- DL manuals

- Daewoo

- Trucks

- G20E-3

- Service Manual

Daewoo G20E-3 Service Manual - Charging System

G424 Service Manual

Charging System

47

CHARGING SYSTEM

General Description

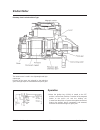

The alternator is an electrical and mechanical

components driven by a belt from engine rotation. It

is used to charge the storage battery during the

engine operation. The alternator is cooled by an

external fan mounted behind the pulley. The fan pulls

air through the holes in the back of the alternator.

The air exits the front of the alternator, cooling it in

the process. The Daewoo CS-121 series also has an

internal fan. This fan is mounted on the rotor. This

fan pulls air through the holes in the back of the

alternator to cool the rectifier bridge and regulator.

The air exits the front of the alternator.

The alternator converts mechanical and magnetic

energy to alternating current (AC) and voltage. This

process is done by rotating a direct current (DC)

electromagnetic field (rotor) inside a three phase

stator. The alternating current and voltage (generated

by the stator) are changed to direct current by a

three phase, full wave rectifier system using six

silicone rectifier diodes. Some alternators have three

exciter diodes or a diode trio. They rectify the current

needed to start the charging process. Direct current

flows to the alternator output terminal.

A solid state regulator is installed in or on the back of

the alternator. Two brushes conduct current, through

two slip rings, to the rotor field. Some alternators

have a capacitor mounted on them. The capacitor

protects the rectifier from high voltages. It also

suppresses electrical noise through a radio, if

equipped.

The alternator is connected to the battery through the

ignition switch for alternator turn on . Therefore,

alternator excitation occurs when the switch is turned

on.

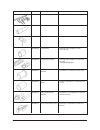

Alternators

The alternators used on these engines have three

phase, full-wave, rectified output. They are the brush

type. Refer to the Alternator Coverage chart for

detailed systems operation information

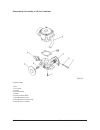

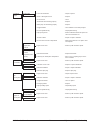

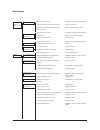

Daewoo CS-121 Alternator

Mico K1 Enclosed Alternator

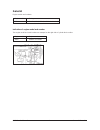

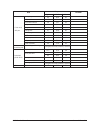

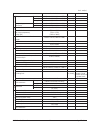

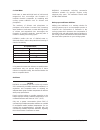

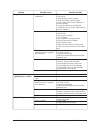

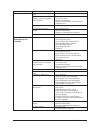

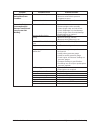

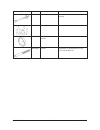

ALTERNATOR COVERAGE

Alternator

Manufacturer/

Part Number

Series

D167411

Daewoo/CS-121

D187478

MICO/K1 Sealed

IDES081P

IDES082P

Summary of G20E-3

Page 1

Service manual g424 gasoline/lp engine g424 lp engine (low emission version) g20e-3, g25e-3, g30e-3 gc20e-3, gc25e-3, gc30e-3 sb2215e01 o c t . 2 0 0 1.

Page 2: Important Safety Information

Important safety information most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to po...

Page 3: Index

G424 service manual index index general information .......................................4 how to read this manual ....................................4 precaution before service ....................................6 general .................................................................8 tighte...

Page 4

G424 service manual index 3 dual fuel system...........................................102 governing system .........................................103 general description ..........................................103 governor,disassembly and reassembly..........104 lubrication system.................

Page 5: General Information

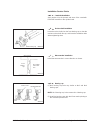

Maintenance and servicing procedures (1) a diagram of the component parts is provided near the front each section in order to give the reader a better understanding of the installed condition of component parts. (2) the numbers provided within the diagram indicate the sequence for maintenance and se...

Page 6

Removal service points a oil pan removal (1) remove the all oil pan bolts. (2) drive in the special tool between the cylinder block and oil pan. (3) side the tool by striking the edge of the special tool to separate the oil pan from the cylinder block. N m l k j i a b c g424 service manual general i...

Page 7: Precautions Before Servce

G424 service manual general information 6 1en0018 1en0019 1en0020 1en0021 precautions before servce removal and disassembly for prevention of wrong installation or reassembly and for ease of operation, put mating marks to the parts where no function is adversely affected. Special tool be sure to use...

Page 8

G424 service manual general information 7 1en0023 1en0024 1en0025 rubber parts do not stain timing belt and v-belt with oil or water. Therefore, do not clean the pulley and sprocket with detergent. Oil and grease before reassembly, apply specified oil to the rotating and sliding parts. Genuine part ...

Page 9: General

G424 service manual general information 8 6en1916 general engine models and numbers indication of engine model and number the engine model and serial number are stamped on the right side of cylinder block surface. Engine model fuel type g424 gasoline, lpg, lpg (low emission version) engine model eng...

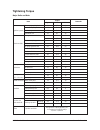

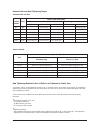

Page 10: Tightening Torque

G424 service manual general information 9 tightening torque major bolts and nuts water pump pulley bolt crankshaft pulley bolt ignition system spark plug distributor nut timing belt cover bolt tensioner spring spacer tensioner belt tensioner bolt oil pump sprocket nut crankshaft bolt tensioner b bol...

Page 11

G424 service manual general information 10 drain plug oil pan bolt oil screen bolt/nut oil pressure switch front case, plug doil pan flange bolt relief plug oil filter bracket oil pump cover bolt oil pump cover screw front case bolt piston, connecting rod bearing nut connecting rod. Flywheel bolt re...

Page 12

G424 service manual general information 11 general bolts and nuts tightening torque standard bolts and nuts nominal torque, kg•m (lb•ft) [n•m] pitch bolt, stud, nut (with spring washer) flange bolt, flange nut diameter m5 m5 m6 m6 m7 m7 m8 m8 m9 m9 m10 m10 tapered threads torque, kg•m (lb•ft) [n•m] ...

Page 13: Sealant

G424 service manual general information 12 semi circular packing 3m tm aad part no.8672 or equivalent rocker cover 3m tm aad part no.8672 or equivalent oil pressure switch 3m tm aad part no.8672 or equivalent oil pan silicone rtv sealant or eguivalent rear oil seal case silicone rtv sealant or eguiv...

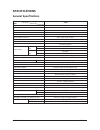

Page 14: Specifications

G424 service manual specifications 13 specifications general specifications engine model g424 item type no. Of cylinders and arrangement combustion chamber type valve mechanism total displacement, cm 3 (cc) [cu in.] bore x stroke, mm (in.) dry weight, kg (lb) compression ratio compression pressure, ...

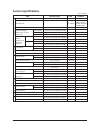

Page 15: Service Specifications

G424 service manual specifications 14 flatness of gasket surface grinding limit overall height 0.05 (0.0020) 0.25 (0.0098) 0.50 (0.0197) intake 0.30 (0.0118) 0.60 (0.0236) exhaust 0.30 (0.0118) 0.60 (0.0236) cam height intake exhaust journal diameter oil clearance overall length intake exhaust valve...

Page 16

G424 service manual specifications 15 end gap no. 1 ring no. 2 ring oil ring ring-to-ring groove no. 1 clearance no. 2 outside diameter press-in load (at room temperature), n (kg) [lbf] big end center-to small end center length bend twist big end thrust clearance end play journal outside diameter pi...

Page 17

G424 service manual specifications 16 nominal output, kw voltage, v no-load characterstics current, a speed, rpm outer diameter commutator runout undercut pinion gap brush length start end end start primary coil resistance, Ω secondary coil resistance, Ω plug gap valve opening temperature, °c (˚f) f...

