- DL manuals

- Daewoo

- Trucks

- G20E-3

- Operation & Maintenance Manual

Daewoo G20E-3 Operation & Maintenance Manual - Important Safety Information

Safety Section

-4-

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic

safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations

before an accident occurs. A person must be alert to potential hazards, and use common sense. Persons

must also have the necessary training, skills and tools before attempting to perform these functions.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read

and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as “WARNING”

as shown below.

WARNING

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is involved.

The message that appears under the warning, explaining the hazard, can be either written or pictorially

presented.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DAEWOO cannot anticipate every possible circumstance that might involve a potential hazard, and common

sense is always required. The warnings in this publication and on the product are therefore not all inclusive.

Before any tool, procedure, work method or operating technique not specifically recommended by DAEWOO

is used, you must be sure that it is safe for you and others. You should also ensure that the product will not be

damaged or made unsafe by the operation, lubrication, maintenance or repair procedures you choose.

The information, specifications, and illustration in this publication are on the basis of information available at

the time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and

other items can change at any time. These changes can affect the service given to the product. Obtain the

complete and most current information before starting any job. DAEWOO dealers have the most current

information available.

Summary of G20E-3

Page 1

Operation & maintenance manual lift trucks d20s-3, d25s-3, d30s-3, d33s-3 g20e-3, g25e-3, g30e-3 gc20e-3, gc25e-3, gc30e-3 g20p-3, g25p-3, g30p-3, g33p-3 gc20p-3, gc25p-3, gc30p-3 d32s-3 (6,500lb@24"l.C.) g32e-3 (6,500lb@24"l.C.) g32p-3 (6,500lb@24"l.C.) gc32e-3 (6,500lb@24"l.C.) gc32p-3 (6,500lb@24...

Page 2

Warning do not start, operate or service this machine unless you have read and understood these instructions and received proper training. Unsafe or improper use of the machine may cause serious injury or death. Operators and maintenance personnel must read this manual and receive training before op...

Page 3: Table of Contents

Information section -1- table of contents information section foreword................................................................ 2 literature information............................................. 2 safety section important safety information ................................. 4 safety..........

Page 4: Foreword

Information section -2- foreword literature information this manual should be stored in the operator’s compartment in the literature holder or seat back literature storage area. This manual contains safety, operation, transportation, lubrication and maintenance information. Some photographs or illus...

Page 5

Information section -3- maintenance the maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by servicing intervals. Items without specific intervals are listed under “when required” topics. Items in the “maintenance intervals” chart are referenced...

Page 6: Important Safety Information

Safety section -4- important safety information most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person ...

Page 7: Safety

Safety section -5- safety the safety rules and regulations in this section are representative of some, but not all rules and regulations noted under the occupational safety and health act (osha) and are paraphrased without representation that the osha rules and regulations have been reproduced verba...

Page 8

Safety section -6- general warning to operator located on the right side of the operator's seat (std ). Located on the overhead guard (if convenience package equipped ). Warning only trained and authorized personnel may operate this machine. For safe operation, read and follow the operation and main...

Page 9

Safety section -7- pressure warning warning contents under pressure may be hot. Allow to cool before opening. Located on the radiator top tank by the radiator cap. Hand placement warning warning no hands. Do not place hands in this area. Do not touch, lean on, or reach through the mast or permit oth...

Page 10

Safety section -8- overhead guard must be in place warning warning operation without this device in place may be hazardous. This guard conforms to a.N.S.I.B56.1 and f.E.M.Section iv. This design has been tested with an impact of appropriate valve. Located on the overhead guard. No riders warning war...

Page 11

Safety section -9- parking brake pull the lever back to engage the parking brake. Push the lever forward to release the parking brake. Applying the parking brake puts the transmission in neutral. The parking brake must be applied when leaving the lift truck and when starting the engine. If the opera...

Page 12

Safety section -10- general hazard information attach a “do not operate” or similar warning tag to start switch or controls before servicing or repairing the lift truck. Do not start or service the lift truck when a “do not operate” or similar warning tag is attached to the start switch or controls....

Page 13

Safety section -11- inhaling freon gas through a lit cigarette or other smoking method or inhaling fumes released from a flame contacting freon can cause bodily harm or death. Do not smoke when servicing air conditioners or wherever freon gas may be present. Never put maintenance fluids into glass c...

Page 14

Safety section -12- make sure the lift truck horn, lights, backup alarm (if equipped) and all other devices are working properly. Check for proper operation of mast and attachments. Pay particular attention to unusual noises or erratic movement which might indicate a problem. Make sure service and p...

Page 15

Safety section -13- tilt the elevated load forward only when directly over unloading area and with load as low as possible. Do not stunt ride or indulge in horseplay. Always look and keep a clear view of the path of travel. Travel in reverse if load or attachment obstructs visibility. Use extreme ca...

Page 16

Safety section -14- maintenance information perform all maintenance unless otherwise specified as follows: z park the lift truck in authorized areas only. Z park the lift truck level, with the forks lowered and the mast tilted forward until the fork tips touch the floor. Z place the transmission con...

Page 17

Safety section -15- burn prevention coolant at operating temperature, the engine coolant is hot and under pressure. The radiator and all lines to heaters or the engine contain hot water or steam. Any contact can cause severe burns. Steam can cause personal injury. Check the coolant level only after ...

Page 18

Safety section -16- fire extinguisher have a fire extinguisher-type bc and 1.5kg minimum capacity-on rear overhead guard leg with latch and know how to use it. Inspect and have it serviced as recommended on its instruction plate. Ether ether is poisonous and flammable. Breathing ether vapors or repe...

Page 19

Safety section -17- dry nitrogen (n 2 ) gas is recommended for inflation of tires. If the tires were originally inflated with air, nitrogen is still preferred for adjusting the pressure. Nitrogen mixes properly with air. Nitrogen inflated tires reduce the potential of a tire explosion, because nitro...

Page 20

Safety section -18- the “survive in tipover” warning is located on the overhead guard. It shows the proper use of the operator restraint system. Seat adjustment move the lever, slide the seat to the desired position, and release the lever. Adjust the seat before operating the lift truck. After adjus...

Page 21

Safety section -19- if optional suspension seat (weight adjusting type) equipped seat belt the operator restraint system, prevents the operator from jumping from the operator’s compartment in the event of a forward or side tipover. The system is designed to keep the operator on the seat and in the o...

Page 22

Safety section -20- 3. In the event of a tipover, the seat and restraint system should be inspected for damage and replaced, if necessary. Note: operator restraints shall be examined at the regular truck service intervals. It is recommended that they be replaced if any of the following conditions ar...

Page 23

Safety section -21- avoiding lift truck tipover lift truck stability counterbalanced lift truck design is based on the balance of two weights on opposite sides of a fulcrum (the front axle). The load on the forks must be balanced by the weight of the lift truck. The location of the center of gravity...

Page 24

Safety section -22- lift truck stability base for the lift truck to be stable (not tip over forward or to the side), the cg must stay within the area of the lift truck stability base – a triangular area between the front wheels and the pivot of the steer wheels. If the cg moves forward of the front ...

