- DL manuals

- Daewoo

- Microwave Oven

- KOT-150S0A

- Service Manual

Daewoo KOT-150S0A Service Manual - Specifications

3

Model

KOT-150S, KOT-151S, KOT-152U, KOT-152C, KOT-155S

Power Supply

120V ~ 60 Hz

Rated Current

14.0 A (microwave oven only).

Power Consumption

1600W, Max.

Microwave

Output Power (IEC 705)

1000W

Frequency

2450 MHz ±50 MHz

Outside Dimensions (WxHxD)

760x427x375 mm

Cavity Dimensions (WxHxD)

492x240x340 mm

Net Weight

24.5Kg

Timer

Digital, 99 min 99sec

Power Selections

10 Levels

Cavity Volume

1.5 ft

3

Magnetron cooling

Forced air

Microwave Distribution

Stirring fan disk and turntable

Rectification voltage doubler, half-wave.

Door Sealing

Choke System

Safety Device Cavity Thermostat

open : 194/90, reset : 32/0

Bottom Thermostat

open : 194/90, reset : 32/0

Hood Thermostat

open : 104/40, reset : 132.8/56

Line Fuse

20 A

Door Interlock Switches

Primary Interlock Switch.

Secondary Interlock Switch.

Interlock Monitor.

Magnetron type

2M218

High Voltage Capacitor

0.98 2.1KV AC

High Voltage Diode

350 mA, 9.0 KV

Cook-top Lamp

125V, 30W

Cavity Lamp

125V, 30W

Tray

Glass

* SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

SPECIFICATIONS

Summary of KOT-150S0A

Page 1

Service manual microwave oven model: kot-150s0a kot-151s0a kot-152u0a kot-152c0a kot-155s0a daewoo electronics co., ltd. S/m no. : t150s0a003 http : //svc.Dwe.Co.Kr feb. 2002.

Page 2

1 precautions to be observed before and during servicing to avoid possible exposure to excessive microwave energy (a) do not operate or allow the oven to be operated with the door open. (b) make the following safety checks on all ovens to be serviced before activating the magnetron or other micro- w...

Page 3

2 proper use and service precautions caution : this device is to be serviced only by properly qualified service personnel. Consult the service manual for proper service procedures to assure cotinued safey operation and for precautions to be taken to avoid possible exposure to excessive microwave ene...

Page 4: Specifications

3 model kot-150s, kot-151s, kot-152u, kot-152c, kot-155s power supply 120v ~ 60 hz rated current 14.0 a (microwave oven only). Power consumption 1600w, max. Microwave output power (iec 705) 1000w frequency 2450 mhz ±50 mhz outside dimensions (wxhxd) 760x427x375 mm cavity dimensions (wxhxd) 492x240x3...

Page 5: External View

4 external view ; refer to the installation guide installation ; refer to the installation guide operations and functions ; refer to the use and care manual.

Page 6: Disassembly and Assembly

5 disassembly and assembly caution to be observed when trouble shooting unlike many ther applicances, the microvave oven is high-voltage, high-current equipment. It is completely safe during normal operation. However, carelessness is servicing the oven can result in an electronic shock or possible d...

Page 7

6 1. General -removing/reinstalling -cabinet cabinet removal refer to fig. 1 for the following steps: 1. Remove the microwave oven from its mounting location and set it on a protected (padded) work surface. 2. Remove the two screws from the top of the microwave oven that secure the vent grille to th...

Page 8

7 fig. 1.

Page 9

8 2.The operating control systems -replacing the control circuit board 1. Remove the two screws from the top of the microwave oven for the vent grille and remove the grille(see fig. 1). Refer to fig. 2, fig. 2-1 for the following steps: 2. Remove the screw from the front of the microwave oven for wi...

Page 10

9 4. Unplug the following connectors from the control circuit board: a) 2-pin connector at cn2. B) 2-pin connector on relay ry1. C) 3-pin connector at cn5. D) 6-pin connector at cn4. E) 6-pin connector at cn3 (only sensor type model). F) lift the end of the locking arm on the ribbon cable at cn1, th...

Page 11

10 3. Replacing stirrer motor 1. Remove the vent grille from the microwave oven (see cabinet removal for this procedure). Refer to fig. 3 and the insets for the following steps: 2. Remove the screw from the lamp bracket(stirrer motor cover). 3. Pull the connectors off the stirrer motor terminals. 4....