Page 18: Maintenance

G424 service manual maintenance 17 maintenance g424 engine requires a certain amount of maintenance. Suggested maintenance requirements are contained in this section. The owner should, however, develop his own maintenance schedule using the requirements listed in this section and any other necessary...

Page 19: Inspect Electrical System

G424 service manual maintenance 18 • lube oil filter gasket with engine oil. • install oil filter as per filter manufacturers instructions. Do not over tighten • fill crankcase with engine oil. • start engine & run approximately 60 seconds. • shut down engine, wait approximately 2 - 5 minutes and th...

Page 20: Test Fuel Lock (Electric)

G424 service manual maintenance 19 replace lp fuel filter element park the lift truck in an authorized refueling area with the forks lowered, parking beake applled and the transmission in neutral. 1. Close the fuel shutoff valve on the lp-gas tank. Run the engine until fuel in the line runs out and ...

Page 21: Replace Gasoline Fuel Filter

G424 service manual maintenance 20 replace gasoline fuel filter (gasoline truck and dual fuel truck) fuel leaked or spilled onto hot surfaces or electrical components can cause a fire. Turn the disconnect switch off if fitted or disconnect the battery when changing fuel filters 1. Raise the hood and...

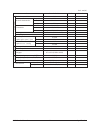

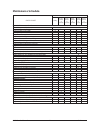

Page 22: Maintenance Schedule

G424 service manual maintenance 21 maintenance schedule check point general maintenance section test fuel system for leaks prior to any service of maintenance activity inspect engine for fluid leaks o check engine oil and filter o change engine oil and filter o inspect accessory drive belts o inspec...

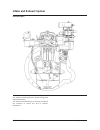

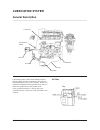

Page 23: Engine System

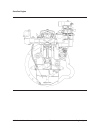

G424 service manual engine system 22 engine system engine overview the cylinder blocks are made of the special cast iron and employ 5-bearing, deep skirt system. The cylinder heads have hemisphere combustion chambers, are of cross flow type arranged with v-type valves and high efficient combustion i...

Page 24

G424 service manual engine system 23 gasoline engine.

Page 25

G424 service manual engine system 24 lpg engine ( low emission version).

Page 26: Timing System

G424 service manual engine system 25 timing system the timing belt is meshed with the sprockets, the crankshaft sprocket becomes the drive sprocket, and thus functions to drive the camshaft and oil pump. Timing belt the timing belt is the cogged type, using rubber as its basic material, and it emplo...

Page 27: Silent Shaft Mechanism

G424 service manual engine system 26 silent shaft mechanism the silent shaft mechanism function mainly to eliminate, by the action of the silent shafts incorporated at both sides of the cylinder block, the vertical vibromotive force of the engine as well as the vibromotive moment in the rolling dire...

Page 28: Auto Lash Adjuster

G424 service manual engine system 27 auto lash adjuster these engines have auto lash adjusters that eliminate the need for valve clearance adjustment and reduce noises of the valve system. The auto lash adjuster automatically absorbs change in the valve clearance caused by engine temperature change ...

Page 29: Intake and Exhaust System

G424 service manual engine system 28 intake and exhaust system the intake manifold employs the shape having good intake performance. The exhaust manifold employs a dual type and intend the reduction of output loss due to exhaust interference. Gasoline engine.

Page 30

G424 service manual engine system 29 lpg engine (low emission version).

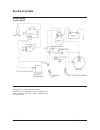

Page 31: Electrical System

G424 service manual engine system 30 electrical system stating motor is of the gear reduction type. Distributor is of a breakerless type and employs the ignition advancer which uses jointly centrifugal type and vacuum type. Wiring diagram (gasoline engine).

Page 32

G424 service manual engine system 31 wiring diagram (lpg engine, low emission version).

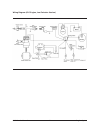

Page 33: Starting System

G424 service manual starting system 32 starting system general description the starting motor is used to turn the engine flywheel fast enough to make the engine run. The starting motor has a solenoid. When the ignition switch is activated, voltage from the electrical system will cause the solenoid t...

Page 34

G424 service manual starting system 33 typical 12 volt starting circuit (1) test point. (2) test point. (3) test point. (4) test point. (5) test point. (x) hold-in coil. (w) pull-in coil. 1 2 3 5 4 w x motor starter rd/wh wh start relap start switc.H mtr bat battery diagnosis procedure the following...

Page 35

G424 service manual starting system 34 the result of these switches and relays is to permit a 5 amp dash-mounted switch to turn on a 500 to 1000 amp motor used to crank an engine. Battery voltage (power) available during cranking varies according to the temperature of the batteries. The following ch...

Page 36: Start Relay Tests

G424 service manual starting system 35 7. Are all the voltages within specifications ? I if the voltage drops are correct, go to step 8, to check the engine. I if the voltage drops are too high, repair and/or replace the faulty electrical component. 8. Rotate the crankshaft by hand to make sure it i...

Page 37: Starter Motor

G424 service manual starting system 36 starter motor the starter motor is small in size light weight and high- output type. Rotation of the motor are reduced by the reduction gear, and high torque is transmitted to the pinion gear. Operation 1. When the ignition key (ig-sw) is turned to the “st” pos...

Page 38

G424 service manual starting system 37 2. The plunger of the magnetic switch is then attracted, and the pinion is pushed out by the shift lever, meshing with the ring gear. As a result of the movement of the plunger, the contacts of the magnetic switch close, and, as a result, the starter is turned ...

Page 39

G424 service manual starting system 38 when the internal gear is fixed as in the case of the starter motor, the carrier rotates in the same direction as the sun gear. This may be used to determine the reduction ratio easily. Namely, the carrier reduction ratio = (43 + 11) / 11 . =. 4.9 permanent mag...

Page 40

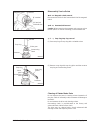

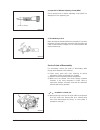

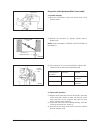

G424 service manual starting system 39 removal and installation removal steps 1. Bolt 2. Starter 6en1918 inspection pinion gap adjustment (1) disconnect the field coil wire from terminal m of the magnetic switch. (2) connect a 12 v battery between terminal s and starter motor body (positive terminal...

Page 41

G424 service manual starting system 40 6en0871 6en0872 6en0873 pull-in test of magnetic switch (1) disconnect field coil wire from terminal m of magnetic switch. (2) connect a 12v battery between terminal s and terminal m. Caution: this test must be performed quickly (in less than 10 seconds) to pre...

Page 42

G424 service manual starting system 41 6en0874 free running test (1) place starter motor in a vise equipped with soft jaws and connect a fully-charged 12-volt battery to starter motor as follows: (2) connect a ammeter (100-ampere scale) and carbon pile rheostat in series with battery positive post a...

Page 43

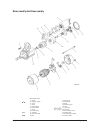

42 g424 service manual starting system 42 disassembly and reassembly disassembly steps 1. Screw 2. Magnetic switch 3. Screw 4. Screw 5. Rear bracket 6. Brush holder 7. Brush 8. Rear bearing 9. Armature 10. Yoke assembly 11. Ball 12. Packing a 13. Packing b 14. Plate 15. Planetary gear 16. Lever 17. ...

Page 44

G424 service manual starting system 43 6en0610 6en0611 6en0612 disassembly service points a magnetic switch removal disconnect the field coil wire from terminal m of the magnetic switch b armature/ball removal caution: when removing the armature, take care not to lose the ball (which is used as a be...

Page 45

G424 service manual starting system 44 1en0298 1en0302 1en0296 i nspection 1. Commutator (1) place the armature on a pair of v-blocks and check the runout using a dial gauge. Standard value: 0.5 mm (0.020 in.) limit: 0.1 mm (0.004 in.) (2) check the outer diameter of the commutator. Standard value: ...

