- DL manuals

- Daewoo

- Refrigerator

- FRN-U20DB series

- Service Manual

Daewoo FRN-U20DB series Service Manual

Refrigerator

S/M No:

RNU20IB001

- May, 2006

✔

Caution

: In this Manual, some parts can be changed for improving, their

performance without notice in the parts list. So, if you need the

latest parts information,please refer to PPL(Parts Price List) in

Service Information Center

FRN-U20IB*

FRS-U20IB*

FRN-U20DB*

FRN-U20EB*

FRS-U20DB*

FRS-U20EB*

FRN-U20FB*

FRN-U20GB*

FRS-U20FB*

FRS-U20GB*

FRU-577I~

FRU-547D/E~

FRU-547F/G~

Summary of FRN-U20DB series

Page 1

Refrigerator s/m no: rnu20ib001 - may, 2006 ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information,please refer to ppl(parts price list) in service information center frn-u20ib* frs-u20ib* ...

Page 2: C O N T E N T S

1 c o n t e n t s 1. Warnings and precautions for safety ----------------------------2 2. External view 2-1. External size ---------------------------------------------------3 2-2. Name of each parts ------------------------------------------6 2-3. Cold air circulation ------------------------------...

Page 3

2 please observe the following safety precautions in order to use safely and correctly the refrigerator and to prevent accident and danger during repair. 1. Be care of an electric shock. Disconnect power cord from wall outlet and wait for more than three minutes before replacing pcb parts. Shut off ...

Page 4

3 2-1. External size 2. External views - frs(n)-u20ib downloaded from fridge-manual.Com manuals.

Page 5

4 - frs(n)-u20db / eb downloaded from fridge-manual.Com manuals.

Page 6

5 - frs(n)-u20fb / gb downloaded from fridge-manual.Com manuals.

Page 7

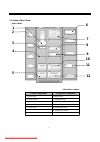

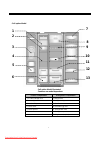

6 12. Refrigerator case 11. Refrigerator pocket 10. Refrigerator shelf 5. Freezer case 9. Movable egg case 4. Freezer shelf 8. Chilled case 3. Ice tray 7. Refrigerator light 2. Freezer pocket 6. Dairy pocket 1. Freezer light refrigerator compartment freezer compartment 1 2 4 3 5 7 8 9 10 11 12 6 2-2...

Page 8

7 12. Refrigerator pocket 6. Freezer case 7. Dairy pocket 1. Ice cubes storage case 13. Magic room (option) 11. Refrigerator shelf 5. Freezer pocket 10. Movable egg case 4. Freezer shelf 9. Wine rack 3. Water/ice dispenser 8. Refrigerator light 2. Freezer light refrigerator compartment freezer compa...

Page 9

8 freezer compartment refrigerator compartment 2-3. Cold air circulation downloaded from fridge-manual.Com manuals.

Page 10

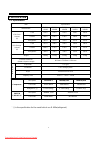

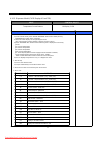

9 3. Specification 3-1. Specification 117kg 115kg 113kg 115kg 330 li 170 li 500 li 352 li 184 li 536 li frs(n)- u20gb 334 li 170 li 504 li 357 li 184 li 541li frs(n)- u20fb 334 li 170 li 504 li 357 li 184 li 541 li frs(n)- u20db c y c l e idΦ0.7 × t0.55 × l2200 capillary tube molecular sieve xh-9 dr...

Page 11

10 dc13v / 1100 ±100 rpm condenser fan motor dc13v / 1950 ±100 rpm r-fan motor dc13v / 2050 ±100 rpm f-fan motor e l e c t r i c a l p a r t s dispenser model specification ( 220~240v models only ) item basic model model name ac250v , 10a , 77℃ fuse temp (defrost) pbn-38 f-sensor d-sensor d e f o r ...

