- DL manuals

- Daewoo

- Engine

- G15S-2

- Service manual

Daewoo G15S-2 Service manual - The N-Ca55-500Tr Mixer

G420E/G424E

Tier LP Engine

N-CA55-500TR Mixer

70

CHAPTER 8 N-CA55-500TR AIR/FUEL MIXER

Propane is a by-product of crude oil and natural gas.

In the extraction process various hydrocarbons such

as gasoline, kerosene, propane and butane are

separated. Each of these carry a certain amount of

by-product residue, commonly called heavy ends.

Under normal circumstances these residues remain

suspended in liquid and pass through the system

undetected.

Engine coolant flows through the regulator/converter

assisting in the propane vaporization process. As the

coolant temperature rises, the regulator/converter

temperature also rises. The gas becomes hot and

expands to the point where it cannot carry the heavier

hydrocarbons or heavy-ends through the system.

Because of this, the heavy-ends are deposited

(dropped out) into the regulator/converter, the vapor

line from the regulator to the mixer and even in the

mixer itself. When these heavy-ends cool they form a

wax-like deposit or sludge. HD5 grade propane is

recommended for motor fuel use, however HD5

propane will carry a certain amount of heavy-ends.

A fuel filter cannot remove this because it is not dirt or

debris but part of the liquid propane. As these

deposits build up over time regulator fuel ports and

valve seats can be affected, reducing the

performance of the regulator. All propane systems

incorporating a regulator/converter are subject to

heavy-end fouling over time. Because of this it may

be necessary for the certified technician to

disassemble, clean and service the

regulator/converter after long periods of operation.

Removal and Installation of

the N-CA55-500TR Mixer

WARNING

z

LP gas is highly flammable. To prevent

personal injury, keep fire and flammable

materials away from the lift truck when work

is done on the fuel system.

z

Gas vapor may reduce oxygen available for

breathing, cause headache, nausea,

dizziness and unconsciousness and lead to

injury or death. Always operate the forklift in

a well ventilated area

z

Liquid propane may cause freezing of tissue

or frostbite. Avoid direct contact with skin or

tissue; always wear appropriate safety

protection including gloves and safety

glasses when working with liquid propane.

CAUTION

The regulator/converter and mixer are

part of a certified system complying with

EPA and CARB 2004 requirements. Only

trained certified technicians should

perform disassemble, service or

replacement of the regulator/converter or

mixer.

Summary of G15S-2

Page 1

Service manual g420e/g424e tier lp engine lift trucks g15s-2, g18s-2, g20sc-2 gc15s-2, gc18s-2, gc20sc-2 with g420e tier lp engine g20e-3, g25e-3, g30e-3, g32e-3 gc20e-3, gc25e-3, gc30e-3, gc32e-3 with g424e tier lp engine sb4136e00 jun. 2004.

Page 2

1 important safety information most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to ...

Page 4

G420e/g424e tier lp engine table of contents 3 warning read this entire manual and all other publications pertaining to the work to be performed before installing, operating, or servicing this equipment. Practice all plant and safety instructions and precautions. Failure to follow instructions can c...

Page 6: Index

G420e/g424e tier lp engine table of contents 5 index working with lpg equipment chapter 0 lpg and lpg fuel tanks lpg fuel supply........................................................ 8 lpg fuel tanks.......................................................... 9 installing lpg fuel tanks ...............

Page 7

G420e/g424e tier lp engine table of contents 6 chapter 7 n2001 pressure regulator /converter removal and installation of n2001 lp regulator/converter................................................. 64 hose connections.................................................... 65 n2001 removal steps: ........

Page 8: Working With Lpg

G420e/g424e tier lp engine working with lpg equipment 7 working with lpg equipment warning propane vapor is heavier than air and can collect in low areas when adequate ventilation or air movement is not present to disperse it. Never check for leaks with a flame or match. Use a leak detector solution...

