- DL manuals

- Daewoo

- Microwave Oven

- KOR-616T0P

- Service Manual

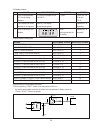

Daewoo KOR-616T0P Service Manual - Features Diagram

4

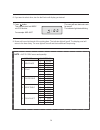

FEATURES DIAGRAM

Power

Defrost

+1min

Auto Cook

STOP

START

CLEAR

Speedy

More

Less

Clock

Tim

er

/W

ei

gh

t/Q

ua

nt

ity

1. Beveroge

2. Soup

3. Casserole

4. Vegetable

5. Fish Fillets

Stop

Defrost

1

2

Weight

Quantity

Time

Lock

Auto cook

Watt

g

Power

Defrost

+1min

Auto Cook

STOP

START

CLEAR

Speedy

More

Less

Clock

Tim

er

/W

ei

gh

t/Q

ua

nt

ity

1. Beveroge

2. Soup

3. Casserole

4. Vegetable

5. Fish Fillets

Stop

Defrost

1

2

Weight

Quantity

Time

Lock

Auto cook

Watt

g

1

2

3

4

5

6

7

8

0

q

t

y

u

i

o

p

r

e

w

9

1

Door latch - When the door is closed it will automatically lock shut. If the door is opened while the

oven is operating, magnetron will immediately stop operating.

2

Door seal - Door seal maintains the microwave energy within the oven cavity and prevents microwave

leakage.

3

Oven cavity.

4

Spatter shield - Protects the microwave outlet from splashes of cooking foods.

5

Safety interlock system.

6

Door viewing screen - Allows viewing of food. The screen is designed so that light can pass through,

but not the microwaves.

7

Glass cooking tray - Made of special heat resistant glass. Food in a proper receptacle is placed on

this tray for cooking.

8

Roller guide - This must always be used for cooking together with the glass cooking tray.

9

Display - Cooking time, power level, present time are displayed.

0 q e

Function buttons - Used to select desired oven operation.

: MICROWAVE, DEFROST, AUTOCOOK.

w

+1 min. button - Used to increase time of operating.

r

Start button - Used to start a selected operation. When lamp blinks, press the start button.

Speedy cook button - Used to set desired time.(It is incresed 30 seconds.)

t

Stop/clear button - Used to pause or clear all information manually put into the oven control panel

except clock.

y u

More/Less button - Used to select auto cook time. (More/less 10% of auto cook time)

i

Clock button - Used to set and recall the time of day.

o

Dial knob - Used to set the cooking time, weight and quantity.

p

Guide lamp - When blinking it informs you to be ready to operte dial knob.

Summary of KOR-616T0P

Page 1

Service manual microwave oven model: kor-616t0p kor-816t0p daewoo electronics co., ltd. ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information,please refer to ppl(parts price list) in servi...

Page 2: Table of Contents

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy (a) do not operate or allow the oven to be operated with the door open. (b) make the following safety checks on all ovens to be serviced before activating the magnetron or other microwav...

Page 3

2 caution: this device is to be serviced only by properly qualified service personnel. Consult the service manual for proper service procedures to assure continued safety operation and for precautions to be taken to avoid possible exposure to excessive microwave energy. Proper use and service precau...

Page 4: Specifications

3 specifications specifications kor-816t kor-616t power supply 220v ~ 60hz, single phase with earthing power consumption 1350 w 1200 w microwave output power 900 w (iec 705) 800 w (iec 705) frequency 2450 mhz outside dimensions (w x h x d) 495 x 289 x 409 mm 465 x 274 x 379 mm cavity dimensions (w x...

Page 5: Features Diagram

4 features diagram power defrost +1min auto cook stop start clear speedy more less clock tim er /w ei gh t/q ua nt ity 1. Beveroge 2. Soup 3. Casserole 4. Vegetable 5. Fish fillets stop defrost 1 2 weight quantity time lock auto cook watt g power defrost +1min auto cook stop start clear speedy more ...

Page 6: Earthing Instructions

5 steady, flat location. This oven should be set on a steady, flat surface. This oven is designed for counter top use only. Leave space behind and side. All air vents should be kept a clearance. If all vents are covered during operation, the oven may overheat and, eventually, oven failure. Away from...

