Service manual microwave oven model : kor-612l0s daewoo electronics co., ltd. Overseas service dept. ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information,please refer to ppl(parts price l...

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy (a) do not operate or allow the oven to be operated with door open. (b) make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave so...

2 1. For safe operation damage that allows the microwave energy (that cooks or heats the food) to escape will result in poor cooking and may cause serious bodily injury tok the operator. If any of the following conditions exist. Operator must not use the appliance. (only a trained service personnel ...

3 specifications power supply 230v ~50hz, single phase with earthing power consumption 1200w microwave output power 800w(iec 705) frequency 2450mhz outside dimensions(wxhxd) 465x274x354mm cavity dimensions(wxhxd) 290x200x290mm net weight approx. 13.5kg timer 59min. 99sec. Power selections 5 levels *...

4 features diagram 1 door latch - when the door is closed it will automatically lock shut. If the door is opened while the oven is operating. The magnetron will automatically shut off. 2 door seal - the door seal maintains the microwave within the oven cavity and pre- vents microwave leakage. 3 oven...

5 this appliance must be earthed. In the event of an electrical short circuit, earthing reduces the risk of electric shock by providing an escape, wire for the electric current. This appliance is equipped with a cord having a earth- ing wire with a earthing plug. The ploug must be plugged into an ou...

6 touch power pad, once the touch high m-high med m-low low power level (display) p-hi p-80 p-60 p-40 p-20 approximate percentage of power 100% 80% 60% 40% 20% this section includes useful information about oven operation. 1. Plug power supply cord into a 230v 50hz power outlet. 2. After placing the...

7 when the oven is first plugged in, the display will flash “ : 0” and a tone will sound. If the ac power ever goes off, the display will flash “ : 0” when the power comes back on. Do this this happens... Controls setting the clock 1. Touch clock / a.Start pad. This is a 12 hour clock system. Clock/...

8 weight defrost lets you easily defrost food by eliminating guesswork in determining defrosting time. The min- imum weight for weight defrost is 200 grams. The maximum weight for weight defrost is 3000 grams. Follow the steps below for easy defrosting. Weight defrosting do this this happens... 1. T...

9 when time defrost is selected, the automatic cycle divides the defrosting time into periods of alternating defrost and stand times by cycling on and off. Time defrosting do this this happens... 1. Touch auto defrost pad. The weight defrost indicator lights and “0” is displayed. And the g indicator...

10 cooking in one stage do this... This happens... 1. Touch the power level pad for the power level you want among and in the second stage. Low m-low med m-high high the stage1 indicator lights and “p-hi” is displayed. The display will show what you touched. This example shows power level high. High...

11 cooking in two stages for best results, some recipes call for one power level for a certain length of time and another power level for a different length of time. Your microwave oven can be set to change from one to another. Do this... This happens... 1. Touch number pads for the cooking time you...

12 weight defrosting and cooking in two stages some recipes require frozen foods to be thawed before cooking. This oven can be programmed to automatically defrost foods before cooking. Do this... This happens... 1. Touch auto defrost pad. The weight defrost indicator lights and “0” is displayed. And...

13 do this... This happens... 5. Touch the power level pad for the power level you want among and in the second stage. Low m-low med m-high high the stage2 indicator lights and “p-80” is displayed. The display will show want you touched. 6. Touch the number pads for the cooking time you want in the ...

14 auto start allows you to program cooking to start at a time you select. The food will automatically start cooking at the desired time. Program is able up to 2 stages (no acceptable defrost) do this... This happens... 1. Program the desired power level and cooking time. 2. Touch clock/a.Start pad....

15 to check auto start time once you have correctly programmed the oven for auto start, the present time will appear on the display. Do this... This happens... Speedy cook speedy cook allows you to reheat for 30 seconds at 100% (full power) by simply touching the speedy cook pad. By repeatedly touch...

16 one touch cooking one touch cook allows you to cook or reheat many of your favorite foods by touching just one pad. To increase quantity, touch chosen pad until number in display is same as desired quantity to cook. (except for dinner plate) do this... This happens... 1. Touch frozen pizza pad. W...

17 ƒn beverage ƒn (250ml/cup) ¡ 1 cups (mugs): touch beverage once. ¡ 2 cups (mugs): touch beverage twice within 1.5 seconds. ¡ 3 cups (mugs): touch beverage three times within 1.5 seconds. Note: 1. This setting is good for restoring cooled beverage to a better drinking temperature. 2. Stir after co...