Page 12

11 4. Replacing an oven light socket 1. Remove the screws for the vent grille and remove the grille.(see fig. 1 on page) 2. Remove the screw from cavity lamp bracket and pull out. 3. Remove the socket mounting screw from the cavity lamp bracket. 4. Remove the old light socket, and mount the new sock...

Page 13

12 5. Replacing the line fuse 1. Remove 2 screws from the vent grille and remove the grille (see fig. 1). 2. Remove the screw from the front of the microwave oven for wire protector and remove the wire protector(see fig. 1). 3. Remove the screw from the top center tab of the control panel (see fig. ...

Page 14

13 6. Replacing the vent motor capacitor 1. Remove the vent grille from the microwave oven (see cabinet removal). 2. Remove the screw from the top center tab of the control panel.(see fig. 2) 3. Remove the screw from the top center tab of wire protector. 4. Disconnect the two wire connectors from th...

Page 15

14 7. Replacing/adjusting - interlock switches -replacing a switch 1. Disconnect the electrical supply to the microwave oven. 2. Remove the vent grille and the cabinet from the microwave oven (see cabinet removal on fig. 1). 3. Remove the screw from the center of wire protector. 4. Remove the screw ...

Page 16

15 -making adjustments refer to fig. 7-1 for the following steps: 1. If necessary, adjust the interlock switch housing so that the switches operate properly. 2. Mount the control panel to the oven with the screw you removed earlier. 3. Mount the vent grille to the microwave oven and check out the op...

Page 17

16 8. Replacing the thermostat (bottom/vent) 1. Disconnect the electric supply to the microwave oven. 2. Remove the vent grille and the cabinet from the microwave oven (see cabinet removal on fig. 1). 3. Remove the wire protector(see fig. 4). 4. Remove the screw from the top center tab of the contro...

Page 18

17 9. Replacing the tray motor 1. Remove 4 screws from the base plate and remove it. Refer to the fig. 9 for the following steps: 2. Pull the connectors off the tray motor terminal. 3. Remove the screws from the tray motor and remove the motor. 4. Install the coupler onto the new tray motor shaft. 5...

Page 19

18 10. Replacing a cooktop light socket 1. Pull the connectors off the cook-top light socket terminals set the base plate aside. 2. Remove the screw for the cook-top light socket and remove it. 3. Mount the new light socket into the holder. 4. Reattatch the connectors with the orange and brown wires...

Page 20

19 11. Replacing the door assembly refer to fig. 11 for the following steps: 1. Remove the grille. 2. Open the door and lift the door. Warning : personal injury hazard disconnect from the electrical supply before servicing the unit. Failure to do so could result in electrical shock or other personal...

Page 21

20 12. Replacing the gasket refer to fig. 12 for the following steps: 1. Open the oven door. 2. Pry out the gasket along the edges of the door with a putty knife. 3. Install the new gasket so that it fits tightly into place inside the door. Warning : personal injury hazard disconnect from the electr...

Page 22

21 13. Replacing -the cavity thermostat 1. Remove the microwave oven from the microwave oven location. 2. Remove the vent grille and cabinet from the microwave oven. (see the cabinet removal) 3. Remove the 2 screws for supporter from the microwave oven. 4. Remove the power cord (see the replacing th...

Page 23

22 fig. 13-1 fig. 13-2.

Page 24

23 14. Replacing the ventilation motor 1. Remove the microwave oven from the microwave oven location. 2. Remove 2 screws for the vent motor cover and remove it. (see cabinet removal). 3. Remove the screws for the vent motor and lift the vent motor. (see fig. 14). 4. Unplug the wire connectors for ve...

Page 25

24 15. Replacing the fan motor 1. Remove the microwave oven from its mounting location. 2. Remove the vent grille, the wire protector and the cabinet from the microwave oven (see cabinet removal). 3. Remove the screw from the top center tab of the control panel. Refer to the inset and perform the fo...

Page 26

25 16. Replacing the power cord 1. Remove the microwave oven from its mounting location. 2. Remove the vent grille, the wire protector and the cabinet from the microwave oven (see “cabinet removal). Refer to fig. 16 and the inset for the following steps: 3. Unplug the black and white power cord lead...