Page 25

Safety section -23- safety rules only properly trained and authorized personnel should operate forklift trucks. Wear a hard hat and safety shoes when operating a lift truck. Do not wear loose clothing. Inspect and check the condition of your forklift truck using the operator's check list before star...

Page 26

Safety section -24- do not raise anyone on the forks of your lift truck unless using an approved safety cage. Do not let other people ride on the truck. Lift trucks are designed to carry loads, not people. Do not operate your truck without the load backrest extension and overhead guard. Keep the loa...

Page 27

Safety section -25- do not permit anyone to stand or walk under the load or lifting mechanism. The load can fall and cause injury or death to anyone standing below. Look out for overhead obstructions when raising or stacking loads. Do not travel with a raised load. Do not travel with the mast raised...

Page 28

Safety section -26- do not stack or turn on ramps. Do not attempt to pick-up or deposit a load unless the lift truck is level. Do not turn on or drive across an incline. Do not go over rough terrain. If unavoidable, slow down. Cross railroad tracks slowly and diagonally whenever possible. A railroad...

Page 29

Safety section -27- do not operate your truck close to another truck. Always keep a safe distance from other trucks and make sure there is enough distance to stop safely. Never overtake other vehicles. Do not use your lift truck to push or tow another truck. Do not let another push or tow your truck...

Page 30

Safety section -28- how to survive in a tipover warning in the event of a tipover, the risk of serious injury or death will be reduced if the operator is using the operator restraint system and follows the instructions provided. Always use operator restraint system. Don’t jump. Hold on tight. Brace ...

Page 31

Safety section -29- lean away from the direction of fall. Lean forward..

Page 32: Specifications

General section -30- specifications characteristics 1 manufacturer dhi&m dhi&m 2 model d20s-3 d25s-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg diesel diesel 6 operator type stand-on, rider seated rider - seated rider -...

Page 33

General section -31- dhi&m dhi&m 1 d30s-3 d32s-3 2 3000 3000(6500lb) 3 500 600(24in) 4 diesel diesel 5 rider - seated rider-seated 6 p p 7 x2/2 x2/2 8 3230 3230 9 152 152 10 11 lll lll 12 45 x 125 x 1050 45x125x1050 286 x 1044 286x1044 13 6/10 6/10 14 2636 2690 15 1197 1197 16 2160 2160 17 4470 4470...

Page 34: Specifications

General section -32- specifications characteristics tier - ii 1 manufacturer dhi&m dhi&m 2 model d20s-3 d25s-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg diesel diesel 6 operator type stand-on, rider seated rider - seat...

Page 35

General section -33- tier - ii dhi&m dhi&m dhi&m 1 d30s-3 d32s-3 d33s-3 2 3000 3000(6500lb) 3250 3 500 600(24in) 500 4 diesel diesel diesel 5 rider - seated rider-seated rider-seated 6 p p p 7 x2/2 x2/2 x2/2 8 3230 3230 3230 9 152 152 152 10 11 lll lll lll 12 45 x 125 x 1050 45x125x1050 45x125x1050 ...

Page 36: Specifications

General section -34- specifications characteristics 1 manufacturer dhi&m dhi&m 2 model g20e-3 g25e-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg gasoline / lpg gasoline / lpg 6 operator type stand-on, rider seated rider ...

Page 37

General section -35- dhi&m dhi&m 1 g30e-3 g32e-3 2 3000 3000(6500lb) 3 500 600(24in) 4 gasoline / lpg lpg 5 rider - seated rider-seated 6 p p 7 x 2/2 x2/2 8 3230 3230 9 152 152 10 11 lll lll 12 45 x 125 x 1050 45x125x1050 286 x 1044 286x1044 13 6/10 6/10 14 2636 2690 15 1197 1197 16 2160 2160 17 447...

Page 38: Specifications

General section -36- specifications characteristics 1 manufacturer dhi&m dhi&m 2 model gc20e-3 gc25e-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg gasoline / lpg gasoline / lpg 6 operator type stand-on, rider seated ride...

Page 39

General section -37- dhi&m dhi&m 1 gc30e-3 gc32e-3 2 3000 3000(6500lb) 3 500 600(24in) 4 gasoline / lpg lpg 5 rider - seated rider - seated 6 c c 7 x2/2 x2/2 8 3230 3230 9 152 152 10 11 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 282 x 954 282 x 954 13 6/8 6/8 14 2333 2368 15 1110 1100 16 2125 2125 1...

Page 40: Specifications

General section -38- specifications characteristics 1 manufacturer dhi&m dhi&m 2 model g20p-3 g25p-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg lpg lpg 6 operator type stand-on, rider seated rider - seated rider - seate...

Page 41

General section -39- dhi&m dhi&m 1 g30p-3 g32p-3 2 3000 3000(6500lb) 3 500 600(24in) 4 lpg lpg 5 rider - seated rider - seated 6 p p 7 x2/2 x2/2 8 3230 3230 9 152 152 10 11 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 286 x 1044 286 x 1044 13 6/10 6/10 14 2636 2690 15 1197 1197 16 2160 2160 17 4470 44...

Page 42: Specifications

General section -40- specifications characteristics 1 manufacturer dhi&m dhi&m 2 model gc20p-3 gc25p-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gasoline, lpg lpg lpg 6 operator type stand-on, rider seated rider - seated rider - sea...

Page 43

General section -41- dhi&m dhi&m 1 gc30p-3 gc32p-3 2 3000 3000(6500lb) 3 500 600(24in) 4 lpg lpg 5 rider - seated rider - seated 6 c c 7 x2/2 x 2/2 8 3230 3230 9 152 152 10 11 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 282 x 954 282 x 954 13 6/8 6/8 14 2333 2368 15 1110 1100 16 2125 2125 17 4470 447...

Page 44: Specifications

General section -42- specifications characteristics tier-2 1 manufacturer dhi dhi 2 model gc20e-3 gc25e-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gas, lpg-gas lpg lpg 6 operator type stand-on, ride- seated rider - seated rider - s...

Page 45

General section -43- tier-2 dhi dhi 1 gc30e-3 gc32e-3 2 3000 3000(6500lbs) 3 500 600 4 lpg lpg 5 rider - seated rider - seated 6 c c 7 x2/2 x 2/2 8 3230 3230 9 152 152 10 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 282 x 954 282 x 954 13 6/8 6/8 14 2333 2368 15 1110 1110 16 2125 2125 17 4470 4470 18 ...

Page 46: Specifications

General section -44- specifications characteristics tier-2 1 manufacturer dhi dhi 2 model gc20p-3 gc25p-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gas, lpg-gas lpg lpg 6 operator type stand-on, ride- seated rider - seated rider - s...

Page 47

General section -45- tier-2 dhi dhi 1 gc30p-3 gc32p-3 2 3000 3000(6500lbs) 3 500 600 4 lpg lpg 5 rider - seated rider - seated 6 c c 7 x2/2 x 2/2 8 3230 3230 9 152 152 10 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 282 x 954 282 x 954 13 6/8 6/8 14 2333 2368 15 1110 1100 16 2125 2125 17 4470 4470 18 ...

Page 48: Specifications

General section -46- specifications characteristics 2004 year (tier-2) 1 manufacturer dhi dhi 2 model g20e-3 g25e-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gas, lpg-gas lpg lpg 6 operator type stand-on, ride- seated rider - seated...

