Summary of KOG-164H

Page 1

Service manual model : kog-164h microwave oven feb. 2002 s/m no. : r164h0a001.

Page 2: Table of Contents

Safety and precautions ........................................................................................................... 2 1. For safe operation .............................................................................................................. 2 2. For safe service procedures ....

Page 3

Safety and precautions 1. For safe operation dam age that allows the m icrowave energy ((that cooks or heats the food) to escape will result in poor cooking and m ay cause serious bodily injury to the operator. If any o f the fo llo w ing co nditio ns exist, o perato r m ust no t use the appliance. ...

Page 4

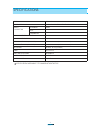

Specifications specificatio ns are subject to chang e w itho ut no tice. M o d e l ko r -164h p o w e r s u p p ly 120v ~ 60h z, s in g le ph a s e w it h g r o u n d in g p o w e r c o n s u m pt io n m ic r o w av e 1400w g r ill c o m b in atio n m ic r o w av e en e r g y o u tp u t 1000w m ic r...

Page 5

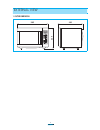

External view 1. Outer dimension 589 486 339 4 1 2 3 4 5 6 7 8 9 0 kichen timer clock power stop/clear start /speedy cook meat more m/w def ons touch & easy cook timer lock ib beverage popcorn fresh vegetable frozen vegetable frozen pizza dinner plate less poultry fish defrost.

Page 6

External view 2. Feature diagram 1. Door seal door seal m aintains the m icrowave within the oven cavity and prevents m icrowave leakage. 2. Door hook w hen door is closed, it will autom atically lock shut. If door is opened while oven is operating, m agnetron tube w ill im m edi- ately stop operati...

Page 7

External view 3. Control panel - ko r-164h0a 1. Time set pad - used to set the cooking tim e and the present tim e. 2. Display - cooking tim e, power level, indicators and present tim e are displayed. 3. One touch - used to cook or reheat specific quantities of food. 4. More - used to add tim e to c...

Page 8

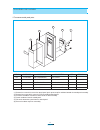

Installation 1. Steady, flat location this m icrowave oven should be set on a steady, flat surface. 2. Leave space behind and side all air vents should be kept a clearance. If all vents are covered during operation, the oven may overheat and, eventually, cause oven failure. 3. Away from radio and tv...

Page 9

Operations and functions 1. Connect the m ain lead to an electrical outlet. 2. After placing the food in a suitable container, open the oven door and put it on the glass tray. The glass tray m ust always be in place during cooking. 3. Close the door securely. 4. The oven door can be opened at any ti...

Page 10

Disassembly and assembly - cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is high-voltage, high-current equipment. It is completely safety during normal operation. However, carelessness in servicing the oven can result in an electric shock or possible...

Page 11

Disassembly and assembly 1. To remove cabinet 1) rem ove three screws on cabinet back. 2) push the cabinet backward. 2. To remove door assem bly 1) rem ove two screws which secure the stopper hinge top. 2) rem ove the door assem bly from top plate of cavity. 3) reverse the above for reassem bly. Not...

Page 12

Disassembly and assembly 3. To remove door parts. Ref. No pa rt code part n ame description q ty remark a 01 3512301800 gasket door pp 1 a 02 3517005200 barrier-screen *i pe t0.1 1 a 03 3515204400 stopper hingn *t as k o r - 1 6 2 j 0 a 1 a 04 3511710500 door painting as kor-161h0a 1 a 05 3513101600...

Page 13

1 2 3 4 5 6 7 8 9 0 kichen timer clock power stop/clear start/speedy cook meat more m/w def ons touch & easy cook timer lock ib beverage popcorn fresh vegetable frozen vegetable frozen pizza dinner plate less poultry fish defrost disassembly and assembly 4. Method to reduce the gap between the door ...

Page 14

Disassembly and assembly 5. To remove control panel parts. Ref.No part code part nam e des cription qty rem ark b 01 3518520890 switch membrane kor-164h0a 1 3511608500 decorator c-panel sus t0.5 1 b 02 3516719140 control-panel abs sg-175, sg-0760d b 03 pkmpmskn00 pcb main manual as kor-161h0a 1 1 b ...

Page 15

Disassembly and assembly 6. To remove high voltage capacitor. 1) rem ove a screw which secure the grounding ring term inal of the h.V.Diode and the capacitor holder. 2) rem ove the h.V. Diode from the capacitor holder. 3) reverse the above steps for reassem bly. High voltage circuit wiring 7. To rem...

Page 16

Disassembly and assembly 8. To remove wind guide assembly. 1) rem ove a screw which secure the wind guide assem bly. 2) draw forward the wind guide assem bly. 3) pull the fan from the m otor shaft. 4) rem ove two screws which secure the m otor shaded pole. 5) rem ove the m otor shaded pole. 6) rever...