Page 46

G424 service manual starting system 45 1en0292 6en0600 6en0601 4. Brush (1) brushes that are worn beyond wear limit line, or oil soaked, should be replaced. (2) when replacing ground brush, side the brush from brush holder by prying retainer spring back. 5. Armature coil short circuit test (1) place...

Page 47

G424 service manual starting system 46 reassembly service points a stop ring/snap ring installation using a suitable pulling tool, pull overrunning clutch stop ring over snap ring. Stop stop ring overrunning.

Page 48: Charging System

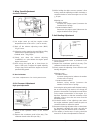

G424 service manual charging system 47 charging system general description the alternator is an electrical and mechanical components driven by a belt from engine rotation. It is used to charge the storage battery during the engine operation. The alternator is cooled by an external fan mounted behind...

Page 49

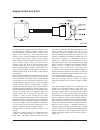

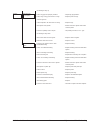

G424 service manual charging system 48 daewoo cs-121 series d167411 rated voltage..................................................12 volts polarity is negative ground. Rotation is clockwise. Output at 6500 rpm (cold) .............................61 amps output voltage .................................

Page 50

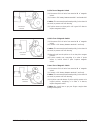

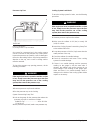

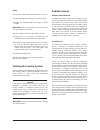

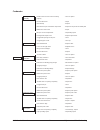

G424 service manual charging system 49 remove & install alternator note : hood, seat and dry air cleaner have been removed for photographic purposes. 1. Disconnect wire (1) and wire (2) 2. Remove bolt and washer (3), and remove belt (4). 3. Remove alternator (5). Note : for the installation of the a...

Page 51: Ignition System

G424 service manual ignition system 50 ignition system breakerless ignition system ignition system schematic (1) battery. (2) ignition switch. (3) coil. (4) distributor. (5) spark plug. The ignition system has battery (1), ignition switch (2), coil (3), distributor (4) with inner electronics circuit...

Page 52: Distributor

G424 service manual ignition system 51 distributor the distributor is the contactless type and is equipped with a centrifugal advancer and vacuum advancer. The distributor is installed at the front side surface of the cylinder head, and is driven directly by the camshaft..

Page 53

G424 service manual ignition system 52 governor advance mechanism in the figure below, pin a rotates together with the shaft. A governor weight is installed to this pin a. There is a pin b on the governor weight which fits into the oblong hole in the cam base. The governor spring is attached to the ...

Page 54

G424 service manual ignition system 53 vacuum advance mechanism there is a diaphragm within the vacuum controller, with a spring at the negative-pressure (vacuum) side which pressure against the diaphragm. A link is attached to the diaphragm and is connected to the pickup plate. The pickup assy is i...

Page 55: Removal and Installation

G424 service manual ignition system 54 removal and installation removal steps 1. Drive belt 2. Water pump pulley 3. Crankshaft pulley 4. Spark plug cable 5. Spark plug 6. High tension cable 7. Vacuum 8. Ignition 9. Harness 10. Distributor a.

Page 56

G424 service manual ignition system 55 1en0393 inspection ignition coil perform the following measurements. Replace the ignition coil if the standard values are not met. (1) measure the resistance values of the primary and secondary coils and of the external resistor with a tester. If the readings a...

Page 57

G424 service manual ignition system 56 disassembly and reassembly disassembly steps 1. Distributor cap 2. Rotor 3. Cover 4. Signal rotor 5. Pickup coil assembly 6. Ignitor 7. Heat sink 8. Breaker assembly 9. Snap ring 10. Vacuum control 11. Connector assembly 12. O-ring 13. Distributor housing a.

Page 58

G424 service manual ignition system 57 1el0052 1el0053 1el0054 inspection pickup coil (1) using a tester, check the resistance of the pickup coil. Standard value: 420 to 540 Ω (2) check to make sure the pointer of the tester oscillates when the tip of a screwdriver is moved past by the core of the p...

Page 59: Gasoline Fuel System

G424 service manual gasoline fuel system 58 the fuel pump pulls the fuel from fuel tank. The fuel flows through filter, which is installed on top of the fuel tank, to carburetor where the fuel is mixed with air at the correct ratio. This air and fuel mixture then goes to the inlet manifold. The air ...

Page 60

G424 service manual gasoline fuel system 59 the carburetor is of the two-barrel, downdraft type which performs well in every engine operation ranging from slow idle to full speed. Construction of carburetor (1) float. (2) front chamber cover. (3) primary inner venturi. (4) choke valve. (5) accelerat...

Page 61

G424 service manual gasoline fuel system 60 1. Air system air passed through the air cleaner flows through the choke bore and venturi into the clearance of the throttle valve and supports idle running of the engine. When engine speed increases to off-idle and more, intake air is metered by the ventu...

Page 62

G424 service manual gasoline fuel system 61 this system provides adequate air-fuel-mixture richness for smooth engine running ranging from slow- idle to light-load operation. Fuel from the float chamber is sent through the main jet to the pilot jet where metering of fuel is made. On the other hand, ...

Page 63

G424 service manual gasoline fuel system 62 the idle compensator uses a bimetal. When the carbretor ambient temperature rises during idle or “off idle” running, the bimetal bends enough to open the compensator valve. Now additional air from the choke bore can flow through the auxiliary air passage t...

Page 64

G424 service manual gasoline fuel system 63 5. Enrichment system the enrichment system provides additional fuel feed to the main metering system during high- speed large-torque operation. This system use the membrane (diaphragm) which is actuated by the intake manifold vacuum and membrane spring to ...

Page 65: Removal and Installation

G424 service manual gasoline fuel system 64 removal and installation removal steps 1. Return set hose assembly 2. Oil seal 3. Air horn 4. Gasket 5. Carburetor 6. Air governor 7. Gasket 8. Fuel pipe 9. Fuel hose 10. Fuel pipe 11. Fuel pump 12. Gasket 13. Insulator 14. Push rod a b a 6en1893.

Page 66

G424 service manual gasoline fuel system 65 6en0841 removal service points a carburetor removal (1) hold the carburetor in a level position while using care not to let fuel spill, remove it from the intake manifold. (2) turn the carburetor upside down on a pan to drain fuel. B fuel pump removal plac...

Page 67: Gasoline Carburetor

G424 service manual gasoline fuel system 66 gasoline carburetor disassembly and reassembly disassembly steps 1. Throttle return spring 2. Damper spring 3. Choke rod 4. Screw 5. Float chamber cover 6. Float chamber cover gasket 7. Cover 8. Packing 9. Bimetal 10. O-ring 11. Accelerator wire bracket 12...

Page 68

G424 service manual gasoline fuel system 67 6en0851 6en0852 service points of disassembly the following parts must not be disassembled at the time of disassembly. (1) choke valve and choke shaft (2) inner venturi (3) throttle valve and throttle shaft a return spring/choke rod removal (1) when the sp...

Page 69

G424 service manual gasoline fuel system 68 6en0853 6en0854 inspection 1. General inspection check the following and repair or replace parts if faulty. (1) check fuel passages (jets) and air passages (jets or orifices) for clogging. If clogged, wash thoroughly with cleaning solvent or detergent and ...

Page 70

G424 service manual gasoline fuel system 69 6en1888 6en0855 6en0852 4. Inspection of mixture adjusting screw (mas) check tapered end of mixture adjusting screw (mas) for damage from over tightening, etc. 5. Throttle body check make sure that the throttle shaft moves smoothly. If any sticky movement ...

