80 service guide electric and gas dryer model : kud-wg55s dwr–wg52s caution +pvjku/cpwcnuqogrctvuecpdgejcpigfhqtkortqxkpivjgkt performance without notice in the parts list. So, if you need the latest parts information, please refer to ppl(parts price list) in 5gtxkeg+phqtocvkqp%gpvgtjvvruxefygeqmt.

Contents p what is a dryer?........................................................................................................................................................ 2 p dryer specification ...................................................................................................

2 a lifter, operated by a rotating drum, rolls laundry in the drum, and hot air heated by electricity (or gas) dries the laundry through time or sensor dry system (a temperature control system) under various conditions. R what is a dryer? 1. What is a dryer? ※ note that some features are options. V ...

V time dry Ŗ#flwuvvjgngpivjqhvkoghqtft[kpi v sensor dry Ŗ#wvqocvkecnn[ft[ceeqtfkpivqvjgv[rguqhncwpft[ v custom program Ŗ4gogodgtoquvŌhtgswgpvn[Ōwugfft[kpieqwtug v 4cem&t[ Ŗ&t[ugpukvkxghcdtkegiuygcvgtuuknmnkpigtkgqpvjgtcem v reduce static Ŗ6jkuqrvkqpkplgevuuvgconcvgkpvjgft[kpie[engvqtgfwegvjguvcvkegn...

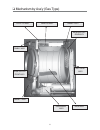

4 r dryer specification 2tqfwev.Qqm ⑥ ⑩ ⑧ ① ⑤ ⑨ ④ ⑪ ② ⑮ ⑭ ⑱ ⑬ ⑦ ⑫ ⑰ ⑯ ③ no. Parts 1 frame door o 2 protector glass 3 deco frame 4 panel front 5 cabinet front 6 plate top 7 cabinet 8 button power 9 button start 10 window course 11 button function 12 button option 13 window display 14 less time 15 mor...

5 r operating mechanism diagram (gas type) laundry control pannel lifter plate top electric input program duct inlet steam as duct outlet impeller fan filter as cabinet front door 0 operating mechanism Ŗ%qpvtqnngtqrgtcvkqp Ŗ1rgtcvqticudwtpgtcktuwrrnkgtxgpvkncvqtqrgtcvkqp Ŗ#wvqocvkeqrgtcvkqpqhvjgeqpv...

Electric input program laundry control pannel lifter plate top duct inlet heater as duct outlet impeller fan filter as cabinet front door steam as 0 operating mechanism Ŗ%qpvtqnngtqrgtcvkqp Ŗ1rgtcvqtjgcvgtcktuwrrnkgtxgpvkncvqtqrgtcvkqp Ŗ#wvqocvkeqrgtcvkqpqhvjgeqpvtqnngt Ŗ&t[kpid[vjgcwvqocvkeugpuqt 1...

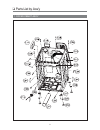

7 r mechanism by ass’y (electric type) plate top ass'y drum support front ass'y panel f ass'y main pcb ass'y cabinet ass'y drum ass'y motor ass'y cabinet f ass'y drum support rear ass'y duct in let ass'y.

8 r mechanism by ass’y (gas type) plate top ass'y drum support front ass'y panel f ass'y main pcb ass'y cabinet ass'y drum ass'y cabinet f ass'y gas burner ass'y drum support rear ass'y duct in let ass'y.

9 1. Dryer cbinet ass'y r parts list by ass’y.

10 no. Part name part code description qtt’y remark c01 cabinet(electric) 3610812350 sgcc 0.8t 1 1 piece svc part cabinet(gas) 3610812360 sgcc 0.8t 1 c01–1 frame top l 3612206500 sgcc 1.6t 1 c01–2 frame top r 3612206600 sgcc 1.6t 1 c01–3 base under 3610392900 sgcd 0.8t 1 c02 lock harness m 361220790...

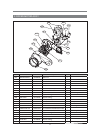

11 2. Dryer motor ass'y m03 m02 m01 m09 m14 m15 m08 m16 m13 m10 m11 m12 m05 m07 m04 m06 no. Part name part code description qtt’y remark m01 bracket motor 3610608500 sgcc 2.0t 1 m02 motor dryer 36189l5d00 ac 120v 60hz 1 m03 clamp motor 3611206000 sk5 0.7t 2 m04 bracket idler as 3610609100 dwr–we31 1...

