no rm ally ? In do or un it d oe s no t ru n(n ote 1 ) c he ck th e f ailu re co de a cc ord in g t o th e s elf d ia gn os tic (n ote 2 ) is th e u nit dis pla y m orm al? Ch ec k t he fa ilu re c...

Page 49: Self-Diagnostic Function

49 note 1) 1 neither indoor unit nor outdoor unit runs. Check the following points first. (there are following case in normal operation) a. Is the timer mode set the "timer on". B. Is the timer mode set the "timer-off" and the time had passed? 2 neither outdoor fan nor compressor runs while indoor f...

Page 50

50 confirm following statement. When the unit operates normally, sometimes the outdoor unit and indoor unit cannot operate. 1 check the function is it timer mode? 2 the function is in the sleep mode and is the setting time over? 3 is the setting mode dehumidifier mode? 4 when the unit is dehumidifie...

Page 51

51 check rotation of indoor fan rotate indoor fan by hand check input voltage of fan motor connector at power p.C.B check the winding resistance of indoor unit fan motor check the fan motor capacitor check the connecting wire of indoor fan motor run again check the starting of indoor fan motor run a...

Page 52

Confirm following statement. When the unit operate normally, sometimes the outdoor unit and indoor unit cannot operate. 1 is the setting temperature proper? 2 is the unit during 3min. Time delay of compressor. 3 during frost prevention of lndoor unit. 4 during dehumidifier mode. Outdoor fan and comp...

Page 53: Only Compressor Does Not Run

53 - check the following at cooling mode check the voltge between and of indoor unit terminal n l check the voltge between and of outdoor unit terminal n l check the wiring of outdoor unit check the compressor (check the winding resistance) check the compressor capacitor check the connecting wire be...

Page 54

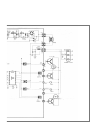

Dm b-1 8 2 2 / 2 1 1 2 / 2 1 2 2 lh (o utdoor) 10. Pc b driving desc riptio n 1 p c b c i r c u i t d i a g r a m.

Page 56

Dm b-1 8 2 2 / 2 1 1 2 / 2 1 2 2 lh (9 k indoor).

Page 58

Dm b-2 1 1 2 / 2 1 2 2 lh (1 2 k indoor).

Page 60

57 part name spec qty loc. Wafer yw396-03avd 1 cn1 wafer yw396-03avd(black) 1 cn2 wafer yw500-02v 1 cn6 pin gp881205-2(187) 1 cn4 wafer yfw800-01d 1 cn3 wafer yfw800-01d(red) 1 cn5 wafer smw250-05 1 cn10 wafer smw250-05(red) 1 cn9 wafer smw250-02 1 cn8 wafer smw250-02(red) 1 cn7 diode 1n4004 tape 6 ...

Page 61

58 part name spec 9k 12k loc. Wafer yw396-03av(red) 1 1 cn1 wafer yw396-05av 1 1 cn2 wafer yw396-03av 1 1 cn3 wafer smw250-05 1 wafer smw250-05(red) 1 wafer smw250-02 1 wafer smw250-08 1 1 cn6 wafer smw250-06 1 1 cn9 wafer 5267-04a 1 1 cn11 wafer yfaw254-02 1 1 test c-cera 104z,50vdc 4 4 cc1,2,8,9 c...

Page 62: Power Supply(1)

59 power supply(1) description dc power supply in circuit needs +12v and +5v. +12v is used for triac driving photo triac, buzzer driving swing, sweep motor. And it is regulated +5v dc by regulator ic7805. { zero cross communication line 12v gnd cn4 o.D.U i.D.U oscillator(2) 19 osc 8m 20 v dd -10% v ...

Page 63: Sensor(3)

60 room temperature and evaporator temperature sensor input description number 24, 25 of micom is terminal of a/d convertor input. Room temperature and evaporator temperature is sensing by change of thermister resistance, micom is put in 5v by ratio between r9 (12.7k Ω ) and r10 (12.7k Ω ). Relation...

Page 64: Triac Driving(4)

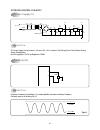

61 triac driving(4) description number 13 terminal of micom is put out pulse output, by way of buffer it is driving photo triac is supplied trigger signal. Trigger test of triac is detected zero cross part of ac input and it is triggered from zero cross part to time delay part according to fan speed...

Page 65

62 des cr ip tio n signal from remote controller put in only control data signal at micom terminal of number 33, which is gotten fid of carrier (38khz) from receive module. Signal wave repeat third as following fig 5-1. But in secondary wave custom code is reversed face. Leader code custom code data...