Page 49

General section -47- 2004 year (tier-2) dhi dhi 1 g30e-3 g32e-3 2 3000 3000(6500lbs) 3 500 600 4 lpg lpg 5 rider - seated rider - seated 6 p p 7 x2/2 x 2/2 8 3230 3230 9 152 152 10 lll lll 12 45 x 125 x 1050 45 x 125 x 1050 286 x 1044 286 x 1044 13 6/10 6/10 14 2636 2690 15 1197 1197 16 2160 2160 17...

Page 50: Specifications

General section -48- specifications characteristics 2004 year (tier-2) 1 manufacturer dhi dhi 2 model g20p-3 g25p-3 3 capacity at rated load center kg 2000 2500 4 load center distance mm 500 500 5 power type electric, diesel, gas, lpg-gas lp lp 6 operator type stand-on, ride- seated rider - seated r...

Page 51

General section -49- 2004 year (tier-2) dhi dhi dhi 1 g30p-3 g32p-3 g33p-3 2 3000 3000(6500lbs) 3250 3 500 600 500 4 lp lp lp 5 rider - seated rider - seated rider - seated 6 p p p 7 x2/2 x 2/2 x 2/2 8 3230 3230 3230 9 152 152 152 10 lll lll lll 12 45 x 125 x 1050 45 x 125 x 1050 45 x 125 x 1050 286...

Page 52: Noise and Vibration

General section -50- noise and vibration noise noise level [unit : db(a)] sound pressure level at operator’s ear (leq.) sound pressure level at by-stander position (as 3713) model as 3713 pren 12053 drive-by lifting mode guaranteed sound power level(l wa ) by new directive 2000/14/ec w/o cabin 80.5 ...

Page 53: Capacity Chart

General section -51- capacity chart single tire std, ffl fft d20s-3, g2 0e-3, g20p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c. 5560mm mfh mast d. 6010mm mfh mast d25s-3, g2 5e-3,g25p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mf...

Page 54

General section -52- double tire std, ffl fft d20s-3, g2 0e-3,g20p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c. 5560mm mfh mast d. 6010mm mfh mast d25s-3, g2 5e-3,g25p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm...

Page 55: Capacity Chart

General section -53- capacity chart narrow tire std, ffl fft gc20e-3, g c20p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c. 5560mm mfh mast d. 6010mm mfh mast gc25e-3, g c25p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4...

Page 56

General section -54- wide tire std, ffl fft gc20e-3, g c20p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c. 5560mm mfh mast d. 6010mm mfh mast gc25e-3, g c25p-3 a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c....

Page 57

General section -55- capacity chart (with side shifter) single tire std, ffl fft d20s-3, g2 0e-3,g20p-3 a. 2030 - 3230mm mfh mast b. 3500 - 3950mm mfh mast c. 4350mm mfh mast d. 4960mm mfh mast a. 3900mm mfh mast b. 4290mm mfh mast c. 4730mm mfh mast d. 5560mm mfh mast e. 6010mm mfh mast d25s-3, g2 ...

Page 58

General section -56- double tire std, ffl fft d20s-3, g2 0e-3,g20p-3 a. 2030 - 3230mm mfh mast b. 3500 - 3950mm mfh mast c. 4350mm mfh mast d. 4960mm mfh mast a. 3900mm mfh mast b. 4290mm mfh mast c. 4730mm mfh mast d. 5560mm mfh mast e. 6010mm mfh mast d25s-3, g2 5e-3,g25p-3 a. 2030 - 3230mm mfh ma...

Page 59

General section -57- capacity chart (with side shifter) narrow tire std, ffl fft gc20e-3, g c20p-3 a. 2030 - 3230mm mfh mast b. 3500 - 3950mm mfh mast c. 4350mm mfh mast d. 4960mm mfh mast a. 3900mm mfh mast b. 4290mm mfh mast c. 4730mm mfh mast d. 5560mm mfh mast e. 6010mm mfh mast gc25e-3, g c25p-...

Page 60

General section -58- wide tire std, ffl fft gc20e-3, g c20p-3 a. 2030 - 3230mm mfh mast b. 3500 - 3950mm mfh mast c. 4350mm mfh mast d. 4960mm mfh mast a. 3900mm mfh mast b. 4290mm mfh mast c. 4730mm mfh mast d. 5560mm mfh mast e. 6010mm mfh mast gc25e-3, g c25p-3 a. 2030 - 3230mm mfh mast b. 3500 -...

Page 61

General section -59- capacity chart: 3,000kg@600mm l.C. (6,500lb@24”) model std, ffl fft single tir e a. 2030 - 4350mm mfh mast b. 4960mm mfh mast a. 3900 - 4290mm mfh mast b. 4730mm mfh mast c. 5560mm mfh mast d. 6010mm mfh mast d32s-3, g32e-3, g32p-3 double tire a. 2030-4960mm mfh mast a. 3900-473...

Page 62

General section -60- capacity chart (with side shifter):3,000kg@600mm l.C. (6,500lb@24”) model std, ffl fft single tir e a. 2030 - 3950mm mfh mast b. 4350mm mfh mast c. 4960mm mfh mast a. 3900mm mfh mast b. 4290mm mfh mast c. 4730mm mfh mast d. 5560mm mfh mast e. 6010mm mfh mast d32s-3, g32e-3, g32p...

Page 63: Serial Number

General section -61- serial number serial number locations for quick reference, record your lift truck's serial numbers in the spaces provided below the photographs. Lift truck serial number •_____________________________ 3.3 liter (db33a) diesel engine serial number •_____________________________ 3...

Page 64

General section -62- 2.4 liter lp and dual fuel engine (g424e) •_____________________________ 3.0 liter lp and dual fuel engine (g430e) •_____________________________ power shift transmission serial number •_____________________________ drive axle serial number •_____________________________ typical...

Page 65

General section -63- attachment abbreviations (includes special forks) sc -special carriage-increased width, height or outreach sss -shaft-type sideshift carriage hss -hook-type sideshift carriage (ita) cw -counterweight sf -special forks sws -swing shift, sideshift ram -ram or boom dbcbh -double cu...

Page 66

General section -64- operator's warning and identification plate familiarize yourself with the operator’s warning plate and identification, lift apacity and attachment plates. Do not exceed capacity as equipped load ratings. Operator's warning plate located on the right side of the operator's seat. ...

Page 67

Operation section -65- operator's station and monitoring systems instrument panel diesel lpg/gas 1. Engine oil pressure indicator light - indicates insufficient engine oil pressure. The light will come on when the ignition switch is turned to the on position. The light should go off after the engine...

Page 68

Operation section -66- 8. G424e/g430e engine malfunction indicator lamp (mil) g424e and g430e engine control systems are equipped with built-in fault diagnostics. Deteted system faults can be displayed by the malfunction indicator lamp (mil) as diagnostic fault codes (dfc) or flash codes, and viewed...

Page 69

Operation section -67- electrical disconnect switch (if equipped) 1. On - connects the battery for electrical power to all electrical circuits. 2. Off - disconnects the battery from all electrical circuits. Engine compartment 1. The engine compartment is accessible by pulling the latch (gc series), ...

