- DL manuals

- Daewoo

- Automobile

- MATIZ

- Service Manual

Daewoo MATIZ Service Manual

SECTION INDEX

FRONT MATTER

0A

GENERAL INFORMATION

0B

ENGINE

1

SERVICE

MATIZ

FOREWORD

This manual includes procedure for maintenance,

adjustment, service operation and removal and

installation of components.

All information, illustrations and specifications con-

tained in this manual are based on the latest prod-

uct information available at the time of manual ap-

proval.

The right is reserved to make changes at any time

without notice.

DAEWOO MOTOR CO., LTD.

INCHON, KOREA

MANUAL

SUSPENSION

2

DRIVELINE/AXLE

3

BRAKES

4

TRANSAXLE

5

STEERING

6

RESTRAINTS

8

BODY AND ACCESSORIES

9

7

HVAC

(HEATING, VENTILATION,

AND AIR CONDITIONING)

(MY2003)

Summary of MATIZ

Page 1

Section index front matter 0a general information 0b engine 1 service matiz foreword this manual includes procedure for maintenance, adjustment, service operation and removal and installation of components. All information, illustrations and specifications con- tained in this manual are based on the...

Page 2: Engine

Engine contents section 1a general engine information section 1b sohc engine mechanical section 1d engine cooling section 1e engine electrical section 1f engine controls section 1g engine exhaust.

Page 3: Suspension

Suspension contents section 2a suspension diagnosis section 2b wheel alignment section 2c front suspension section 2d rear suspension section 2e tires and wheels.

Page 4: Driveline/axle

Driveline/axle contents section 3b manual transaxle drive axle.

Page 5: Brakes

Brakes contents section 4a hydraulic brakes section 4b master cylinder section 4c power booster section 4d front disc brakes section 4e rear drum brakes section 4f antilock brake system section 4g parking brake.

Page 6: Transaxle

Transaxle contents section 5b five–speed manual transaxle section 5c clutch.

Page 7: Steering

Steering contents section 6a power steering system section 6b power steering pump section 6c power steering gear section 6d manual steering gear section 6e steering wheel and column.

Page 8: And Air Conditioning)

Hvac (heating, ventilation, and air conditioning) contents section 7a heating and ventilation system section 7b manual control heating, ventilation, and air conditioning system.

Page 9: Restraints

Restraints contents section 8a seat belts section 8b supplemental inflatable restraints (sir).

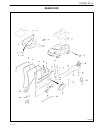

Page 10: Body And Accessories

Body and accessories contents section 9a body wiring system section 9b lighting systems section 9c horns section 9d wipers / washer systems section 9e instrumentation / driver information section 9f audio systems section 9g interior trim section 9h seats section 9i waterleaks section 9j windnoise se...

Page 11: Section 1A

Daewoo m-150 bl2 section 1a general engine information table of contents description and operation 1a-2 . . . . . . . . . . . . . . . . . . Cleanliness and care 1a-2 . . . . . . . . . . . . . . . . . . . . . . On-engine service 1a-2 . . . . . . . . . . . . . . . . . . . . . . . . Component locator 1...

Page 12

1a – 2 general engine information daewoo m-150 bl2 description and systemoperation cleanliness and care an automobile engine is a combination of many ma- chined, honed, polished and lapped surfaces with toler- ances that are measured in the ten–thousandths of an inch. When any internal engine parts ...

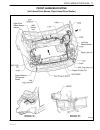

Page 13: Component Locator

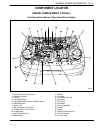

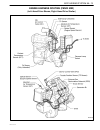

General engine information 1a – 3 daewoo m-150 bl2 component locator engine compartment (typical) (left–hand drive shown, right–hand drive similar) d102a401 1 power steering oil reservoir 2 coolant reservoir 3 canister 4 canister solenoid 5 manifold absolute pressure (map) sensor 6 intake manifold 7...

Page 14

1a – 4 general engine information daewoo m-150 bl2 engine compartment (euro iii) (left–hand drive shown, right–hand drive similar) maa1a010 1 power steering oil reservoir 2 coolant reservoir 3 canister purge solenoid 4 manifold absolute pressure (map) sensor 5 intake manifold 6 throttle position (tp...