Page 7: Operation Procedure

6 when the oven door is opened, the light turns off. The oven door can be opened at any time during operation by touching the door release button on the control panel. The oven will automatically shut off. To restart the oven, close the door and then touch start. Each time a pad is touched, a beep w...

Page 8: Controls

7 tips: • be sure to read the cookbook's introduction before operating the oven. • also remember to read this operating instruction for proper safety information and instruction bfore using the oven. • see the cookbook for specific recipes. • prior to setting the controls, place one cup of water in ...

Page 9: Time Defrost

8 time defrost setting the control 1. Press defrost button twice. This time defrost indicator light will light up. Time 4. Press clock button. The display will show present time, and the colon starts blinking. This digital clock allows you to set to “10:10” 2. Turn the dial knob for the desired defr...

Page 10: Weight Defrost

9 weight defrost setting the control 1. Press defrost button once. The weight defrost indicator light will come on. The g indicator light will start blinking. Weight g 2. Turn the dial knob for the desired defrosting weight. For example: 1000g the 1000 will show in the display. It is represent 1000g...

Page 11: Cooking In One Stage

10 cooking in one stage setting the control 1. Press power button by repeatedly pressing this button, you can also select other power levels. For example: kor-616t the stage1 indicator light will light. The watt indicator light start blinking. 1 watt stage 2. Turn the dial knob for the desired cooki...

Page 12: Cooking In Two Stages

11 cooking in two stages setting the control 1. Press power button more than three times. By repeatedly pressing this button, you can also select other power levels. For example: kor-616t the stage1 indicator light will light. The watt indicator light start blinking. 1 watt stage 2. Turn the dial kn...

Page 13

12 5. Press button. When you touch start, both stage1 & 2 indicator lights come on. Stage1 indicator light blinking to show you that the oven is cooking in the first of two cook stages. The oven will cook at the power you selected for stage 1. 1 2 stage at the end of stage 1, the oven will beep and ...

Page 14: Auto Cook

13 auto cook setting the control 1. Press auto cook button the auto cook indicator light will light “ac-1” will show in the display. Quantity auto cook 2. Select the desired cooking. For example: soup press auto cook button twice. “ac-2” will show in the display. The quantity indicator light will st...

Page 15

14 7. Press button. This example don't set more or less function. For example: kor-616t the oven will now start auto cook for menu2. The indicator light starts blinking. Auto cook note : • auto cook menu and quantity. 6. If you want to select other, turn the dial knob until display you desired. 8. B...

Page 16: Speedy Cook

15 1. Press button. Then start lamp will start blinking. Whenever the button is pressed, cooking time is increased 30 seconds. If the time was setting, this oven is operated automatically after 2 seconds to microwave high power. Stage comvinations this oven has the ability to be programmed to do up ...

Page 17: Erasing Instructions

16 to stop the oven whileitis operating erasing instructions general cooking hints 1. When cook a roast with an excess amount of drippings, it is helpful to remove the drippings at turnover time to prevent spattering. 2. Prick the meats, fish or poultry with a fork to prevent bursting. Steam builds ...

Page 18

17 the door lock mechanism is a device which has been specially designed to completely eliminate microwave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) primary interlock switch when the door is closed, the h...

Page 19

18 adjustment 2. Interlock monitor switch when the door is closed, the interlock monitor switch should be opened before other switches close. When the door is opened, the interlock monitor switch should be closed after other switches open. Secondary interlock switch the movement of the switch button...

Page 20: Microwave Radiation Test

19 warning make sure to check the microwave leakage before and after repair or adjustment. • always, start measuring of an unknown field to assure. Safety for operating personnel from microwave energy. • do not place your hands into any suspected microwave radiation field unless the safe density lev...

Page 21: Wiring Diagram

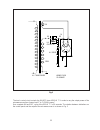

20 fm rd rd live primary interlock switch(upper) l r rd high voltage transformer or or h.V. Capacitor magnetron h.V. Diode gy gy gn gn bl gy gy relay-1 relay-2 control p.W.B. Ass'y gy 3 2 1 note : rd : red wh : white bk : black gn : green br : brown or : orange bl : blue gy : gray ge : green/yellow ...

Page 22: Circuit Description

21 refer to the “wiring diagram” (fig. 1) on page 20. Microwave cooking time cooking 1. When the food is placed incide the oven and door is closed. 1) the low voltage transformer supplies the necessary voltage to the touch control circuit when the power cord is plugged in. 2) the contacts of the int...