Page 27

26 17. Replacing the high-voltage transformer 1. Remove the vent grille, the wire protector and the base plate from the microwave oven (see fig. 1,2). 2. Remove the control panel so that you can access the high-voltage section in the microwave oven(see fig.1). Fig. 17 warning : personal injury hazar...

Page 28

27 3. Discharge the high-voltage capacitor. 4. Remove 4 screws from the h.V. Transformer and save the screws. Refer to fig. 17-1 for the following steps: 5. Unplug the five high-voltage transformer wire connectors and remove high voltage transformer. 6. Mount the new high-voltage transformer to the ...

Page 29

28 18. Replacing the high voltage rectifier 1. Remove the vent grille, the wire protector and the control panel from the microwave oven (see fig.1, fig.2). 2. You can access the high-voltage section in the microwave oven. 3. Discharge the high-voltage capacitor. 4. Unplug one end of the high-voltage...

Page 30

29 19. Replacing the high voltage capacitor 1. Remove the vent grille(see fig.1, fig2). 2. Remove the wire protector. 3. Remove the control panel so that you can access the high-voltage section in the microwave oven. (see fig. 1) 4. Discharge the high-voltage capacitor. 5. Unplug the wire connector ...

Page 31

30 7. Position the new high-voltage capacitor with the round blister (between the leads). Make sure that the flange on the strap is against the front end of the capacitor, and tighten the screw just enough to hold the capacitor in place. 8. Connect the end of the high-voltage rectifier and red wire ...

Page 32

31 20. Replacing the magnetron 1. Remove the microwave oven from its mounting location. 2. Remove the vent grille, the wire protector and the cabinet from the microwave oven (see “cabinet removal). 3. Remove the control panel so that you can access the high-voltage section in the microwave oven. 4. ...

Page 33

32 9. Mount the magnetron cover lamp to the new magnetron with its 1 mounting screw. 10. Position the new magnetron so that the magnetron the cover lamp the front of the oven, and mount the magnetron to the top of the chassis with its four mounting hex unts. Make sure that you tighten the nuts secur...

Page 34: Trouble Shooting Guide

33 trouble shooting guide following the procedures below to check if the oven is defective or not. 1. Check grounding before checking trouble. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor. 4. When checking the continuity of the switches, fuse or high voltage tra...

Page 35: Measurement and Test

34 measurement and test caution : 1. Wather load should be measured exactly to 1 liter. 2. Input ower voltage should be exactly 120v as specified. 3. Ambient temperature should be 20 2˚c(68 ±3.6˚f) 1. Measurement of the microwave power output microwave output power can be checked by indirectly measu...

Page 36

35 2. Microwave radiation test on every service call, checks for microwave energy emission must be made according to the following manner. 1. Remove the cooking rack from the oven cavity, if the microwave oven is, so equipped. 2. Place 275ml(9. Oz.) glass of water in the center of the oven bottom. 3...

Page 37

36 if a microwave oven is found to operate with the door open, report to department of service, the manufacturer and cdrh* immediately. Also tell the owner not to use the oven. The interlock monitor switch acts as the final safety switch protecting the customer from microwave radiation. If the inter...

Page 38

37 3. Component test procedure the thermostat and thermal cut out there are one thermostats and two thermal cut out in the otr microwave oven. They are the cavity thermal cut out and the bottom thermal cut out. The cavity thermal cut out is located air guide top. This thermal cut out is “normally- c...

Page 39

38 vent motor capacitor the vent motor capacitor is located directly behind the control panel. It is in use any time the vent motor is on. The capacitor helps to maintain a constant voltage to the vent motor so that it runs more efficiently. Test charts componet test procedure result high voltage tr...

Page 40

39 componet test procedure result switches (with wire leads removed). All of the switches are measured in the same manner. Fan motor (with leads disconnected) blower motor (with leads disconnected) stirrer motor (with leads disconnected) turn table motor (with leads disconnected) n. O. And c termina...

Page 41

40 componet test procedure result high voltage capacitor vent motor capacitor high voltage diode terminal-to-terminal set the ohmmeter to the rx10k scale, and measure the resistance across the capacitor terminals. Terminal-to-case set the ohmmeter to the rx1 scale, and measure the resistance between...