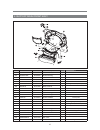

12 3. Gas burner ass'y no. Part name part code description qtt’y remark g01 valve as 3615417200 dc12v,130ma 0.5psi 1 lpg 3615417300 dc12v,130ma 0.5psi 1 lng ) 5%4'96#22+0) 6/ (qtſzkpi)) g03 guide bunner 3612511100 sgcc 1.0t 1 g04 mixing venturi as 3612209200 venturi as+ flame damper 1 welding(spot) ...

13 4. Inletduct ass'y a01 a02 a04 a05 a06 a03 4–1. Electric type 4–2. Gas type no. Part name part code description qtt’y remark a01 duct inlet rear 3617510200 alcosta 0.6t 1 electric type 3617510210 alcosta 0.6t 1 gas type a02 duct inlet front 3617510300 alcosta 0.6t 1 electric type 3617510310 alcos...

14 5. Support drum rear ass'y b07 b02 b01 b04 b03 b02 b02 b05 no. Part name part code description qtt’y remark b01 support drum rear 3615304500 sts430 2b 0.8t 1 3615304550 alcosta,sa1d 0.8t,dryer b02 bracket sup.R–side 3610608810 sgcc 1.0t 2 b03 bracket sup.R–upper 3610608910 sgcc 1.0t 1 Ō 5%4'96#22...

15 6. Support drum front ass'y no. Part name part code description qtt’y remark s01 sup. Drum f 3615304610 secd 0.8t, we51, steam 1 s02 housing lamp 3613053400 pp(heat resisting) 1 s03 socket lamp 3613053300 14 base lead wire type 1 s04 lamp 3613625400 ac 125v 15w 1 s05 window lamp 3615505100 abs(tr...

16 7. Drum ass'y d01 d04 d02 d03 d03 d04 d05 no. Part name part code description qtt’y remark d01 drum 3617011010 sts430 0.5t, enami 1 3617011010 sa1c 0.5t,alcosta drum d02 lifter 361a401050 heat resisting pp 3 Ō 5%4'96#22+0) 6645z575 (qtſzkpinkhvgt d03 seal drum as 3614010600 felt + synthetic leath...

17 8. Door ass'y d01 d02 d03 d04 d05 d06 d08 d09 d10 d07 no. Part name part code description qtt’y remark d01 frame door i 3612210900 pp (tb53) 1 d02 gasket door 3612323000 we31 1 d03 door glass 36117abr00 glass , we31 1 d04 protector glass 3618304300 abs , ut0510tnp 1 d05 frame door o 3612211000 ab...

18 9. Plate top ass'y no. Part name part code description qtt’y remark t01 plate top 3614533010 secd 1.2t 1 t02 handle rear 3615304100 abs 2 – screw tapping 7122401411 t2s trs 4x14 mfzn 4.

19 10. Cabinet front ass'y g01 g07 g04 g06 g02 g09 g03 g08 g05 no. Part name part code description qtt’y remark g01 cabinet–f 3610812500 sgcd 0.8t 1 g02 gasket cabinet f 3612323350 epdm 5x10 3.0t r207 4 g03 support hinge 3615304410 sgcc 1.6t 1 left door type 3615304415 1 right door type g04 door loc...

20 11. Panel f ass'y f01 f20 f02 f03 f05 f08 f07 f09 f10 f12 f15 f11 f13 f14 f16 f17 f18 f20 f19 f04 f06 no. Part name part code description qtt’y remark f1 panel–f 3614289700 abs , we52 1 f2 deco power 3611692110 abs , gilding_base 1 f3 deco start 3611692210 abs , gilding_base 1 f4 button function ...

21 70+656'#/&4;'4#570+6%1.&524#;#5 s03 s04 c05 c02 c03 c01 s02 s06 s05 s01 c04 no. Part name part code description qtt’y remark s unit steam dryer as 3619606900 r–we52s,hot steam as 1 s01 unit steam as 3619606700 d–wd1351,steam as 1 s02 hose spray 3613275100 ul, silicon, id=9.5, od=16.5 0.33 s03 hos...

