- DL manuals

- Daewoo

- Refrigerator

- FRN-T30H2MW

- Service Manual

Daewoo FRN-T30H2MW Service Manual

Summary of FRN-T30H2MW

Page 1

Frn-t30h3gp ( frt-803zg..) frn-t30h3tb ( frt-803hb..) frn-t30h3pw ( frt-813hp..) frn-t30h2mw ( frt-822hw..) may. 2013..

Page 2

Specification 1. Information image 374.2 530.0 780.2 330.7 449.5 frn-t30h3pw ( preuve white ) frt-813hp.. 904.2 374.2 530.0 817.9 frn-t30h3tb ( stella black ) frt-803hb.. 904.2 frt-803zg.. 904.2 330.7 487.2 factory no. Refrigerator 907.5 374.2 533.3 buyer no. Gross vol. (iec 62552) total 447.9 330.7...

Page 3

Specification 2. Outside diemension 2.

Page 4

Specification 3. Interior parts 1) t30h3gp / t30h3tb 1. Door storage compartment 7. Egg case 2. Ice maker / ice storage bin 8. Door storage compartment 3. Freezer shelf 9. Can pocket 4. Freezer compartment drawer 10. Multi crisper 5. Takeout case 11. Vegetable / fruit drawer 6. Refrigerator shelf 12...

Page 5

Specification 2) t30h3pw / t30h2mw 1. Door storage compartment 6. Egg case 2. Ice maker / ice storage bin 7. Door storage compartment 3. Freezer shelf 8. Can pocket 4. Freezer compartment drawer 9. Ez home bar 5. Refrigerator shelf 10. Vegetable / fruit drawer * the real features are model dependent...

Page 6

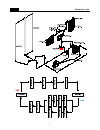

Refrigerant cycle 5.

Page 7

Air flow [ side view ] [ freezer compartmnet ] [ refrigerator compartmnet ] * the illustration is 'frn-t30h3gp / frn-t30h3tb' model. 6.

Page 8

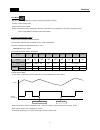

1. Display a multi crisper ( option ) button ; to select fish - meat - vegetable - speed mode. ( speed mode works for 60 minutes.) b frz. Set button 1) initial plug in : medium ( -20c ) 2) every time you press the frz. Set button, the setting temperature changes below order. Functions a b c ref. Set...

Page 9

Eco mode ; eco mode is automatically lights up when energy-saving mode is driving. 1) green : power saving mode 2) blue : normal control mode 3) pink : acceleration mode ( refrigerator is driving continually to lower temperature of inside of refrigerator when there is a big difference between inside...

Page 10

2. Refrigerator compartment control 1) adjust by the pushing the ref.Set button. 2) refrigerator compartment on/off difference - dial 5c / 4c / 3c : 2.0c - dial 2c : 2.1c - dial 1c : 2.6c - dial 0c : 3.5c * medium off point : 3.5c 3) quick refrigerator mode : this mode runs for 40 minutes. Functions...

Page 11

3. Multi crisper control ( *option ) 1) adjust by the pushing the multi crisper button. 2) display is 'fish → meat → vegetable → speed' 3) each mode controls compressor, fan motor, step valve and damper. 4) speed mode - it works 60 minutes. After finishing this mode it changes to vegetable mode. - i...

Page 12

1. Freezer defrost process - time limit : 50 minutes. ( comp., freezer fan, step valve is active. ) or - until freezer defrost sensor is below -27c. ( if error f3 happens, precool is over. ) - until freezer defrost sensor is 13c. - if error f3 happens, defrost heater is active for 30 minutes. - for ...

Page 13

3. When freezer compartment defrost mode start? ; when total compressor runnig time becomes at 10, 12 ~ 60hours. - any error happens ( r1, f1, d1, f3, rt-sensor, c1, door switch etc. ) or door opening time is over 2 minutes. - door opening time is over 1 minutes and compressor operating rate is over...

Page 14

4. When refrigerator compartment defrost mode start? ; when total compressor runnig time becomes at 4, 6 ~ 40hours. - any error happens ( r1, f1, d1, f3, rt-sensor, c1, door switch etc. ) or door opening time is over 2 minutes. - door opening time is over 1 minutes and compressor operating rate is o...

Page 15

1. Plug-in defrost 1) when freezer & refrigerator defrsot sensor is below 3.5c, defrost mode start. 2) freezer and refrigerator compartment defrost start by defrost sensor. 3) plug-in defrost makes compressor delay 6 min. 2. Pull down mode 1) how to start? - push the lock button to enter test mode. ...

Page 16

1. Buzzer 1) when fcp buttoning. 2) after 3 seconds plug-in. 3) when pull down or a/s defrosting start. 4) every 1 minute with door opening for 5 minutes. 2. Electric parts time delay 1) compressor / all fan motor - check step valve position and after 90 seconds compressor start. ( but, after 5 seco...