Page 15

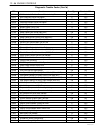

General engine information 1a – 5 daewoo m-150 bl2 diagnostic information procedure general diagnosis ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction hard starting (with malfunction of d fault...

Page 16

1a – 6 general engine information daewoo m-150 bl2 general diagnosis (cont’d) ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction hard starting (with others d broken timing belt. D replace the belt. Normal cranking) d malfunction of pos...

Page 17

General engine information 1a – 7 daewoo m-150 bl2 general diagnosis (cont’d) ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction rough engine idling malfunction of ignition system d loosening or damage of the distributor rotor or cap. ...

Page 18

1a – 8 general engine information daewoo m-150 bl2 general diagnosis (cont’d) ÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction engine surging (engine power makes fluctuation in a fixed others d...

Page 19

General engine information 1a – 9 daewoo m-150 bl2 general diagnosis (cont’d) ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction poor fuel malfunction of d improper ignition timing. D adjust the ignition timing. Consumption ignition sy...

Page 20

1a – 10 general engine information daewoo m-150 bl2 general diagnosis (cont’d) ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ condition ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ probable cause ÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑ correction low oil pressure malfunction of lubrication d lowered function of the oil pump. D replace the pump. Syste...

Page 21

General engine information 1a – 11 daewoo m-150 bl2 checking engine fluid level check the engine fluid level or condition. If needed, refill or replace the oil. Check the engine oil level within engine normal operat- ing temperature as follows ; 1. After stopping the engine, wait for a few minutes t...

Page 22

1a – 12 general engine information daewoo m-150 bl2 checking engine timing belt after checking the timing belt for looseness, crack, wear or tension, replace the belt if necessary. Checking accessory belt after checking the alternator belt (e), air conditioning/ power steering belt (f), air conditio...

Page 23

General engine information 1a – 13 daewoo m-150 bl2 checking air cleaner element if the air cleaner element becomes dirty, engine efficien- cy could be deteriorated. Be sure to check the element often. Especially, if a vehicle frequently runs on a dusty road, check and replace the element often. Che...

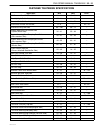

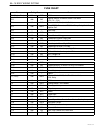

Page 24: Specifications

1a – 14 general engine information daewoo m-150 bl2 specifications general specifications ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ application ÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑ description ÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑÑ maximum speed ÑÑÑÑÑÑÑÑÑÑÑÑÑ ÑÑÑÑÑÑÑÑÑÑÑÑÑ 144 km/h (90 mph...

Page 25

General engine information 1a – 15 daewoo m-150 bl2 engine performance curve d maximum power : 51 ps (37.5 kw) (at 6,000 rpm) d maximum torque : 7 kg s m (68.6 n s m) (at 4,600 rpm) d12a101a.

Page 26: Section 1B

Daewoo m-150 bl2 section 1b sohc engine mechanical caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury a...

Page 27: Description And Operation

1b – 2 sohc engine mecanical daewoo m-150 bl2 description and operation engine type the engine is 4-cycle, water-cooled, in-line 3 cylinders with displacement of 796cc (68.5 × 72.0mm) (2.70 × 2.83 in.). Engine model (specifications) f8c type sohc / 2 valve (mpi) maximum power (kw/rpm) 37.5 / 6,000 m...

Page 28

Sohc engine mecanical 1b – 3 daewoo m-150 bl2 parts are installed in the cross flow arrangement. The rocker arm (i) operates in seesaw motion to close and open the intake and exhaust valves (j) with camshaft by turning the rocker arm shaft of each intake and exhaust part. Engine block as the largest...

Page 29

1b – 4 sohc engine mecanical daewoo m-150 bl2 timing belt and pulley the timing belt connects the camshaft timing pulley (w) and the crankshaft timing pulley (x). The timing belt coordinates the crankshaft and the camshaft and keeps them synchronized. The timing belt also turns the cool- ant pump (y...

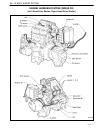

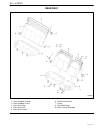

Page 30: Component Locator

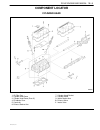

Sohc engine mecanical 1b – 5 daewoo m-150 bl2 component locator cylinder head d12b4011 1 oil filler cap 2 cylinder head cover 3 cylinder head cover (euro iii) 4 distributor case 5 camshaft 6 exhaust rocker arm 7 cylinder head gasket 8 cylinder head 9 intake rocker arm 10 exhaust valve 11 intake valv...