Page 17

Interlock mechanism and adjustment the door lock m echanism is a device which has been specially designed to com pletely elim inate m icrowave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) prim ary interlock ...

Page 18

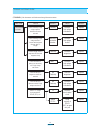

Trouble shooting guide following the procedure below to check if the oven is defective or not. 1) check grounding before trouble checking. 2) be careful of the high voltage circuit. 3) discharge the high voltage capacitor. 4) w hen checking the continuity of the switches, fuse or high voltage transf...

Page 19

Trouble shooting guide ( trouble 2 ) display shows all figures selected, but oven does not start cooking, even though desired program and tim e are set and start pad is tapped. Con dition check result cause rem edy o utlet has proper voltage f use does not blow. C heck con tinuity of m agn etron n o...

Page 20

Trouble shooting guide ( trouble 3 ) no m icrowave oscillation even though fan m otor rotates. Con dition check result continuity continuity in backw ard direction 0 Ω or no continuity no continuity 0 v approx 15 vdc cause defective high voltage transform er defective high voltage rectifier defectiv...

Page 21

Trouble shooting guide ( trouble 4 ) the following visual conditions indicate a probable defective touch control circuit or m em brane switch assem bly 1. Incom plete segm ents, 1) segm ents m issing. 2) partical segm ents m issing. 3) digit flickering other than norm al display slight flickering. 4...

Page 22

Measurement and test 1. Measurement of the microwave power output m icrowave output power can be checked by indirectly m easuring the tem perature rise of a certain am ount of water exposed to the m icrowave as directed below. Procedure 1. M icrowave power output m easurem ent is m ade wit the m icr...

Page 23

Measurement and test 2. Microwave radiation test procedure 1. Prepare m icrowave energy survey m eter, 600cc glass beaker, and glass therm om eter 100˚ c (212˚ f ). 2. Pour 275cc ±15cc of tap water initially at 20 ± 5 ˚ c (68 ± 9˚ f) in the 600 cc glass beaker with an inside diam eter of approx. 95 ...

Page 24

Measurement and test 3. Component test procedure high voltage is present at the high voltage term inal of the high voltage transform er during any cooking cycle. It is neither necessary nor advisable to attem pt m easurem ent of the high voltage. Before touching any oven components or wiring, always...

Page 25

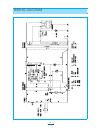

Wiring diagram 24.

Page 26

Printed circuit board 1. Circuit check procedure 1. Low voltage transformer check the low voltage transform er is located on the p.C.B. M easuring condition: input voltage: 120 v / frequency: 60hz 2. Voltage check - key check point - check m ethod term inal voltage lo ad n o lo a d 4 - 7 a c 24.7 v ...

Page 27

Printed circuit board m p1 m p2 measure point 26.

Page 28

Printed circuit board 3. W hen there is no microwave oscillation 1) w hen touching start pad, oven lam p does not turn on. Fan m otor do not rotate, but cook indicator in display com es on. Cause : relay 2 does not operate. Refer to circuit diagram ( point 3) - check m ethod 2) w hen touching start ...

Page 29

Printed circuit board 2. Pcb circuit diagram 28.

Page 30

Printed circuit board 3. P.C.B. Location no. No nam e sym bol sp ecific ation part code q 'ty 1 b uz z e r b z1 b m -20k 3515600100 1 2 c ar r ay c a 1 7p(6) 102 m 50v cn 6x b-102m 1 3 c apac ito r ele c e c 1 50v rs 1mf ce x e1h 109a 1 4 c apac ito r ele c e c 2 25v r s s 1000uf c e x f 1e 102v 1 5...

Page 31

Exploded view and parts list 1. Door assembly refer to disassem bly and assem bly. 2. Control panel assembly refer to disassem bly and assem bly. 3. Total assembly 30

Page 32

Exploded view and parts list ref no part co de part nam e descr iptio n q'ty a 00 3511710430 d o o r a s k o r -164h 0a 1 b 00 p k c ps w k n00 c o n t r o l pan e l as k o r -161h 0a 1 f 01 3510802400 c a bin e t p cm t 0.6 1 f 02 7112401011 s c r e w ta p pin g t 1 t r s 4*10 m fz n 3 f 03 7122401...

Page 33

F 36 4419w 88004 r t ay g la s s 1350g 1 f 37 3515202900 s to p pe r h ing e to p a s k o r -121m 0a 1 f 38 3511403200 c o ve r w av e g u id e h eatp r o o f p p 1 f 39 3516003700 s p e c ia l sc r e w t t3 h e x 4 *8 f lg m f zn 2 f 40 3516109800 c av it y a s k o r -161h 0a 1 f 41 7122401211 s c ...

Page 34

Daewoo electronics co., ltd. Printed date: jan, 2002 686, ahyeon-dong mapo-gu seoul, korea c.P.O box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” s/m no. :.