Page 12

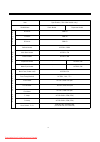

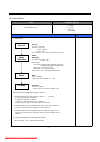

11 4-1. Display 5 4 3 2 1 temp indication max medium max mid medium min min temperature chang 5 4 3 2 1 temp indication max medium max mid medium min min temperature change 1. “frz.Temp” button 1) temperature control of freezer compartment 2) 5 step mode of successive temperature mode. 3) initial mo...

Page 13

12 1. Display control 2. “freezer set” button 1) temperature control of freezer compartment 2) 7 step mode of successive temperature mode. 3) initial mode by power input : “medium(-19℃)” ※whenever pressing button, setting is repeated in the order of medium (-19℃) → medium max 1 (-20℃) → medium max 2...

Page 14

13 contents remarks 4. “refrigerator set” button. 1) temperature control of refrigerator compartment 2) 5 step mode of successive temperature mode. 3) initial mode by power input : “medium (4℃)” ※whenever pressing button, setting is repeated in the order of medium (4℃) → medium max (3℃) → max (2℃) →...

Page 15

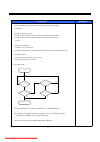

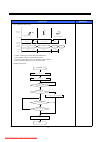

14 1. Defrost mode input control object contents remarks 1. Defrosting cycle 1. Comp 2. F-fan 3. R-fan 4. D-heater pre-cool pause fan-delay heater defrosting pre-cool 1) time : 50 minutes 2) comp , f-fan : on r-fan : control d-htr : off 3) if f-sensor ≤ -27℃, then pre-cool becomes. Off heater defros...

Page 16

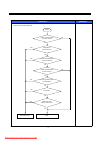

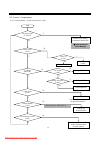

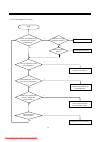

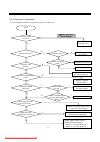

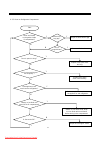

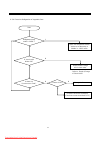

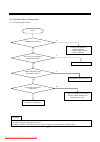

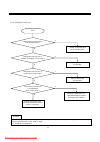

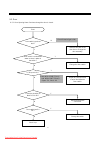

15 contents remarks 4. Flow chart of defrosting start start comp. Operating time is over 24 hours? Total time is over 60 hours? Comp. Operating time is over 6 hours? End defrosting start comp. Operating time is over 2 hours? Any error ? No yes no no yes total door open time is over 2 min? Yes yes ye...

Page 17

16 1. A/s defrosting mode (heater defrost → pause → fan delay) input control object contents remarks 1. Defrosting cycle 1. Comp 2. F-fan 3. R-fan 4. D-heater heater defrosting 1) comp, f-fan, r-fan : off d-htr : on 2) time limit 30 seconds : heater is on regardless of d-sensor temperature right aft...

Page 18

17 it is linked with comp. Input control object contents remarks 1. Comp louver heater 1. Buzzer sounds if any button of inner control is pushed. 2. Buzzer sounds 4 times 3 seconds after initial power input. 3. Buzzer sounds for 3 or 1 times in case of a/s forced defrosting and short (pull down) ope...

Page 19

18 1. Start open and close “freezer door switch” 5 times while pushing “frz. Temp” button simultaneously. 2. Control 1) all other electrical components are off except for f-fan / r-fan 2) fan control door open → fan on / door close → fan off. 3) display control “frz. Led” and “ref. Led” are on in go...

Page 20

19 compensation of r-sensor on/off temp. (down) in case temperature of refrigerator compartment is weak or insufficient, take the following action. Input control object contents remarks main pcb resistance of r-sensor mid on/off point r36 : r-sensor standard resistance in normal mode (31.4k) r37 : i...