Page 31

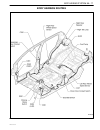

1b – 6 sohc engine mecanical daewoo m-150 bl2 engine block d21b0011 1 oil level gauge stick 2 piston 3 connecting rod 4 engine block 5 oil filter 6 flywheel 7 crankshaft 8 oil pan 9 oil pump strainer 10 oil pump assembly.

Page 32

Sohc engine mecanical 1b – 7 daewoo m-150 bl2 manifold & air flow system d21b0021 1 intake manifold 2 exhaust gas recirculation (egr) pipe 3 exhaust gas recirculation (egr) valve and solenoid 4 throttle body assembly 5 air filter assembly 6 resonator 7 snorkel 8 oxygen sensor 9 exhaust manifold 10 e...

Page 33

1b – 8 sohc engine mecanical daewoo m-150 bl2 timing belt & engine mount d12b4041 1 engine mount damping block 2 engine mount intermediate bracket 3 engine mount brace bracket 4 transaxle mount bracket 5 transaxle mount damping block 6 engine mount front bracket 7 engine mount front damping bush 8 t...

Page 34

Sohc engine mecanical 1b – 9 daewoo m-150 bl2 diagnostic information and procedure compression pressure check tools required 09915–64510 compression pressure gauge check the compression pressure in the following proce- dures: 1. Warm up the engine to the normal operating tempera- ture (cooling tempe...

Page 35

1b – 10 sohc engine mecanical daewoo m-150 bl2 adjustment of valve clearance adjust the valve clearance in the following procedures: 1. Remove the air filter/resonator assembly and the relevant parts installed on the cylinder head cover. 2. Remove the cylinder head cover hexagon bolts and remove the...

Page 36

Sohc engine mecanical 1b – 11 daewoo m-150 bl2 the measured value of valve clearance should meet the specified value. If not, adjust the valve clearance. Important: in case of hot engine, warm up the engine until the electric cooling fan begins to work and stop the engine to adjust the clearance wit...

Page 37

1b – 12 sohc engine mecanical daewoo m-150 bl2 d102b310 5. If the ignition timing exceeds the specified value, loosen the distributor bolts and adjust it to the speci- fied ignition timing by turning the distributor body (s). D102b311 valve timing check and adjustment check the valve timing in the f...

Page 38

Sohc engine mecanical 1b – 13 daewoo m-150 bl2 adjust the valve timing in the following procedures: 1. Loosen the bolt and remove the timing belt pulley (c). In loosening the bolt, use the driver (h) in the picture shown. D102b315 2. Remove the oil level gauge guide tube (i) and the tim- ing belt fr...

Page 39: Section 1D

Daewoo m-150 bl2 section 1d engine cooling caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and damag...

Page 40: Description And Operation

1d – 2 engine cooling daewoo m-150 bl2 description and operation general description the cooling system maintains the engine temperature at an efficient level during all engine operating conditions. When the engine is cold the cooling system cools the engine slowly or not at all. This slow cooling o...

Page 41

Engine cooling 1d – 3 daewoo m-150 bl2 coolant pump the belt-driven centrifugal coolant pump consists of an impeller, a drive shaft, and a belt pulley. The impeller is supported by a completely sealed bear- ing. The coolant pump is serviced as an assembly and, therefore, cannot be disassembled. Ther...

Page 42

1d – 4 engine cooling daewoo m-150 bl2 the main fan size is 320 mm (12.6 in.) in diameter with seven blades(k) to aid the air flow through the radiator and the condenser. An electric motor(l) attached to the radiator support drives the fan. A/c off or non-a/c model d the cooling fan is actuated by t...

Page 43: Component Locator

Engine cooling 1d – 5 daewoo m-150 bl2 component locator coolant hose and components d12d4011 1 radiator coolant return hose 2 upper radiator hose 3 not used 4 radiator assembly 5 lower radiator hose 6 throttle body assembly 7 surge tank hose 8 surge tank 9 coolant temperature sensor 10 engine coola...

Page 44

1d – 6 engine cooling daewoo m-150 bl2 radiator/fan d12d4021 1 radiator assembly 2 electric cooling fan assembly.