Page 9: Lpg Fuel Supply

G420e/g424e tier lp engine lpg and lpg fuel tanks 8 chapter 0 lpg and lpg fuel tanks lpg fuel supply liquefied petroleum gas (lpg) consists mainly of propane, propylene, butane, and butylenes in various mixtures. Lpg is produced as a by-product of natural gas processing or it can be obtained from cr...

Page 10: Lpg Fuel Tanks

G420e/g424e tier lp engine lpg and lpg fuel tanks 9 lpg fuel tanks the two styles of lpg storage containers available for industrial use and lift truck applications are portable universal cylinders and permanently mounted tanks. Portable universal cylinders are used primarily for off-highway vehicle...

Page 11: Lpg Fuel Tank Components

G420e/g424e tier lp engine lpg and lpg fuel tanks 10 lpg fuel tank components (1) fuel gauge (2) 80% stop bleeder (3) pressure relief valve (4) service valve (tank end male coupling) (5) filler valve (6) alignment pin (7) vapor withdrawal tube (only used with vapor withdrawal) (8) 80% limiter tube (...

Page 12: Quick Disconnect Coupling

G420e/g424e tier lp engine mi-04 system overview 11 quick disconnect coupling the liquid withdrawal or service valve on a dot tank has male threads and accepts the female portion of a quick disconnect coupling (figure 8). The female portion is adapted to the liquid hose going to the fuel system. Bot...

Page 13

G420e/g424e tier lp engine engine specification 12 chapter 1 engine specification indication of engine serial number.

Page 14: Specifications(G420E)

G420e/g424e tier lp engine engine specification 13 specifications(g420e) general description engine type: water-cooled, inline 4-cycle, 4-cylinders naturally aspirated 1-venturi intake manifold combustion system: semi-spherical combustion chamber exhaust system: cast iron, dry valve configuration: o...

Page 15: Specifications(G424E)

G420e/g424e tier lp engine engine specification 14 specifications(g424e) general description engine type: water-cooled, inline 4-cycle, 4-cylinders combustion system: naturally aspirated 1-venturi intake manifold semi-spherical combustion chamber exhaust system: cast iron, dry valve configuration: o...

Page 16: Overview

G420e/g424e tier lp engine system operational overview 15 chapter 2 mi-04 lpg system operational overview mi-04 general description mi-04 control system is designed to provide a complete, fully integrated solution that will meet or exceed tier-2 large spark ignited engines emission standards establi...

Page 17

G420e/g424e tier lp engine system operational overview 16 the secm makes any necessary corrections to the air fuel ratio by controlling the inlet fuel pressure to the air/fuel mixer by modulating the fuel trim valve (ftv) connected to the regulator. Reducing the fuel pressure leans the air/fuel mixt...

Page 18: Mi-04 Lp Fuel Filter

G420e/g424e tier lp engine system operational overview 17 mi-04 lp fuel filter after exiting the fuel tank, liquid propane passes through a serviceable inline fuel filter to the electric fuel lock off. (figure 11) shows a typical inline type lp fuel filter manufactured by century. The primary functi...

Page 19: Mi-04 N-2001

G420e/g424e tier lp engine system operational overview 18 mi-04 n-2001 regulator/converter after passing through the electric fuel lock-off, liquid propane enters the n-2001 regulator/converter (figure 13). The n-2001 functions as a fuel vaporizer, converting liquid propane to vapor propane and as a...

Page 20: N-2001 Theory Of Operation

G420e/g424e tier lp engine system operational overview 19 n-2001 theory of operation liquid propane, at tank pressure, enters the n-2001 through the fuel inlet port (1). Propane liquid then flows through the primary valve (2). The primary valve located at the inlet of the expansion chamber (3), is c...

Page 21: Mi-04 N-Ca55-500Tr Mixer

G420e/g424e tier lp engine system operational overview 20 mi-04 n-ca55-500tr mixer vapor propane fuel is supplied to the n-ca55-500tr mixer by the n-2001 pressure regulator/converter. The n-ca55-500tr mixer uses a piston type air valve assembly to operate a gas-metering valve inside the mixer. The g...