Page 70

Operation section -68- caution when closing the engine hood, be careful not to pinch your hand. Circuit breaker circuit breaker - protects the main electrical circuits. To reset the circuit breaker, push the button in. Located in the engine compartment. Seat note: seat arrangements may vary. Basic o...

Page 71: Lift Truck Controls

Operation section -69- fuel selector switch (g424e/g430e dual fuel only) 1. Lpg - this position supplies electrical power to the lp fuelock solenoid, when the ignition switch is in the on or the start position. With the lp-gas fuel tank valve open, lp-gas can then flow the tank through the converter...

Page 72

Operation section -70- service brake pedal push down on the brake pedal to slow or stop the lift truck. Release the brake pedal to allow the lift truck to move. Accelerator pedal push down on the pedal to increase engine rpm (speed). Release the pedal to decrease engine rpm (speed). Parking brake le...

Page 73

Operation section -71- tilt control 1. Mast tilt forward - push the lever forward smoothly to tilt the mast forward. 2. Mast hold - when the lever is released it will return to the hold or center position. Tilting action will stop. 3. Mast tilt back - pull the lever back smoothly to tilt the mast ba...

Page 74: Refueling

Operation section -72- refueling gasoline or diesel engine equipped warning explosive fumes may be present during refueling. Do not smoke in refueling areas. Lift truck should be refueled only at designated safe locations. Safe outdoor locations are preferable to those indoors. Stop the engine and g...

Page 75

Operation section -73- changing lp - gas tanks warning only trained, authorized personnel should fill or exchange lp-gas tanks. Personnel engaged in filling of lp-gas containers should wear protective clothing such as face shield, long sleeves and gauntlet gloves. Do not refuel or store lp-gas power...

Page 76

Operation section -74- notice if the location pin (dowel) is missing or broken, be sure the pin is replaced. 6. Check to be sure that the lp - gas warning plate is in position on the lift truck, and is legible. 7. Check to be sure the replacement tank is of the correct type. 8. Inspect the replaceme...

Page 77: Before Starting The Engine

Operation section -75- before starting the engine walk - around inspection make a thorough walk - around inspection before mounting the lift truck or starting the engine. Look for such items as loose bolts, debris buildup, oil or coolant leaks. Check condition of tires, mast, carriage, forks or atta...

Page 78

Operation section -76- db33a diesel engine b3.3 diesel engine 11. Measure the engine crankcase oil level with the dip stick. Maintain the oil level between the max. And min., (or full and add) notches on the dip stick. Db33a diesel engine b3.3 diesel engine 12. Observe the engine coolant level in th...

Page 79

Operation section -77- warning personal injury may occur from accidents caused by improper seat adjustment. Always adjust the operator’s seat before starting the lift truck engine. Seat adjustment must be done at the beginning of each shift and when operators change. 14. To position the seat, push t...

Page 80: Starting The Engine

Operation section -78- starting the engine prestart conditions note: the engine will not start unless the transmission directional control lever is in the neutral position. 1. Engage the parking brake, if not already engaged. Place the transmission directional control lever in the neutral position. ...

Page 81

Operation section -79- lp - gas engine warning lp - gas fuel is flammable and can cause personal injury. Inspect lp - gas fuel lines and fitting for leaks. Inspect tank for secure mounting. 1. Turn the tank fuel valve on by slowly turning the valve counterclockwise. Observe the lp - gas gauge (if eq...

Page 82

Operation section -80- starting from a 12 volt external source warning sparks occurring near the battery could cause vapors to explode. Always connect the external power source ground cable to a point away from and below the battery, and well clear of fuel system components. Notice do not reverse ba...

Page 83

Operation section -81- dual fuel system (if g424 dual fuel engine equipped) changing from gasoline to lp – gas note: the underwriter’s laboratory (u.L.) requires that the gasoline tank must be at least one - quarter full when operating on lp - gas. This will allow the lift truck to be restarted on g...

Page 84

Operation section -82- 4. Move lever (1) from the lpg (3) position to the gas (4) position. 5. Lower the hood and seat assembly. 6. Turn the ignition switch key to the on position. Note: on trucks equipped with electric fuel pumps wait approximately 15 seconds to fill the carburetor with gasoline. 7...

Page 85

Operation section -83- dual fuel system (g424e/g430e engine only) changing from gasoline to lp – gas note: the underwriter’s laboratory (u.L.) requires that the gasoline tank must be at least one - quarter full when operating on lp - gas. This will allow the lift truck to be restarted on gasoline an...

Page 86

Operation section -84- 4. Close the fuel valve on the lp - gas tank. Allow the engine to run until the fuel in the line runs out and the engine stops. 5. Lower the hood and seat assembly. When stop the engine (g424e dual fuel only) engine wiring harness includes timer relay. The purpose of it is to ...

Page 87

Operation section -85- after starting the engine observe all indicator lights and gauges frequently during operation, to make sure all systems are working properly. The entire indicator lights will come on with the ignition switch in the on position before the engine is started. Diesel lpg/gas 1. Th...

Page 88: Lift Truck Operation

Operation section -86- lift truck operation power shift transmission/ drive axle 1. Start the engine. See topic “starting the engine”. 2. Push down on the service brake pedal to hold the lift truck until ready to move it. 3. Release the parking brake. Note: the parking brake must be released before ...

Page 89

Operation section -87- 7. To change the lift truck direction of travel, release the accelerator pedal. 8. Push down on the service brake pedal to reduce the lift truck speed as necessary. 9. Move the directional lever to the desired direction of travel. Slowly push down on the accelerator pedal as t...

Page 90

Operation section -88- inching note: the purpose of the inching pedal is to provide precise lift truck inching control at very slow travel speed and high engine rpm. This is used for fast hydraulic lift, during load approach, pick up or load positioning. 1. To inch (creep) in either direction, slowl...

Page 91

Operation section -89- g424e/g430e electronic controlled lp and dual fuel engines (if equipped) general description the mi-04 is a closed loop system utilizing a catalytic muffler to reduce the emission level in the exhaust gas. In order to obtain maximum effect from the catalyst, an accurate contro...

Page 92

Operation section -90- mi-04 dual fuel system key switch foot pedal lp fuel filter fuel lock converter secm fuel trim valve mixer distributor engine vr sensor oil pressure switch coolant temp sensor catalytic muffler oxygen sensor tmap dbw throttle fault light air cleaner lp fuel line coolant line t...

Page 93

Operation section -91- basic troubleshooting(lpg) the mi-04 systems are equipped with built-in fault diagnostics. Detected system faults can be displayed by the malfunction indicator lamp (mil) and are covered in the advanced diagnostics section. Items such as fuel level, plugged fuel lines, clogged...

Page 94

Operation section -92- problem probable cause corrective action fuel container almost empty lpg vapor from liquid outlet z fill fuel container z do not exceed 80% of liquid capacity excess flow valve closed reset excess flow valve z close liquid valve z wait for a “click” sound slowly open liquid va...

Page 95

Operation section -93- problem probable cause corrective action fuel container almost empty lpg vapor from liquid outlet z fill fuel container z do not exceed 80% of liquid capacity excess flow valve closed reset excess flow valve z close liquid valve z wait for a “click” sound slowly open liquid va...