Page 23

22 fig.2 the touch control circuit controls the on-off time of relay “1” in order to vary the output power of the microwave oven from “power level 1” to “5 (100%) power”. One complete on and off cycle of the relay “1” is 29 seconds. The relation between indications on the control panel and the outpu...

Page 24

23 power level output power relay “1” turn on, off time against full power 1 5/29 2 11/29 3 17/29 4 23/29 5 29/29 auto defrost cycle when auto defrost is selected and the desired defrosting time is chosen, the automatic cycle divides the defrosting time into 5 periods of alternating defrost and stan...

Page 25

24 -cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is a high-voltage, high-current equipment. It is completely safety during normal operation. However, carelessness in servicing the oven can result in an electric shock or possible danger from a short ...

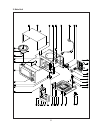

Page 26: Disassembly and Assembly

25 1. To remove cabinet. Remove three screws on cabinet back. 2. To remove door assembly. 1) remove two screws 1 which secure the stopper hinge top. 2) remove the stopper hinge top 2 and door assembly 3 from top plate of cavity. 3) remove the stopper hinge top 2 from door assembly. 4) reverse the ab...

Page 27

26 (1) remove the gasket door(a07) from door painting ass’y(a05). (2) remove the door frame(a01) from door painting ass’y(a05). (3) remove the barrier screen outer(a02) and the supporter barrier screen outer(a03). (4) remove the hook spring(a09) and the hook(a08). (5) remove the hinge stopper top as...

Page 28

27 5. To remove control panel parts. (1) remove the screw which secure the control panel, push up two snap fits and draw forward the control panel assembly. (2) pull out the knob volume (b07) form the control panel ass’y. (3) remove eight screws (b05) which secure the pcb ass’y(b10). (4) remove the ...

Page 29

28 6. To remove high voltage capacitor. (1) remove a screws 1 which secure the grounding ring terminal of the h.V. Diode 2 and the capacitor holder 3 . (2) remove the h.V. Diode 2 from the capacitor holder 3 . (3) remove the above steps for reassembly. High voltage circuit wiring 7. To remove magnet...

Page 30

29 8. To remove fan motor assembly. (1) remove two screws 1 which secure the back cover 2 from the cavity outer. (2) remove two screws 3 which secure the fan motor 4 from the back cover 2 . (3) pull out the fan 5 from the fan motor 4 . (4) reverse the above steps for reassembly. 9. To remove transfo...

Page 31: Trouble Shooting Guide

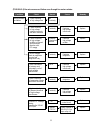

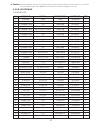

30 folling the procedure below to check if the oven is defective or not. 1. Check earthing before fault finding. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor. 4. When checking the continuity of the switches, fuse or high voltage transformer, disconnect one lead ...

Page 32

31 (trouble 2) oven does not operte at all; any inputs can not be acceted condition check cause result remedy check continuity of interlock monitor switch with door closed. (com nc) continuity malfunction of interlock monitor switch replace fuse blows no continuity check continuity of both primary a...

Page 33

32 condition check cause result remedy outlet has proper voltage fuse does not open check continuity both magnetron and heater thermostat no continuity defective magnetion and heater thermostat replace check continuity of noise filter board no continuity defective line filter borard replace check co...

Page 34

33 (trouble 4) no microwave oscillation even though fan motor rotates. Condition check cause result remedy replace no microwave oscillation check continuity of high voltage fuse no continuity check continuity of high voltage capacitor terminals with wires removed continuity defective high voltage tr...

Page 35: Keyboard Check Procedure

34 1. Type of encoding and key names the tact switch keyboard consists of 9 keys whose aconfigurations are described above. 2. Key check procedure to determine if the tact switch keyboard is defective or not, check the continuity of each button contacts with a multimeter. 1) clock button: between 7 ...

Page 36: Component Test Procedure

35 1. High voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle. 2. It is neither necessary nor advisable to attempt measurement of the high voltage. 3. Before touching any oven components or wiring, always unplug the oven from its power source and...

Page 37

36 safety interlock continuity test • disconnect the oven from the power supply. • you can test continuity of safety interlocks and monitor switch by using switch tester or ohmmeter. • the switch operation is checked by the lamp on/off of resistance zero/unlimited. • the sequence of check is interlo...