Page 17

4. Led lamp control 1) each door switch connected to each compartment led lamp. 2) when door switch is opened for 10 minutes, led lamp is off automatically. 3) when door switch is opened for 1 hour, fcp display error 'd f' or 'd r' or 'd h'. ( 'd f' = freezer door switch error, 'd r' = refrigerator ...

Page 18

7. Multi crisper compartment ( option parts ) 1) every 'multi crisper' buttoning, fish → meat → vegetable → speed ( default is fish mode ) 2) when choosing 'speed' mode, after 60 minutes' operation ( max. Time limit ), back to 'fish' mode. 3) damper control ; damper is controlled by refrigerator sen...

Page 19

1. How to enter this check mode 1) push the lock button. 2) push the lock button 5 times while pressing the frz.Set button. 2. The front led displays the current error code ( if happens ). ; every time you press the freezer set button, the following value display. 1) the appliance running time. ( fr...

Page 20

No 15) 16) 17) 18) 19) 5. Troubleshooting when error display ( if the relative parts is normal, error code display will be reset. ) 1) 'f 1' error - cause : freezer sensor disconnection or short. - control : short - continuous operation. Disconnection - no operation. 2) 'r 1' error - cause : refrige...

Page 21

5. Troubleshooting when error display 8) 'd 2' display ( no error ) - display a/s defrosting is operating. 9) 'c o' display ( no error ) - display pull down mode is operating. 10) 'r d' error - cause : refrigerator defrost sensor disconnection or short. - control : defrost heater is on for 10 minute...

Page 22

7) ef error - cause : when flow-sensor abnormal. ( there is no pulse during some time. ) the number of pulse signal is below 10 by 1 second during water supply. - check point : water supply line. 8) et error - cause : level switch abnormal. ( no pulse is sensed for some time. ) - control : by time. ...

Page 23

Function key summary ; all function key is active in lock mode. ( after pushing lock button ) [ a/s deforsting mode ] → ref. Set 5 times while pushing frz. Set [ pull down mode ] → lock 10 times while pushing ref. Set [ demo mode ] function key → frz. Set 10 times while pushing ref. Set [ error disp...

Page 24

Wiring diagram 23.

Page 25

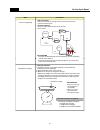

1. Inner led lamp refrigerator led lamp disassemble & assemble each parts freezer led lamp take out the led window. Unscrew 2 point. Exchange led pcb. 24.

Page 26

2. Multi crisper & ionizer led ( *option parts ) multi crisper led lamp ionizer led lamp disassemble & assemble each parts take out the led cover. Unscrew 2 point. Disassemble led cover pushing back side. Unscrew 2 point. P exchange the led pcb. Exchange the led pcb. 25.

Page 27

3. Freezer inner led panel disassemble & assemble each parts disassemble freezer louver screw ( 4ea ). Unscrew 4 points. Disassemble with pushing the hook. Pull out freezer louver with proper tools. Disconnect the wire. Disconnect the wire from the freezer louver. ( check wire harness disconneted or...

Page 28

4. Refrigerator inner led panel disassemble & assemble each parts disassemble ref. Louver screw ( 3ea ). Unscrew 7 points. Disassemble with pushing the hook. Pull out refrigerator louver with proper tools. Disconnect the wire. Disconnect the wire from the freezer louver. ( check wire harness disconn...

Page 29

5. Freezer side evaporator (1) remove freezer louver a : previous page. Disassemble & assemble each parts remove screw cap & screw. ( 1 point ) - freezer inner led panel - defrost sensor freezer fan defrost heater (temp. Fuse include) pull out freezer louver b. Freezer compartmnet evaporator shape. ...

Page 30

6. Refrigerator side evaporator (1) remove ref. Louver a : previous page. Disassemble & assemble each parts remove screw cap & screw. ( 2 point ) - ref. Inner led panel - ionizer (*option) ref. Fan defrost heater (temp. Fuse include) defrost sensor ref. Damper (*option) pull out ref. Louver b. Disco...

Page 31

7. Freezer fan motor (1), (2) remove frz. Louver a : previous page. Disassemble & assemble each parts remove 4ea screws. Disassemble with holding the hook. Disasseble the fan motor. Remove the spring from the fan. Unscrew 2 points. Remove the fan blade. 30

Page 32

8. Refrigerator fan motor (1), (2) remove ref. Louver a : previous page. Disassemble & assemble each parts remove 4ea screws. Disassemble with holding the hook. Disasseble the fan motor. Unscrew 2 points. Remove the spring from the fan. Remove the fan blade. 31.