Page 71

G424 service manual gasoline fuel system 70 6en0869 6en0856 6en0858 (2) main jets have size symbols stamped on their ends for identification. Size symbols : 132.5 b check ball/weight installation install the acceleration check ball and weight. C float/float pin installation after the float and float...

Page 72

G424 service manual gasoline fuel system 71 6en0859 6en1889 6e0860 i nspection and adjustment after reassembly 1. Fast idle opening (1) move the choke lever to place the choke valve in fully closed position. (2) measure the clearance “a” (primary throttle valve to throttle bore). Note: refer to the ...

Page 73

G424 service manual gasoline fuel system 72 6en0861 3. Ports (1) connect a hand vacuum pump and check each port for clogging. (2) if clogged, clean the port and then blow air into it..

Page 74: Lp Fuel System

G424 service manual lpg fuel system 73 lp fuel system general description electric fuelock model . Lp fuel system components the basic components of this liquid petroleum (lp) fuel system are: the fuel tank, the fuel filter and relief valve, fuelock (2), converter (1) and carburetor (3). Liquid fuel...

Page 75

G424 service manual lpg fuel system 74 electric fuelock fuelock (2) is electrically activated by an oil pressure switch. When the engine is stopped, or if the engine oil pressure gets lower than the pressure for operation, the oil pressure switch will open. When the oil pressure switch opens, it wil...

Page 76

G424 service manual lpg fuel system 75 the converter is a combination regulator and vaporizer. It receives liquid fuel through opening (1) at tank pressure from the fuelock. The fuel is available inside converter vaporizing chamber (9) when carburetor vacuum is felt in converter opening (8). When va...

Page 77

G424 service manual lpg fuel system 76 carburetor lp fuel carburetor schematic (1) idle air screw. (2) air valve. (3) diaphragm. (4) metering spring. (5) passage. (6) lp gas metering valve. (7) power mixture adjustment. (8) carburetor. (9) piston. (10) throttle valve. Lift trucks with lp (liquid pet...

Page 78: Tests Or Adjustments

G424 service manual lpg fuel system 77 tests or adjustments adhere to the following warnings when performing any tests or adjustments while the engine is running. Work carefully around an engine that is running. Engine parts that are hot, or parts that are moving, can cause personal injury. Exhaust ...

Page 79

Power mixture adjustment the method of adjustment depends upon the test equipment that is available. The power mixture can be adjusted using a co meter, vacuum gauge or electri- cal system analyzer. The co meter method is the pre- ferred method for reduced emissions. The vacuum gauge method is the n...

Page 80

G424 service manual lpg fuel system 79 fuel system leak check outer fuel system leak check lp gas is highly flammable. To prevent personal injury, keep fire and flammable materials away from the lift truck when work is done on the fuel system. Combustion gases from lp gas fuel system can be a danger...

Page 81

G424 service manual lpg fuel system 80 carburetor components (carburetor shown removed for better illustration) (6) spring. (7) backup plate and diaphragm. (8) air valve ring. (9) air-gas valve assembly. (10) inner carburetor body. 1. Remove carburetor cover (3), spring (6), backup plate and diaphra...

Page 82

G424 service manual lpg fuel system 81 lp converter - check, clean test lp-gas converter 1. Obtain a test kit. 2. Start engine. 3. Close the liquid outlet valve in the fuel storage container. 4. Run engine out of fuel. 5. Install the 0-30kpa (0-5 psi) gauge in the primary test port. 6.. Install the ...

Page 83: Disassembly & Assembly

G424 service manual lpg fuel system 82 removal steps 1. Throttle return spring 2. Accel wire assembly 3. Return spring support 4. Lpg carburetor 5. Throttle chamber gasket 6. Throttle body 7. Carburetor gasket 8. Air governor 9. Air governor gasket 10. Fuel pump cover disassembly & assembly lpg carb...

Page 84

G424 service manual lpg fuel system 83 disassemble lp gas carburetor start by: a. Remove lp gas carburetor. 1. Remove four screws (1) and cover (2). 2. Remove spring (3). Remove diaphragm assembly (4). 3. Remove four screws (5), backup plate (6), diaphragm (7) and the air valve ring from the inner c...

Page 85

G424 service manual lpg fuel system 84 assemble lp gas carburetor 1. Check all parts for damage. Replace damaged parts with new as necessary. 2. Make sure all parts are clean and free of dirt and foreign material. 3. Put throttle shaft (17) in position in the throttle body, and install stop lever (1...

Page 86

G424 service manual lpg fuel system 85 lp gas converter remove & install lp gas converter start by : remove lp gas fuelock. 1. Remove lines (1). 2. Remove two bolts and nut (2). 3. Remove lp gas converter (3). Note : for the installation of the lp gas converter, reverse the removal steps. Note : whe...

Page 87

G424 service manual lpg fuel system 86 4. Remove spring and plunger (10) from the intermediate cover. 5. Remove intermediate cover (11), diaphragm (12) and the secondary regulator valve (13). Inspection, assembly of lp gas converter 1. Clean primary and secondary valves with soap and warm water and ...

Page 88

G424 service manual lpg fuel system(low emission version) 87 lpg fuel system (low emission version) general description schematic of g424 lp fuel system (low emission version) g242 lp engine (low emission version) is different from standard g424 lp engine. To reduce emission of exhaust gas, closed l...

Page 89

G424 service manual lpg fuel system(low emission version) 88 fuelock valve lp converter lp carburetor muffler governer engine open-loop lp carburetion system : g424 lp engine closed-loop lp carburetion system : g424 lp engine (low emission version) fuelock valve lp converter lp carburetor governer e...

Page 90

G424 service manual lpg fuel system(low emission version) 89 lp carburetor (variable venturi) the variable venturi air/fuel mixer is mounted in the intake air stream between the air cleaner and the intake manifold. The design of the main section incorporates a cylindrical bore through the center (1)...

Page 91

G424 service manual lpg fuel system(low emission version) 90 vacuum switch (map) 1. Electrical 2. Vacuum port 3. Main body the vacuum switch is a simple direct acting contact pressure switch, consisting of a main body (3), an electrical connector with two pins (1) and a vacuum port connection (2). T...

Page 92

G424 service manual lpg fuel system(low emission version) 91 1. Fuel inlet 2. Primary valve 3. Primary spring 4. Primary heat exchanger chamber 5. Pressure transfer port 6. Primary diaphragm chamber 7. Secondary valve 8. Secondary spring 9. Primary diaphragm 10. Primary pivot 11. Primary pin 12. Coo...

Page 93

G424 service manual lpg fuel system(low emission version) 92 fuel control valve 1. Carburetor avv port connection 2. Vaporizer secondary vent chamber connection 3. Electrical connectors 4. Balance line connection the fuel control valve is a three way valve, operated by a pulse width modulated electr...

Page 94

G424 service manual lpg fuel system(low emission version) 93 in order to obtain maximum emission reductions from the exhaust gas catalyst, accurate control of the engines operating air fuel ratio (afr) is required. The engine control unit (ecu) uses input from three sources: excess oxygen informatio...

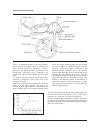

Page 95

G424 service manual lpg fuel system(low emission version) 94 oxygen sensor stoichiometric ratio rich lean air/fuel ratio electromotive force (v) performance of three-way catalytic converter stoichiometric point air/fuel ratio operating window for converter nox co cxhy % conversion the oxygen sensor ...

Page 96

G424 service manual lpg fuel system(low emission version) 95 catalytic muffler the catalytic muffler is mounted in the exhaust gas stream of g430 engine. The catalytic muffler facilitates oxidation and reduction reactions that reduce the amount of unwanted constituents in the exhaust gas stream. Cat...