Page 96

Operation section -94- problem probable cause corrective action clogged fuel filter repair/replace as required z see maintenance z section, lp fuel filter replacement faulty vapor connection between the pressure regulator/converter and the mixer check connection z verify no holes in hose z clamps mu...

Page 97

Operation section -95- problem probable cause corrective action fuel lock-off malfunction repair/replace fuel lock-off z see g424e/g430e engine service manual faulty vapor connection between the pressure regulator/converter and the mixer check connection z verify no holes in hose z clamps must be ti...

Page 98

Operation section -96- problem probable cause corrective action incorrect idle speed control incorrect timing or spark control see advanced diagnostics & see g424e/g430e engine service manual rough idle engine mechanical see engine service manual incorrect idle speed control throttle sticking see ad...

Page 99

Operation section -97- problem probable cause corrective action air/fuel mixer malfunction check mixer z see g424e/g430e engine service manual air filter clogged check air filter z clean/replace as required vacuum leak check system vacuum hoses from regulator to ftv and mixer z repair/replace as nec...

Page 100

Operation section -98- basic troubleshooting (gasoline) problem probable cause corrective action fuel tank empty fill fuel container z the tank should be at least ¼ full to properly prime the fuel pump. Z fuel select switch is not on gas clogged fuel filter repair/replace as required z see maintenan...

Page 101

Operation section -99- problem probable cause corrective action fuel tank almost empty fuel pump cavitations z the tank should be at least ¼ full to properly prime the fuel pump z fuel select switch is not on gas clogged fuel filter repair/replace as required z see maintenance section, primary and s...

Page 102

Operation section -100- problem probable cause corrective action electric fuel pump malfunction (gas) check electrical connection z check relay and fuse turn key on and verify pump is operating z see g424e/g430e dual fuel engine service manual pressure regulator malfunction test pressure regulator o...

Page 103

Operation section -101- problem probable cause corrective action throttle butterfly valve not opening or sticking foot pedal signal incorrect or intermittent incorrect air/fuel or ignition control see advanced diagnostics will not accelerate/hesita tion during acceleration or engine stalls (gas) eng...

Page 104

Operation section -102- problem probable cause corrective action incorrect idle speed control incorrect timing or spark control see advanced diagnostics & g424e/g430e dual fuel engine service manual rough idle (gas) engine mechanical see engine service manual incorrect idle speed control throttle st...

Page 105

Operation section -103- problem probable cause corrective action isolate the gasoline system by running the lift truck on lpg verify lpg cylinder is full and valve is open. If the problem does not exist in lpg mode proceed with the corrective action steps below. If the problem also exists in lpg mod...

Page 106

Operation section -104- advanced diagnostics advanced diagnostics the mi-04 systems are equipped with built-in fault diagnostics. Detected system faults can be displayed by the malfunction indicator lamp (mil) as diagnostic fault codes (dfc) or flash codes, and viewed in detail with the use of servi...

Page 107

Operation section -105- displaying fault codes (dfc) from secm memory to enter code display mode you must turn off the ignition key. Now turn on the key but do not start the engine. As soon as you turn the key to the on position you must cycle the foot pedal by depressing it to the floor and then fu...

Page 108

Operation section -106- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 12 none signifies the end of one pass through the fault list none none, used as a beginning and end of the fault list identification 14 ectsensorinputlow coolant senso...

Page 109

Operation section -107- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 26 etcsticking throttle plate sticking inside the throttle body or the etc driver signal is open engine shutdown check for debris or obstructions inside the throttle b...

Page 110

Operation section -108- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 42 est1low coil driver signal low or under-current stored fault code (mil only) check coil driver wiring and connector for shorts 43 est1high coil driver signal high o...

Page 111

Operation section -109- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 56 xdrpsensorinputhigh +5vdc transducer power supplied by the secm to the sensors is above +5.20vdc engine shutdown measure transducer power at the tmap connector with...

Page 112

Operation section -110- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 65 pedal2sensorinputlo app2 sensor failure or shorted circuit min power limit check foot pedal connector 66 pedal2sensorinputhi app2 signal disconnected, open circuit ...

Page 113

Operation section -111- table a. Mi-04 diagnostic fault codes (flash codes) dfc probable fault action corrective action, first check 73 afrtrimvalveupperdc ftv duty cycle at high (rich) limit (expected fault when ftv connector is unplugged) stored fault code (mil, disable adaptive learns) engine mea...

Page 114

Operation section -112- auto shift controller asc-100 (if equipped) product description the autoshift controller is an electrical control system, specially designed for use on forklift trucks with internal combustion engines. Its primary purpose is to prevent the operator from driving the truck outs...

Page 115

Operation section -113- diagnostics features asc-100 has an internal indicator on the right side of the controller for displaying the selected gear and the abnormal condition. Below is a description applicable for many asc- 100 implementations. Display for operator this information is given during n...

Page 116

Operation section -114- manual mode (fail-safe mode) the system still allows movement of the vehicle in case of controller breakdown by selecting the manual mode with the fail-safe mode switch in the controller. Warning in the manual mode, direction inhibition function can not be operated normally. ...

Page 117: Operating Techniques

Operation section -115- operating techniques inching into loads typical example 1. Move the lift truck slowly forward into position and engage the load. The lift truck should be square with load, forks spaced evenly between pallet stringers and as far apart as load permits. Typical example 2. Move t...

Page 118

Operation section -116- traveling with the load notice travel with the load as low as possible, while still maintaining ground clearance. Typical example 1. Travel with the load uphill on upgrades and downgrades. Typical example 2. For better vision, travel in reverse with bulky loads. Unloading typ...

Page 119

Operation section -117- typical example 3. Deposit the load and back away carefully to disengage the forks. Typical example 4. Lower the carriage and forks to the travel position or to the park position. Turning 1. When turning sharp corners, keep close to the inside corner. Begin the turn when the ...

Page 120

Operation section -118- lifting drums or round objects 1. Block drums or round objects. Tilt the mast forward and slide the fork tips along the floor to get under the load. 2. Before lifting, tilt the mast back slightly until the load is cradled on the forks. Operating in hot weather keep the follow...

Page 121: Parking The Lift Truck

Operation section -119- parking the lift truck note: park the lift truck level with the fork lowered and the mast tilted forward until the fork touches the floor. Block the drive wheels when parking on an incline. 1. Park in an authorized area only. Do not block traffic. If lp - gas equipped, do not...

Page 122: Lift Fork Adjustment

Operation section -120- lift fork adjustment warning when adjusting the fork spread, be careful not to pinch your hand between forks and the carriage slot. Hook-on type fork 1. Move up the hook pin to the free position. 2. Raise the hook pin in each fork to side the fork on the carriage bar. 3. Adju...

Page 123: Storage Information

Operation section -121- storage information before storage before storing your lift truck, clean and inspect as the following procedures. Z wipe away grease, oil, etc. Adhering to the body of the truck with waste cloth, and use water, if needed. Z while cleaning the truck, check general condition of...

Page 124: Transportation Hints

Operation section -122- transportation hints lift truck shipping check travel route for overpass clearances. Make sure there is adequate clearance if the lift truck being transported is equipped with a high mast, overhead guard or cab. To prevent the lift truck from slipping while loading, or shifti...