Page 66: Micom Power Supply(7)

63 description micom power is supplied 5v at number 42 using vdd, number 19, 20 using oscillator. Micom power supply(7) vdd 42 ce4 10 µ f 16v cc9 104 + 5v 22 21 19 osc 8mhz 20 vss micom.

Page 67: Reset(8)

64 description voltage less than about 0.8v put in micom terminal of number 18 and then micom reset. Reset ic detect power on and voltage less than 4.25v, and then send reset signal. Reset(8) r3 5.6k 1k r13 18 cc6 ce3 4.7uf/50v ic3 7042p 10.3 micom 4.25v h l t t power on vcc (+5v) delay time for pow...

Page 68: Buzzer Driving(10)

65 description micom 35 terminal put out buzzer driving pulse, its output is driving buzzer through buffer. Ocillatory frequency of buzzer is selected by internal micom. This unit is setting at 4khz. Vcc 12v micom 35 r6 1k bz1 buzzer driving(10) description indoor fan motor rpm is set by each regist...

Page 69: Zero Crossing Detect(11)

66 description it defect zero cross part of trans output voltage, transistor tr1 is used to put in the micom. Detail driving is as following fig 11-1. R19 is resistance to limit current. Micom r36 5.6k 1 2 cc12 103 tr7 krc120m 1 2 1 2 3 2 1 r33 10k r32 1k vcc cn4 31 detect point h the number 31 of m...

Page 70: Stepping Motor Driving(12)

67 description there are one stepping motor for flap (up and down) and it is used 4 face drive method. It is driving as following fig 12-1. (ring count method of 8 status) Ø 4 Ø 3 Ø 2 Ø 1 b+ 6 5 4 3 2 1 12v ic4 kid65004 cn9 1 micom 2 3 4 m1 for swing Ø 4 Ø 3 Ø 2 Ø 1 fig 12-1 (normal rotating) (rever...

Page 71: Communication Circuit (13)

68 description each 2 ports 34, 32 are using communication between i.D.U and o.D.U. 34 micom 32 cc11 103 r35 1k tr5 c102m r34 10k r19 10k cn4 a1270 tr6 communication circuit (13).

Page 72

69 pow er supply (1 ) des cr ip tio n dc power supply in circuit needs +12v and +5v. +12v is used for triac driving photo triac, buzzer driving swing, sweep motor. And it is regulated +5v dc by regulator ic7805. Ac 220v cl1 cc3 275v 104k var fuse1 3.15a power trans d2 cc1 ce1 d3 d1 d4 104 + 35v 2200...

Page 73: Sensor(3)

70 room temperature and evaporator temperature sensor input description number 13 of micom is terminal of a/d convertor input. Room temperature and evaporator temperature is sensing by change of thermister resistance, micom is put in 5v by ratio between r14 (12.7k Ω ) relation between temperature an...

Page 74: Micom Power Supply(5)

71 description micom power is supplied 5v at number 28 using vdd, number 1, 2 using oscillator. Micom power supply(5) vdd 42 ce4 10 µ f 16v cc9 104 + 5v 22 21 19 osc 8mhz 20 vss micom 1 2 vdd 28.

Page 75: Reset(6)

72 description voltage less than about 0.8v put in micom terminal of number 3 and then micom reset. Reset ic detect power on and voltage less than 4.25v, and then send reset signal. Reset(6) r1 5.6k 1k r2 3 cc4 ce3 4.7uf/50v ic4 7042p 103 micom 4.25v h l t t power on vcc (+5v) delay time for power o...

Page 76: Communication Circuit (7)

73 description each port 7, 8, 9, 10 is using communcation between i.D.U and o.D.U. Communication circuit (7) cc5 103 r16 10k r5 cc6 103 r6 1k 1r3 c102 cn12 cn11 r12 1k r11 1k r15 10k r10 1k r9 1k r7 10k tr2 a1270 tr1 a1270 r8 10k tr4 102 ic1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 description relay is con...

Page 77

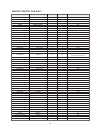

Error no error no error no no no no yes select on/off button select mode button select fan speed button select fan dir. Button power supply test start power supply again check the following battery spring micom pcb lcd is display at the beginning on? Is display at the beginning on? Is it normal? Is ...

Page 78

75 (0.5~24 hour) error no select timer on button select timer enter button select cancel button select on/off button select off (timer) button select sleep button select sleep button test ok! Is lcd display off? Is it normal display? Timer is all display off? Is it normal? Sleep mode display on? Is ...