Page 97: Tests Or Adjustments

G424 service manual lpg fuel system(low emission version) 96 tests or adjustments adhere to the following warnings when performing any tests or adjustments while the engine is running. Work carefully around an engine that is running. Engine parts that are hot, or parts that are moving, can cause per...

Page 98

G424 service manual lpg fuel system(low emission version) 97 lp converter-check, clen see, “lp converter-check, clean” in lp fuel system section. Inspection of fuel lock - off 1. When voltage is impressed to the terminal of fuel lock-off, check whether there si operation sound. 2. If there is an abn...

Page 99

G424 service manual lpg fuel system(low emission version) 98 inspection of oxygen sensor (1) before checking, warm up the engine until engine coolant temperature reaches 80 to 95°c (2) in the state where engine is poerated disconnent the oxygen sensor connector and connect a voltmeter. Caution the r...

Page 100: Disassembly & Assembly

G424 service manual lpg fuel system(low emission version) 99 disassembly & assembly lpg carburetor removal and installation of lp gas carburetor removal steps 1. Bracket - accel wire 2. Lpg carburetor 3. Carburetor gasket 4. Air governor 5. Governor gasket 6. Fuel pump cover 7. Bolt 6en2143 7.

Page 101

G424 service manual lpg fuel system(low emission version) 100 disassembly & assembly of lp gas carburetor removal steps 1. Bolt 2. Lpg mixer 3. Gasket 4. Vacuum switch 5. Fitting 6. Vacuum switch (map) 7. Idle adjustment screw 8. Idle adjustment screw spring 9. Throttle body assembly 6en2147.

Page 102

G424 service manual lpg fuel system(low emission version) 101 lp gas converter removal & installation of lp gas converter removal steps 1. Vacuum hose 2. Vacuum hose 3. Vacuum hose 4. Fuel control valve 5. Lpg shut off valve assembly 6. Balance hose 7. Check valve elbow fitting 8. Balance hose 9. Va...

Page 103: Dual Fuel System

G424 service manual dual fuel system 102 dual fuel system dual fuel basic schematic (1) gasoline inlet line (from gasoline tank). (2) mechanical fuel pump. (3) lp mixer. (4) balance hose. (5) lp electric fuelock. (6) lp fuel line. (7) gasoline electric fuelock. (8) converter. (9) selector switch. (1...

Page 104: Governing System

G424 service manual governing system 103 governing system general description sectional view of air governor (1) body. (2) stabilizer rod. (3) stabilizer piston. (4) throttle plate. (5) throttle plate shaft. (6) bearing. (7) nipple. (8) spring. (9) bush nut. (10) adjusting screw. (11) plate. (12) ca...

Page 105: Air Governor

G424 service manual governing system 104 air governor disassembly and reassembly disassembly steps 1. Ventilation hose 2. Gasket 3. Sealing cap 4. Cover plate assembly 5. Gasket 6. Adjusting nut 7. Adjusting screw 8. Plate assembly 9. Valve assembly 10. Valve shaft assembly 11. Piston cover 12. Gask...

Page 106

G424 service manual governing system 105 inspection 1. Check the plate assembly (8) composed of a ribbon spring and coil spring for cracks and any other damage. 2. Check the valve shaft for wear, and also make sure that it rotates smoothly when mounted in the body. 3. Check the piston for damage. Ch...

Page 107: Lubrication System

G424 service manual lubrication system 106 lubrication system general description lubricating system is the full-flow filtered pressure- feed oil system and the oil reserved in the oil pan is fed with pressure to each part of engine. After the oil pressure is adjusted through the relief valve, the o...

Page 108: Testing & Adjusting

G424 service manual lubrication system 107 testing & adjusting adhere to the following warnings when performing any tests or adjustments while the engine is running. Work carefully around an engine that is running. Engine parts that are hot, or parts that are moving, can cause personal injury. Exhau...

Page 109

G424 service manual lubrication system 108 note: too much oil consumption can also be the result if oil with the wrong viscosity is used. Oil with a thin viscosity can be caused by fuel leakage into the crankcase, or by increased engine temperature. Low oil pressure instrument panel (1) engine oil l...

Page 110

G424 service manual lubrication system 109 oil pressure check oil pressure check (1) lp pressure switch. (2) oil pressure switch. (two-terminals) (one-terminal) 1. With the engine off, make sure the oil level is correct. Connect the analyzer to the engine as shown in engine rpm check in the testing ...

Page 111: Cooling System

G424 service manual cooling system 110 cooling system general description cooling system schematic (1) cylinder head. (2) thermostat. (3) recovery tank. (5) radiator top hose. (6) radiator pressure cap. (7) cylinder walls. (8) radiator. (9) radiator lower hose. (10) water pump. Water pump (10) is in...

Page 112: Testing & Adjusting

G424 service manual cooling system 111 testing & adjusting adhere to the following warnings when performing any tests or adjustments while the engine is running: work carefully around an engine that is running. Engine parts that are hot, or parts that are moving, can cause personal injury. Exhaust f...

Page 113

G424 service manual cooling system 112 pressure cap test pressure cap diagram (a) sealing surface of cap and radiator. One cause for a pressure loss in the cooling system can be a bad seal on the pressure cap of the system. Inspect the pressure cap carefully. Look for damage to the seal or the seali...

Page 114

G424 service manual cooling system 113 thermostat the thermostat is the wax pellet type. A jiggle valve (which improves air bleeding during water supply) is provided on the flange part. When the thermostat is closed, the circulation of coolant is stopped, thereby making warm-up faster. Operation whe...

Page 115

G424 service manual cooling system 114 cooling system heat problems to check if there is a good reason for heat problems do the checks that follow: 1. The indications of a heat problem are as follows: a. High coolant temperature indicator light is on or needle of coolant temperature gauge is in red ...

Page 116

G424 service manual cooling system 115 coolant water hard water, or water with high levels of calcium and magnesium ions, encourages the formation of insoluble chemical compounds by combining with cooling system additives such as silicates and phosphates. The tendency of silicates and phosphates to ...

Page 117

G424 service manual cooling system 116 belt adjustment drive belts must grip the entire contact area of the pulley. When drive belts are too loose, the belts can slip, tear, burn, or grab and snap. More belts fail from being too loose than too tight. Belts that are too tight can damage the engine by...

Page 118: Service Procedures

G424 service manual cooling system 117 gouged edge a gouged edge in a belt can be caused by a damaged pulley, a misaligned pulley, or the belt being too loose or too long. Check the pulley and the belt for proper alignment and tension. Make sure other components are not misaligned and rubbing agains...

Page 119

G424 service manual cooling system 118 filling 1. Check the radiator drain cock to be sure it is closed. 2. Check the engine drain plug to be sure it is tight. 3. Premix the antifreeze with clear water in 50/50 mixture. Important: if the old coolant is to be re-used, check it for glycol/water mix of...

Page 120

G424 service manual cooling system 119 remove & install water temperature sender 1. Disconnect one wire connection (1). 2. Remove water temperature sender (2). Note: for the installation of the water temperature sender, reverse the removal steps. 3. Use thread sealant on the water temperature sender...

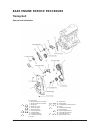

Page 121: Timing Belt

G424 service manual base engine service procedure 120 removal steps 1. Timing belt front cover upper 2. Timing belt front cover lower 3. Timing belt 4. Tensioner spacer 5. Tensioner spring 6. Tensioner pulley 7. Oil pump sprocket 8. Crankshaft bolt 9. Crankshaft washer 10. Crankshaft sprocket 11. Fl...