Page 22

G420e/g424e tier lp engine system operational overview 21 when the engine is cranked over it begins to draw in air, creating a negative pressure signal. This negative pressure signal is transmitted through a port in the check valve plate to the avv chamber. A pressure/force imbalance begins to build...

Page 23: Mi-04 Electronic Throttle

G420e/g424e tier lp engine system operational overview 22 mi-04 electronic throttle conventional throttle systems rely on mechanical linkage to control the throttle valve. To meet fluctuating engine demands a conventional system will typically include throttle valve actuators designed to readjust th...

Page 24: Mi-04 Fuel Trim Valve

G420e/g424e tier lp engine system operational overview 23 mi-04 fuel trim valve the fuel trim valve (ftv) is a two-way electric solenoid valve and is controlled by a pulse width modulated (pwm) signal provided by the secm. The ftv is used to bias the output fuel pressure on the lpg regulator/convert...

Page 25: Heated Exhaust Gas Oxygen

G420e/g424e tier lp engine system operational overview 24 heated exhaust gas oxygen sensor (hego) the hego sensor (figure 24) installed in the exhaust manifold before the catalytic muffler is a basic zirconium type oxygen sensor comprised of a hollow cone-shaped internal element made of zirconium di...

Page 26: Mi-04 Secm

G420e/g424e tier lp engine system operational overview 25 mi-04 secm (general description) the woodward small engine control module (secm) controller has full authority over spark, fuel and air. Utilizing motorola’s hcs12 micro controller, the secm has 24 pins of i/o and is fully waterproof and shoc...

Page 27

G420e/g424e tier lp engine system operational overview 26 catalytic muffler all exhaust gases pass through a catalyst that is mounted in the catalytic muffler. It filters the harmful gases through a dense honeycomb structure coated with precious metals such as platinum, palladium, and rhodium. Chemi...

Page 28: Mi-04 Secm

G420e/g424e tier lp engine system operational overview 27 mi-04 secm (load/speed management) drive by wire refers to the fact that the mi-04 control system has no throttle cable from the acceleration pedal (figure 26) to the throttle body. Instead, the secm is electronically connected both to the ac...

Page 29

G420e/g424e tier lp engine system operational overview 28 the mi-04 system also performs minimum (min) and maximum (max) governing through the secm and dbw throttle. For min governing, or idle speed control, the idle speed is fixed by the secm. Unlike a mechanical system, the idle speed is not adjus...

Page 30: Mi-04 Ignition Management

G420e/g424e tier lp engine system operational overview 29 mi-04 ignition management in the normal course of events, with the engine operating at the correct temperature in defined conditions, the secm will use load and engine speed to derive the correct ignition timing. In addition to load and speed...

Page 31: Recommended

G420e/g424e tier lp engine maintenance schedule 30 chapter 3 mi- 04 maintenance schedule recommended maintenance schedule suggested maintenance requirements for an engine equipped with an mi-04 fuel system are contained in this section. The owner should, however, develop his own maintenance schedule...

Page 32: Inspect Acceleration Pedal

G420e/g424e tier lp engine maintenance schedule 31 inspect acceleration pedal operation z verify acceleration pedal travel is smooth without sticking. Check coolant level z the items below are a general guideline for system checks. Refer to the engine manufacturers specific recommendations for prope...

Page 33: Replace Lp Fuel Filter

G420e/g424e tier lp engine maintenance schedule 32 replace lp fuel filter element park the lift truck in an authorized refueling area with the forks lowered, parking brake applied and the transmission in neutral. 1. Close the fuel shutoff valve on the lp-fuel tank. Run the engine until the fuel in t...

Page 34: Testing Fuel Lock-Off

G420e/g424e tier lp engine maintenance schedule 33 testing fuel lock-off operation z start engine. Z locate the electrical connector for the fuel lock (a). Z disconnect the electrical connector. Z the engine should run out of fuel and stop within a short period of time. Z turn the ignition key switc...