Page 21

20 1. How to start 1) press “frz.Temp” button 5 times while pressing “ref.Temp” button at the same time. 2. How to stop 1) push “frz.Temp” button 1 time. 2) it stops automatically in 4 minutes from the start. 3. All the error codes are reset if they turn to be normal. 4. Error display input control ...

Page 22

21 5. Control way of errors (if any) 1) “f-sensor” error cause : f-sensor open or short control : condition of ambient temperature how to reset : if f-sensor is normal, the error is terminal temperature. Contents remarks 2) “r-sensor” error cause : r-sensor open or short control : condition of ambie...

Page 23

22 1. How to start 1) under “lock” mode, press “super freezer” button 5 times while pressing “freezer set” button at the same time. 2) the front cled displays as the right diagram shows ( [ex.] time display of 0003 signifies 3 minutes of power on time.) 3) press “freezer set” button and the followin...

Page 24

23 1) “f1” error cause : f-sensor disconnection or short check point : measure the resistance between both terminals after separating cn8 (or cn15) of the main pcb. (refer to the 5-2.) if f-sensor is disconnected or shorted , change the f-sensor in the freezer compartment. How to reset : if f-sensor...

Page 25

24 9) “ei”error cause : i-sensor disconnection / short check point : measure the resistance between both terminals after separating cn11 of the main pcb. (refer to the 5-2.) if f-sensor is disconnected or shorted , change the i-sensor in the automatic ice maker. Contents remarks 10) “ef” error cause...

Page 26

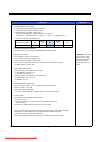

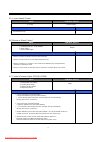

25 element a/s function input control object contents remarks each button resistance of r-sensor mid on/off point “ref.Temp”+ “frz.Temp” 5 times error display “frz.Temp”+ “frz.Door” open/close 5 times demo function “ref.Temp”+ “frz.Door” open/close 5 times pull down “frz.Temp” + “ref.Temp” 5 times f...

Page 27

26 1. Filter exchange information : record as a real-time from the point of power input 2. P factor (information about ice maker) input control object contents remarks none 1. F-fan, r-fan, c-fan input control object contents remarks full ice sensing switch ice maker lock sensors ice separating moto...

Page 28

27 contents remarks 2) with the initial power input, ice tray turns to be horizontal and ice making mode starts. 3) control of water hose heater * heater is always on if rt-sensor has an error or rt is below 15 degree. * heater is always on for 60 minutes (max. Limit time) if flow-sensor has an erro...

Page 29

28 contents remarks 3. Ice separating (drop) mode ccw cw stop cw motor revolution level sw status of ice tray horizontal position ice separation start 8~11sec max1.1sec 8.5~12.2sec 0.2sec normal level sw level sw error 1.1 sec 11 sec 10 sec 1) time of each zone used to verify level switch error 2) t...

Page 30

29 contents remarks 1) water supply valve is open when water supply mode starts after separation of ices. 2) water is supplied by time in case sensor has error. 3) factor valve is variable which can be useful in as action ① water flow pulse is set to 238 if flow sensor is in normal condition. (if wa...

Page 31

30 contents remarks 4) control flow & timing chart ① crushed ice ② cubed ice ③ water delay time : a = 500ms, b = 500ms, c = 2.0s, d = 5.0s d.P sw gear motor d.P lamp d.P s/v (flap) d a a c d.P sw cube s/v d.P s/v (flap) gear motor d.P lamp a c a a b d d.P lamp d.P sw water s/v d a downloaded from fr...

Page 32

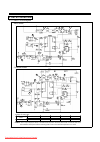

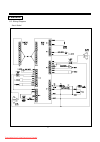

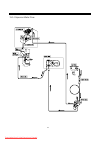

31 5-1. Power circuit diagram 5. Circuit operation - basic model 5vdc 14.5vdc 12vdc 310vac 230vdc voltage ce6 ce4 ce3 ce1 mc1 e d c b a parts a - dispenser model b d c e a b c d e ※ voltage of every part ※ caution : since high voltage (dc310v) is maintained at the power terminal, please take a measu...

