- DL manuals

- Daewoo

- Microwave Oven

- KOC-910K0P(AL)

- Service Manual

Daewoo KOC-910K0P(AL) Service Manual

Summary of KOC-910K0P(AL)

Page 1

Service manual microwave oven model: ko c-910k0p(al) daewoo electronics co., ltd. S/m no. : c910k0pal1 http : //svc.Dwe.Co.Kr mar. 2002.

Page 2

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy do not operate or allow the oven to be operated with the door open. Make the following safety checks on all ovens to be serviced before activating the magentron or other microwave source...

Page 3

2 1. For safe operation damage that allows the microwave energy (that cooks or heats the food) to escape will result in poor cooking and may cause serious bodily injury to the operator. If any of the following conditions exist, operator must not use the appliance. (only a trained service personnel s...

Page 4

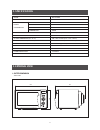

3 koc-910k0p 220v~60hz single phase with earthing 1550w 1600w 2300w 3000w 1000w(iec705) 2450mhz 542 × 329 × 515mm (21.3 × 13.0 × 20.3in.) 350 × 230 × 355mm (13.8 × 9.1 × 14.0in.) approx. 21kg(46.3 lbs.) 60minutes microwave/grill/convection/combination 10 levels 1.0 cu. Ft model power supply microwav...

Page 5

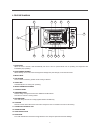

4 2. Feature diagram 1. Door hook when the door is closed, it will automatically lock shut. If door is opened while oven is operating, the magnetron will immediately stop operating. 2. Door viewing screen allows viewing of food. The screen is designed so that light can pass through, but not the micr...

Page 6

5 4. Installation earthing instructions warning improper use of the earthing plug can result in a risk of electric shock. Consult a qualified electrician or serviceman if the earthing instructions are not completely understood, or if doubt exists as to whether the appliance is properly earthed, and ...

Page 7

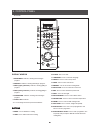

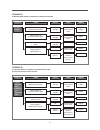

6 buttons 6 5. Control panel buttons more less clock language memory cake crusty auto cook defrost auto stop/ clear start/ speedy cook t grill m/w co ve n cti on m bi co ime w eig ht q ua n ti ty 1 7 6 5 2 3 4 8 11 10 15 12 9 14 13 17 18 20 21 16 19 23 22 6 5. Control panel buttons 6 5. Control pane...

Page 8

7 6. Disassembly and assembly - cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is high-voltage, high-current equipment. It is completely safe during normal operation. However, carelessness in servicing the oven can result in an electric shock or possi...

Page 9

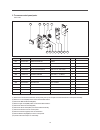

8 a01 a02 a03 a04 a05 a06 a07 a08 a09 ref no. A01 a02 a03 a04 a05 a06 a07 a08 a09 part code 3512603600 3512204800 3517007100 3515204900 3512302400 7122400811 3513101200 3515101800 3511714700 part name handle door frame door barrier-screen o stopper hinge t as gasket door screw tapping hook spring ho...

Page 10

9 (1) remove the gasket door from door plate. (2) remove screws from door plate. (3) remove the door frame from door plate. (4) remove the stopper hinge top from door plate. (5) remove the spring and the hook. (6) remove the handle door and barrier screen outer from door frame. (7) reverse the above...

Page 11

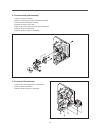

10 b01 b02 b04 b05 b03 b06 b07 b08 b09 b10 b11 b12 b13 ref no. B01 b02 b03 b04 b05 b06 b07 b08 b09 b10 b11 b12 b13 part code 3515501800 3516725200 3516909000 3516909200 3516909100 7122401211 pkmpmsym00 7121301011 3514323800 3513406300 3516909300 3516909400 3511605200 part name window display control...

Page 12

11 11 11 1) remove a screw which secure the grounding ring terminal of the h.V. Diode and the capacitor holder. 2) remove the h.V. Diode from the capacitor holder. 3) reverse the above steps for reassembly. 1) remove a screw which secure the magnetron. 2) remove the magnetron. 3) reverse the above s...

Page 13

12 9. To remove h.V.Transformer. 1) remove four screws holding the h.V.Transformer. 2) remove the h.V.Transformer. 3) reverse the above steps for reassembly. 8. To remove wind guide assembly. 1) remove a screw for earthing. 2) remove a screw which secure the wind guide assembly. 3) draw forward the ...