Page 35: Inspect For Intake Leaks

G420e/g424e tier lp engine maintenance schedule 34 inspect for intake leaks z visually inspect the intake manifold, throttle assembly (d), and manifold adapters (e), for looseness and leaks. Repair as necessary. (d) throttle assembly (e) manifold adapter (f) tmap sensor inspect throttle assembly z v...

Page 36: Maintenance Schedule

G420e/g424e tier lp engine maintenance schedule 35 maintenance schedule interval hours check point daily every 250hrs or a month every 500 hours or 3 months every 1000 hours or 6 months every 1500 hours or 9 months every 2600 hours or 15 months every 4500 hours or 2 years general maintenance section...

Page 37

G420e/g424e tier lp engine maintenance schedule 36 maintenance schedule continued interval hours check point daily every 250hrs or a month every 500hrs or 3 months every 1000 hours or 6 months every 1500 hours or 9 months every 2600 hours or 15 months every 4500 hours or 2 years carburetor section c...

Page 38: Basic Troubleshooting

G420e/g424e tier lp engine basic troubleshooting 37 chapter 4 mi-04 lp basic troubleshooting basic troubleshooting the mi-04 systems are equipped with built-in fault diagnostics. Detected system faults can be displayed by the malfunction indicator lamp (mil) and are covered in the advanced diagnosti...

Page 39

G420e/g424e tier lp engine basic troubleshooting 38 problem probable cause corrective action engine cranking but will not start no vr sensor signal verify the vr signal is present z see chapter 5 advanced diagnostics fuel container almost empty lpg vapor from liquid outlet z fill fuel container z do...

Page 40

G420e/g424e tier lp engine basic troubleshooting 39 problem probable cause corrective action fuel container almost empty lpg vapor from liquid outlet z fill fuel container z do not exceed 80% of liquid capacity excess flow valve closed reset excess flow valve z close liquid valve z wait for a “click...

Page 41

G420e/g424e tier lp engine basic troubleshooting 40 problem probable cause corrective action clogged fuel filter repair/replace as required z see chapter 3 fuel filter replacement faulty vapor connection between the pressure regulator/converter and the mixer check connection z verify no holes in hos...

Page 42

G420e/g424e tier lp engine basic troubleshooting 41 problem probable cause corrective action fuel lock-off malfunction repair/replace fuel lock-off z see chapter 3 fuel lock-off faulty vapor connection between the pressure regulator/converter and the mixer check connection z verify no holes in hose ...

Page 43

G420e/g424e tier lp engine basic troubleshooting 42 problem probable cause corrective action incorrect idle speed control incorrect timing or spark control see chapter 5 advanced diagnostics & chapter 9 tests and adjustments rough idle engine mechanical see engine manufacturers service manual incorr...

Page 44

G420e/g424e tier lp engine basic troubleshooting 43 problem probable cause corrective action air/fuel mixer malfunction check mixer z see chapter 8 air/fuel mixer section air filter clogged check air filter z clean/replace as required vacuum leak check system vacuum hoses from regulator to ftv and m...

Page 45: Advanced Diagnostics

G420e/g424e tier lp engine advanced diagnostics 44 chapter 5 mi-04 lp advanced diagnostics advanced diagnostics the mi-04 systems are equipped with built-in fault diagnostics. Detected system faults can be displayed by the malfunction indicator lamp (mil) as diagnostic fault codes (dfc) or flash cod...

Page 46: From Secm Memory

G420e/g424e tier lp engine advanced diagnostics 45 displaying fault codes (dfc) from secm memory to enter code display mode you must turn off the ignition key. Now turn on the key but do not start the engine. As soon as you turn the key to the on position you must cycle the acceleration pedal by dep...

Page 47: Fault List Definitions

G420e/g424e tier lp engine advanced diagnostics 46 fault list definitions several sensors in the mi-04 system have input low/high faults and a sensor range fault. These are the coolant temperature sensor, the throttle position sensor and the pedal position sensors. Signals to these sensors are conve...

