- DL manuals

- Daewoo

- Air Conditioner

- DSB-092LHG

- Service Manual

Daewoo DSB-092LHG Service Manual

Service Manual

Split System

Air Conditioner

Model: DSB-092LHG

DSB-242LHG

S/M No. : R1A1G0A004

MAR. 2006

✔

Caution

: In this Manual, some parts can be changed for improving,

their performance without notice in the parts list. So, if you

need the latest parts information, please refer to PPL(Parts

Price List) in Service Information Center

S/M No. : SB092LH001

Summary of DSB-092LHG

Page 1

Service manual split system air conditioner model: dsb-092lhg dsb-242lhg s/m no. : r1a1g0a004 mar. 2006 ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to ppl(parts pri...

Page 2: Contents

Contents p contents 1 service and maintenance 2 performance parameters 4 controls specification 6 operation of air conditioner 11 installation explanations 15 disassembly and reassembly 23 troubleshooting 31 exploded views and parts list 33 wiring diagram 42.

Page 3: Service and Maintenance

1 1 3 3 2 2 1 1 3 3 2 2 air conditioner no use for a long time. Start fan only for 3-4 hours to comple- tely dry the inside of the indoor unit. Set cool mode or heat mode, and select the highest setting tempera- ture, then fan turns. Turn off air conditioner, unplug the power plug. Otherwise, the ac...

Page 4: Service and Maintenance

1 1 1 4 4 3 3 2 2 1 1 4 4 3 3 2 2 filters should be cleaned once every two weeks. Take out filters. Clean filters with a vacuum cleaner or by typing them gently. ( if they are very dirty, wash them in warm water below 45 dissolved with neutral scouring agent.) clean filters with clean water, then dr...

Page 5: Performance Parameters

Performance parameters 3 1 4 2 5 6 7 the indicated noise value is from laboratories test before leaving factory. The rated cooling capacity and rated heating capacity value is tested under below conditions all above should be changed without notice.There are latest and accurate specifications on the...

Page 6: Performance Parameters

Performance parameters 3 1 4 2 5 6 7 the indicated noise value is from laboratories test before leaving factory. The rated cooling capacity and rated heating capacity value is tested under below conditions all above should be changed without notice.There are latest and accurate specifications on the...

Page 7: Controls Specification

Controls specification 1 1 2 2 abbrevia tion ts: setting temperature tr: room t emperature ti: indoor defrost sensor temperature to: outdoor defrost sensor temperature opera tion of main board cool mode if t r > ts, cool operation is activated. Compressor and outdoor fan are turned on. Indoor fan ru...

Page 8: Controls Specification

Outdoor de-ice after 40 minutes of continuous heating operation, if to -4 , the outdoor de-ice operation is activated. Compressor is turned off. Indoor fan speed reduces to low speed. After 30 seconds delay, 4 way value and outdoor fan will be turned off, indoor fan reduces to low speed, 15 seconds ...

Page 9: Controls Specification

Timer timer off can only be set when the system is operating. Timer on can only be set when the system is off. The maximum set time is 12 hours. Changing of on/off state will cancel timer mode. Sleep mode in cool mode, after sleep mode is set, ts will increase 1 in first hours, will increase 2 in se...

Page 10: Controls Specification

Manual swing (stepping motor) if the indoor fan is operating, the louver will swing or can be stopped at a preferred location in any mode. The louver change location follow the order of : if a command is received, the system will respond with a beep. Buzzer in cool mode, if tr-ts if 0 no change in s...

Page 11: Controls Specification

Manual operation button 3 3 operation of control panel on indoor unit every press of this button will turn the system on or off. System led light when system is operating, the run light is on. When system is off, the light is off. (cool only type) every time the switch is pressed, it changes in sequ...

Page 12

Operation of air conditioner 1 1 1 4 4 1 2 2 operation procedure-control under the remote controller run/stop press i/o button, start operation, and stop when repressed. Temperature adjustment press temperature adjustment button, decreases 1 by press button once, and increase 1 c c by press button o...

Page 13: Advice

2 (1) (2) (3) (4) (5) press auto swing button, the deflector start to opreate. Change right/left air flow direction manually swing ,to change right/left air flow direction.Complete ad- justment before operation, if adjusted during operation,the auto swinging deflector may pinch your fingers.(fig. 1)...

Page 14: Advice

1 6 6 1 2 3 4 5 1 operation mode adjustment auto mode when started, operation mode will turn into cool or dry or heat mode as per room temperature, if operation stops for two hours, it restarts in the same mode set as before operation was stopped. Once operation mode is set,it will not be influenced...

Page 15

2 3 if power sets off, time must be set again, otherwise timer operation is not right. Dry mode: 70% humidity is the limit for people to feel comfortable. When people feel hot and suffocating, water vapor content in air is high, in other words, humidity is high. Humidity has relation to temperature ...