22 22 13. Accessories 14. Procedure for reversing the door the door on your dryer can be installed to open either to the left or the right. Follow these instructions to tgxgtugvjgfktgevkqpkpyjkej[qwtfqqtqrgpu note : door and latch should be aligned at the center when closed. Rack–dry(option) pedestr...

23 23 r pcb function specification 1. 27–inch dryer pcb function specification comprehensive function specification of the unit including operation of a 27–inch dryer by drying courses and drying functions, control of electronic devices by pcb, operation by s/w, test function, error mode, and so on....

24 24 2–1. Setting by courses 1) sensor dry course a. Temperatures are not changed in sensor dry course so the initial setting is not altered. $#pvkŌ%tgcugkuugngevgfkp%qvvqp6qygnu*gcx[&wv[cpf$wnm[.Ctig%qwtug#pf6gor.Gxgnku set to “high” while dry level is set to “very dry”. C. All options of dry leve...

25 25 2) manual dry course a. Only temp is selected in manual dry course. B. Dry level is not selected in manual dry course. C. Operation time does not change even if temp is changed. D. Dry level and course led are off (not selected) if time dry is set while only temp is on (the default set is high...

26 26 2–2. Operation 1) overview ¡ different operation processes are applied to sensor dry course and manual dry course. ¡ 5gpuqt &t[ %qwtug lwfigu vjg eqpfkvkqp qh ncwpft[ ykvj jwokfkv[vgorgtcvwtg ugpuqtu uq cu vq decide appropriate dry level. ¡ manual dry course dries laundry as per temperature co...

27 27 3) process of manual dry course a. Power button on ¡ őaaaŒkufkurnc[gfcv.'& ¡ ő%jgem(knvgtŒqh%wuvqo.'&iqguqpcpfqhhdghqtg[qwrtguu5vctv$wvvqp ¡ “high” of initial beeper goes on and the previous beeper value is displayed when you switch on the power. B. Operation selection ¡ select operation with ...

28 28 2–3. Operation of load and sensor 1) operation of heater – electric type ¡ on/off goes on according to temperatures set or measured by the sensor. Regardless of the control by the microcomputer, however, the heater may go off if a temperature reaches thermostat off temperature as per outlet co...

29 29 2–4. Operation of buttons 1) power a. The electric power switch turns on/off the display. B. Automatic switch off function ① power is immediately switched off after an operation is done. ② power is switched off after 10 minutes if no button is selected while power is on. C. Initial display whe...

30 30 4) temp control a. If you press this button, the following is displayed in order. Medium – mid high – high – ultra low – low – medium $'cejngxgnvctigvuvgorgtcvwtgucuhqnnqyu6ctigvvgorgtcvwtgu6jgtoquvcvhcp c. This is available only in manual dry course not sensor dry course. 5) time dry a. If yo...

31 31 8) less time a. Pressing this button decreases time by a minute. $6jgvkogfgetgcuguwrvqokpwvgu %;qw ecp ejcpig vkog kp /cpwcn &t[ %qwtug cpf 6kog 5gngevkqp #nuq 9tkpmng %ctg ecp dg selected/cancelled. 9) custom program a. The function remembers most–frequently–used course and operation. B. If y...

32 32 2–5. Option #+h[qwugngev4cem&t[vjgrtgxkqwueqwtugcpfqrgtcvkqpiqguqhh $+h[qwugngev4cem&t[9tkpmng%ctg#pvkŌ$cevgtkcnqt&corŌ&t[Ō$ggrkupqvcxckncdng level time dry more time less time custom program 4cem dry 9tkpmkng care anti crease damp dry beep perm press o o o o o $wnm[ o o o o o o delicate o o o...

33 33 2-6. Error mode 1) h1 error – humidity sensor error ① this occurs when there is a short defect in the humidity sensor (the indicated value is lower than 24) ② the unit buzzes, indicating the error, every 10 minutes for 10 seconds. ③ the error display goes off when the power is switched on/off....

34 34 2-7. Test mode 1) pcb test mode(electric type) #*qyvqgpvgtvjgoqfguykvejvjgrqygtqpyjkngrtguukpi&t[.Gxgncpf6kog&t[dwvvqpu $1rgtcvkqpqtfgtejgemnqcfd[rtguukpi6kog&t[qt&t[.Gxgn$wvvqpeqpvkpwcnn[ - press time dry button - press dry level button 2) pcb test mode(gas type) #*qyvqgpvgtvjgoqfguykvejvjgrq...