Page 125: Towing Information

Operation section -123- towing information warning personal injury or death could result when towing a disabled lift truck incorrectly. Block the lift truck wheels to prevent movement before releasing the brakes. The lift truck can roll free if it is not blocked. Follow the recommendations below, to...

Page 126

Maintenance section -124- inspection, maintenance and repair of lift truck forks the following section gives practical guidelines for inspection, maintenance and repair of lift truck forks. It also provides general information on the design and application of forks and the common cause of fork failu...

Page 127

Maintenance section -125- causes of fork failure improper modification or repair fork failure can occur as a result of a field modification involving welding, flame cutting or other similar processes which affect the heat treatment and reduces the strength of the fork. In most cases, specific proces...

Page 128

Maintenance section -126- fork inspection establish a daily and 12 month inspection routine by keeping a record for the forks on each lift truck. Initial information should include the machine serial number on each the forks are used, the fork manufacturer, type, original section size, original leng...

Page 129

Maintenance section -127- 12 months inspection forks should be inspected, at a minimum, every 12 months. If the truck is being used in a multi-shift or heavy duty operation, they should be checked every six months. See “forks” in the “2000 service hours or yearly” in “maintenance intervals.” mainten...

Page 130: Tire Inflation Information

Maintenance section -128- tire inflation information tire inflation warning personal injury or death could result when tires are inflated incorrectly. Use a self - attaching inflation chuck and stand behind the tread when inflating a tire. Proper inflation equipment and training in using the equipme...

Page 131: Torque Specifications

Maintenance section -129- torque specifications metric hardware most of the nuts, bolts, studs, and threaded holes in your lift truck are metric. In this manual we provide specifications in both metric and u.S. Customary measurement. Always replace metric hardware with metric hardware. See the parts...

Page 132

Maintenance section -130- torques for taperlock studs standard taperlock stud torque thread size inch n•m 1 lb•ft 1/4 8 ± 3 6 ± 2 5/16 17 ± 5 13 ± 4 3/8 35 ± 5 26 ± 4 7/16 45 ± 10 33 ± 7 1/2 65 ± 10 48 ± 7 5/8 110 ± 20 80 ± 15 3/4 170 ± 30 125 ± 22 7/8 260 ± 40 190 ± 30 1 400 ± 60 300 ± 45 1/8 500 ±...

Page 133

Maintenance section -131- cooling system specifications coolant information note: the following information is generic and valid for lift trucks. Engine operating temperatures have increased to improve engine efficiency. This means proper cooling system maintenance is especially important. Overheati...

Page 134

Maintenance section -132- coolant water hard water, or water with high levels of calcium and magnesium ions, encourages the formation of insoluble chemical compounds by combining with cooling system additives such as silicates and phosphates. The tendency of silicates and phosphates to precipitate o...

Page 135: Fuel Specifications

Maintenance section -133- fuel specifications general fuel information use only fuel as recommended in this section. Notice fill the fuel tank at the end of each day of operation to drive out moisture laden air and to prevent condensation. Maintain a constant level near the top of the day tank to av...

Page 136

Maintenance section -134- daewoo recommends infrared analysis (in conjunction with wear metal analysis) of used oil in determining the effectiveness of oil tbn and acid neutralization. For fuel with sulfur exceeding 1.5% by weight, use oil with a tbn of 30 and reduce the oil change interval by one h...

Page 137: Lubricant Information

Maintenance section -135- lubricant information lubricant information certain abbreviations follow society of automotive engineers (sae) j754 nomenclature and some classifications follow sae j183 abbreviations. The mil specifications are u.S.A. Military specifications. The recommended oil viscositie...

Page 138

Maintenance section -136- drive axle oil note: do not use gear oil in the final drives or differentials. Gear oil can cause seal material to fail and possibly leak oil. Note: failure to follow the recommendation will cause shortened life due to excessive gear wear. The api cd/to-2 specification or m...

Page 139

Maintenance section -137- lubricant viscosities and refill capacities lubricant viscosities lubricant viscosities for ambient (outside) temperatures °c °f compartment or system oil viscosities min max min max sae 10w30 -20 +40 -4 +104 g424(e) engine crankcase (gasoline and lp-gas) api sl sae 5w30 -3...

Page 140: Maintenance Intervals

Maintenance section -138- maintenance intervals notice all maintenance and repair, except every 10 service hours or daily, on the lift truck must be performed by qualified and authorized personnel only. Notice careless disposal of waste oil can harm the environment and can be dangerous to persons. A...

Page 141

Maintenance section -139- inspect coolant hoses (lp engine only) .......... 183 lp regulator/converter inspection (lp engine only) .................................................................. 183 fuel lines & fittings - check............................. 184 inspect mixer assembly (g424e/g430e...

Page 142

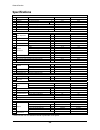

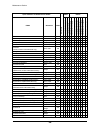

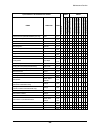

Maintenance section -140- quick reference to maintenance schedule first every items services page when re quired 50-100 service hour s or a w eek 250 ser v ice h ours or a month 10 servic e ho urs or a day 250 ser v ice h ours or a month s 500 ser v ice h ours or 3 month s 1000 s e rvice hours or 6 ...

Page 143

Maintenance section -141- quick reference to maintenance schedule first every items services page whe n r e qui re d 50- 10 0 s e rvi c e h our s or a w e e k 25 0 s e rv ice h our s o r a mo nth 10 s e rv ic e h o urs or a d a y 25 0 s e rv ice h our s o r a mo nth 50 0 s e rv ice h our s o r 3 mo ...

Page 144: When Required

Maintenance section -142- when required you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Engine valve lash (db33a diesel engine only) - check, adjust notice the valve clearances are t...

Page 145

Maintenance section -143- seat, hood latch & support cylinder - check, lubricate 1. Check the operation of the seat adjuster rod. Make sure that the seat slides freely on its track. Lightly oil the seat slider tracks if necessary. 2. Push the lever down to raise the hood and seat assembly (d, g-seri...

Page 146

Maintenance section -144- fuses, bulbs, circuit breaker & relay - change, reset fuses note: if a fuse filament separates, use only the same type and size fuses for replacement. If the filament in a new fuse separates, have the circuits and instruments checked. Notice always replace fuses with ones o...

Page 147

Maintenance section -145- fuse & relay (g424e/g430e only) g25e-3 (g20/25/30e-3) located rear side of valve mounting bracket. G25p-3 (g20/25/30/33p-3) located rear side of valve mounting brackcet. Gc25e-3 (gc20/25/30e-3) located on the top of engine. Located on the frame left side. Gc25p-3 (gc20/25/3...

Page 148

Maintenance section -146- g20/25/30/32e-3 (dual fuel only) located on the right frame rail. Located on the left frame. Located rear side of valve mounting bracket. G20/25/30/33p-3 (dual fuel only) main power relay, main fuse, fuel fuse located rear side of valve mounting bracket. Fuel select relay1,...

Page 149

Maintenance section -147- priming the fuel system (diesel engine only) bleeding the fuel system after changing the fuel filter cartridge assembly, or after having serviced any part of the fuel system, make sure that the air is bled from the system. Db33a diesel engine b3.3 diesel engine 1. Remove a ...