Page 16: Installation Sketch

Installation sketch 1 1 2 5 3 4 4 2 5 6 7 2 8 1 9 1 10 1 1 indoor unit accessories mounting plate tapping screw st4 25 expansion rubber plug expansion bolt battery remote controller felt adiabatic underlay connecting cable drain joint remark quantity (supplied by customer) a 1 b 2 c 3 d 5 e 1 f 1 g ...

Page 17: Installation Sketch

1 e a 9 5 6 7 g h f c d b 2 3 4 installation sketch 1 1 2 5 3 4 4 2 5 6 7 2 8 1 9 1 10 1 1 indoor unit accessories mounting plate tapping screw st4 25 expansion rubber plug expansion bolt battery remote controller felt adiabatic underlay connecting cable drain joint remark quantity (supplied by cust...

Page 18: Installation

1 1 1 2 2 secure the mounting plate the mounting plate should be attached to the structural part of wall (post etc.). Notice the holes at solid arrow position must be secured to avoid the shake of mounting plate. When the expansion screws are used, two holes ( 11 20 or 11 26 ) that the distance betw...

Page 19: Installation

Indoor unit terminal fastener connecting cable electrical box cover screw pull the connecting cable's wire in completely indoor unit terminal screw connecting cable diagram 1 1 2 2 5 5 3 3 4 4 open the front panel; remove the screw from electrical box cover, pull the electrical box cover away from t...

Page 20: Installation(Dsb-092Lhg)

Connecting cable outdoor unit outdoor unit terminal installation(dsb-092lhg) dsb-092lhg connecting cable heat pump type cool only type indoor unit terminal outdoor unit terminal connecting joint blue blue white white red yellow/green yellow/green 3 2 n 3 2 n 4 r1r2 2 n 2 n 4 yellow warning special c...

Page 21: Installation(Dsb-242Lhg)

Discharge the air procedure connect assembly pipe to the appropriate valve on the indoor unit and outdoor unit and tighten the flare nut(as fig.1). 1.The number of bent position of the pipe in the indoor unit should not exceed 10. 2.The number of bent position of the pipe in the indoor unit and the ...

Page 22: Installation(Dsb-242Lhg)

Outdoor unit wiring 1 1 1 1 remove the self-tapping screws (2 pcs) onthe maintenance board and take out the maintenance board. Outdoor unit maintenance board terminal board fix the cable wire with anchor cable piping cover please utilize outdoor pipe support when the cable wire is led from the backs...

Page 23: Installation(Dsb-242Lhg)

2 remove the maintenance board and pipe cover( there are two screws respectively) 3 don't flatten the copper pipe while rebuild the elbow pipes. (the circle radium is 100 to 150 mm) 1 direction of distribution pipes led out ( can be led out from four directions) removing direction of maintenance boa...

Page 24: Indoor Unit

Stop operation of the conditoner and remove the power cord before repairing the unit indoor unit disassembly and reassembly no parts procedure remark 1 front grille 1.Stop the air conditioner operation and block the main power. 2.Contract the second finger to the left ,and right handle and pull to o...

Page 25: Disassembly And Reassembly

5.Loosen the earth screw in evaporator. 8.Separate the electrical box from the indoor unit. 4.Take all the connector of the pcb upper side out. 3.Loosen the screw of the inside terminal board , separate the board. 6.Pull softly the indoor pipe temperature sensor out from the pipe casing. Earth screw...

Page 26: Disassembly And Reassembly

3 3.Separate the evaporator from the indoor unit. Ass’y tray drain 1.Push the left and right hooks to make the assíy pulled out. 4 evaporator 2.Separete the assíy tray drain from the body. 1.Push the left hook and separate the left part out of evaporator. 3.Separate the fan motor from the fan. No pa...

Page 27: Outdoor Unit

1 cabinet 1.Turn off the unit and remove the power cable. 2.Remove the upper cabinet, the front cabinet and back cabinet. 2.Separate the propeller fan from fan motor. 1.Remove the nut flange. (turn to the right to remove as it a left turned screw ) 1.Loosen the fixing screw of the base-electrical co...

Page 28: Indoor Unit

Stop operation of the conditoner and remove the power cord before repairing the unit indoor unit 1 front grille 1.Stop the air conditioner operation and block the main power. 2.Contract the second finger to the left , and right handle and pull to open the inlet grille. 3.Take the left and right filt...

Page 29: Disassembly And Reassembly

2 5.Separate the electric box from the indoor unit. 3.Loosen the lowerscrew of electrical box. Electrical parts 7.Pull front of the front panel, then take front panel out. 1.Loosen the earth screw in electric box, separate the grounding wire on the evaporator. No parts procedure remark 4.Push the ho...

Page 30: Disassembly And Reassembly

2.Loosen the right screw of the evaporator 3.Separate the evaporate from indoor unit. 1.Loosen the screw of the assíy tray drain. 3 assíy tray drain 1.Loosen the fixing screw of fan motor,then separate the fan motor from the fan. No parts procedure remark 1.Loosen the left screw of the evaporator 4 ...