Page 33

9. Damper as, ionizer ( *option parts ) & deodorizer (1), (2) remove ref. Louver a & b : previous page. (1) pull out the case. Disassemble & assemble each parts cut the sealing material. Remove 2 screws, disassemble damper cover. Remove the air return cover pushing the mark point. Remove damper as. ...

Page 34

10. Step valve as disassemble & assemble each parts disconnet the housing. Step valve as step valve connector pull out the step valve as. ( yellow - yellow / blue - blue ) ※ when assembling the step valve as, check capi-pipe color. Cut the capi-pipe 2 point. Remove dryer as & pipe by torching. Unscr...

Page 35

11. Door switch, rt sensor & humidity sensor disassemble & assemble each parts unscrew 5 points. [door switch] remove door switch arrow direction with flat tool. [humidity sensor] (4) exchange any defected parts. Disconnect wire harness. Door switch humidity sensor rt sensor door switch harness [rt ...

Page 36

12. Fcp panel disassemble & assemble each parts remove upside 1 screw. Lift up fcp panel about 10 cm disconnect the wire harness. About 10 cm. Holding the topside and rotate the fcp panel ccw. 35.

Page 37

1. Summary of heavy repair cooling cycle repair bombe (mass cylinder), refrigerant manifold gauge, l i l hi weigh and control the bombe in a vacuum conditions with electronic scales and charge through compressor inlet (process tube) refrigerant charging and h i vacuum pump , manifold gauge. Evacuate...

Page 38

2. Precautions during heavy repair cooling cycle repair 1) remove retained refrigerant more than 5 minutes after turning off a refrigerator. (if not, oil will leak inside.) 2) remove retained refrigerant by cutting first high pressure side (drier part) with a nipper and then cut low pressure side. (...

Page 39

3. Practical work for heavy repair cooling cycle repair 1) remove residual refrigerant more than 5 minutes later after turning off the refrigerator. ( if not, compressor oil may leak inside.) 2) remove retained refrigerant slowly by cutting first high pressure side (drier part) with a nipper and the...

Page 40

Cooling cycle repair * pipe connection connect a red hose to the high pressure side and a blue hose to the low pressure side. * vacuum sequence open 1,2 valves and evacuate for 40 minutes. Close valve 1. 3.Vacuum degassing precautions items compresso evaporato drye condense vaccu m hot blu yello re ...

Page 41

Cooling cycle repair precautions item 4) refrigerant charging charge refrigerant while operating a compressor as shown above. 5) pinch a charging pipe with a pinch-off plier after completion of charging. 6) braze the end of a pinched charging pipe with copper brazer and take a gas leakage test on th...

Page 42

1 - assy cab urt - 1 2 3012936801 hinge *t *r as fr-t89lr 1 3 3012936701 hinge *t *l as fr-t89lr 1 4 3014808610 sensor rt as pbn-43b 1 5 3018125601 switch h/bar dr as sp101b-2d1(g) gray 2 6 3012777500 harness r dr s/w as frx-621b 2 7 3014810600 sensor humid as dw-hs001a 1 8 301149ba00 cover hi*t pp ...

Page 43

No part-code part name spec. Q'ty 1 3010365700 base comp as fr-t89lr.. 1 2 39591a5280 compressor env4a5g-l2b , 220-240v/50hz 1 3 3814300600 box inverter assy sbc3-lc3 1 4 3010101480 absorber comp as fru-541d 4 5 3016002520 washer comp sk-5 t0.8xw19xl19.5(2stage) 4 6 301119uv10 case vapori as pp(natu...

Page 44

1 3012547000 guide drn f ga t0.4 1 2 3018931100 louver f b as fr-t89lr.. 1 3 3010924600 cap f louver hips t2.3 5 4 3018930801 louver f a as 10-led fr-4 131*20-1.6t(2pin) 1 7 3012040000 fixture f motr as fr-t89lr.. 1 7-1 3015921700 motor r fan as drep9020lr 1 7-2 3012040100 fixture f motr pp 1 7-3 30...

Page 45

1 3012547100 guide drn r ga t0.4 1 2 3018931700 louver r c as fr-t89lr… 1 3 301099ap00 cap r luvr b hips 2 4 301149bu00 cover return as fr-t89lr 1 4-1 3018701800 deo anti as t5*w40*l40 1 5 3018932600 louver r b as fr-t88lr.. 1 6 3012040300 fixture r motr as pbn-34b 1 6-1 3015921700 motor r fan as dr...

Page 46

No part-code part name spec. Q'ty 1 30100c1700 assy f dr - 1 2 3012330200 gasket f dr as pvc-s+magnet 1 3 3019067400 pocket f *t gpps 2 4 3012244900 frame i/maker as fr-t89lr 1 5 3019068320 pocket i/maker as secc+paint(wh) 1 6 3019067420 pocket f *t gpps,2 star print 3 no part-code part name spec. Q...