18 feeding bottle this key is for feeding bottle disinfection effect. At first, detach the nipple from the bottle and pour the 30cc water into each bottle, arrange the bottle symmetrically on the glass tray and operate. Do this... This happens... More, less more pad: adds for 10 seconds to 20 second...

19 the door lock mechamism is a device has been specially designed to completely eliminate microwave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) primary interlock switch when the door is closed, the hook lo...

20 (2) secondary interlock switch and interlock monitor switch when the door is closed, the hook pushes the push lever down ward, and push lever presses the button of the interlock monitor swich to bring it under “off”, condition and presses the button of the secondary interlock switch to bring it u...

21 measurement of the microwave output power microwave output power can be checked by indirectly measuring the temperature rise of a certain amount of water exposed to the microwave as directed below. Proedure 1. Microwave power output measurement is made with the microwave oven supplied at rated vo...

22 wiring diagram procedure a) prepare microwave energy survey meter, 600cc glass beaker, glass thermometer 100˚c or 212˚f. B) pour 275cc ¡ 15cc of tap water initially at 20 ¡ 5˚c(68 ¡ 9˚f) in the 600cc beaker with an inside diam- eter of approx. 8.5cm (3.5in). C) place it at the center of the tray ...

23 circuit description refer to the “kor-612l0s wiring diagram” (fig. 1) on page 22. Microwave cooking time cooking 1. When the food is placed inside the oven and door is closed. 1) the low voltage transformer supplies the necessary voltage to the touch control circuit when the power cord is plugged...

24 fig. 2 the touch control circuit controls the on-off time of relay “1” in order to vary the output power of the microwave oven from “power level low” to “hi (100%) power”. One complete on and off cycle of the relay “1” is 29 seconds. The relation between indications on the control panel and the o...

25 low 5/29 (17%) m-low 11/29 (38%) med 17/29 (59%) m-high 23/29 (79%) high 29/29 (100%) power level fig. 3 auto defrost cycle when auto defrost is selected and the desired defrosting time is chosen, the automatic cycle divides the defrosting time into 5 periods of alternating defrost and stand time...

26 – cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is a high-voltage, high-current equipment. It is com pletely safety during normal operation. However, carelessness in servicing the oven can result in an electeric shock or possible danger from a sho...

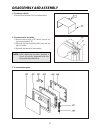

27 disassembly and assembly 3. To remove door parts. 1. To remove cabinet. Remove three screws (f02) on cabinet back. 2. To remove door assembly. 1) remove two screws (f40) which secure the top hinge stopper(f37). 2) remove the door assembly (a00) from the top plate of cavity. 3) reverse the above f...

28 (1) remove the gasket door (a06) from door painting as (a04). (2) remove the barrier screen inner (a05) from door painting as (a04). (3) remove the door frame (a02) from door painting as (a04). (4) remove the top hinge stopper (a03) from door painting as (a04). (5) remove the spring (a08) and the...

29 5. To remove control panel parts. (1) remove the screw which secure the control panel, push up two snap fits and draw forward the control panel assembly. (2) remove the door open lever (b05) from the control panel (b02). (3) remove three screws (b04) which secure the p.C.B. Ass’y (b03). (4) remov...

30 6. To remove high voltage capacitor. (1) remove a screw (f13) which secure the grounding ring terminal of the h.V. Diode (f16) and the capacitor holder (f14). (2) remove the capacitor holder (f14) with h.V. Capacitor (f15). (3) reverse the above steps for reassembly. High voltage circuit wiring 7...

31 8. To remove fan motor assembly. (1) remove two screws (f08) which secure the back cover (f10) from the cavity outer. (2) remove two screws (f09) which secure the fan motor (f11) from the back cover (f10). (3) pull out the fan (f12) from the motor (f11). (4) remove the above steps for reassembly....

32 following the procedures below to check if the oven is defective or not. 1. Check grounding before checking trouble. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor. (see page 26) 4. When checking the continuity of switches or of the high voltage transformer, di...

33 (trouble 2) digital readout display does not show programming, even if the membrane keyboard is programmed by touching proper pads. Membrane keyboard check procedure 1. Check the pad termination order and nomenclature. Note :before following the particular steps listed above in the trouble shooti...

34 2. Type of encoding and pad names. Fig. 5 key matrix the membrane keyboard consists of 27 keys whose configurations are described above and provide 11 pad ter- minations to be connected to the touch control circuit as fig. 4. 3. Key check procedure. To determine if the membrane keyboard is defect...

