Service manual microwave oven model : kog-366t0s daewoo electronics co., ltd. Overseas service dept..

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy (a) do not operate or allow the oven to be operated with the door opened. (b) make the following safety checks on all ovens to be serviced before activating the magnetron or other microw...

2 caution : this device is to be serviced only by properly qualified service personnel. Consult the service manual for proper service procedures to assure continued safety operation and for precautions to be taken to avoid possible exposure to excessive microwave energy. Caution microwave radiation ...

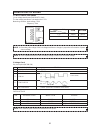

3 item specification power supply 230v~50hz, single phase with earthing microwave 1200 w power grill 1050 w consumption combination 2200 w microwave energy output 800 w(iec 705) microwave frequency 2450 mhz outside dimensions (w x h x d) 465 x 274 x 379 mm cavity dimensions (w x h x d) 290x 200 x 29...

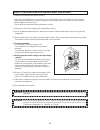

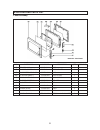

4 1 1 door latch - when the door is closed it will automatically lock shut. If the door is opened while the oven is operating, magnetron will immediately stop operating. 2 2 door seal - door seal maintains the microwave energy within the oven cavity and prevents microwave leakage.. 3 3 oven cavity. ...

5 caution : improper use of the earthing pulg can result in a risk of electric shock. Consult an qualified electrician or serviceman if the earthing instructions are not completely understood, or if doubt extension to whether the appliance is properly earthed. If it necessary to use an extension cor...

6 wattage output chart • the power-level is set by pressing the m/w pad. The chart shows the display, the power level and the percentage of power. Touch power pad, power level(display) approximate percentage once the touch of power 5 800w 100% 4 650w 80% 3 450w 60% 2 300w 40% 1 140w 20% make sure th...

7 this example is 24 hour clock system. Note : • when the oven is plugged in, “0:00” appears in the display window. • the two dots between the hour and minute are the clock indicator lights. They will start to flash on and off. • the time of day will be displayed at all times, except when the oven i...

8 4. Press clock button. Setting the control the display will show present time, and the colon strats blinking. This digital clock allows you to set to “10:10”. 1. Press defrost button twice. This time defrost indicator light will light up. 2. Turn the dial knob for the desired defrosting time. For ...

9 setting the control 1. Press defrost button once. The weight defrost indicator light will come on. The g indicator light will start blinking. 2. Turn the dial knob for the desired defrosting weight. For example : 1000g the 1000 will show in the display. It is represent 1000g. 3. Press button. The ...

10 setting the control 1. Press power button by repeatedly pressing this button, you can also select other power levels. For example : 800watt the m/w indicator light will light. The watt indicator light start blinking. 2. Turn the dial knob for the desired cooking time. For example : 10minutes. 10:...

11 setting the control 1. Press grill button once. The grill indicator light will light. 2. Turn the dial knob for the desired cooking time. For example : 25 minutes. 25:00 will show in the display. 3. Press button. The grill indicator light will start blinking. 4. Buzzer will sound at the end of th...

12 note : setting the control 1. Press combi button once again. The corresponding combi indicators will light on the display. 2. Turn the dial knob for the desired cooking time. For example : 10 minutes. 10:00 will show in the display. 3. Press button. The combi indicator light will start blinking. ...

13 setting the control you can operate more or less than programmed time as pressing more or less button whenever more or less button, display is changed “10” or “-10”. 10 : adds 10% for programmed time. -10 : remove 10% for programmed time. 1. Press auto cook button. The auto cook indicator light w...

14 6. If you want to select other, turn the dial knob until display you desired. 8. Buzzer will sound at the end of the cooking time. The indicator light will go off. The display panel will return to the time of day. The oven light will turn off and the turntable will stop turning. The oven will now...

15 setting the control 1. Press button. Then start lamp will start blinking. Whenever the button is pressed, cooking time is increased 30 seconds. If the time was setting, this oven is operated automatically after 2 seconds to microwave high power. • the safety lock prevents unwanted oven operation ...

16 note : oven stops operating when door is opened. General cooking hints 1. When cook a roast with an excess amount of dripping, it is helpful to remove the dripping at turnover time to prevent spattering. 2. Prick the meats, fish or poultry with a fork to prevent bursting. Steam builds up pressure...

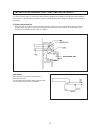

17 the door lock mechanism is a device has been specially designed to completely eliminate microwave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) primary interlock switch when the door is closed, the hook lo...

18 note : microwave emission test should be performed after adjusting interlock mechanism. If the microwave emission exceed 4m w/cm 2 , readjust interlock mechanism. (2) secondary interlock switch and interlock monitor switch when the door is closed, the hook pushes the push lever down ward, and pus...