Page 42

41 4. Safety interlock continuity test • you can test continuity of safety interlock and monitor switch by using ohmmeter. • the switch operation is checked by zero/untimited. The meter should indicate zero resistance. • the sequence of check is interlock monitor switch, primary and secondary interl...

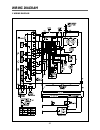

Page 43: Wiring Diagram

42 wiring diagram 1. Wiring diagram.

Page 44

43 2. Circuit description microwave cooking - time cooking 1. When the food is placed inside the oven and door is closed. 1) the low voltage transformer supplies the necessary voltage to the touch control circuit when the power cord is plugged in. 2) the contacts of the interlock monitor switch open...

Page 45

44 the touch control circuit controls the on-off time of relay 1 in order to vary the output power of the microwave oven from power level 1 to hi (100%) power. One complete on and off cycle of the relay 1 is 29 seconds. The relation between indications on the control panel and the output of the micr...

Page 46

45 3) fan motor and turn table stop rotating 4) the oven lamp turns off. 5) as soon as the door is opened, the interlock monitor switch contacts close and creates the short circuit. 6) if the contacts of primary interlock switch malfunction the 20a fuse blows open due to the large current surge caus...

Page 47: Printed Circuit Board

46 1. Circuit check procedure 1) low voltage transformer (dmr-210p) check the low voltage transformer is located on the pcb measuring condition : input voltage : 120 v frequency : 60hz 2. Voltage check - key check point - check method printed circuit board terminal voltage 6 - 7 8 - 10 load ac 17v a...

Page 48

47 3) display problems - the display trouble shooting data no cause measurement result remedy 1 poor contact between pcb check the voltage of pin 1, 2 2.6 vac fix the pin 1,2 & and display filament & pin 32, 33 32, 33 on the pcb 2 defective display refer to the display trouble replace pcb shooting d...

Page 49

48 measure point 4) when there is no microwave oscillation when touching start pad, oven lamp does not turn on. Fan motor does not rotate, but cook indicator in display comes on. *cause: relay 6 does not operate. - check method when touching start pad, oven lamp turns on. Fan motor and turntable rot...

Page 50

49 5)when the door is opened during operation, the count down timer does not stop. - check method 6) when the digital clock does not operate properly. - check method if clock does not keep exact time, you must check resistor r20, transistor q6 stage point 1) door open 2) door closed a open closed b ...

Page 51

50 6) when er01 & er03 come on display. -check method when auto reheating is just operating, check the point a, b, c, & d after 1~2 minutes. R 6~10 & connecting status of humidity sensor must be checked before checking point a, b, c & d. No 1 2 3 4 check point a b c d remark 0.5v ≤ value ≤ 3.5v 11.3...

Page 52

51 trouble shooting following the procedures below to check if the oven is defective or not. 1. Check grounding before checking trouble. 2. Be careful of the high voltage circuit. 3. Discharge the high voltage capacitor. 4. When checking the continuity of switches of of the high voltage transformer,...

Page 53

52 (trouble 2) digital readout display does not show programming, even if the membrane keyboard is programmed by touching proper pads. Membrane keyboard check procedure 1. Check the pad termination order and nomenclature note : before following the particular steps listed above in the trouble shooti...

Page 54

53 2. Type of encoding and pad names the membrane keyboard consists of 35 keys whose configurations are described above and provide 12 pad termintions to be connected to the touch control circuit. 3. Key check procedure to determine if the membrane keyboard is defective or not, check the continuity ...

Page 55

54 20) popcorn pad : between f and j 21) beverage pad : between g and j 22) start pad : between a and k 23) favorite choice pad : between b and k 24) turntable on/off pad : between c and k 25) clock/auto start pad : between d and k 26) auto defrost pad : between e and k 27) cook time pad : between f...

Page 56

55 2. Component information 1) transistor 2) diode and zener diode 2. Component information 1) transistor.

Page 57

56 3. Printed circuit board film.

Page 58

57.

Page 59

58 4. Pcb circuit diagram.

Page 60

59 5. Pcb location no no name symbol specifcation part code q’ty remark 1 buzzer bz1 bm-20k 3515600100 1 2 capacitor array ca1 6p(5) 102 m 50v cn5xb-102m 1 3 capacitor ceramic c1, c2, c7, c8, 104 50v z axial cczf1h104z 8 c10~13 kot-150s 4 capacitor ceramic c3 102 50v z axial cczb1h102k 1 kot-151s ko...