Page 45

Engine cooling 1d – 7 daewoo m-150 bl2 diagnostic information and procedure coolant leaks test 1. Remove the surge tank cap after the engine cools. 2. Check the coolant level. 3. Install a suitable cooling system pressure tester(b) to the surge tank filler neck using the adapter(a) and pressurize (1...

Page 46

1d – 8 engine cooling daewoo m-150 bl2 cooling system diagnosis ÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁ condition ÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁ probable cause ÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁ correction engine overheats d a loss of the coolant. D add the coolant. D a weak coolant solution. D confirm that the coolant solut...

Page 47: Repair Instructions

Engine cooling 1d – 9 daewoo m-150 bl2 repair instructions on–vehicle service d12d5011 draining and refilling the cooling system caution: do not remove the surge tank cap while the engine and the radiator are hot. Scalding fluid and steam may be blown out under pressure. 1. Place a pan below the veh...

Page 48

1d – 10 engine cooling daewoo m-150 bl2 d102d503 d add the clean water to the surge tank (2). 5. Run the engine until the thermostat opens. You can tell the thermostat is open when both radiator hoses are hot to the touch. 6. Stop the engine and disconnect the lower radiator hose to drain the coolan...

Page 49

Engine cooling 1d – 11 daewoo m-150 bl2 d102d505 installation procedure 1. Install the surge tank to the vehicle. D install the surge tank with pressing down (1). D connect the overflow hoses to the surge tank (2). 2. Secure the overflow hoses to the surge tank with the hose clamps. 3. Fill the surg...

Page 50

1d – 12 engine cooling daewoo m-150 bl2 d12d5091 4. Remove the electric cooling fan. Refer to “electric cooling fan” in this section. 5. Remove the radiator. D remove the bolts (1). D remove the radiator support brackets (2). D remove the radiator (3). 6. Check the radiator for breaking, clog or oth...

Page 51

Engine cooling 1d – 13 daewoo m-150 bl2 d loosen the hose clamp (1). D disconnect the upper radiator hose (2). D102d513 4. Remove the thermostat. D remove the bolts (1). D remove the thermostat housing (2). D remove the thermostat with the gasket (3). 5. Check the gasket for crack or other damage. 6...

Page 52

1d – 14 engine cooling daewoo m-150 bl2 maa1d020 4. Remove the thermostat. D remove the bolts. D remove the thermostat housing. D remove the thermostat with the gasket. 5. Check the gasket for crack or other damage. 6. Inspect the valve seat for foreign matter that could prevent the valve from seati...

Page 53

Engine cooling 1d – 15 daewoo m-150 bl2 d102d517 engine coolant temperature sensor removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the lower radiator hose and drain the coolant “draining and refilling the cooling system” in this section. 3. Remove the engine coolant tempera...

Page 54

1d – 16 engine cooling daewoo m-150 bl2 9–12 n s m 9–12 n s m d12d520a d12d521a installation procedure 1. Install the coolant pump with the new gasket. Tighten tighten the bolts and the nuts to 9–12 n s m (80–106 lb-in) (a). 2. Install the rear timing belt cover. Tighten tighten the bolts to 9–12 n ...

Page 55: Specifications

Engine cooling 1d – 17 daewoo m-150 bl2 specifications general specifications application description unit standard limit cooling system cooling type – forced water circulation coolant coolant capacity l/qt 3.8/4.00 thermostat type – pellet type temperature(opened initially) ° c( ° f) 82(180) thermo...

Page 56

1d – 18 engine cooling daewoo m-150 bl2 fastener tightening specifications application n s m lb-ft lb-in engine coolant temperature sensor 10 – 89 coolant temperature sensor 20 15 – coolant pipe bolt 8 – 15 – 71 – 130 electric cooling fan motor nut 3.0 – 3.2 – 27 – 28 electric cooling fan assembly b...

Page 57: Section 1E

Daewoo m-150 bl2 section 1e engine electrical caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and da...

Page 58: Description And Operation

1e – 2 engine electrical daewoo m-150 bl2 description and operation battery the battery has three major functions in the electrical system. First, the battery provides a source of energy for cranking the engine. Second, the battery acts as a voltage stabilizer for the electrical system. Finally, the...

Page 59

Engine electrical 1e – 3 daewoo m-150 bl2 charging procedure 1. Batteries with the green dot showing do not require charging unless they have just been discharged, such as in cranking a vehicle. 2. When charging sealed-terminal batteries out of the vehicle, install the adapter kit. Make sure all the...