Page 33

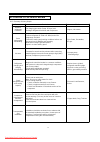

32 [f-sensor] 1) it senses the temperature of freezer compartment and control comp., f-fan on/off 2) how it works; -19℃ -16℃ -11℃ working temp. ≒3.24v ≒9.32㏀ low on ≒2.73v ≒2.93v sensing voltage ≒15.58㏀ ≒15.19㏀ resistance high off mid off working point [r-sensor] 1) it senses the temperature of refr...

Page 34

33 contents remarks - dispenser model [f-sensor (a)] 1) it senses the temperature of freezer compartment and control comp., f-fan on/off 2) how it works; -19℃ -16℃ -11℃ working temp. ≒3.24v ≒9.32㏀ low on ≒2.73v ≒2.93v sensing voltage ≒15.58㏀ ≒15.19㏀ resistance high off mid off working point [r-senso...

Page 35

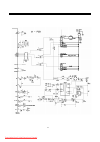

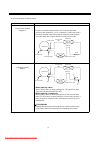

34 1. Circuit diagram #14≒12v #12≒12v #10≒12v #14≒0.7v #12≒0.7v #10≒0.7v ic7 #3≒0v #3≒5.0v relay 3 louver heater off condition on condition #5≒0v #5≒5.0v relay 5 d-heater relay 1 control mode method ic7 ic uln2004 output pin #1≒5.0v micom port #1≒0v micom port comp ic uln2004 output pin control cont...

Page 36

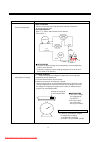

35 1. Circuit diagram contents remarks - dispenser model 2. How it works; #15≒12v #14≒12v #13≒12v #12≒12v #11≒12v #10≒12v #15≒12v #14≒12v #13≒12v #12≒12v #11≒12v #10≒12v #15≒0.7v #14≒0.7v #13≒0.7v #12≒0.7v #11≒0.7v #10≒0.7v #15≒0.7v #14≒0.7v #13≒0.7v #12≒0.7v #11≒0.7v #10≒0.7v off condition on condi...

Page 37

36 5-4. Fan function - basic model - dispenser model - vref is the reference voltage for the adjustment of the output voltage by the voltage distribution of vs (maximum output voltage), and the output voltage applied to the fan is determined by the pwm control using the software. 2. Explanation for ...

Page 38

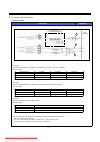

37 6-1. Wiring diagram 6. Diagram - basic model downloaded from fridge-manual.Com manuals.

Page 39

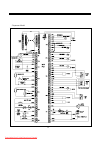

38 - dispenser model downloaded from fridge-manual.Com manuals.

Page 40

39 6-2. Circuit diagram of main pcb - basic model downloaded from fridge-manual.Com manuals.

Page 41

40 downloaded from fridge-manual.Com manuals.

Page 42

41 - dispenser model downloaded from fridge-manual.Com manuals.

Page 43

42 downloaded from fridge-manual.Com manuals.

Page 44

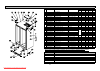

43 7. Component locate wiew 7-1. Front view ( dispenser + home bar model ) f-sensor automatic ice maker geared motor r-sensor r-sensor inner controller f-door switch r-door switch r-door switch freezer compartment (dispenser model) f-lamp f-fan motor r-lamp r-fan motor 7-2. Inner view refrigerator c...

Page 45

44 d-sensor temp fuse defrost heater water pipe evaporator compressor condenser dryer running capacitor olp & ptc water valve condenser fan-motor tray drip power cord 7-3. Evaporator 7-4. Machine compartment downloaded from fridge-manual.Com manuals.