Page 150

Maintenance section -148- draining the water from the fuel filter db33a diesel engine 1. Check "diesel engine water in fuel filter indicator light" in instrument panel. Refer to, "diesel engine water in fuel filter indicator light" in operator's station and monitoring systems section. 2. Turn the wi...

Page 151

Maintenance section -149- test fuel system for leaks(lp and dual fuel engines only) 1. Obtain a leak check squirt bottle or pump spray bottle. 2. Fill the bottle with an approved leak check solution. 3. Spray a generous amount of the solution on the fuel system fuel lines and connections, starting a...

Page 152

Maintenance section -150- tires and wheels (d, g-series) - inspect, check warning servicing and changing tires and rims can be dangerous and should be done only by trained personnel using proper tools and procedures. If correct procedures are not followed while servicing tires and rims, the assembli...

Page 153

Maintenance section -151- carriage roller extrusion – adjust 1. Set the mast vertical. 2. Lower the carriage completely. 3. On full free lift and full free triple lift models, the bottom of the inner mast must be flush with the bottom of the stationary mast. 4. Measure the distance from the bottom o...

Page 154

Maintenance section -152- every 10 service hours or daily you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Inspect engine for fluid leaks 1. Start the engine and allow it to reach dpe...

Page 155

Maintenance section -153- 1. Observe the coolant level with engine cold. Maintain coolant level to the proper line on expansion bottle. If the expansion bottle has no coolant, it will be necessary to check coolant at the radiator filter neck. 2. Remove the radiator cap. Fill radiator to the top of t...

Page 156

Maintenance section -154- walk-around inspection - inspect for maximum service life of the lift truck, make a thorough walk-around inspection. Look around and under the truck for such items as loose or missing bolts, debris or dirt buildup, fuel, oil or coolant leaks and cut or gouged tires. Have an...

Page 157

Maintenance section -155- mast channels – lubricate the channels on the roller-type mast require a break-in period. Apply a light film of lubricant on the channels where the rollers ride. This will prevent metal peel until the rollers set a pattern. Transmission oil level – check warning hot oil and...

Page 158

Maintenance section -156- parking brake - inspect inspection from operator's seat, engine off 1. Grasp the parking brake lever with your hand and press down the release button with your thumb. The lever should move freely forward and backward. 2. Remove your thumb from the release button. The lever ...

Page 159

Maintenance section -157- first 50 - 100 service hours or a week you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Engine oil & filter (db33a diesel engine only) - change db33a diesel ...

Page 160

Maintenance section -158- 11. Start the engine and allow the oil to fill the filter and passages. 12. Check for oil leaks. 13. Stop the engine and measure the oil level. Maintain the oil level between the max and min marks on dip stick. 14. Close hood and seat assembly. Notice servicing of the engin...

Page 161

Maintenance section -159- 3. Remove the floor mat and the floor plate. Remove and discard the oil filter. 4. Wipe off the filter base. Make certain that all of the old seal is removed. 5. Apply a small amount of clean oil on the seal of the new filter. 6. Install the filter by hand. When the filter ...

Page 162

Maintenance section -160- 6. Install the dip stick/filter cap. Note: tighten the dipstick plug fully not to allow foreign parts(rain, water etc) to enter into drive axle. Parking brake - test, adjust parking brake testing notice osha requires the parking brake to hold the lift truck, with capacity l...

Page 163

Maintenance section -161- 3. Remove the floor mat and floor plate. 4. Make sure the parking brake lever is released. 5. Make sure the brake lever (1) is held against stop pin (2). If the brake lever (1) is held against the stop pin (2), go to step 7. If the brake lever (1) is not held against the st...

Page 164

Maintenance section -162- first 250 service hours or a month you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Hydraulic return filter – change warning hot oil and components can cause...

Page 165

Maintenance section -163- every 250 service hours or monthly you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Air intake system - check, clean precleaner (if equipped) notice never se...

Page 166

Maintenance section -164- 8. Install the cover and tighten the cover latches. 9. Start the engine and observe the position of the indicator. If the indicator shows red after the installation of the primary element, install another clean or a new element or, replace the secondary element. See topic, ...

Page 167

Maintenance section -165- checking element 1. Insert a light inside the clean dry element and examine it. Discard the element if tears, rips or damage are found. 2. Wrap and store good elements in a clean, dry place. Hydraulic oil level – check warning at operating temperature, the hydraulic tank is...

Page 168

Maintenance section -166- drive axle oil level - check park the lift truck on a level surface. Apply the parking brake. The engine at low idle. Place the directional control lever in neutral. 1. Remove the dip stick/filter cap. Observe the oil level. 2. Maintain the oil level between the lower mark ...

Page 169

Maintenance section -167- battery terminal - clean, inspect warning batteries give off flammable fumes that can explode. Do not smoke when observing the battery electrolyte levels. Electrolyte is an acid and can cause personal injury if it contacts skin or eyes. Always wear protective glasses when w...

Page 170

Maintenance section -168- 5. Remove and discard oil filter element. 6. Wipe sealing surface of oil filter element mounting base. Make sure the entire old gasket is removed. 7. Before installing a new filter element, apply a small amount of clean engine oil to the filter element gasket. 8. Install th...

Page 171

Maintenance section -169- wheel bolts & nuts - inspect inspect tightness (d, g - series) steer wheels typical example 1. Inspect tightness of wheel bolts in a sequence opposite each other 110 n•m (75 lb•ft). Drive wheels typical example 2. Inspect tightness of wheel nuts in a sequence opposite each ...

Page 172

Maintenance section -170- every 500 service hours or 3 months you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Belts - check, adjust typical example 1. Check the condition and adjustm...

Page 173

Maintenance section -171- mast pivot eyes-lubricate typical example 1. Lubricate two fittings for the mast pivot eyes, one on each side of the pin. 2. Check the pivot eye pins for loose retainer bolts and wear. Cylinder rod extension-adjust note: the following description is for forward tilt. For cy...

Page 174

Maintenance section -172- transmission oil filter – change warning hot oil and components can cause personal injury. Do not allow hot oil or components to contact skin. Park the lift truck level, with the forks lowered, parking brake engaged, direction control lever in neutral and the engine stopped...

Page 175

Maintenance section -173- 1. Remove drain plug. Allow the oil to drain into a suitable container. Clean the magnetic drain plug. Check o - ring seal and replace if necessary. 2. Install the drain plug. 3. Wash the strainer assembly in clean, non flammable solvent and dry it. Install the strainer ass...

Page 176

Maintenance section -174- inching & braking control shaft - lubricate 1. Lubricate two fittings for the inching and brake pedal control shaft. Horn and lights (if equipped) - check 1. Press horn button, to determine if horn is operational. 2. Check and replace all defective gauges. 3. Check all ligh...

Page 177

Maintenance section -175- typical example 4. Raise the hood and seat assembly. 5. Remove and discard oil filter element. 6. Wipe sealing surface of oil filter element mounting base. Make sure the entire old gasket is removed. 7. Before installing a new filter element, apply a small amount of clean e...

Page 178

Maintenance section -176- fuel strainer (b3.3 diesel engine only) – clean at every engine oil exchange, clean the strainer of fuel feed pump. Fuel passes through fuel strainer from fuel tank to fuel filter. The first filtering device uses the mesh strainer and the second one uses the paper element. ...

