Service manual microwave oven model: kor-6n0a5s s/m no. : or6n0a5001 jul. 2005 ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to ppl(parts price list) in service infor...

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy (a) do not operate or allow the oven to be operated with the door open. (b) make the following safety checks on all ovens to be serviced before activating the magnetron or other micro- w...

2 safety and precautions 1. For safe operation damage that allows the microwave energy (that cooks or heats the food) to escape will result in poor cooking and may cause serious bodily injury to the operator. If any of the following conditions exist, operator must not use the appliance. (only a trai...

3 model kor-6n0a5s power supply 230v-50hz, single phase with earthing microwave 1200w power consumption grill combination microwave energy output 800w microwave frequency 2450mhz outside dimensions (w x h x d) 465 x 279 x 340 mm (18.3 x 11.0 x 13.4 in) cavity dimensions (w x h x d) 301 x 230 x 283 m...

4 external view 1. Outer dimension 465 340 279.

5 1. Door seal door seal maintains the microwave within the oven cavity and prevents microwave leakage. 2. Door hook when the door is closed, it will automatically lock shut. If door is opened while oven is operating, magnetron tube will immediately stop operating. 3. Door screen allows viewing of f...

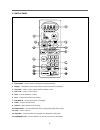

6 bverage 3. Control panel 1. Time set pad – used to set the cooking time and the present time. 2. Display – cooking time, power level, indicators and present time are displayed. 3. One touch – used to cook or reheat specific quantities of food. 4. Auto cook – used to cook or reheat. 5. More – used ...

7 1. Steady, flat location this microwave oven should be set on a steady, flat surface. This microwave oven is designed for counter top use only. 2. Leave space behind and side all air vents should be kept a clearance. If all vents are covered during operation, the oven may overheat and, eventually,...

8 make sure the oven is properly installed and plugged into the electrical. Operations and functions 1 1. Connect the main lead to an electrical outlet. 1 2. After placing the food in a suitable container, open the oven door and put it on the glass tray. The glass tray must always be in place during...

9 disassembly and assembly cautions to be observed when trouble shooting. Unlike many other appliances, the microwave oven is high-voltage, high-current equipment. It is completely safe during normal operation. However, carelessness in servicing the oven can result in an electric shock or possible d...

10 1. To remove cabinet 1) remove three screws on cabinet back. 2) push the cabinet backward. 2. To remove door assembly 1) remove one screw which secure the stopper hinge top. 2) remove the door assembly from top plate of cavity. 3) reverse the above for reassembly. Note : after replacing the door ...

11 3. To remove door parts. Ref no. Part code part name description q’ty remark a01 3512203810 frame door abs sg-175v, sg-076d 1 a02 3517006180 barrier-screen*0 san t1.5 1 a03 3515304610 supporter barr-s*0 pp 1 a04 3515204100 stopper singe *t as kor-63150s 1 a05 3511705500 door weld as kor-61150s 1 ...

12 4. Method to reduce the gap between the door seal and the oven front surface. (1) to reduce gap located on part ‘a’ loosen a screws on stopper hinge top, and then push the door to contact the door seal to oven front surface. Tighten two screws. (2) to reduce gap located on part ‘b’ loosen two scr...

13 5. To remove control panel parts. 1) remove the screw which secure the control panel, push up two snap fits and draw forward the control panel assembly. 2) remove the door open lever from the control panel. 3) remove four screws which secure the pcb assembly to control panel. 4) disconnect membra...

14 note : never install the magnetron without the metallic gasket plate which is packed with each magnetron to pre- vent microwave leakage. Whenever repair work is carried out on magnetron, check the microwave leakage. It shall not exceed 4mw/cm 2 for a fully assembled oven with door normally closed...

15 8. To remove wind guide assembly. 1) remove a screw for earthing. 2) remove the noise filter from the wind guide. 3) remove a screw which secure the wind guide assembly. 4) draw forward the wind guide assembly. 5) pull the fan from the motor shaft. 6) remove two screws which secure the motor shad...

16 interlock mechanism and adjustment the door lock mechanism is a device which has been specially designed to completely eliminate microwave radiation when the door is opened during operation, and thus to perfectly prevent the danger resulting from the leakage of microwave. (1) primary interlock sw...

17 (trouble 1) oven does not operate at all ; any inputs can not be accepted. Trouble shooting guide following the procedure below to check if the oven is defective or not. 1. Check grounding before trouble checking. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor....

18 condition check check continuity of primary inter- lock switch malfunction of pri- mary interlock switch result no continuity cause remedy adjust or replace turn table motor and oven lamp do not turn on check continuity of secondary interlock switch malfunction of sec- ondary interlock switch no ...

19 (trouble 3) no microwave oscillation even though fan motor rotates. Condition check result check continuity of high voltage capacitor terminals with wires removed continuity cause defective high voltage trans- former remedy replace no microwave oscillation check continuity of high voltage fuse re...

20 (trouble 4) the following visual conditions indicate a probable defective touch control circuit or membrane switch assembly. 1 1. Incomplete segments (1) segments missing (2) partical segments missing (3) digit flickering other than normal display slight flickering (4) :0 does not display when po...

21 measurement and test 1. Measurement of the microwave power output microwave output power can be checked by indirectly measuring the temperature rise of a certain amount of water exposed to the microwave as directed below. Procedure 1. Microwave power output measurement is made with the microwave ...

22 2. Microwave radiation test procedures 1. Prepare microwave energy survey meter, 600cc glass beaker, and glass thermometer 100˚c(212˚f). 2. Pour 275cc±15cc of tap water initially at 20±5˚c(68±9˚f) in the 600cc glass beaker with an inside diameter of approx. 95mm(3.5in.). 3. Place it at the center...

23 3. Component test procedure ¥ high voltage is present at the high voltage terminal of the high voltage transformer during any cooking cycle. ¥ it is neither necessary nor advisable to attempt measurement of the high voltage. ¥ before touching any oven components or wiring, always unplug the oven ...

24 wiring diagram 24.

1. Circuit check procedure 1. Low voltage transformer check the low voltage transformer is located on the p.C.B. Measuring condition: input voltage : 230v/frequency : 50hz 2. Voltage check key check point check method printed circuit board no check point remark 1 ic 1 pin 5 5 vdc 2 ic 1 pin 8 3 ic 1...

26 measure point mp1 mp2 gnd.

3. When there is no microwave oscillation 1) when touching start pad, oven lamp does not turn on. Fan motor does not rotate, but cook indicator in display comes on. - check method 2) when touching start pad, oven lamp turns on. Fan motor and turntable rotate and cook indicator in display comes on. -...

28 2. Pcb circuit diagram.

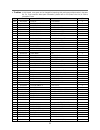

29 no name symbol specification part code q’ty 1 buzzer bz1 bm-20k 3515600100 1 2 c array ca1 7p(6) 1000pf m 50v cn6xb-102m 1 3 capacitor elec ec1 50v rs 10uf cexe1h100a 1 4 capacitor elec ec2 25v rss 1000mf cexf1e102v 1 5 connector wafer cn1 yw396-02v 3519150520 1 6 connector wafer cn2 fcz 254-11 4...

30 1. Door assembly refer to disassembly and assembly. 2. Control panel assembly refer to disassembly and assembly. 3. Total assembly exploded view and parts list.

31 ✔ caution : in this manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to ppl(parts price list) in service information center no part code part name description q'ty a00 3511710320 door as...

S/m no. : or6n0a5001 daewoo electronics corp. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” printed date: jul. 2005.