Page 46

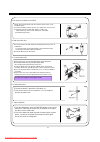

45 no disassembling procedure no disassembling procedure 1 5 2 6 3 7 4 8 ▷pull forward ice storage case ▷remove 2 screws at the cove guide cab w/tube a. ▷remove 2 screws. ▷disassemble cover guide cab w/tube a ▷pull forward ice maker. ▷pull forward hose ice maker tube as. ▷remove water hose heater's ...

Page 47

46 no disassembling procedure no disassembling procedure 1 4 2 5 3 6 ▷remove 2 screws. ▷pull forward bracket geared motor. ▷unscrew (4 points). ▷separate 6 pin housing of bracket geared motor from the top connector. ▷check solenoid valve and geared motor. 2) how to check hose ice maker tube assembly...

Page 48

47 no disassembling procedure no disassembling procedure 1 3 2 ▷ insert (-) screw driver into bottom hole of dispenser button guide. Pull up forward to remove the guide. (be careful not to damage guide surface.) ▷ remove micro switch. 2) how to check micro switch criterion ▷good : ▷defective : chang...

Page 49

48 no disassembling procedure no disassembling procedure 1 4 3 6 ▷ separate 2 housings of 10p / 7p from front pcb. (do not hold only wires to pull out.) ▷unscrew (3 points) to remove sol valve. ▷unscrew (2 points) to remove box dispenser shut. ▷unscrew (1 point) to remove cover ice flap. 2) how to c...

Page 50

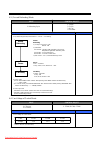

49 8-5. Main pcb 1 2 3 4 5 6 item remark no check point compensation of weak refrigeration →making r-temp cooler 1 * used when making r-temp. Down to compensate for weak refrigeration without changing fcp temp. Setting. ▷cutting of j1 ; down by 1.5℃ ▷cutting of j1, j2 ; down by 3℃ relay power contro...

Page 51

50 item remark no check point compensation of weak refrigeration →making r-temp cooler 1 * used when making r-temp. Down to compensate for weak refrigeration without changing fcp temp. Setting. ▷cutting of j18 ; down by 1.5 ℃ ▷cutting of j18, j19 ; down by 3℃ relay power controller 2 * to check norm...

Page 52

51 no disassembling procedure no disassembling procedure 1 6 3 8 ▷ pull forward ice maker. ▷unscrew (3 points) plate gear fixture. ▷unscrew fixture of frame ice maker. ▷ check if ice dropping motor is normal (ok). 8-6. Ice maker 1) disassembling procedure 2 7 ▷ remove 2 screws on top front of ice ma...

Page 53

52 parts how to check criterion ice dropping motor 2) how to check ice maker ▷ check resistance value of 2 wires with a multi tester. ▷ good : rs-360rh-14250 : 6 ~ 14Ω ▷ defective : change the motor. I-sensor (ice sensor) ▷ check resistance value of 2 wires with a multi tester. ▷ good : 4.4 ~ 50kΩ (...

Page 54

53 1) insert a flat tip driver into the left down groove of panel frame and snap it out smoothly. 2) separate 2 housings of 10p / 7p from front pcb. (do not hold only wires to pull out.) 3) unscrew (7 points) to remove front pcb. * follow the reverse order when assembling. ※ how to replace front pcb...

Page 55

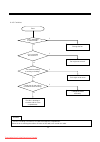

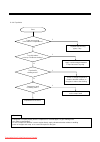

54 refer to error display in operation and function start change the comp. Change fuse. Temp y n n y n y y n y n change olp/ptc change f/c-motor change m-pcb check lead wire change the defrost heater check ice formation on eva. And if refrigerant leak is found, repair it. N n y y y n n defrost heate...

Page 56

55 1) remove foods. 2) remove ice bucket, shelves and cases in freezer compartment. (1) removing and replacing freezer parts * remove 2 screws of ice maker. * remove the housing of ice maker as. (right side) * remove 4 screws of geared motor. * remove the housing of geared motor as. (center) (2) (3)...