Page 14

13 1) remove a screw① and pull out guide air outlet②. 2) remove two screws④ and pull out insulator heater t③. 3) pull out the lamp assembly. 4) remove two screws⑥ pull out the lamp assembly. 5) pull out the holder lamp assembly⑦ from the cover lamp⑤. 6) pull out the lamp⑧ from the holder lamp assemb...

Page 15

14 1) remove a screw① and pull out guide air outlet②. 2) remove two screws④ and pull out insulator heater t③. 3) pull out the top heater assembly. 4) pull out the harness heater⑤. 5) pull out the braket heater t from the cover heater t⑧. 6) pull out the heater miraclon⑦ from the cover heater t⑧. 7) ...

Page 16

15 1) remove a screw① and pull out cover motor b②. 2) remove a screw③ and pull out cover b④. 3) pull out the harness convection-b⑤. 4) remove four screws⑮ and then pull out the rear heater assembly. 5) remove a nut⑪ and the pull out the fan convection⑩ and washer plain⑨. 6) remove three screws⑧ and ...

Page 17

16 1) cut the motor syncro. Cover parts from the base plate. 2) remove a screw and then pull out motor syncro. 3) remove a screw① and then pull out the under heater u. Assembly. 4) remove a screw⑤. 5) pull out the heater u④ from the cover heater u②. 6) reverse the above steps for reassembly. 13. To ...

Page 18

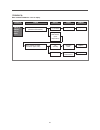

17 bracket switch mounting bracket switch mounting primary interlock switch primary interlock switch interlock dom switch dom switch door latch door latch secondary condition : door open condition : door close interlock switch secondary interlock switch monitor interlock monitor switch 7. Interlock ...

Page 19

18 8. Trouble shooting guide following the procedure below to check if the oven is defective or not. 1) check grounding before trouble checking. 2) be careful of the high voltage circuit. 3) discharge the high voltage capacitor. 4) when checking the continuity of the switches, fuse or high voltage t...

Page 20

19 condition result cause remedy no continuity defective magnetron. Replace check outlet has proper voltage fuse does not blow? Check continuity of magnetron no continuity open power supply cord replace check continuity of power supply cord no continuity defective touch control circuit replace condi...

Page 21

20 (trouble 3) no microwave oscillation even though fan motor rotates. Condition result cause remedy check no microwave oscillation continuity defective high voltage transformer replace check continuity of high voltage capacitor terminals with wires removed continuity in backward direction defective...

Page 22

21 condition result cause remedy check grill heater is not heated. No continuity malfunction of primary interlock switch adjust or replace check continuity of primary interlock switch no continuity malfunction of secondary interlock switch adjust or replace check continuity of secondary interlock sw...

Page 23

22 condition result cause remedy check lower heater is not heated no continuity malfunction of primary interlock switch adjust or replace check continuity of primary interlock switch no continuity malfunction of secondary interlock switch adjust or replace check continuity of secondary interlock swi...

Page 24

23 condition result cause remedy check “error 2 & error 3” come on display 0 Ω or infinite replace replace check continuity of thermistor (resistance of thermistor) (trouble 8) when “error 2 error 3” come on display. Approx. 200k~300k Ω (room temperature) no continuity defective heater replace check...

Page 25

24 1. Measurement of the microwave power output microwave output power can be checked by indirectly measuring the temperature rise of a certain amount of water exposed to the microwave as directed below. Procedure 1. Microwave power output measurement is made with microwave oven supplied at rated vo...

Page 26

25 2. Microwave radiation test procedure 1. Prepare microwave energy survey meter, 600cc glass beaker, and glass thermometer 100℃ ( 212℉). 2. Pour 275cc ± 15cc of tap water initially at 20 ± 5℃ (68 ± 9℉) in the 600 cc glass beaker with an inside diameter of approx. 95mm(3.5 in.). 3. Place it at the ...

Page 27

26 3. Component test procedure · high voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle. · it is neither necessary nor advisable to attempt measurement of the high voltage. · before touching any oven components or wiring, always unplug the oven ...

Page 28

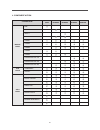

27 4. Component action magne- tron upper element lower element rear element convec- tion fan cooking mode manual mode one touch auto mode m/w grill-1 grill-2 grill-3 combi-1 combi-2 combi-3 combi-4 combi-5 convection 100~130 convection 140~150 convection 160~250 cake/bread crusty roast beef roast ch...