35 35 3. Electric dryer pcb pin layout motor operating relay tr a n s r e gu la tor heat sin k h eater operating relay s t ea m h ea t e r operating relay front p cb s /w , le d : se n s or2 : se n s or2 : se n s or , :g n d : a c i n p ut : h ea t e r i nn e r : motor : door ch e ck : h ea t e r ou...

36 36 4. Gas dryer pcb pin none orange : temp se n s or2 re d : h umidity se n s or2 blue : h umidity se n s or none , gr een : gnd i gn i t e r operating relay s t ea m h ea t e r operating relay tr a n s g as v al v e pr opor tional contr o ller front p cb s /w , le d purple : door c h e ck, w hit...

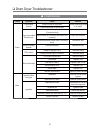

37 37 r drum dryer troubleshooter o power/noise trouble symptom cause solution power service wire problem a fault of lead–in wire power call the electricity provider or an expert fuse disconnection of service wire dryer wire problem electric parts disconnection of the power cable (connection fault) ...

38 38 1. Electric dryer wiring diagrams.

39 39 2. Gas dryer(on/off control) wiring diagrams.

40 r dryer installation 1. Installation order ① place the dryer on the flat ground. Keep the unit at least 12 inch away from the wall. ② %jgemvjgngiucpfvjgicrdgvyggpvjgwpkvcpfhnqqt6jgft[gtujqwnfuvcpfuvcdn[yjgp[qw try to move the unit to the left or right. ± $cncpegvjgwpkvqpvjghnqqtykvjvjgngicflwuvcu...

41 r electrical requirements for electric dryers the following are additional instructions regarding electrical connections and requirements for electric dryers. Instructions for grounding of your electric dryer: a) this dryer must be connected to a grounded metal, permanent wiring system or an equi...

42 review the following options to determine the appropriate electrical connection for your home: use the instructions in this section if your home has a 4–wire receptacle (nema type 14–30r) and you will be using a ul listed, 120/240 volt minimum, 30 amp, dryer power supply cord. Use the instruction...

43 important : grounding through the neutral conductor is prohibited for (1) new branch–circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor. Prepare minimum 5 ft (1.52 m) of length in order for dryer to ...

44 important : grounding through the neutral conductor is prohibited for (1) new branch–circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductor. Prepare minimum 5 ft (1.52 m) of length in order for dryer to ...

45 Ŗnh[qwtnqecneqfguqtqtfkpcpegufqpqvcnnqyvjgwugqhcŌyktgeqppgevkqpqt[qwctgkpuvcnnkpi[qwt dryer in a mobile home, you must use a 4–wire connection. %qppgevpgwvtcnyktgyjkvgqhrqygteqtfvqegpvgtvgtokpcndnqemuetgy %qppgevtgfcpfdncemyktguvqvjgnghvcpftkijvvgtokpcndnqemuetgyu 3. Connect ground wire (green) o...

46 lf your local codes or ordinances permit the connection of a frame–grounding conductor to the neutral wire, use these instructions. If your local codes or ordinances do not allow the connection of a frame–grounding conductor to the pgwvtcnyktgwugvjgkpuvtwevkqpuwpfgt5gevkqp1rvkqpcnŌyktgeqppgevkqp ...

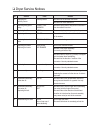

47 r dryer service notices no. Service parts notices 1 replacing the humidity sensor humidity sensor be careful of the terminal connection be careful of loose attachment 2 replacing/fixing panel f assy pcb/button/ harness be sure that the panel f assy does not interfere in the drum after the service...

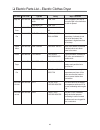

48 r electric parts list – electric clothes dryer part name part code type no rating major functions lamp as 3612625300 .Cor*qnfgt series 75w, 125v power is applied to the lamp to turn up the light in the drum when the door is opened. .Cor$cug' 15w, 125v switch door 3619047700 spe110f–1d3 7.5a 125v ...