Page 57

56 * remove light cover screws. * pull down smoothly the bottom of light cover to remove. * remove the screw of bracket f-lamp. * remove the left housing. * hold the end of f-fan cover and pull forward slowly. * remove the screw cap on the f-louver a with a flat tip driver. Removing and replacing fr...

Page 58

57 removing and replacing freezer parts f-louver b heater housing d-sensor housing 1st : f-louver b heater housing 2nd : none. 3rd : defrost heater housing. Temp. Fuse defrost heater d-sensor defrost heater temp. Fuse housing downloaded from fridge-manual.Com manuals.

Page 59

58 reassemble the door. Start explain not to open doors too frequently. Y n n y remove the gap. Wipe out dews on the louver surface and run the refrigerator again. Change the louver assembly. Y n y y y n n make enough distance between heat appliances and refrigerator. Y n n 9-2-2. Ice formation on f...

Page 60

59 change the light bulb. Start repair the f-door switch. Check the f door switch connection and f-light socket. Y n n y change of f lights change of f door switch * remove 2 screws of light cover. * hold the bottom of light cover and pull forward to remove. * change the light bulb. (ac240v 25w) * i...

Page 61

60 9-3. Refrigerator compartment solve error code problem, if any. Start y n n y n n y y change the r-motor. Change the main pcb. Check the wirings. Explain not to place foods close to r-sensor or cold air spout. Explain not to open doors unnecessarily or frequently. N y n y y refer to “freezing doe...

Page 62

61 * remove screws of light cover. * hold the bottom of cover and pull forward to remove. ① ② ③ * change the light bulbs. (ac240v 25w) change the light bulb. Start repair the r-door switch. Check the r-door switch connection and r-light socket. Y n n y freezer light filament is disconnected or break...

Page 63

62 reassemble the doors. Start explain not to open doors unnecessarily. Y y repair to eliminate the gap. Make enough distance between the appliances and refrigerator. Advise to cool down foods, wrap or cover foods with much water before storing in the compartment. Repair and change r-motor. Y n y y ...

Page 64

63 start explain the temperature modes. Advise to set the temp. To “middle” or “low” mode. N repair and/or change the r-check valve. Change the r-sensor. Y n n y check the r-sensor connection. (check the connector to main pcb.) n y ※ refer to “repair /change of check valve”. Y 9-3-4. Excessive refri...

Page 65

64 * hold the bottom and right of damper to pull down to remove. * lift up a piece of check valve flap and insert a finger to the valve frame to hold out. ⑤ ⑦ ⑥ ⑧ removing of check valve * remove screws of light cover. * hold the bottom of cover and pull forward to remove. ① ② ③ ④ * disconnect light...

Page 66

65 start level the refrigerator by adjusting wheels. ☞ refer to user’s guide and svc manual. Y n set it right. Y n change the rubber absorber. Y n attach a restrainer on the comp. Head to reduce vibration and high frequency noise. Y n change the compressor. Remarks ● compressor sound is somewhat nor...

Page 67

66 start attach an absorber gum on the capillary tube. N y apply a gum on the accumulator. Y n apply a gum on the accumulator. Y n fasten the evaporator in f- compartment tightly against touching (liner) surfaces. N y explain refrigerator work mechanism and sound to the users or customers. Remarks ●...

Page 68

67 troubleshooting of evaporator sound 1. Hiss sound from capillary tube 1) “i” tube is used to connect the capillary tube and evaporator. (2 welding points : ①, ②) 2. Sizzling sound from accumulator 3. Shaking or trembling sound of evaporator 1 2 2) when such a sound is made, attach a absorber on t...

Page 69

68 remarks ● the fan is sending out cold air to circulate it through the compartments. When the air is touching the surface of louver or liner wall, such sound can make. Start change the fan. N y set it right not to touch. Y n set it right not to move. Y n change the motor assembly. N y explain to t...