Page 48

G420e/g424e tier lp engine advanced diagnostics 47 iatsensorinputhigh: (intake air temperature sensor input is high) normally set if the tmap temperature signal wire has become disconnected or the circuit is open to the secm. Est1low: (electronic spark trigger) is a current driver signal and normall...

Page 49

G420e/g424e tier lp engine advanced diagnostics 48 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 12 none signifies the end of one pass through the fault list none none, used as a beginning and end of the fault list identification 14 ects...

Page 50

G420e/g424e tier lp engine advanced diagnostics 49 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 23 throttlesensorinputhi tps1 sensor failure or shorted circuit disable throttle check throttle connector and tps1 sensor wiring for a short...

Page 51

G420e/g424e tier lp engine advanced diagnostics 50 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 26 etcsticking throttle plate sticking inside the throttle body or the etc driver signal is open engine shutdown check for debris or obstruc...

Page 52

G420e/g424e tier lp engine advanced diagnostics 51 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 29 etcdriverfault throttle driver over-current or driver signals shorted disable throttle check etc driver wiring for a shorted circuit etc+...

Page 53

G420e/g424e tier lp engine advanced diagnostics 52 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 34 mapsensorinputhigh tmap sensor failure or shorted circuit disable throttle check tmap connector and map signal wiring for a shorted circu...

Page 54

G420e/g424e tier lp engine advanced diagnostics 53 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 38 iatsensorinputhigh iat signal disconnected, open circuit or sensor malfunction stored fault code (mil only) check tmap connector and iat ...

Page 55

G420e/g424e tier lp engine advanced diagnostics 54 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 43 est1high coil driver signal high or over-current stored fault code (mil only) check coil driver wiring for an open circuit or disconnecte...

Page 56

G420e/g424e tier lp engine advanced diagnostics 55 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 54 batterysensorinputhigh battery voltage measured above +15.9 vdc stored fault code (mil only) check battery and charging system voltage z ...

Page 57

G420e/g424e tier lp engine advanced diagnostics 56 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 56 xdrpsensorinputhigh +5vdc transducer power supplied by the secm to the sensors is above +5.20vdc engine shutdown measure transducer power...

Page 58

G420e/g424e tier lp engine advanced diagnostics 57 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 65 pedal2sensorinputlo app2 sensor failure or shorted circuit min power limit check acceleration pedal connector z cycle the pedal several t...

Page 59

G420e/g424e tier lp engine advanced diagnostics 58 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 72 afrtrimvalvelowerdc ftv duty cycle at lower (lean) limit stored fault code (mil, disable adaptive learns) engine measured air/fuel ratio ...

Page 60

G420e/g424e tier lp engine advanced diagnostics 59 table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 74 o2sensorswitching o2 sensor is not switching across the reference afr voltage stored fault code (mil, disable adaptive learns) check the ...

Page 61

G420e/g424e tier lp engine electrical connections 60 chapter 6 mi-04 electrical connections figure e1.

Page 62

G420e/g424e tier lp engine electrical connections 61 figure e2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 secm connector b a coo lant sen sor 1 2 vr se ns o r 3 2 1 electronic throttle 4 5 6 c b a smart coil d a b fu el lock -of f a b fu el t r im va lv e 2 3 4 tmap sensor 1 b c ...

Page 63: Resistance Checks

G420e/g424e tier lp engine n2001 regulator/converter 62 resistance checks note all resistive checks are made with the sensor or device disconnected from the harness. Sensor point to point expected range tmap pin 1 (gnd) to pin 4 (pressure signal kpa) 2.4k Ω - 8.2k Ω tmap pin 3 (pwr) to pin 4 (pressu...

Page 64: Voltage Checks

G420e/g424e tier lp engine n2001 regulator/converter 63 sensor point to point expected range vr sensor vr pin 1 (+) to pin 2 (-) ~320 Ω coil pin a (signal) to pin b ~10k Ω coil pin a (signal) to pin d ~34k Ω coil pin a (signal) to pin e (pwr) ~15k Ω coil pin b to pin d ~44k Ω coil pin b to pin e (pw...