Page 60

1e – 4 engine electrical daewoo m-150 bl2 3. In both vehicles, apply the parking brake firmly. Notice: make sure the cables are not on or near pulleys, fans, or other parts that will move when the engine starts, damaging the parts. 4. Shift a manual transaxle to neutral. Caution: do not use cables t...

Page 61

Engine electrical 1e – 5 daewoo m-150 bl2 the sequence of ignition order. It also adjusts the ignition timing according to the engine condition. This vehicle uses the distributor (optical sensor type) which controls the preminary current of the ignition coil by the ecm. The ignition timing change is...

Page 62: Component Locator

1e – 6 engine electrical daewoo m-150 bl2 component locator starting system d102e401 1 starter motor assembly 2 starter solenoid assembly 3 starter housing 4 shift lever 5 armature set 6 armature 7 pinion gear assembly 8 ring set 9 field frame assembly 10 brush holder assembly 11 contact end frame a...

Page 63

Engine electrical 1e – 7 daewoo m-150 bl2 charging system (a-type : mando) d102e402 1 generator assembly 2 generator shackle 3 generator drive end nut 4 generator pully 5 generator collar (large) 6 generator front bracket 7 front bearing 8 bearing spot plate 9 generator collar (small) 10 generator r...

Page 64

1e – 8 engine electrical daewoo m-150 bl2 charging system (b-type : dac) d102e403 1 generator assembly 2 generator shackle 3 generator drive end nut 4 generator pully 5 generator collar 6 generator drive end bracket 7 generator stator assembly 8 frame bearing 9 generator fan 10 generator rotor assem...

Page 65

Engine electrical 1e – 9 daewoo m-150 bl2 ignition system d102e404 1 ignition coil 2 spark pulg 3 ignitoin wire (#0) 4 ignition wires (#1, #2, #3) 5 support clamp 6 mounting clamp 7 distributor assembly 8 coupling 9 distributor oil seal 10 distributor housing 11 distributor shaft 12 plate 13 optical...

Page 66

1e – 10 engine electrical daewoo m-150 bl2 diagnostic information and procedure ignition system condition probable cause correction no crank d low battery voltage. D charging the battery or replace the battery. D battery cable is loose, corroded, or damaged. D repair or replace the battery cable. D ...

Page 67

Engine electrical 1e – 11 daewoo m-150 bl2 ignition system (cont’d) condition probable cause correction hard to starting the engine d faulty ignition coil. D replace the ignition coil. D faulty distributor (include the optical sensor). D replace the distributor or the optical sensor. D faulty spark ...

Page 68

1e – 12 engine electrical daewoo m-150 bl2 battery load test 1. Check the battery for obvious damage, such as a cracked or broken case or cover, which could permit the loss of electrolyte. If obvious damage is noted, re- place the battery. Caution: do not charge the battery if the hydrometer is clea...

Page 69

Engine electrical 1e – 13 daewoo m-150 bl2 generator system check when operating normally, the generator indicator lamp will come on when the ignition switch is in the on posi- tion and go out when the engine starts. If the lamp oper- ates abnormally or if an undercharged or overcharged battery cond...

Page 70: Repair Instructions

1e – 14 engine electrical daewoo m-150 bl2 repair instructions on–vehicle service d12e5011 starter removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the electrical connector and clip around the starter. D remove the engine oil temperature sensor to dis- connect the harness co...

Page 71

Engine electrical 1e – 15 daewoo m-150 bl2 d102e504 generator removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the harness connector. D remove the battery harness connector nut to dis- connect the battery positive connector (1). D disconnect the generator harness connector (...

Page 72

1e – 16 engine electrical daewoo m-150 bl2 d12e508a 35–41 n s m 68–83 n s m installation procedure 1. Install in the reverse order of removal except genera- tor driver velt. 2. Install the engine mounting lower bracket bolts and nut. Tighten d tighten the engine mounting lower bracket bolts to 35–41...

Page 73

Engine electrical 1e – 17 daewoo m-150 bl2 d12e513a installation procedure 1. Install in the reverse order of removal. 2. Install the battery rod and cable nuts. Tighten d tighten the battery rod nut to 6–8 n s m (53–71 lb- in) (a). D tighten the battery cable nut to 9-12 n s m (80–106 lb-in) (b). D...