Page 70

69 2) check if fan motor and fan are hanged down. Fan working sound can be louder if they are not set right. 2. Any touch sound from fan troubleshooting of fan noise 1. Fixing or fastening of fan motor 1) check if fan motor frame of the assembly is fastened tightly with screws to the liner wall. Unl...

Page 71

70 remarks ● refrigerant is erupting rapidly from the compressor to circulate pipes, so pipe shaking noise can make to some degree. ● in case compressor vibration is sent to a pipe directly, apply vibration absorber rubbers to welding points of the pipe and comp. Or to a much bent point on the pipe....

Page 72

71 door switch is soaked with water or there is water in the switch ? Pcb input is ok ? Start change the door switch. N y repair any disconnection of wires and defective door switch. Y connector insertion to main pcb is ok ? N repair the defective connection. Y door switch itself is ok ? N change th...

Page 73

72 10-1. Summary of heavy repair * installation should be conducted in accordance with the standard installation procedure. (leave space of more than 5 cm from the wall for compressor compartment cooling fan mounted model.) transportation and installation * copper brush, rag, tool box * remove flux ...

Page 74

73 1) nitrogen only should be used when cleaning inside of cycle pipes inside and sealing. 2) check leakage with an electronic leakage tester. 3) be sure to use a pipe cutter when cutting pipes. 4) be careful not the water let intrude into the inside of the cycle. Others. 1) weld under nitrogen atmo...

Page 75

74 1) remove residual refrigerant more than 5 minutes later after turning off the refrigerator. ( if not, compressor oil may leak inside.) 2) remove retained refrigerant slowly by cutting first high pressure side (drier part) with a nipper and then cut low pressure side. 1. Removal of residual refri...

Page 76

75 * pipe connection connect a red hose to the high pressure side and a blue hose to the low pressure side. * vacuum sequence open ①,② valves and evacuate for 40 minutes. Close valve ①. 3.Vacuum degassing. Precautions items * charging sequence 1) check the amount of refrigerant supplied to each mode...

Page 77

76 precautions items 4) refrigerant charging charge refrigerant while operating a compressor as shown above. 5) pinch a charging pipe with a pinch-off plier after completion of charging. 6) braze the end of a pinched charging pipe with copper brazer and take a gas leakage test on the welded parts. 4...

Page 78

77 10-5. Brazing reference drawings. ▶ welding point ● ■ copper welding (ag 5%) 7 points 3 points silver welding (ag 35%) hot pipe f r evaporator condenser i-pipe accumulator suction pipe dryer capi-tube pipe suc conn pipe conn b compressor ▶ flow of refrigeration cycle compress or pipe co nn. B wir...

Page 79

78 11-1. Installation preparation 11. Installation guide check if the refrigerator can pass a doorway or enter a door first. Dimensions( including door handles) (width*depth*height) 903mm x 734.5mm x 1790mm find a suitable place to install sufficient space from refrigerator back to the ※wall for fre...

Page 80

79 11-2. If the refrigerator can not enter the door removing freezer door 1 ※remove front bottom cover first, if it is attached. Remove front bottom cover first, pull out the left collar of the coupling first, then hold the coupling and pull out the left water tube. 2 unscrew top hinge cover with a ...

Page 81

80 replacing freezer door 1 insert the water tube into the hole of the bottom hinge pin first, then insert the bottom of freezer door into the bottom hinge pin. 2 insert the bottom hole of freezer door straight to the bottom hinge pin. 3 let the top of door close to the cabinet and insert the top hi...

Page 82

81 11-3. Refrigerator leveling & door adjustment in case freezer door is lower than refrigerator door insert a screw driver (flat tip) into a groove of the left wheel (bottom of freezer) and turn it clockwise until the door is balanced. (clockwise to raise freezer door ; counterclockwise to lower) ※...