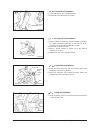

Page 122

G424 service manual base engine service procedure 121 6en0716 6en0884 6en0663 6en0868 removal service points a timing belt removal (1) when the timing belt is to be re-used, make an arrow mark on the back surface on the belt to indicate the rotating direction with a chalk or the like so that the bel...

Page 123

G424 service manual base engine service procedure 122 6en0642 6en1322 6en0636 6en0637 d crankshaft sprocket removal (1) if it is difficult to remove the sprocket, use the special tool. E timing belt “b” removal (1) make a mark on the back of the timing belt indicating the direction of rotation so it...

Page 124

G424 service manual base engine service procedure 123 6en0668 8en0066 8en0044 8en0067 h crankshaft sprocket removal (1) using the special tool show in the illustration, lock the camshaft sprocket in position. (2) loosen the camshaft sprocket bolt. Inspection 1. Timing belt replace belt if any of the...

Page 125

G424 service manual base engine service procedure 124 8en0068 6en0669 6en0739 6en0636 (7) abnormal wear on teeth earlier stage: canvas worn (canvas fibers napped, rubber lost, discolored whitish, and unclear canvas texture) latter stage: canvas lost, rubber exposed (tooth width thinner) (8) missing ...

Page 126

G424 service manual base engine service procedure 125 den0602 6en0571 6en0572 6en0573 d timing belt “b” installation (1) align timing mark on the crankshaft sprocket “b” and counterbalance shaft sprocket with the marks on the front case respectively. (2) install the timing belt “b” on the crankshaft...

Page 127

G424 service manual base engine service procedure 126 6en0634 6en0564 6en0555 6en0670 e crankshaft bolt installation (1) using the special tool, hold the flywheel. (2) install the crankshaft pulley in position. F oil pump sprocket installation (1) insert a phillips screwdriver (shank diameter 8 mm[0...

Page 128

G424 service manual base engine service procedure 127 6en0671 6en0672 6en0015 6en0562 (2) align the timing mark on the crankshaft sprocket with that on the front case. (3) align the timing mark on the oil pump sprocket with its mating mark. (4) install the timing belt on the crankshaft sprocket, oil...

Page 129

G424 service manual base engine service procedure 128 6en0017 6en0015 6en0616 (8) apply force to the tensioner in the direction shown by arrow to make the belt engage completely with each sprocket. (9) tighten the tensioner attaching bolt to the specified torque. (10) tighten the tensioner spacer to...

Page 130: Intake Manifold

G424 service manual base engine service procedure 129 removal steps 1. Water outlet 2. Gasket 3. Thermostat 4. Engine hanger 5. Intake manifold 6. Gasket intake manifold removal and installation 6en1894.

Page 131

G424 service manual base engine service procedure 130 exhaust manifold and water pump gasoline/lpg engine removal and installation removal steps 1. Oil level gauge 2. Oil level gauge guide 3. O-ring 4. Heat protector a 5. Heat protector b 6. Engine hanger 7. Exhaust manifold 8. Gasket 9. Water inlet...

Page 132

G424 service manual base engine service procedure 131 a o-ring and water pipe installation replace the water inlet pipe o-ring with a new one. Apply water to the outer circumference of the o-ring for easier insertion into the water pump and thermostat housing. Caution: 1) never apply engine oil or a...

Page 133

G424 service manual base engine service procedure 132 lpg engine (low emission version) removal and installation removal steps 1. Oil level gauge 2. Oil level gauge guide 3. O-ring 4. Heat protector a 5. Heat protector b 6. Oxygen sensor 7. Engine hanger 8. Exhaust manifold 9. Gasket 10. Water inlet...

Page 134: Rocker Arms And Camshaft

G424 service manual base engine service procedure 133 rocker arms and camshaft removal and installation removal steps 1. Breather hose 2. P.C.V. Hose 3. P.C.V. Valve 4. Oil filler cap 5. Rocker cover 6. Gasket 7. Semi-circular packing 8. Rocker arms and rocker shafts 9. Rear bearing cap 10. Rear arm...

Page 135

G424 service manual base engine service procedure 134 6en0569 9en0058 6en1698 removal service points a rocker arm and rocker shaft removal caution: if the lash adjuster is re-used, clean the lash adjuster. (1) fit the lash adjuster onto the rocker arm without allowing diesel fuel to spill out. Fit. ...

Page 136

G424 service manual base engine service procedure 135 6en1699 6en1808 6en1809 6en1808 (2) place the lash adjuster in container a and clean its outside surface. Note: use a nylon brush if deposits are hard to remove. (3) while gently pushing down the internal steel ball using special tool md998442, m...

Page 137

G424 service manual base engine service procedure 136 6en1809 6en1810 6en1811 6en1704 (6) remove the lash adjuster from the container. Then, push down the steel ball gently and push the plunger to eliminate diesel fuel from the pressure chamber. (7) place the lash adjuster in container c. Then, gent...

Page 138

G424 service manual base engine service procedure 137 6en0575 6en0576 6en0024 installation service points a camshaft installation apply engine oil to the journals and cams of the camshafts. Install the camshaft on the cylinder head. B rocker shaft installation insert the rocker shafts into the front...

Page 139

G424 service manual base engine service procedure 138 6en0569 6en0650 den0053 e lash adjuster installation caution: if the lash adjuster is re-used, clean the lash adjuster. (1) set special tool md998443 to prevent the lash adjuster coming free and falling to the floor. F camshaft oil seal installat...

Page 140: Cylinder Head And Valves

G424 service manual base engine service procedure 139 cylinder head and valves removal and installation removal steps 1. Cylinder head bolt 2. Cylinder head assembly 3. Cylinder head gasket 4. Retainer lock 5. Valve spring retainer 6. Valve spring 7. Intake valve 8. Retainer lock 9. Valve spring ret...

Page 141

G424 service manual base engine service procedure 140 6en0717 6en0652 6en0718 6en0719 removal service points a cylinder head bolt removal using special tool, loosen the cylinder head bolts. Loosen each bolt evenly, little by little, by two or three steps. B retainer lock removal store removed valves...

Page 142

G424 service manual base engine service procedure 141 6en0542 1en0264 1en0279 2. Valve (1) check the valve face for correct contact. If incorrect, reface. Valve seat contact should be maintained uniform at the center of valve face. (2) if the margin exceeds the service limit, replace the valve: stan...

Page 143

G424 service manual base engine service procedure 142 den0212 1en0105 1en0274 1en0275 5. Valve seats (1) assemble the valve, than measure the valve stem projection between the end of the valve stem and the spring seating surface. If the measurement exceeds the specified limit, replace the valve seat...

Page 144

G424 service manual base engine service procedure 143 6en0543 6en0743 6en0437 valve guide replacement procedure (1) using a press, remove the valve guide toward the cylinder block side. (2) rebore the valve guide hole to the new oversize valve guide outside diameter. Note: do not install a valve gui...

Page 145

G424 service manual base engine service procedure 144 6en0652 6en0782 6en0694 c retainer lock installation the valve spring, if excessively compressed, causes the bottom end of the retainer to be in contact. D cylinder head bolt installation (1) when installing the cylinder head bolts, check that th...

Page 146

G424 service manual base engine service procedure 145 front case and oil pan removal and installation removal steps 1. Oil filter 2. Oil pressure switch 3. Drain plug 4. Drain plug gasket 5. Oil pan 6. Oil screen 7. Oil screen gasket 8. Plug 9. O-ring 10. Flange bolt 11. Relief plug 12. Gasket 13. R...

Page 147

G424 service manual base engine service procedure 146 6en0698 6en0909 6en1026 6en0565 removal service points a oil pan removal (1) remove the all oil pan bolts. (2) drive in the special tool between the cylinder block and oil pan (3) side the tool by striking the edge of the special tool to separate...