Page 31: Outdoor Unit

Outdoor unit 1 cabinet 1.Turn off the unit and remove the power cable. 2.Remove the upper cabinet . 3 ass' y control out. 2.Loosen the nut flange on compressor. 3.Separate the connector. 4.Separate the ass y c ontrol out from the outdoor unit. 1.Loosen the fixing screw of the base-electrica control....

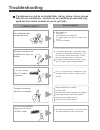

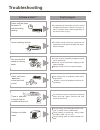

Page 32: Troubleshooting

If problems can not be corrected after doing below items, please stop the air conditioner, contact our air conditioner specially eng- aged service centre nearest to you to get help. Is there a fault ? Fault analysis air conditioner does not operate at all. Does power fail ? Is plug out ? Does power ...

Page 33: Troubleshooting

Indoor unit fan stops for about 10 minutes during heating. It is defrosting of the outdoor unit coil.It should complete this process in about 10 minutes at most.( it freezes when outdoor temperature is low and humidity is high. ) issues cracking sounds the friction sounds caused by expansion and con...

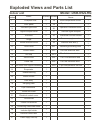

Page 34: Indoor Unit

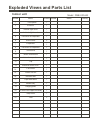

Indoor unit model: dsb-092lhg 34-1 34-6 34-4 34-3 34-2 34-5 34 exploded views and parts list 1 2 3 4 5 6 7 8 9 10 11 12 13 15 16 14 17 18 27 28 29 30 31 32 26 20 21 22 23 24 25 19 33.

Page 35: Indoor Unit

Indoor unit model: dsb-092lhg name dustproof filter front panel indicator light cover encloser hinge airflow direction louver drain hose louver motor art strip screw cover drain cap air outlet vent support assembly evaporator indoor unit fan back body hanging plate pipe fixed board indoor fan motor ...

Page 36: Outdoor Unit

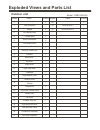

Outdoor unit model: dsb-092lhg 31-1 31-6 31-5 31-4 31-3 31-2 31 exploded views and parts list 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 3 0

Page 37: Outdoor Unit

Outdoor unit model: dsb-092lhg name air outlet grille front plated trademark axial flow fan motor support condesator handle top cover back coer capacitor of the compressor electrical appliance cover connecting cable clip capacitor of the outdoor unit motor electrical appliance holder solenoid capill...

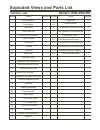

Page 38: Indoor Unit

Indoor unit model: dsb-242lhg exploded views and parts list 20 21 17 18 19 15 16 6 5 9 7 8 4 3 1 2 13 12 11 14 10 22.

Page 39: Indoor Unit

Exploded views and parts list bottom body name front panel indoor fan capacitor quantity number 1 2 3 4 5 6 7 8 9 10 11 quantity number 12 13 14 15 16 17 18 19 20 21 22 1 1 1 1 1 3 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 name screw cover left cover of evaporator motor install board transformer indicate ligh...

Page 40: Outdoor Unit

Outdoor unit exploded views and parts list 1 2 1 2 33 4 5 6 7 9 10 12 11 13 14 19 18 17 1616 15 20 8 22 23 24 25 26 27 28 29 30 21 model: dsb-242lhg.

Page 41: Outdoor Unit

Exploded views and parts list name air outlet grill back cover quantity 28 number 1 2 3 4 5 6 7 8 9 10 11 29 30 quantity number 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 2 1 3 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 4 name motor fixed plate condensator fixed clip electrical control...

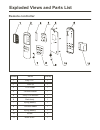

Page 42: Remote Controller

Remote controller 1 2 3 4 5 6 7 8 10 10 quantity 1 1 1 1 1 1 1 1 1 1 4 assíy pcb remocon screw case up conduct rubber inlay lcd lcd screen spring battery name back body number 11 10 1 2 3 4 5 6 7 8 9 back cover conduct rubber 9 11 11 spring battery exploded views and parts list.

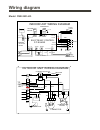

Page 43: Wiring Diagram

Wiring diagram model: dsb-092lhg 2 n s mc mf yl w/grn c r run outdoor unit wiring diagram 4 3 r1 r2 ¶» ¶» fan motor master switch power source brn blu ylw/grn ylw/grn blu wht red ylw to outdoor unit brn blu blk blk ylw red blu room thermistor pipe thermistor compressor unit to indoor red thermistor ...

Page 44: Wiring Diagram

L mf louver motor mv remote controller 4 room thermistor pipe thermistor display receiver board ¶» ¶» cn-disp1 ylw/grn 3 ot orn ylw transformer red red ac220v pt rt trans blk blk ac13.5v hot out trans1 brn brn connector ylw 2 1 4 3 orn 1 2 3 4 terminal block ylw/grn ac l in ac n in com out wfan out ...

Page 45

Daewoo electronics corp. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” printed date: mar. 2006 s/m no. : sb092lh001.