Page 38: Printed Wiring Board

37 1. Circuit check procedure 1) low voltage transformer (dmr-814fs) check. The low voltage transformer is located on the p.C.B. Measuring condition: input voltage:220v frequency : 60hz printed wiring board a b c d e f note 1 : secondary side voltage of the low voltage transformer changes in proport...

Page 39

38 2) display prolems no. Cause measurement result remedy 1 poor contact between 1. Check the voltage of pin 2.6 vac fix the pin 1 & p.C.B and display 1 & pin 25. 25 on the filament. P.C.B. 2 the display has some refer to “the display replace p.C.B. Troubles in its segment trouble shooting data” ass...

Page 40

39 fig. 5 measurement point mp2 mp3 mp1.

Page 41

40 fig. 5 measurement point.

Page 42

41 check method point a b stage relay “2” on – 5vdc gnd relay “2” off gnd –24vdc point a b stage relay “2” on – 5vdc gnd relay “2” off gnd –24vdc point a b stage 1) door opened open -5vdc 2) door closed closed gnd check no. Method remedy 1 check the state (on,off) of the secondary replace secondary ...

Page 43

42 6) when the digital clock does not operate properly. 44 c8 d10 r26 r24 r27 a b -5v c c6 q8 c4 micom d12 d11 d13 d14 8 9 r21 r23 point waveform a b c t: 16.67 ms(60hz) -5v 0v t if clock does not keep exact time, you must check diode d10, transistor q8..

Page 44

43 2. P. C. B circuit diagram.

Page 45

44 1) transistor(npn type) 2) diode and zener diode emitter collecftor base cathode (k) cathode (k) anode(a) d1-16 anode(a) zd1-6 diode zener diode 3. Component information.

Page 46

45 4. Printed circuits board.

Page 47

46.

Page 48

47 1) pcb part list 5. P.C.B location no. No part name symbol specification partcode q’ty 1 pcb main m156 m156 3514313851 1 2 r carbon filem r6, r9, r10, r12, r17 1/4w 1k Ω j rd-4z102j- 5 3 r carbon filem r13 1/4w 100 Ω j rd-4z101j- 1 4 r carbon filem r27 1/4w 2k Ω j rd-4z202j- 1 5 r carbon filem r8...

Page 49

48 2) sub pcb part list no part name symbol specification partcode q’ty 41 sw relay ry1 g5j-1tp-m 24v 5sc0101107 1 42 sw relay ry2 g5b-1 24v 5sc0101107 1 43 trans power lvt1 dmr-814fs 5ep035301 1 44 digitron dp1 svm-05ss13 dsvm5ss13- 1 45 holder vfd pp(balck) 351302600 1 46 jumper wire j3~j7, j13~j1...

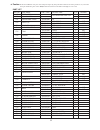

Page 50: Exploded and Parts List

49 1. Door assembly exploded and parts list a01 a02 a03 a04 a05 a06 a07 a08 a09 a10 a11 ref no. Part name part code description q’ty remark a01 frame door 3512202220 abs 1 kor-816t 3512202020 kor-616t a02 barrier-screen * o 3517003140 acryle 1.5t 1 kor-816t 3517003040 kor-616t a03 supporter barr-s *...

Page 51

50 2. Control panel ass’y b01 b02 b03 b04 b05 b06 b07 b08 b09 b10 ref no. Part name part code description q’ty remark b01 decorator c-panel 3511602100 abs 1 kor-816t 3511602300 kor-616t b02 c-panel 3516710930 abs 1 kor-816t 3516713350 kor-616t b03 button start 3516905800 abs 1 milky b04 button funct...

Page 52

51 3. Main unit.

Page 53

52 ref no part name part code description q'ty remark a00 door ass’y exploded and part list 1 b00 c/panel ass’y 1 f01 cover wave guide 3511403200 pp 1 f02 cavity as 3516105600 kor-81150s 1 816t 3516104800 kor-61150s 1 616t f03 coupler 3517400600 pps 1 f04 guide roller as 3512510600 kor-61150s 1 f05 ...

Page 54

S/m no. : r616t0p001 daewoo electronics co., ltd. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” fax: 02) 360-8184 tel: 02) 360-8183 http://www.Dwe. Daewoo.Co.Kr printed date: sep. 1998.