Page 179

Maintenance section -177- inspect vacuum lines and fittings (g424e/g430 engine only) 1. Visually inspect vacuum lines and fittings for physical damage such as bittleness, cracks and kinks. Repair/replace as required. 2. Slovent or oil damage may cause vacuum lines to become soft resulting in a colla...

Page 180

Maintenance section -178- fuel filter (b3.3 diesel engine only) - change diesel engine b3.3 diesel engine 1. Remove fuel filter cartridge assembly. 2. Remove sensor assembly from cartridge assembly. 3. Before installing a new cartridge assembly, assemble existing sensor assembly and apply a small am...

Page 181

Maintenance section -179- every 1000 service hours or 6 months you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Hydraulic return filter, breather & strainer - check, change warning ho...

Page 182

Maintenance section -180- transmission oil, oil filter & strainer - check, clean, change see topic, “transmission oil, oil filter & strainer- check, clean, change” in “first 50 - 100 service hours” lift chains - test, check, adjust lift chain wear test inspect the part of the chain that is normally ...

Page 183

Maintenance section -181- carriage chain adjustment make sure that carriage height is correct. If correct, adjust the chain for equal tension. If not, adjust the chain for correct carriage height by adjusting anchor nuts (1), (2). Note: see the previous section, “carriage roller extrusion” in “when ...

Page 184

Maintenance section -182- 2. Loosen nut (3) and adjust nut (4) to make inner mast rail flush with outer mast rail bottom. 3. Make adjustment anchor nuts (3), (4) for equal chain tension. 4. Raise the inner mast and check equal chain tension. If not equal, repeat the same procedure as step 1 through ...

Page 185

Maintenance section -183- air intake system - change changing primary element see topic, “air intake system - check, clean” in “every 250 service hours or monthly” changing secondary element 1. Remove the primary air cleaner element. See topic “servicing filter element.” clean the inside of the air ...

Page 186

Maintenance section -184- fuel lines & fittings - check visually inspect fuel lines and fittings for physical damage. Replace as required. (1) fuel lines (2) lp mixer (3) throttle assembly inspect mixer assembly (g424e/g430e engine only) refer to the lp mixer section of the engine service manual for...

Page 187

Maintenance section -185- every 1500 service hours or 9 months inspect ignition system (lp-gas, gasoline & dual fuel engines only) 1. Disconnect battery cables. 2. Remove and inspect the spark plugs. Replace as required. 3. Test secondary cables with an ohmmeter.If maximum resistance is higher than ...

Page 188

Maintenance section -186- replace gasoline primary fuel filter(g424e/g430e dual fuel only) park the lift truck in an authorized refueling area with the forks lowered, parking brake applied and the transmission in neutral. 1. Place the fuel select switch in the gasoline position. Remove the fuse for ...

Page 189

Maintenance section -187- replace lp fuel filter element (lp-gas, dual fuel engine only) park the lift truck in an authorized refueling area with the forks lowered, parking brake applied and the transmission in neutral. 1. Close the fuel shutoff valve on the lp-fuel tank. Run the engine until the fu...

Page 190

Maintenance section -188- every 2000 service hours or yearly you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Fuel filter (g424 gasoline & dual fuel engine only) - change note: engine...

Page 191

Maintenance section -189- steer wheel bearings - reassemble park the lift truck level with the forks lowered, parking brake engaged, transmission in neutral and the engine stopped. Note: the procedure is shown on a gc-series lift truck. It is the same for d, g-series lift trucks. Typical example 1. ...

Page 192

Maintenance section -190- 8. Install the outer wheel bearing and the out washer. Install a new lock washer and fit the locknut. Typical example 9. Tighten the locknut to 135 n•m (100 lb•ft), while turning wheel hub to seat the bearing. 10. Loosen the locknut. Retorque it to 50 ± 5n•m (37 ± 4 lb•ft)....

Page 193

Maintenance section -191- drive wheel bearing (power shaft and drive wheel) – reassemble consult your daewoo lift truck dealer for the proper wheel bearing reassembling procedure. Packing of bearings and adjustment procedure must be made by a trained mechanic or dealer personnel. Pack power shaft be...

Page 194

Maintenance section -192- cooling system - clean, change warning at operating temperature, the engine coolant is hot and under pressure. Steam can cause personal injury. Check the coolant level only after the engine has been stopped and the filter cap is cool enough to touch with your bare hand. Rem...

Page 195

Maintenance section -193- forks – inspect forks should be inspected, at a minimum, every 12 months. If the truck is being used in a multi-shift or heavy duty operation, they should be checked every six months. 1. Inspect the forks carefully for cracks. Special attention should be given to the heel s...

Page 196

Maintenance section -194- 5. Check the fork blade (j) and shank (h) for wear with special attention to the heel (g). The fork should be withdrawn from service if the thickness is reduced to 90 percent or less of the original thickness. Fork blade length may also be reduced by wear, especially on tap...

Page 197

Maintenance section -195- every 2500 service hours or 15 months you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Hydraulic oil - check, clean, change warning hot oil and components ca...

Page 198

Maintenance section -196- replace gasoline secondary fuel filter(g424e/g430e dual fuel only) park the lift truck in an authorized refueling area with the forks lowered, parking brake applied and the transmission in neutral. 1. Place the fuel select switch in the gasoline position. Remove the fuse fo...

Page 199

Maintenance section -197- checking the tmap sensor (g424e/g430e engine only) 1. Verify that the tmap sensor (f) is mounted tightly into the manifold adapter (e), with no leakage. 2. If the tmap is found to be loose, remove the tmap retaining screw and the tmap sensor from the manifold adapter. 3. Vi...

Page 200

Maintenance section -198- every 3000 service hours or 18 months you must read and understand the warnings and instructions contained in the safety section of this manual, before performing any operation or maintenance procedures. Timing belt [g424(e) lp-gas, gasoline dual fuel engine only] - change ...

Page 201

Maintenance section -199- every 4500 service hours or two years replace oxygen sensor (g424e/g430e engine only) g424e engine g430e engine 1. Stop engine and wait until the exhaust pipe and exhaust pipe is cooled. 2. Disconnect the electrical connector of oxygen sensor 3. Remove oxygen sensor 4. Asse...

Page 202: Index

Index section -200- index # 12 months inspection......................................... 127 2.4 liter gasoline engine(g424) ......................... 78 a accelerator pedal ................................................ 70 adjustments ....................................................... 112 a...

Page 203

Index section -201- engine valve lash (db33a diesel engine only) - check, adjust..................................................... 142 environment management .................................... 3 environment protection ..................................... 124 every 10 service hours or daily.......

Page 204

Index section -202- inspect mixer assembly (g424e/g430e engine only) .................................................................. 184 inspect the fuel pump insulated mounting clamps(g424e/g430e dual fuel only)............ 186 inspect throttle assembly (g424e/g430e engine only) ...................

Page 205

Index section -203- replace oxygen sensor (g424e/g430e engine only) .................................................................. 199 replace pcv valve and breather element - change (lp-gas, gasoline and dual fuel engines) ...... 197 replace spark plugs (lp-gas, gasoline & dual fuel engines onl...