Page 79: (1) Ic1 (Micom) Indoor Pcb

76 (1) ic1 (micom) indoor pcb 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 vdd (xtout)p22 (xtin)p21 (int5/stop)p20 p17 p16 (tc2)p15 (ppg)p14 (dvo)p13 (int2/tc1)p12 (int1)p11 (into)p10 (ain7)p67 (ain6)p66 (ain5)p65 (ain4)p64 (ain3)p63 (ain2)p62 (ain1)p61 (ain0)p60 varef p77(hso) p76(hsck) p7...

Page 80: (2) Ic1 (Micom) Outdoor Pcb

77 (2) ic1 (micom) outdoor pcb 1 2 3 4 5 6 7 8 9 10 11 12 13 14 vdd hold(keo) r92(sck) r91(so) r90(si) r83(t1) r82(int1) r81(t2) r80(int2) r63 r62 r61 r60 r53(ain7) xout xin reset r70 r71(pulse) r72/varef r40(aino) r41(ain1) r42(ain2) r43(ain3) r50(ain4) r51(ain5) r52(ain6) vss 28 27 26 25 24 23 22 ...

Page 81

78 (3) u2, 4 (kid65004) darlington arrays (4) u8 (kia7805p) : voltage regulator (5vdc) (5) u7 (kia7812p) : voltage regulator (12vdc) in1 1 16 out 1 in2 2 15 out 2 in 3 3 14 out 3 in 4 4 13 out 4 in5 5 12 out 5 in6 6 11 out 6 in7 7 10 out 7 gnd 8 9 common free wheeling diodes common 10.5k Ω 7.2k Ω 3k...

Page 82: (6) U9 (Kia7042P) : Reset Ic

79 (6) u9 (kia7042p) : reset ic kia70 42p outline input ground output vcc 1 3 2 out gnd.

Page 83

80 1 i n d o o r u n i t procedures photos 1. Stop the air conditioner and disconnect the power cord from the wall outlet. 2. Removing the insert grille and frame grille. (fig 1~2) draw up the insert grille and remove it. Loosen the screw fixed at the cover ter-block. Loosen two screw at the frame g...

Page 84

81 procedures photos 1. Stop the air conditioner and disconnect the power cord from the wall outlet. 2. Removing the insert grille and frame grille. (fig 1~2) draw up the insert grille and remove it. Loosen two special screws fixed at the cover ter-block. Loosen three screws at the body. Remove the ...

Page 85

82 procedures pho tos 1. Stop the air conditioner and disconnect the power cord from the wall outlet. 2. Removing the insert grille and frame grille. (fig 1~2) draw up the insert grille and remove it. Loosen the screw fixed at the cover ter-block. Loosen two screw at the frame grille. Remove the fra...

Page 86: Outdoor Unit

83 procedures photos 1.Stop the air conditioner and disconnect the wire from indoor unit to out door unit. 2. Disassemble the case. (fig 1~2) 1 remove the top panel. (loosen nine screws) 2 remove the service cover (loosen two screws) 3 remove the front cabinet. (loosen seven screws) 4 remove the sid...

Page 87

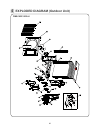

84 3 e x p lo d e d d i a g r a m ( i n d o o r u n i t) dmb-1822lh, dmb-2112/2122lh unit b (9k).

Page 88

85 dmb-1822lh, dmb-2112/2122lh unit b (9k) no part code part name q'ty spec remark 1 3100400301 body 1 hips t2.0 2 3108008700 motor idu 1 ydk-8-4b 3 3101500400 cushion motor 2 cr i.D 30 4 3106400200 bearing plastic 1 o.D37.0 x i.D 6.0 5 3100053700 fan cross flow ass'y 1 p90.0xl540 6 7485401012 set s...

Page 89

86 dmb-2112lh unit a (12k).

Page 90

87 dmb-2112lh unit a (12k) no part code part name q'ty spec remark 1 3100400201 body 1 hips t2.0 2 3108008800 motor idu 1 ydk-8-4b/a 3 3101500400 cushion motor 2 cr i.D 30 4 3106400200 bearing plastic 1 o.D37.0 x i.D 6.0 5 3100014400 fan cross flow ass'y 1 san+g. F30% 6 7485401012 set screw 1 6s-4 x...

Page 91

88 no part code part name q'ty spec remark 15-8 3102797910 harness i/d earth 1 i.D earth 15-9 3103400300 knob reset switch 1 abs t2.5 15-10 3112703500 harness select s/w 1 mode select 15-11 7111301611 tapping screw 2 t1s pan 3 x 16 mfzn 16 3102200401 frame grille 1 hips t2.5 buyer 17 3103600300 lamp...

Page 92

89 dmb-2122lh unit a.