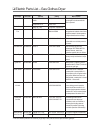

49 r electric parts list – gas clothes dryer part name part code type no rating main function lamp as 3612625300 .Cor*qnfgt series 75w, 125v power is applied to the lamp to turn up the light in the drum when the door is opened. .Cor$cug' 15w, 125v switch door 3619047700 spe110f–1d3 7.5a 125v / 5a 25...

50 thermostat fan 1. Function Ŗ6jkukucdkogvcnŌv[rguykvejyjkejrtqvgevuvjgenqvjguhtqofcocigd[ overheating. Ŗ+hvjggzcwuvcktkuvqqjqvvjkuvjgtoquvcvuvqruvjgoqvqtcpfchvgtvjgcktku cooled down, it restarts the motor. 2. Specification Ŗ#dkogvcnvjgtoquvcvykvjvjgvgtokpcnupqtocnn[eqppgevgf Ŗ'ngevtketcvkpi#cv8 Ŗ1...

51 thermostat cut–out 1. Function Ŗ6jkukucdkogvcnŌv[rguykvejyjkejrtqvgevuvjgjgcvgthtqoqxgtjgcvkpi Ŗ+hvjgjgcvgtkuqxgtjgcvgfcdpqtocnn[vjkuvjgtoquvcvewvuqhhvjgjgcvgt permanently. Ŗ0qvgvjcvvjkuvjgtoquvcvku010Ō4'5'66#$.'khkvkuqrgpgfkvujqwnfdg replaced by new one. 2. Specification Ŗ#dkogvcnvjgtoquvcvykvjv...

52 thermostat hi–limit 1. Function Ŗ6jkukucdkogvcnŌv[rguykvejyjkejeqpvtqnuvjgjgcvgtqrgtcvkqp Ŗ+hvjgjgcvgtkuvqqjqvvjkuvjgtoquvcvuvqruvjgjgcvgtcpfchvgtvjgjgcvgt is cooled down, it restarts the heater. 2. Specification Ŗ#dkogvcnvjgtoquvcvykvjvjgvgtokpcnupqtocnn[eqppgevgf Ŗ'ngevtketcvkpi#cv8 Ŗ1rgpkpivgo...

53 lamp assembly 1. Function Ŗ6jkukucncorcuugodngfykvjkvudtcemgvcpfykpfqy Ŗ+hvjgwugtqrgpuvjgfqqtvjgfqqtuykvejikxgugngevtkerqygtvqvjku lamp and it turns on. 2. Specification Ŗ#pcuugodn[qhcpgngevtkencordtcemgvcpfykpfqy Ŗ2qygteqpuworvkqp9cv8 Ŗ6[rgpcog6)'Ō. 3. Checking method of mal–function Ŗ6jgncorkuv...

54 switch door 1. Function Ŗ6jkukucuykvejvjcvejgemuyjgvjgtvjgfqqtkuqrgpqtenqugf Ŗ+hvjgwugtqrgpuvjgfqqtvjkuuykvejfkueqppgevurqygtuwrrn[vqvjg motor and turns the lamp on. Ŗ+hvjgwugtenquguvjgfqqtvjkuuykvejeqppgevurqygtuwrrn[vqvjg motor and turns the lamp off. 2. Specification Ŗ#rwujuykvejŌuvtqmgoovtggv...

55 heater assembly 1. Function Ŗ6jkukucpcuugodn[vjcvjgcvucktkpvjgftwo Ŗ6yqŌ9wrrgtnqygtjgcvgtuctgeqppgevgfkpcrctcnngnektewkv producing 5,000w Ŗ#eeqtfkpivqvjgrtqitcougvgkvjgtqpgqtvyqjgcvgtuqrgtcvg 2. Specification Ŗ6yqjgcvgtuykvjvjgucogurgekhkecvkqpctgeqppgevgfkpcrctcnngnektewkv Ŗ5kpingjgcvgt0k%tyktgo...

56 belt switch (switch micro) 1. Function Ŗ6jguykvejewvuvjgrqygtuwrrn[vqvjgoqvqtyjgpcdgnvkudtqmgp Ŗ6jguykvejkuqpyjgpvjgdgnvjcucfgswcvgvgpukqpdwvqhhyjgp vjgdgnvigvunqqugpgfqtdtqmgpdnqemkpivjgrqygtuwrrn[vqvjg motor. 2. Specification Ŗ/ketquykvejykvjvyqvgtokpcnu0%pqtocnn[enqugfv[rg htgguvcvg%1/cpf01ctg...