Page 148

G424 service manual base engine service procedure 147 3en0166 6em0207 den0711 d counterbalance shaft front bearing removal (1) using the special tool, remove the counterbalance shaft front bearing from the cylinder block. Note: be sure to remove the front bearing first. If it has not been removed, t...

Page 149

G424 service manual base engine service procedure 148 6lu0013 6en1034 4. Oil pump (1) assemble the oil pump to the front case and rotate it to ensure smooth rotation with no looseness. (2) check the side clearance using a thickness gauge. (3) check the side clearance standard value: 0.08 to 0.14 mm ...

Page 150

G424 service manual base engine service procedure 149 6en0208 6en0557 6en1035 b left counterbalance shaft rear bearing installation (1) install the special tool (guide plate) to cylinder block. (2) apply engine oil to the rear bearing outer circumference and bearing hole in the cylinder block. (3) u...

Page 151

G424 service manual base engine service procedure 150 6en0580 6en0494 6en0579 6lu0015 d counterbalance shaft oil seal installation (1) using a suitable socket wrench, install the counterbalance shaft oil into the front case. E oil pump oil seal installation (1) using a suitable socket wrench, instal...

Page 152

G424 service manual base engine service procedure 151 6en0746 6en0747 6en0564 6en0565 h front case installation (1) set the special tool on the front end of the crankshaft and apply a thin coat of engine oil to the outer circumference of the special tool to install the front case. (2) install the fr...

Page 153

G424 service manual base engine service procedure 152 6en0909 6en0213 6en0449 7en0179 j plug installation (1) install a new o-ring to the groove of the front case. (2) install a plug to the front case. (3) fit the special tool md998162 on the plug, and then hold in position with special tool md99878...

Page 154

G424 service manual base engine service procedure 153 9en0094 6en0591 m oil pressure switch installation specified sealant: 3m tm aad part no. 8672 or equivalent caution: 1) keep the end of threaded portion clear of sealant. 2) avoid an over tightening. N oil filter installation (1) clean the instal...

Page 155

G424 service manual base engine service procedure 154 piston and connecting rod removal and installation removal steps 1. Nut 2. Connecting rod cap 3. Connecting rod bearing 4. Piston and connecting rod assembly 5. Connecting rod bearing 6. Piston ring no. 1 7. Piston ring no. 2 8. Oil ring 9. Pisto...

Page 156

G424 service manual base engine service procedure 155 den0050 7en0431 7en0390 removal service points a connecting rod cap removal mark the cylinder number on the side of the connecting rod big end for correct reassembly. B piston pin removal the special tool, piston pin setting tool (md998780), cons...

Page 157

G424 service manual base engine service procedure 156 7en0475 7en0476 1en0246 inspection 1. Piston ring (1) check for the clearance between the piston ring and ring groove. If the limit is exceeded, replace the ring or both piston and ring. (2) install the piston ring into the cylinder bore. Force i...

Page 158

G424 service manual base engine service procedure 157 a7en0432 7en0433 7en0391 installation service points a piston pin installation (1) measure the following dimensions of the piston, piston pin and connecting rod. A: piston pin insertion hole length b: distance between piston bosses c: piston pin ...

Page 159

G424 service manual base engine service procedure 158 6en0585 7en0451 9en0524 b oil ring installation (1) fit the oil ring spacer into the piston ring groove. First, install the upper side rail, and then install the lower side rail. Note: 1) the side rails and spacer may be installed in either direc...

Page 160

G424 service manual base engine service procedure 159 7en0452 6en0549 9en0072 (2) using piston ring expander, fit no.2 and then no.1 piston ring into position. Note: install piston ring with identification mark facing up, to the piston crown (3) install the no.1 piston ring in the same manner as ste...

Page 161

G424 service manual base engine service procedure 160 6en0700 6ae0115 den0051 6en0621 e connecting rod bearing installation when the bearings are replaced, select and install them according to the identification colors on the crankshaft and identification marks stamped on the connecting rod bearing....

Page 162

G424 service manual base engine service procedure 161 g connecting rod cap nut installation (1) since the connecting rod bolts and nuts are torque using a plastic area tightening method, they should be examined before reuse. If the bolt threads are “necked down”, the bolts should be replaced. Neckin...

Page 163

G424 service manual base engine service procedure 162 crankshaft and cylinder block removal and installation removal steps 1. Flywheel bolt 2. Flywheel 3. F/w housing 4. Cover - f/w housing 5. Oil seal case 6. Oil seal 7. Crankshaft bearing cap bolt 8. Crankshaft bearing cap 9. Crankshaft bearing lo...

Page 164

G424 service manual base engine service procedure 163 6en0703 6en0623 9en0074 6en0553 inspection 1. Crankshaft oil clearance (plastic gauge method) use of the plastic gauge can facilitate the oil clearance measurement work. To use the plastic gauge, proceed as follows: (1) remove oil from the cranks...

Page 165

G424 service manual base engine service procedure 164 6en0554 6en1557 3. Cylinder boring (1) oversize pistons to be used should be determined on the basis of largest bore cylinder. (2) oversize pistons are available in four size 0.50 mm (0.0197 in.), and 1.00 mm (0.0394 in.). Rebore the cylinder to ...

Page 166

G424 service manual base engine service procedure 165 6en0705 6en1632 b crankshaft bearing installation (1) from the following table, select a bearing whose size is appropriate for the crankshaft journal outside diameter. If the crankshaft journal outside diameter id color is “yellow” and the cylind...

Page 167

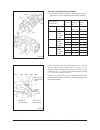

G424 service manual base engine service procedure 166 crankshaft journal cylinder block bearing support section crankshaft bearing identification o.D. Mm (in.) identification i.D. Mm (in.) identification thickness mm(in.) color mark mark yellow 0 61.000 to 61.006 1 1.988 to 1.991 (2.40157 to 2.40181...

Page 168

G424 service manual base engine service procedure 167 6en0624 6en0625 6en0709 c bearing cap/bearing cap bolt installation (1) install the bearing caps so that their arrows are positioned on the timing belt side. (2) when installing the bearing cap bolts, check that the shank length of each bolt meet...

Page 169

G424 service manual base engine service procedure 168 6en0626 6en1919 e sealant application to oil seal case. Specified sealant: silicone rtv sealant or equivalent. Note: 1) be sure to install the case quickly while the sealant is wet(within 15 minutes). 2) after installation, keep the sealant area ...

Page 170: Adjustment

G424 service manual adjustment and troubleshooting 169 adjusting and troubleshooting adjustment the following is the method of adjustment of the carburetor and pneumatic governor on a reassembled engine. Caution : (1) the pneumatic governor hss been properly adjusted and sealed in the factory before...

Page 171

G424 service manual adjustment and troubleshooting 170 timing plate in stored position (6) timing plate. Timing plate rotated 180° (6) timing plate. Note engine timing can be measured at not only engine crankshaft pulley but also flywheel assy. The measurement of engine timing at crankshaft pulley i...

Page 172

G424 service manual adjustment and troubleshooting 171 3. Idling speed adjustment gasoline carburetor (1) let engine warm up until the engine coolant temperature rises to 80 to 95°c (176 to 203°f) (2) back off the mixture adjussting screw (mas) 3.5 l 0.5 turns. (3) adjust the engine speed to the spe...

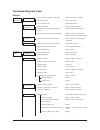

Page 173: Troubleshooting

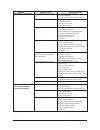

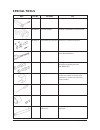

G424 service manual adjustment and troubleshooting 172 troubleshooting engine performance symptom cause 1. Poor engine idle. A. Clogged air breather. B. Improper idle-fuel mixture adjustment. C. Cap or spark-plug wires arcing. D. Low grade fuel. E. Incorrect ignition timing. F. Spark plugs (fouled, ...