Page 74

1e – 18 engine electrical daewoo m-150 bl2 d102e517 ignition coil removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the ignition wires and ignition coil connec- tor. D disconnect the ignition wire (1). D disconnect the ignition coil connector by pushing the connector’s lock(2...

Page 75: Repair Instructions

Engine electrical 1e – 19 daewoo m-150 bl2 repair instructions unit repair d102e701 starter motor inspection / measurement (before the overhaul) 1. Remove the starter. Refer to “starter” in this section. 2. Pinion clearance inspection. D disconnect the starter motor terminal m (1). D connect the 12-...

Page 76

1e – 20 engine electrical daewoo m-150 bl2 d102e704 d inspect the pinion gear’s moving to the outside (2). D if the pinion gear does not move outside, replace the magnetic switch. D102e705 4. Solenoid hold-in test. D disconnect the starter motor terminal m (1). D connect the 12-volt battery lead to ...

Page 77

Engine electrical 1e – 21 daewoo m-150 bl2 d102e708 d check the returning speed of pinion gear (2). If the returning speed is fast, the operation is nor- mal. D replace the solenoid if the operation is abnormal. D102e709 5. No-road test. D connect the 12-volt battery lead to the starter cir- cuit. D...

Page 78

1e – 22 engine electrical daewoo m-150 bl2 d102e712 2. Remove the brush holder assembly. D remove the starter motor terminal m nut (1). D remove the brush holder assembly (2). D102e713 3. Remove the field frame assembly from the armature set (1). D102e714 4. Remove the solenoid assembly. D remove th...

Page 79

Engine electrical 1e – 23 daewoo m-150 bl2 d102e716 inspection / measurement (after the overhaul) 1. Ground test for armature coil. D inspect the insulation between commutator and ar- mature coil using the voltmeter. D replace the armature assembly if necessary. D102e717 2. Short circuit test for ar...

Page 80

1e – 24 engine electrical daewoo m-150 bl2 d12e720a 9-12 n s m 4-6 n s m assembly procedure 1. Install in the reverse order of removal. 2. Install the bolts / nuts. Tighten tighten the starter motor terminal m nut to 9–12 n s m (80–106 lb-in) (a). Tighten the through-bolts to 4–6 n s m (35–53 lb-in)...

Page 81

Engine electrical 1e – 25 daewoo m-150 bl2 d102e724 4. Remove the front bracket, rotor and collar. D remove the collar (large) (1). D remove the rotor from the front bracket (2). D remove the collar (small) from the rotor shaft (3). D102e725 5. Remove the front bearing. D remove the support plate sc...

Page 82

1e – 26 engine electrical daewoo m-150 bl2 d102e728 8. Remove the rectifier / brush holder / regulator from the stator. D remove the rectifier / brush holder / regulator con- nections (1). D remove the stator and rectifier connections (2). Notice: if the stator connections are welded, melt the lead....

Page 83

Engine electrical 1e – 27 daewoo m-150 bl2 d102e732 d test the stator for open or ground circuit by using the ohmmeter (2). Replace the starter if necessary. D102e733 3. Inspect the rectifier. D positive rectifier test: inspect the open circuit for stator coil lead termi- nals using the ohmmeter (1)...

Page 84

1e – 28 engine electrical daewoo m-150 bl2 d12e736a 5. Inspect the brush wear. D if the brush wear exceeds the specified valve (a), replace the brush. Desciption standard limit brushes wear 18.5 (0.73) 13.5 (0.53) d102e737 assembly procedure 1. Install in the reverse order of removal. D assemble the...

Page 85

Engine electrical 1e – 29 daewoo m-150 bl2 d12e740a 4–6 n s m 80–110 n s m d tighten the generator pulley nut to 80–110 n s m (59–81 lb-ft) (d). D tighten the through-bolts to 4–6 n s m (35–53 lb-in) (e). D102e741 generator (b-type: dac) disassembly procedure 1. Remove the generator. Refer to “gener...

Page 86

1e – 30 engine electrical daewoo m-150 bl2 d102e744 4. Remove the regulator / brush holder / rectifier. D remove the rectifier and regulator connection (1). D remove the regulator and brush holder connection (2). D visibly inspect the rectifier / regulator / brush hold- er for damage or broken. A. R...