Page 65: /converter

G420e/g424e tier lp engine n2001 regulator/converter 64 chapter 7 n2001 pressure regulator /converter propane is a by-product of crude oil and natural gas. In the extraction process various hydrocarbons such as gasoline, kerosene, propane and butane are separated. Each of these carry a certain amoun...

Page 66: Hose Connections

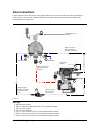

G420e/g424e tier lp engine n2001 regulator/converter 65 hose connections proper operation of the closed loop control greatly depends on the correct vacuum hose routing and fuel line lengths. Refer to the connection diagram (figure r1) for proper routing and maximum hose lengths when reinstalling sys...

Page 67: N2001 Removal Steps:

G420e/g424e tier lp engine n2001 regulator/converter 66 n2001 removal steps: 1. Close the liquid outlet valve in the fuel storage container. 2. Purge the system of fuel by starting the engine and running until all trapped fuel in the system is exhausted and the engine shuts down. 3. Remove the fuel ...

Page 68: N2001 Regulator

G420e/g424e tier lp engine n2001 regulator/converter 67 n2001 regulator disassembly steps: 1. Remove the six secondary cover screws (1), the secondary cover (2) and the secondary diaphragm (3). 2. Remove the six primary diaphragm cover screws (4) and the primary cover assembly (5). 3. Remove the six...

Page 69

G420e/g424e tier lp engine n2001 regulator/converter 68 5. Turn the regulator body over with the rear fuel inlet plate facing up. Remove the primary valve access plug (7), the primary valve (8) and the primary valve o-ring seal (9). The primary valve goes through the inlet plate, then through the bo...

Page 70: N2001 Disassembled Service

G420e/g424e tier lp engine n2001 regulator/converter 69 n2001 disassembled service 1. Clean the primary and secondary valves with soap and warm water to remove heavy-end deposits. Inspect the valve seats and o-rings for wear. Replace worn components as necessary. 2. Clean the primary and secondary d...

Page 71: The N-Ca55-500Tr Mixer

G420e/g424e tier lp engine n-ca55-500tr mixer 70 chapter 8 n-ca55-500tr air/fuel mixer propane is a by-product of crude oil and natural gas. In the extraction process various hydrocarbons such as gasoline, kerosene, propane and butane are separated. Each of these carry a certain amount of by-product...

Page 72: N-Ca55-500Tr Mixer

G420e/g424e tier lp engine n-ca55-500tr mixer 71 n-ca55-500tr mixer removal steps: 1. Close the liquid outlet valve in the forklift cylinder or fuel storage container. 2. Purge the system of fuel by starting the engine and running until all trapped fuel in the system is exhausted and the engine shut...

Page 73: N-Ca55-500Tr Disassembly

G420e/g424e tier lp engine n-ca55-500tr mixer 72 n-ca55-500tr disassembly and service (1) body (2) screw (3) valve (4) spring (5) assembly (6) gasket (7) gasket (8) screw (9) washer (10) screw (11) orifice fitting (12) label (13) label (14) cap 1. With the mixer/adapter assembly removed, and the air...

Page 74

G420e/g424e tier lp engine n-ca55-500tr mixer 73 4. Replace the air-valve sealing ring as shown (figure m7). The ring is similar to a piston ring and forms a seal from the air valve assembly to the mixer main body. Small raised circular formations can be found on one side of this ring. Place the rin...

Page 75: N-Ca55-500Tr Disassembled

G420e/g424e tier lp engine n-ca55-500tr mixer 74 10. Check for binding of the air valve assembly by pressing down with two fingers on opposite sides of the air valve assembly (figure m13). The air valve assembly should move freely without binding and have full travel. If the air valve is binding, lo...

Page 76: Installing The

G420e/g424e tier lp engine test and adjustments 75 installing the mixer/throttle assembly (1) gasket-intake manifold (2) adapter-intake manifold (3) bolt-adapter (4) bracket-tmap (5) bolt-tmap bracket (6) tmap sensor (7) washer-tmap mtg (8) bolt-tmap mtg (9) gasket-itb(32mm) (10) itb(32mm) (11) o-ri...