35 (trouble3) the oven not operate at all; display window does not display any figures and any inputs can not be accepted. Check result cause remedy replace primary interlock switch and secondary interlock switch and monitor interlock switch. Check continuity interlock monitor switch with door close...

36 (trouble 4) display shows all figures selected, but oven does not start cooking, even though desired program and time are and start pad is taped. Check result cause remedy replace check continuity of oven thermostat condition no continuity defective oven thermostat. Replace check continuity of po...

37 (trouble 5) no microwave oscillation even though fan motor rotates. Check result cause remedy replace check continuity of primary wind- ing of high voltage transformer and touch control circuit condition turn table motor, fan motor and oven lamp turn on for a second when the start pad is tapped n...

38 relay “1” off time 24 18 12 6 0 check result cause remedy customer education check the power source voltage with magnetron condition output power is low. Lower than 207 volts descrease in power source voltage normal replace check the timing periods of the relay “1” coil abnormal note 3 defective ...

1. High voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle. 2. It is neither necessary nor advisable to attempt measurement of the high voltage. 3. Before touching any oven components or wiring, always unplug the oven from its power source and di...

¡ disconnect the oven from the power supply. ¡ you can test continuity of safety interlocks and monitor switch by using switch tester or ohmmeter. ¡ the switch operation is checked by the lamp on/off of resistance zero/unlimited. ¡ the sequence of check is interlock monitor switch; primary and secon...

1. Circuit check procedure 1) low voltage transformer (dmr-604fs) check. The low voltage transformer is located on the p.C.B. Measuring condition: input voltage: 230v frequency: 50hz 2) voltage check key check point check method 1 mp1 dc -5v ¡ 0.25 replace zd2, ec1, ec2 no load 2 mp2 dc -30v ¡ 1.0 r...

3) display problems the display trouble shooting data 4) when there is no microwave oscillation. (1) when touching “start” pad, oven lamp does not turn on. Fan motor and turntable do not rotate, but cook indicator in display comes on. ƒn cause: relay “2” does not operate. Stage1, lock don’t come on....

Fig. 6 measurement point 43.

Check method (2) when touching “start” pad, oven lamp turn on. Fan motor and turntable rotate and cook indicator in display comes on. ƒn cause: relay “1” does not operate. Check method 5) when the door is opened during operation, the count down timer does not stop. Check method check method remedy n...

5) when the digital clock does not operate properly. Point waveform a 45 if clock does not keep exact time, you must check resistor r21, r34. T:20ms.

46 2. P.C.B. Circuit diagram(l-type).

47 3. Component information 1) transistor 2) diode and zener diode.

48 4. Printed circuits board.

49 5. P.C.B. Location no. Ref no. Part code part name description remark r1~3, 6, 10, 11~14 rd-az122j- resistor 1.2k Ω 1/6w 5% r5, 7, 28, 30, 31, 42 rd-az472j- resistor 4.7k Ω 1/6w 5% r19 rd-az203j- resistor 20k Ω 1/6w 5% r20 rd-az105j- resistor 1m Ω 1/6w 5% r22 rd-az201j- resistor 200 Ω 1/6w 5% r23...

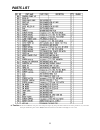

50 exploded and parts list ref. No part code part name description q’ty remarks a01 3517003020 barrier-screen *o pmma t1.5 1 a02 3512202010 frame door abs 1 a03 3515201500 stopper hinge *t scp-1 t2.5 1 a04 3511706100 door painting as kor-6115os 1 a05 3517002800 barrier-screen *i polyester t0.1 1 a06...

51 ref. No part code part name description q’ty remarks b01 3518513500 switch membrane kor-612l0s 1 b02 3516710710 control-panel abs 1 b03 pkmpmscn00 pcb main as kor-611l0s 1 b04 7621401211 screw tapping t2s pan 4x12 pw mfzn 3 b05 3513701400 lever door open pom 1 b06 441g430171 spring door button hs...

52 exploded view.

53 parts list ✔ caution: in this service manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to ppl(parts price list) in service information center(http://svc.Dwe.Co.Kr).

S/m no. : daewoo electronics co., ltd. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” fax: 02) 590-6291 tel: 02) 360-7114/590-6151~5 http://www.Dwe. Daewoo.Co.Kr printed date: oct.1998.