57 thermistor fan 1. Function Ŗ6jghcpugpuguvjgvgorgtcvwtgqhgzjcwuvckt Ŗ6jgjkijgtvjgvgorgtcvwtgkuvjguocnngtvjgtgukuvcpegku 2. Specification Ŗ6jgtokuvqtykvjhqnnqykpivgorgtcvwtgŌtgukuvcpegejctcevgtkuvke cvu%4mš cvu%4mš Ŗ6[rgpcog%96Ō&9'Ō%Ō# 3. Checking method of mal–function Ŗ+hvjgtgukuvcpegdgvyggpvgtok...

58 motor dryer 1. Function Ŗ6jgoqvqttqvcvguvjgftwowukpivjgdgnvcuygnncuvjghcpvqgzrgnygvckt Ŗ6jkukucujwpv#%oqvqt9jgpvjgoqvqtdgikpuvqtwpcegpvtkhwicnuykvejujqtvuqwvvjgqrgtcvkqp coil. Ŗ6jgegpvtkhwicnuykvejcnuquwrrnkgurqygtvqvjgjgcvgt6jwukhvjgoqvqtuvqruvjgjgcvgtiqguqhh also. 2. Specification Ŗ5jwpvv[rg*2#...

59 ⑤ drum ass'y remove ⑥ cover fan remove ⑧ remove the 4 screws and the motor ass’y. ⑦ remove the cover fan and 3 screws. ⑨ remove wires and 2 clamps that fix the motor bearing to detach the motor. ⑩ assemble the parts in reverse order. Loosen the 3 screws as indicated with a circle. Loosen the 3 sc...

60 igniter as 1. Function Ŗ+ipkvgthqthwgnicukipkvkqp Ŗ+ipkvgtjgcvuwrswkemn[yjgprqygtkuuwrrnkgf+hhwgnicuku kplgevgfvqvjguwttqwpfkpictgcqhkipkvgticukukipkvgfd[vjg heat of igniter. 2. Specification Ŗ a heating element made by silicon carbide Ŗ 'ngevtketcvkpi8#uvgcf[Ōuvcvgewttgpv Ŗ 6gorgtcvwtgtcvkpitgce...

61 flame sensor 1. Function Ŗ5gpuqthncogkuvjguykvejvjcvqrgtcvgud[fgvgevkpihwgnicu ignition or heating of igniter. Ŗ%qpvcevrqkpvkuqrgpgfyjgpuwhhkekgpvtcfkcpvjgcvkufgvgevgf through the transparent window at the bottom of sensor. Ŗ9jgpkipkvgtkuuwhhkekgpvn[jgcvgfvjkukufgvgevgfvqvwtpqhhkipkvgt then, stat...

62 thermostat hi–limit 1. Function Ŗ6jkukucdkogvcnŌv[rguykvejyjkejuvqruvjgdwtpgtqxgtjgcvkpi Ŗ+hvjgdwtpgtkuvqqjqvvjkuvjgtoquvcvujwvuqhhvjgicuxcnxgucpfchvgtvjg burner is cooled down, it allows the gas valves to operate. 2. Specification Ŗ#dkogvcnvjgtoquvcvykvjvjgvgtokpcnupqtocnn[eqppgevgf Ŗ'ngevtketcv...

63 thermostat cut–out 1. Function Ŗ6jkukucdkogvcnŌv[rguykvejyjkejrtqvgevuvjgdwtpgthtqoqxgtjgcvkpi Ŗ+hvjgdwtpgtkuqxgtjgcvgfcdpqtocnn[vjkuvjgtoquvcvewvuqhhvjgicuxcnxgu permanently. Ŗ0qvgvjcvvjkuvjgtoquvcvku/#07#..;Ō4'5'66#$.'d[rtguukpivjg mpqdqpvjgvqrvjkurctvkutgvwtpgfvqtgwucdnguvcvg 2. Specification ...