Page 83

82 11-4. Water line installation 1.The water pressure should be 3kgf/cm2 or more to run the automatic icemaker. ※checkup your tap water pressure ; if a cup of 180cc is full within 10 seconds, the pressure is ok. 2.When installing the water tubes, ensure they are not close to any hot surface. 3.The w...

Page 84

83 3. Remove any substance from filter 1) open the main tap water valve and check if water comes out of the water tube. 2) check if the water valve is open in case water does not come out. 3) leave the valve open until clean water is coming out. ※initial water may contain some substances out of filt...

Page 85

84 11-5. Dispenser water flow downloaded from fridge-manual.Com manuals.

Page 86

20ib 20db 20eb 20fb 20gb 1 assy cab urt 1 1 1 1 1 2 3012924400 hinge *t *r as po t3.0+paint 1 1 1 1 1 3 3012924300 hinge *t *l as po t3.0+paint 1 1 1 1 1 4 3016042300 special *t hi bolt 6x13 swch18a 2 2 2 2 2 5 7051401065 screw machine pan 4x10 sw bsni 1 1 1 1 1 6 3011446200 cover *t hi *r pp 1 1 1 ...

Page 87

20ib 20db 20eb 20fb 20gb 29 3010340400 base comp as fru-571i 1 1 1 1 1 30 3016003300 speical bolt t2 m6.5x20 4 4 4 4 4 31 cord power as 1 1 1 1 1 32 7112401211 screw tapping t1 trs 4x12 mfzn 1 1 1 1 1 33 7051401065 screw machine pan 4x10 sw bsni 1 1 1 1 1 34 capacitor run model dependent 1 1 1 1 1 3...

Page 88

20ib 20db 20eb 20fb 20gb 60 3011492810 cover damp as fru-571i 1 60-1 3014235200 panel contl *i as 1 61 3012214100 frame check valve as fru-571i 1 1 1 1 1 62 3012024200 fixture motr as 1 1 1 1 1 62-1 3015916000 motor r fan d4612aaa20 1 1 1 1 1 63 3011495100 cover damp as fru-541d - 1 1 1 1 63-1 30148...

Page 89

20ib 20db 20eb 20fb 20gb 76 3012514500 guide case a *l as abs 1 1 1 1 1 77 3012514600 gudie case a *r as abs 1 1 1 1 1 96 3012529000 guide drn ga 1 1 1 1 1 97 3017842700 shelf f ice as nude glass 1 98 3011186300 case ice pp 1 100 3015915900 motor f fan d4612aaa21 1 1 1 1 1 101 3018921300 louver f a ...

Page 90

20ib 20db 20eb 20fb 20gb 134 3019026700 pocket f *t hips 1 1 1 1 1 3019027401 pocket f as fru-541d - 3 3 3 3 3019026600 pocket f fru-571i 5 3000067600 assy f dr fru-547e, sus - 1 1 1 1 3000067610 assy f dr fru-577i, sus 1 136-1 3010964600 cap ice path frame hips - 1 1 1 1 136-2 3012318800 gasket f d...

Page 91

20ib 20db 20eb 20fb 20gb 137 3012027200 fixture hndl suport *t hips 1 1 1 1 1 138 3012018700 fixture hndl suport *m hips 2 2 2 2 2 139 3015311500 supporter hndl *u abs+spray 1 1 1 1 1 140 7002401011 screw machine trs 4x10 mfzn 4 4 4 4 4 141 3016040100 special screw hndl m5x20 4 4 4 4 4 142 301264530...

Page 92

1. 1. Electric device specification part code specification part code specification part code hpl30yg-5 395s130r50 400vac/ 5㎌ 3016401920 308nhb, s330 3018129810 mk183q-l2u 3956183d50 350vac/ 5㎌ 3016401170 265rhb, s330 3018129600 mk183c-l2u 3956183d10 250vac/ 12㎌ 3016405000 445phb, 4r7m 3018129610 mk...