19 microwave output power can be checked by indirectly measuring the temperature rise of a certain amount of water exposed to the microwave as directed below. Procedure 1. Microwave power output measurement is made with the microwave oven supplied at rated voltage and operated at its maximum microwa...

20 procedure a) prepare microwave energy survey meter, 600cc glass breaker, glass thermometer100°c or 212°f. B) pour 275cc±15cc of tap water initially at 20±5°c (68±9°f) in the 600cc beaker with an inside diameter of approx. 8.5 cm (3.5 in). C) place it at the center of the tray and set it in a cavi...

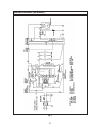

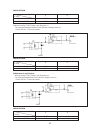

21 wiring diagram (germany) fig. 1.

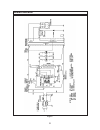

22 wiring diagram fig. 1-1.

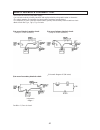

23 refer to the “wiring diagram” on page 21, 22. Microwave cooking time cooking 1. When the food is placed inside the oven and door is closed. 1) the low voltage transformer supplies the necessary voltage to the touch control circuit when the power cord is plugged in. 2) the contacts of the interloc...

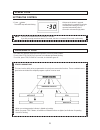

24 fig. 2 the touch control circuit controls the on-off time of relay “1” in order to vary the output power of the microwave oven from “power level 1“ to “hi (100%) power”. One complete on and off cycle of the relay “1” is 29 seconds. The relation between indications on the control panel and the out...

25 fig. 3 auto defrost cycle when auto defrost is selected and the desired defrosting time is chosen, the automatic cycle divides the defrosting time into 5 periods of alternating defrost and stand times, by cycling on and off. 4. When the door is opened during cooking. 1) the primary interlock swit...

26 safety precautions for disassembly and repair – cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is a high-voltage, high-current equipment. It is completely safety during normal operation. However, carelessness in servicing the oven can result in an ...

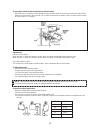

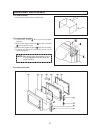

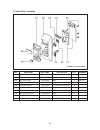

27 disassembly and assembly 1. To remove cabinet. Remove three screws (f09) on cabinet back. 2. To remove door assembly. 1) remove two screws 1 1 which secure the stopper hinge top. 2) remove the stopper hinge top 2 2 and door assembly 3 3 from top plate of cavity. 3) remove the stopper hinge top 2 ...

28 (1) remove the gasket door(a07) from door painting ass’y (a05) (2) remove the door frame(a01) from door painting ass’y (a05) (3) remove the barrier screen outer(a02) and the supporter barrier screen outer(a03). (4) remove the hook spring (a09) and the hook (a08). (5) remove the hinge stopper top ...

29 5. To remove control panel parts. (1) remove the screw which secure the control panel, push up two snap fits and draw forward the control panel assembly. (2) pull out the knob volume (b07) form the control panel ass’y (3) remove eight screws (b05) which secure the pcb ass’y (b10). (4) remove the ...

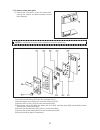

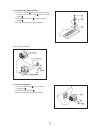

30 6. To remove high voltage capacitor. (1) remove a screws 1 1 which secure the grounding ring terminal of the h.V. Diode 2 2 and the capacitor holder 3 3 . (2) remove the h.V. Diode 2 2 from the capacitor holder 3 3 . (3) remove the above steps for reassembly. High voltage circuit wiring 7. To rem...

31 8. To remove fan motor assembly. (1) remove two screws 1 1 which secure the back cover 2 2 from the cavity outer. (2) remove two screws 1 1 which secure the fan motor 4 4 from the back cover 2 2 . (3) pull out the fan 5 5 from the motor 4 4 . (4) remove the above steps for reassembly. 9. To remov...

32 no part name part code q’ty description remark 10. To remove insulator heater assembly. (1) remove the four hex nuts 1 1 . (2) remove the iinsulator heater assembly 2 2 . (3) reverse the above steps for reassembly. 11. To remove heater part. 1 2 3 4 5 6 7 3513301100 3512801700 7002500613 73925000...

33 following the procedures below to check if the oven is defective or not. 1. Check earthing before fault finding. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor. 4. When checking the continuity of switches, fuse or high voltage transformer, disconnect one lead w...

34 (trouble2) oven does not operate at all; any inputs can not be acceted. Check result cause remedy replace check continuity of interlock monitor switch with door closed. (com nc) condition fuse blows continuity (com nc) (com nc) no continuity malfunction of interlock monitor switch replace replace...

35 note 1 : all these switches must be replaced at the same time, please refre to page 17 and 18 for adjustment instructions (trouble3) display shows all figures selectdd, but oven does not start cooking, even though desired program and time are set and start button is tapped. Check result cause rem...