Page 77

G420e/g424e tier lp engine test and adjustments 76 3. Check for free travel of the mixer’s piston diaphragm assembly by pushing the piston diaphragm downward (figure m18). If you detect any binding, loosen the retaining screws, re-align the gasket and re-tighten the retaining screws. Check for bindi...

Page 78

G420e/g424e tier lp engine test and adjustments 77 9. Tighten the four mounting bolts hand tight using a crossing pattern from one side of the adapter to the other. This prevents the adapter o-ring from misaligning against the throttle, which may cut the o-ring and cause an intake leak. Finally, tig...

Page 79: N2001 Service Testing

G420e/g424e tier lp engine test and adjustments 78 chapter 9 test and adjustments warning z lp gas is highly flammable. To prevent personal injury, keep fire and flammable materials away from the lift truck when work is done on the fuel system. Z gas vapor may reduce oxygen available for breathing, ...

Page 80: Primary Stage Test Hardware

G420e/g424e tier lp engine test and adjustments 79 secondary stage test connection primary stage test hardware 1. Hand vacuum pump. 2. Regulator fuel inlet test fitting (¼” npt standard air coupling). 3. Test gauge fitting (1/4” npt x 1/4” hose barb). 4. Vacuum hose or vinyl tubing. 5. 0-60 in w.C. ...

Page 81

G420e/g424e tier lp engine test and adjustments 80 3. Apply compressed air, wait for air to exit the hose barb in the test port, and then connect the magnahelic gauge (figure r13) to the hose barb using the vacuum hose or vinyl tubing. This prevents the gauge from reading maximum pressure due to the...

Page 82: N-Ca55-500Tr Service Avv

G420e/g424e tier lp engine test and adjustments 81 n-ca55-500tr service avv (air valve vacuum) testing avv test hardware 1. Mixer avv test fitting ¼” npt x ¼” hose barb. 2. Union tee ¼” npt with three ¼” npt x ¼” hose barb. 3. Vacuum hose. 4. 0-20 in w.C. Magnehelic gauge (inches of water column). A...

Page 83: Ignition Timing Adjustment

G420e/g424e tier lp engine test and adjustments 82 ignition timing adjustment with the mi-04 system both mechanical and vacuum advance are no longer inside the distributor. All ignition timing advance is controlled by the secm. The only timing adjustment that can be made by a technician is the mecha...

Page 84

G420e/g424e tier lp engine test and adjustments 83 4. Loosen the distributor hold down nut and rotate the distributor so that the signal rotor gear tooth of the #1 cylinder (tooth opposite the flat side of the distributor shaft) lines up with the sensor pickup. (figure g4). 5. To correctly set the d...

Page 85

G420e/g424e tier lp engine test and adjustments 84 7. After you have completed setting the distributor alignment you will need to adjust the vr sensor used by the secm for speed reference. This sensor is mounted near the crankshaft pulley wheel (figure g6). 8. Rotate the crankshaft pulley so that on...

Page 86: Idle Mixture Adjustment

G420e/g424e tier lp engine test and adjustments 85 idle mixture adjustment the method for making the idle mixture adjustment to a running engine is to use the service tool software by connecting a laptop computer to the secm. If you do not have the service tool proceed to (step 12). A usb (universal...

Page 87

G420e/g424e tier lp engine test and adjustments 86 7. While on the run screen adjust the idle mixture screw on the mixer until a reading of 25-50% is reached for the ftv duty cycle (figure g10). 8. To make this adjustment you will need to adjust the nylon screw all the way inward and then back out t...

Page 88: Chapter 10 Service Tool Kit

G420e/g424e tier lp engine service tool kit 87 chapter 10 service tool kit a343079 usb (universal serial bus) to can (controller area network) converter assembly a343080 service tool software (includes cd and crypt token (license dongle)) a334071 extension cable crypt token.