Page 87

Engine electrical 1e – 31 daewoo m-150 bl2 d102e748 8. Remove the stator assembly from the frame. D remove the remains after the welding. D remove the stator assembly (2). D102e749 inspection / measurement 1. Inspect the rotor assembly. D test the rotor coil for an open circuit by using the ohmmeter...

Page 88

1e – 32 engine electrical daewoo m-150 bl2 d102e752 d test the stator for open or ground circuits by using the ohmmeter. The reading should be sufficiently high, or the stator must be replaced (2). D102e753 3. Inspect the rectifier. D positive rectifier test: inspect the open circuit for stator coil...

Page 89

Engine electrical 1e – 33 daewoo m-150 bl2 d12e756a 5. Inspect the brush wear d if the brush wear exceeds the specified value, re- place the brush. A. Brush wear limit. Desciption standard limit brushes wear 20 (0.79) 14 (0.55) d12e757a 9–12 n s m assembly procedure 1. Install in the reverse order o...

Page 90

1e – 34 engine electrical daewoo m-150 bl2 d12e760a 4–7 n s m 4–6 n s m d tighten the through-bolts to 4–6 n s m (35–53 lb-in) (f). D tighten the battery positive terminal nut to 4–7 n s m (35–62 lb-in) (g). D102e761 distributor assembly disassembly procedure 1. Remove the distributor. Refer to “dis...

Page 91

Engine electrical 1e – 35 daewoo m-150 bl2 d102e764 4. Remove the optical sensor cover and adaptor from the distributor housing. D remove the screw (1). D remove the adaptor (2). D remove the screws (3). D remove the cover (4). D remove the gasket (5). D102e765 5. Remove the optical sensor unit from...

Page 92

1e – 36 engine electrical daewoo m-150 bl2 d102e768 assembly procedure 1. Install in the reverse order of removal. D lubricate the shaft with clean engine oil..

Page 93

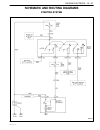

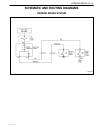

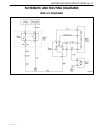

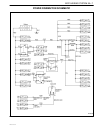

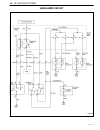

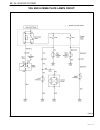

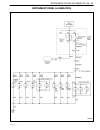

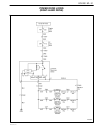

Engine electrical 1e – 37 daewoo m-150 bl2 schematic and routing diagrams starting system d12e2011.

Page 94

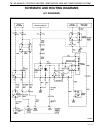

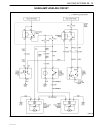

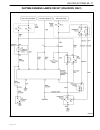

1e – 38 engine electrical daewoo m-150 bl2 charging system d12e2021.

Page 95

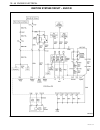

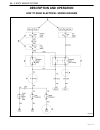

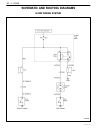

Engine electrical 1e – 39 daewoo m-150 bl2 ignition system circuit – typical d12e2031.

Page 96

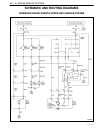

1e – 40 engine electrical daewoo m-150 bl2 ignition system circuit – euro iii maa1e010

Page 97: Specifications

Engine electrical 1e – 41 daewoo m-150 bl2 specifications starter specifications application description unit standard limit starter motor type – sd 80 – output(capacity) kw 0.8 – no load test @ 9 volts drive pinion speed a rpm 150 2,000 – brushes length mm (in.) 11.3–11.5 (0.445–0.453) 7.0–7.25 (0....

Page 98

1e – 42 engine electrical daewoo m-150 bl2 battery specifications application description unit standard limit battery type – mf – capacity ah 35 – cold cranking amps cca 246 – fastener tightening specifications application n s m lb-ft lb-in distributor bolts 10–16 – 89–142 battery retainer clamp–to–...

Page 99: Section 1F

Daewoo m-150 bl2 section 1f engine controls caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and dama...

Page 100

1f – 2 engine controls daewoo m-150 bl2 dtc p0122 throttle position sensor low voltage 1f-76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dtc p0123 throttle position sensor high voltage 1f-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dtc p0131 oxygen sensor low v...