36 (trouble4) no microwave oscillation even though fan motor rotates. Check result cause remedy check continuity of high voltage fuse condition no microwave oscillation no continuity check continuity of high voltage capacitor terminals with wires removed continuity defective high voltage transformer...

37 check result cause remedy check each button for continuity the tach switch deyboard as the following keyboard check procedure. Condition display does not show program ming at all, even if button key is pressed normal malfunction of touch control circuity of control box main-assembly replace contr...

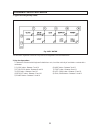

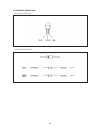

38 keyboard check procedure the tact switch keyboard consists of 9 keys whose aconfigurations are described above. 2. Key check procedure to determine if the tact switch keyboard is defective or not, check the continuity of each button contacts with a multimeter. 1. Type of encoding and key names. 1...

39 1. High voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle. 2. It is neither necessary nor advisable to attempt measurement of the high voltage. 3. Before touching any oven components or wiring, always unplug the oven from its power source and...

40 • disconnect the oven from the power supply. • you can test continuity of safety interlocks and monitor switch by using switch tester or ohmmeter. • the switch operation is checked by the lamp on/off of resistance zero/unlimited. • the sequence of check is interlock monitor switch; primary and se...

1. Circuit check procedure 1) low voltage transformer (dmr-814fs) check. The low voltage transformer is located on the p.C.B. Measuring condition: input voltage : 230v frequency: 50hz 2) voltage check key check point (micom pin) check method no. Check point remark 1 pin 21,24,32,33 or 34 -5vdc 2 pin...

3) display problems display trouble shooting data 4) when there is not microwave oscillation. (1) when pressing “start” button, oven lamp does not turn on. Fan motor and turntable motor do not rotate, but cook indicator in display comes on. * cause: relay “2” does not operate. Time defrost, g do not...

43 check method (2) when touching “start” button, oven lamp turn on. Fan motor and turntable rotate and cook indicator in display comes on. * cause: relay “1” does not operate. Check method 5) when there is not grill heat. When pressing “start” button, oven lamp turns on. Fan motor and turntable and...

44 6) when the door is opened during operation, the count down timer does not stop. Check method 7) when the digital clock does not operate properly. If clock does not keep exact time, you must check diode d10, transistor q8. Point a b stage 1) door opened open -5vdc 2) door closed closed gnd no. Me...

45 2. P.C.B circuit diagram.

46 3. Component information 1) transistor (npn type) 2) diode and zener diode d1-16 zd1-6.

47 4. Printed circuits board.

48.

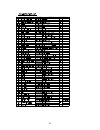

49 printed location no. 1 pcb main m156 m156 3514313851 1 2 r carbon film r6, r9, r10, r12, r17 1/4w 1k Ω j rd-4z102j- 5 3 r carbon film r13 1/4w 100 Ω j rd-4z101j- 1 4 r carbon film r24 1/4 10k Ω j rd-4z103j- 1 5 r carbon film r8, r21 1/4w 4.7k Ω j rd-4z472j- 2 6 r carbon film r7, r23 1/4w 100k Ω j...

50 1 pcb sub m157 m157 3514313861 1 2 led l102 slr-34vr dslr34vr- 1 3 switch tact sw101~sw109 kpt-1115am 5s50101z93 9 4 switch tact cn101 hlem15r-1 4cw215rbd0 1 5 led l101 dly-5013t dly-5013t- 1 6 sw rotary en101 sdb161pvb17f- 5s10109002 1 1-2-36-36pc(pitch5) 7 r carbon r101~103 1/4w 1k Ω j rd-4z102...

51 1. Door assembly no. Part name part code description q’ty remarks a01 frame door 3512202020 abs 1 a02 barrier-screen*o 3517003040 acryle 1.5t 1 a03 supporter barri-s*o 3515304600 abs 1 a04 stopper hinge*t 3515201500 kor-61150s 1 a05 door painting as 3511706100 kor-61150s 1 a06 barrier-screen*i 35...

52 2. Control panel assembly no. Part name part code description q’ty remarks b01 decorator c-panel 3511602300 abs 1 b02 c-panel 3516710730 abs 1 b03 button start 3516905800 abs 1 milky b04 button function(cook) 3516905700 abs 1 b05 screw tapping 7621301011 t2s pan 3x10 pw mfzn 8 b06 window display ...

53 3. Main unit.

54 3516003700 7112401011 3 flg tapping 7112401011 tapping 7112401011 tapping 7112401011 7272400811 7272400811 3516003700 7112401011 3516002700 tapping tapping 7122401211 tapping taptite taptite 3 3 3 trs z z.

S/m no. : daewoo electronics co., ltd. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” fax: 02) 590-6291 tel: 02) 360-7114/590-6151~5 http://www.Dwe. Daewoo.Co.Kr printed date: june 1998.