Page 174

G424 service manual adjustment and troubleshooting 173 engine starting problems (continued) symptom cause 1. No spark. A. Distributor cap or spark plug leads arcing. B. Spark plugs fouled, burned or cracked porcelain. C. Spark plug wires are broken or have faulty insulation. D. Battery, electrical c...

Page 175

G424 service manual adjustment and troubleshooting 174 symptom cause 1. Noise around the a. Rocker arm striking valve cover. Valve cover area. B. Rocker arm out of adjustment. C. Worn rocker arm. D. Bent push rod. E. Collapsed lifter. 2. Noise around the a. Sticking valve. Cylinder area. B. Carbon b...

Page 176

G424 service manual adjustment and troubleshooting 175 engine noise (continued) symptom cause 5. Noise in camshaft area a. Valve lifter. (center of engine). B. Cam bearings. 6. Noise in camshaft area a. Valve lifter. (rear of engine). B. Cam bearings. 7. Noise in crankshaft area a. Loss of oil press...

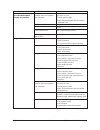

Page 177

G424 service manual adjustment and troubleshooting 176 oil pressure diagnostics the following table contains important information for the checking of oil pressure. Condition information 1. Measuring oil pressure. Use a good automotive oil pressure test gauge. Do not rely on the oil pressure gauge i...

Page 178

G424 service manual adjustment and troubleshooting 177 oil pressure problems symptom cause 1. Low oil pressure. A. Low oil level in crankcase. B. Defective oil-pressure gauge and/or sender. C. Oil broken down, contains water, wrong viscosity, engine running too hot or too cold, excessive idling with...

Page 179

G424 service manual adjustment and troubleshooting 178 water in engine determine location of water in engine. This information is necessary to determine where the water came from and how it got into the engine. The most common problems are water on top of pistons and/or water in crankcase oil. 1. Af...

Page 180

G424 service manual adjustment and troubleshooting 179 engine overheating symptom cause 1. Mechanically related. A. Engine rpm below specification for w.O.T. (engine laboring). B. Wrong ignition timing. C. Spark plug wires crossed (wrong firing order). D. Lean fuel mixture. E. Wrong heat range spark...

Page 181

G424 service manual adjustment and troubleshooting 180 problem probable cause probable solution will not start/fcv fuel container empty fill fuel container staying on • do not exceed 80% of liquid capacity. Liquid valve closed open liquid valve slowly excess flow valve closed reset excess flow valve...

Page 182

G424 service manual adjustment and troubleshooting 181 problem probable cause probable solution difficult to start fuel container almost empty lpg vapor from liquid outlet • fill fuel container • do not exceed 80% of liquid capacity excess flow valve closed reset excess flow valve • close liquid val...

Page 183

G424 service manual adjustment and troubleshooting 182 problem probable cause probable solution won’t run continuously fuel container almost empty lpg vapor from liquid outlet • fill fuel container • do not exceed 80% of liquid capacity excess flow valve closed reset excess flow valve • close liquid...

Page 184

G424 service manual adjustment and troubleshooting 183 problem probable cause probable solution won’t run continuously faulty vapor connection check connection accelerate/hesitation between pressure regulator • no holes in hose during acceleration and carburetor • clamps must be tight • watch for ki...

Page 185

G424 service manual adjustment and troubleshooting 184 problem probable cause probable solution engine stalls pressure regulator test pressure regulator operation malfunction • use test kit • install primary pressure gauge • install secondary pressure gauge • crank engine and observe readings on pre...

Page 186

G424 service manual adjustment and troubleshooting 185 problem probable cause probable solution carburetor backfire incorrect full load air/fuel duty verify full load air/fuel duty cycle faulty vapor connection check connection between pressure regulator • no holes in hose and carburetor • clamps mu...

Page 187

G424 service manual adjustment and troubleshooting 186 problem probable cause probable solution poor high speed restricted exhaust system check exhaust system performance/lean • measure exhaust back-pressure condition • compare to specs engine mechanical see troubleshooting section excessive fuel ca...

Page 188

Insufficient coolant –add coolant and check for leaky points. Leaks from radiator –repair or replace radiator. Loosened or damaged radiator –retighten clamp or replace hose. Hose connection leaks from water pump –replace. Coolant leaks from cylinder head gasket –retighten cylinder head bolts or repl...

Page 189

G424 service manual adjustment and troubleshooting 188 loose fan belt tension –adjust or replace. Worm or damaged fan belt –replace. Oil on fan belt –clean. Thermostat not functioning properly –replace. Water pump not functioning properly –replace. Clogged radiator –clean radiator and coolant passag...

Page 190

G424 service manual adjustment and troubleshooting 189 incorrect valve clearance –cleaned or replace auto-lash adjuster. Valve not in close contact with valve seat –reface seat surface. Excessive clearance between valve stem –replace valve and valve guide. And valve guide incorrect valve clearance –...

Page 191

G424 service manual adjustment and troubleshooting 190 piston ring gaps in improper positions –adjust ring gap positions. Piston rings or ring grooves worn or rings –replace piston or rings. Seized in grooves carbon deposit in oil return hole of oil ring –replace rings. Worn piston and cylinder –reb...

Page 192

G424 service manual adjustment and troubleshooting 191 needle valve and valve seat not seating –clean or replace properly incorrect float level –adjust worn float lip –replace worn float level pin and related components –replace level pin and its related parts malfunction choke valve –repair idle rp...

Page 193

G424 service manual adjustment and troubleshooting 192 cracked distributor cap and burnt or –clean or replace. Contaminated cord insertion hole centrifugal and vacuum advance device –repair or replace. Malfunction improper spark plug gap –adjust or replace. Carbon deposit in spark plug –clean or rep...

Page 194

G424 service manual adjustment and troubleshooting 193 brush holder not properly insulated –clean brush or replace holder. Worn bearing bushing –replace bushing. Wires of armature coil about to be –rewind or replace. Shortcircuited or grounded field coil not properly connected or –repair connections...

Page 195

G424 service manual adjustment and troubleshooting 194 drive belt slipping –adjust belt. Alternator stator coil grounded or open-circuited –replace or repair. Rotor coil open-circuited –replace. Brush and slip ring not properly connected –replace brush if worn. (clean holder.) (brush does not proper...

Page 196: Special Tools

G424 service manual special tools 195 special tools md998781 flywheel stopper holding flywheel md998785 sprocket stopper holding counterbalance shaft sprocket md998778 crankshaft spocket puller removal of crankshaft sprocket mb990767 end yoke holder md998719 pulley holding pins md998443 lash adjuste...

Page 197

G424 service manual special tools 196 md998772 valve spring compressor compression of valve spring md998729 valve stem seal installer installation of valve stem seal md998727 oil pan remover removal of the oil pan md998162 plug wrench md998783 plug wrench retainer md998375 md998285 md998705 md998371...

Page 198

G424 service manual special tools 197 md998372 silent shaft bearing puller md998780 piston pin setting tool md998776 mb990938 handle removal of counterbalance shaft rear bearing removal and installation of piston pin installation of crankshaft rear oil seal installation of crankshaft rear oil sear (...

Page 199

G424 service manual special tools 198 itk-1 pressure gauge kit the impco itk-1 pressure gauge kit is designed for testing and troubleshooting impco gaseous fuel systems. The kit contains the following: ● 0-160 psi gauge - for measuring fuel container pressure or on dual fuel systems it may be used t...