Page 61

60 no name symbol specifcation part code q’ty remark kot-150s 35 resistor r8 1/6w 301k ohm 1% rn-az3013f 1 kot-151s kot-155s kot-150s 36 resistor r9 1/6w 150k ohm 1% rn-az1503f 1 kot-151s kot-155s kot-150s 37 resistor r10 1/6w 75k ohm 1% rn-az7502f 1 kot-151s kot-155s kot-150s 38 resistor r11, r12 1...

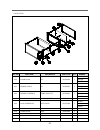

Page 62: Exploded View and Parts List

61 exploded view and parts list 1. Door assembly 1) kot-150s0a ref. No. Part name description part code q’ty remark black a00 frame door pc 3512204400 1 bisque white black a01 handle door *i pc 3512602900 1 bisque white black a02 barrier screen *o temp glass t3.2 3517006200 1 bisque white black a03 ...

Page 63

62 2) kot-151s0a ref. No. Part name description part code q’ty remark black a00 frame door pc 3512204410 1 bisque white black a01 handle door *i pc 3512602910 1 bisque white black a02 barrier screen *o temp glass t3.2 3517006210 1 bisque white a03 frame door handle silicon rubber 3517304100 1 black ...

Page 64

63 3) kot-152u0a, kot-152c0a ref. No. Part name description part code q’ty remark black a00 frame door pc 3512204420 1 bisque white black a01 handle door *i pc 3512603000 1 bisque white black a02 barrier screen *o temp glass t3.2 3517006220 1 bisque white black a03 handle door *i pc 3512602920 1 bis...

Page 65

64 4) kot-155s0a a00 a13 a01 a03 a10 a11 a12 a02 a05 a06 a09 a08 a04 a07 ref. No. Part name description part code q’ty remark black a00 frame door pc 3512204430 1 bisque white black a01 handle door pc 3512604400 1 bisque white black a02 barrier screen *o temp glass t3.2 3517006280 1 bisque white bla...

Page 66

65 2. Control panel assembly 1) kot-150s0a, kot-151soa, kot-152u0a, kot-152c0a ref. No. Part name description part code q’ty remark black kot-150s0a 3518522300 1 bisque white black kot-151s0a 351822310 1 bisque white b00 switch membrane black kot-152u0a 351822320 1 bisque white black kot-152c0a 3518...

Page 67

66 2) kot-155s0a b00 b01 b02 b03 b04 b05 ref. No. Part name description part code q’ty remark black b00 switch membrane kot-155s0a 3518522340 1 bisque white b01 decorator c-panel sts430 t0.5 3511609200 1 black b02 control panel pc 3516722730 1 bisque white b03 back plate secc t0.6 3516802110 1 kot-1...

Page 68

67 3. Total assembly.

Page 69

68 ref. No. Part name description part code q’ty remark black kot-150s0a 3511712200 1 bisqu white black kot-151s0a 3511712210 1 bisque a00 door as white black kot-152u0a, kot-152c0a 3511712220 1 bisque white black kot-155s0a 3511712250 1 bisque white black kot-150s0a pkcpswla00 1 bisque white black ...

Page 70

69 ref. No. Part name description part code q’ty remark f12 harness main kot150s0a 3512717100 1 f13 cord power as 3x14awg 80x80 250-rtml 35113udny8 1 f14 fuse cera ul/csa 65ts 125v 20a 5f1cd2031s 1 f15 thermostat off:40 on:56 v#250 3518905500 1 f16 screw tapping t2s pan 4x6 mfzn 7121400611 1 f17 the...

Page 71

70 ref. No. Part name description part code q’ty remark f53 coupler stirrer pps 3517401800 1 f54 stirrer blade al050-h18 t0.7 3517100900 1 f55 motor syncro 120v 2.4w st-16 kx63mraa 3966820710 1 f56 screw tapping t2s pan 4x6 mfzn 7121400611 2 f57 screw tapping t2s pan 4x6 mfzn 7121400611 1 f58 motor ...

Page 72

S/m no. : t150s0a003 daewoo electronics co., ltd. 686, ahyeon-dong mapo-gu seoul, korea c.P.O. Box 8003 seoul, korea telex: dwelec k28177-8 cable: “daewooelec” printed date: feb, 2002.