Page 93

90 dmb-2122lh unit a no part code part name q'ty spec remark 1 3110400300 body 1 hips t2.0 (gy171a) 2 3110078100 motor idu assy 1 assy 3 3118003500 motor idu 1 rb13b(220v, 50/60v) 4 3106400200 bearing plastic 1 o.D37.0 x i.D 6.0 5 3110046000 fan cross flow ass`y 1 san+g.F 30% 100xl615 6 3113000400 h...

Page 94

91 no part code part name q'ty spec remark 33 7111301611 screw tapping 2 t1s pan 3x16 mfzn 34 3114302110 control pcb ass`y 1 dmb-2112/2122lh(12k, unit a) 35 5epv050120 transformer 1 dwa-220b 36 3116501000 blade vertical 3 p.P t1.5 (gy176a) 37 3117600100 flap 1 hips t2.0 (gy171a) 38 3100700700 bushin...

Page 95

92 4 exploded diagram (outdoor unit) dmb-1822/1832lh 5.

Page 96

93 dmb-1822/1832lh no part code part name q'ty spec remark 1 3110055700 base pan ass'y 1 secc t1.2(painting) 2 3102100901 foot 2 secc t1.6 3 3111500400 cushion rubber 4 nbr 54x63.5 4 3rc0020km1 compressor ass'y 1 rbb095m011 5 3rc0020km1 compressor ass'y 1 rbb095m011 6 3101500800 comp. Grommet 6 daew...

Page 97

Dmb-2112/2122lh 94.

Page 98

95 dm b-2 1 1 2 / 2 1 2 2 lh no part code part name q'ty spec remark 1 3110055800 base pan ass`y 1 secc t1.2(painting) 2 3102100901 foot 2 secc t1.6 3 3111500400 cushion rubber 4 nbr 54x63.5 4 3rc0020km1 compressor ass`y 1 rbb095m011 5 3rc0030cm0 compressor ass`y 1 rcb120m001 6 3101500800 comp. Grom...

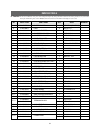

Page 99: Control Box Assembly

96 5 control box assembly dmb-1822/1832lh, dmb-2112/2122lh unit b (9k) l n.

Page 100

97 dmb-1822/1832lh, dmb-2112/2122lh unit b (9k) no part code part name q'ty spec remark 1 3100084000 control box 1 p.P+g.F 20% 2 3114302170 control pcb ass'y 9k 1 3 3108914100 terminal block 1 jxo-ch-3p 4 3106900300 capacitor sh.M.B 1 1.0µf 400vac 5 3104896300 sensor id assÕy 1 ptm-kd43c-d2 6 310439...

Page 101

98 dmb-2112lh unit a (12k).

Page 102

99 dmb-2112lh unit a (12k) no part code part name q'ty spec remark 1 3103500300 control box 1 pp+gf 20% 2 3114302110 control pcb ass'y 12k 1 dmb-2112/2122lh (12k, unit a) 3 3104301600 led pcb ass'y 1 dsb-122l/lh 4 3103400300 knob reset switch 1 abs t2.5 5 3108914100 terminal block 1 jxo-ch-3p 6 3106...

Page 103

100 dsb-2122lh unit a (12k).

Page 104

101 dsb-2122lh unit a (12k) no part code part name q'ty spec remark 1 3110504000 control box 1 hips t2.0(black) 2 3114302110 control pcb ass'y 1 3 3108914100 terminal block 1 jxo-ch-3p 4 3108003910 stepping motor 1 mp24ga 5 3112716100 harness led pcb 1 ul1007 7x26awg 6 3112709500 harness id power 1 ...

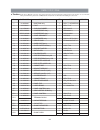

Page 105: Control Panel Assembly

102 6 control panel assembly 7 j.

Page 106

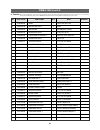

103 dmb-1822/1832/2112/2122lh control panel no part code part name q'ty spec remark 1 3114203300 control panel 1 sgcc t0.8 2 3116903300 capacitor 1 25uf 370vac 3 3116903400 capacitor dual 1 5+25uf 370vac 4 3108912320 terminal block 1 dtb-04p 5 3118900200 terminal block 1 jxo-ch-2p 6 3113538900 label...

Page 107

Deawoo electronics co., ltd 686, ahyeon-dong mapogu, seoul, korea. C.P.O. Box 8003 seoul korea telex: dwelec k28177-8 cable:"daewooelec" fax: +82-2-364-5588 tel: +82-2-360-7114, 8114 http://www.Dwe.Co.Kr s/no. : 3113907400 printed date: april. 2002.

Page 108: Service Manual

Service manual dual & split system air conditioner model: dmb-1822lh dmb-1832lh dmb-2112lh dmb-2122lh daewoo electronics co., ltd. By nemko ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts inform...