Page 29

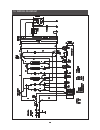

28 10. Wiring diagram 28 10. Wiring diagram yw : yellow br : brown : off cook door : closed condition cm : convection fan motor [ ol : oven lamp fm : fan motor rd : red wh : white bk : black bl : blue ] ge : green/yellow gn : green ttm : turntable motor note : ttm fm secondary primary interlock inte...

Page 30

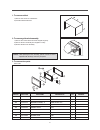

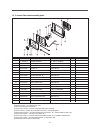

29 11. Exploded view and parts list a 00 b 00 f 01 f 03 f 04 f 18 f 19 f 14 f 05 f 06 f 07 f 31 f 34 f 33 f 32 f 28 f 27 f 26 f 24 f 23 f 17 f 16 f 30 f 29 f 11 f 10 f 09 f 13 f 12 f 15 f 44 f 45 f 46 f 47 f 48 f 43 f 42 f 81 f 41 f 40 f 39 f 38 f 37 f 51 f 50 f 49 f 25 f 35 f 36 f 55 f 54 f 56 f 57...

Page 31

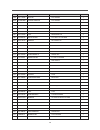

No part code part name description q’ty 30 a00 b00 f01 f02 f03 f04 f05 f06 f07 f09 f10 f11 f12 f13 f14 f15 f16 f17 f18 f19 f20 f21 f22 f23 f24 f25 f26 f27 f28 f29 f30 f31 f32 f33 f34 f35 3511714500 pkcpwym00 3515202800 7172400811 3510313600 7112401011 3512101400 3516003700 3518118120 3518302100 3518...

Page 32

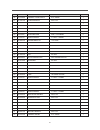

31 f36 f37 f38 f39 f40 f41 f42 f43 f44 f45 f46 f47 f48 f49 f50 f51 f54 f55 f56 f57 f58 f59 f60 f61 f62 f63 f64 f65 f66 f67 f68 f69 f70 f71 f72 3512766800 3511407700 3513302900 7113400814 3963514300 3511800800 7601400811 7112401011 3512804700 3512766900 3511407900 7112401011 3511407300 3511800100 396...

Page 33

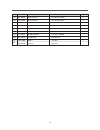

32 f73 f74 f75 f76 f77 f78 f79 f80 f81 3517202611 3517202601 3517205200 3512521000 3516003700 3514801400 7112401011 3511407810 7402704600 tray rack as tray rack as tray metal guide roller as special screw sensor temperature screw tapping cover lamp ring-c koc-961c0s 117mm koc-961c0s 27mm spp t0.6 ko...

Page 34

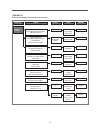

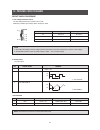

33 12. Printed circuit board circuit check procedure 1. Low voltage transformer check the low voltage transformer is located on the p.C.B. Measuring condition: input voltage: 220v / frequency: 60hz 2. Voltage check - key check point - check method ic1 pin 63, 64 ic1 pin 38 ic1 pin 33 or 34 t : 16.6 ...

Page 35

34 3) when touching m/w button, oven lamp turn on and turns on and fan motor does not rotate but cook indicator in display comes on. *cause: relay 5 does not operate. 2) when touching m/w button, oven lamp does not turn on and turntable motor does not rotate but cook indicator in display comes on. *...

Page 36

35 6. Case of no heating of convection grill when touching convection button, oven lamp turns on and fan motor and turntable rotate and cook indicator in display comes on. *cause: relay 3 does not operate. 5. Case of not heating of lower grill when touching grill2 & combi button, oven lamp turns on ...

Page 37

36 7. Case of no stopping of the count down timer when the door is opened during operation, the count down timer does not stop. Point a point b door open door closed open close +5v dc gnd method remedy check no 1 check the stage(on, off)of the door open monitor switch by resistance measurement. Repl...

Page 38

37 13. P.C.B. Circuit diagram.

Page 39

38 buzzer capacitor ceramic capacitor ceramic capacitor array capacitor electro capacitor electro capacitor electro capacitor electro capacitor electro connector film connector wafer connector wafer connector wafer diode switching diode rectifying diode zener diode zener diode zener diode zener diod...

Page 40

S/m no.: c910k0pal1 daewoo electronics co., ltd. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” printed date: mar, 2002.