64 valve gas as 1. Function Ŗ8cnxgicu#5uwrrnkguqtdnqemuqhhhwgnicu Ŗxcnxguctgjqtk\qpvcnn[eqppgevgfvquchgn[dnqemqhhicungcmcig Ŗ'cejxcnxgkuuqngpqkfxcnwg)curcuugfvjtqwijvjkuxcnxgkukplgevgfchvgt being stabilized to the prescribed output pressure in regulator. Ŗ6jgtghqtggxgpkhkprwvrtguuwtgqhuwrrnkgficuejc...

65 panel front ass’y plate top ass'y 1.Remove left cap and unfasten screw. 2. Separate panel front. (caution : internal hook damage attention) 3. Separate plate top by pushing it at the front part in the direction of arrow. 1. Remove 3 screws at the front. 2. Remove 4 screws at the back. R dismantli...

66 cabinet front ass'y 1. Remove 4 screws at the top. 2. Remove filter. 3. Remove 3 screws. 4. Lift cabinet front in the direction of arrow and pull it forward. 5. Remove door switch connector..

67 frame upper separation of lamp,pcb main connector 1. Separate lamp connector. 2. Separate main pcb connector. 3. Separate humidity sensor connector. 1. Remove 2 screws from left and right in front part. 2. Remove 2 screws from left and right at the top. 3. Separate frame upper after removing harn...

68 pcb main duct outlet ass'y 1. Remove 2 left and right screws. 2.Remove 1 screw. 3. Remove duct outlet f in the direction of 1. Remove 2 screws. 3. Separate frame upper after removing harness at the back. 1 2.

69 support drum front ass'y 1. Push up idler in the direction of arrow to remove belt. Then, separate belt and remove drum. Drum ass'y 1. Remove 1 rear screw and separate pipe exhaust in the direction of arrow. Pipe exhaust 1. Remove 1 rear screw and separate pipe exhaust in the direction of arrow..

70 cover back 1. Remove 10 screws. Support drum rear ass'y 2 1 1. Remove heater terminal connection cable. 2. Remove 7 screws. 3. Remove support drum rear ass'y in the direction of.

71 motor connector 1. Separation of temperature sensor: separate connector. Remove 1 screw. 2. Separation of thermostat fan: separate connector. Remove 2 screws. 3. Separation of micro switch: 4. Separation of motor connector..

72 terminal block 1. Remove cover terminal. 2. Remove 3 screws..

73 motor ass'y 1. Remove 6 screws and separate motor ass'y. 2. Separation of cover fan: remove 2 screws. 3. Separation of impeller fan: fix motor axis and separate fan..

74 4. Dismantling of case fan: remove 3 screws. 5. Dismantling of bracket motor: remove 2 clamp motors each..

75 heater ass'y 1. Remove 4 screws. 2. Unfold 4 side fixing parts. 3.Remove thermostat 2 screws. 4.Remove 13 screws. Lamp ass'y 1. Remove 1 screw..

76 filter dust ass'y / humidty sensor 1. Filter dust ass'y: remove 2 screws. 2. H/s: remove connector. 3. Remove h/s..

77 3. Door lock ass'y: separate door lock ass'y after removing 2 screws. Door ass'y 1. Separation of hinge and support drum front: remove 2 screws. 2. Remove 13 screws..

78 4. Door switch.

79 gas burner ass'y 1. Remove 6 screws. And separate 2 valve connectors. 2. Remove 1 screws at the back of cabinet. 3. Remove 2 screws and separate igniter connecter. 3. Remove 2 screws after removing harness at thermostat cut–out, hi–limit..

Daewoo electronics corp. 686, ahyeon–dong mapo–gu seoul, korea c.P.O. Box 8003 seoul, korea 6'.':&9'.'%-Ō %#$.'ő'911'.'%Œ 8'45+104gx.

About this manual about this manual 담 당 김용욱 님 f.Model buyer b.Model dwr–we52s_wg52s brand 대우일렉 언 어 영어 country 일 정 1차 2차 3차 4차 5차 제 판 인 쇄 애드컴 규 격 memo 접수 : vision creative. Inc . 서울 종로구 통의동 6번지 이룸빌딩 4층 연락처 vision 담 당 방 문 수(chois) tel : 730–0660 fax : 730–3788 인디자인 작업동시에 내용 신규 교체 090616 – 신규 총 81p(1~8...