Page 101

Engine controls 1f – 3 daewoo m-150 bl2 dtc p1628 immobilizer no successful communication 1f-270 . . . . . . . . . . . . . . . . . . . . . . . Dtc p1629 immovilizer wrong computation 1f-272 dtc p0656 fuel level gauge circuit fault 1f-274 . Dtc p1660 malfunction indicator lamp (mil) high voltage 1f-2...

Page 102: Description And Operation

1f – 4 engine controls daewoo m-150 bl2 description and operation ignition system operation this ignition system does not use a conventional distrib- utor and coil. It uses a crankshaft position sensor input to the engine control module (ecm). The ecm then de- termines electronic spark timing (est) ...

Page 103

Engine controls 1f – 5 daewoo m-150 bl2 fuel is delivered under one of several conditions, called “modes.’’ starting mode when the ignition is turned on, the ecm turns the fuel pump relay on for 2 seconds. The fuel pump then builds fuel pressure. The ecm also checks the engine coolant temperature (e...

Page 104

1f – 6 engine controls daewoo m-150 bl2 pors. Fresh air from the air cleaner is supplied to the crankcase. The fresh air is mixed with blowby gases which then pass through a vacuum hose into the intake manifold. Periodically inspect the hoses and the clamps. Replace any crankcase ventilation compone...

Page 105

Engine controls 1f – 7 daewoo m-150 bl2 manifold to decrease combustion temperature. The amount of exhaust gas recirculated is controlled by vari- ations in vacuum and exhaust back pressure. If too much exhaust gas enters, combustion will not take place. For this reason, very little exhaust gas is a...

Page 106

1f – 8 engine controls daewoo m-150 bl2 tions. With the ignition on and the engine not running, the engine control module (ecm) will read the manifold pressure as barometric pressure and adjust the air/fuel ratio accordingly. This compensation for altitude allows the system to maintain driving perfo...

Page 107

Engine controls 1f – 9 daewoo m-150 bl2 appropriate wiring diagram. Refer to “ecm wiring dia- grams” in this section. 95 91 terminal 49 ground open strategy-based diagnostics strategy-based diagnostics the strategy-based diagnostic is a uniform approach to repair all electrical/electronic (e/e) syst...

Page 108

1f – 10 engine controls daewoo m-150 bl2 fuels use alcohol to increase the octane rating of the fuel. Although alcohol-enhanced fuels may raise the oc- tane rating, the fuel’s ability to turn into vapor in cold temperatures deteriorates. This may affect the starting ability and cold driveability of ...

Page 109

Engine controls 1f – 11 daewoo m-150 bl2 d the fault identified by the diagnostic test is currently active. D the fault has been active during this ignition cycle. D the operating conditions at the time of the failure. Remember, a fuel trim diagnostic trouble code (dtc) may be triggered by a list of...

Page 110

1f – 12 engine controls daewoo m-150 bl2 the enable criteria for each diagnostic is listed on the first page of the diagnostic trouble code (dtc) descrip- tion under the heading “conditions for setting the dtc.” enable criteria varies with each diagnostic and typically includes, but is not limited t...

Page 111

Engine controls 1f – 13 daewoo m-150 bl2 data link connector (dlc) the provision for communicating with the control mod- ule is the data link connector (dlc). The dlc is used to connect to a scan tool. Some common uses of the scan tool are listed below: d identifying stored dtcs. D clearing dtcs. D ...

Page 112

1f – 14 engine controls daewoo m-150 bl2 termittent fault will also be erased from memory. If the fault that caused the dtc to be stored into memory has been corrected, the diagnostic executive will begin to count the ‘‘warm-up” cycles with no further faults de- tected, the dtc will automatically be...

Page 113

Engine controls 1f – 15 daewoo m-150 bl2 made to enter dtc numbers for tests which the diag- nostic executive does not recognize, the requested in- formation will not be displayed correctly and the scan tool may display an error message. The same applies to using the dtc trigger option in the snapsh...

Page 114

1f – 16 engine controls daewoo m-150 bl2 the obstruction of the reference air and degrade the o2s performance. Misfire monitor diagnostic operation the misfire monitor diagnostic is based on crankshaft rotational velocity (reference period) variations. The en- gine control module (ecm) determines cr...

Page 115: System Diagnosis

Engine controls 1f – 17 daewoo m-150 bl2 diagnostic information and procedures system diagnosis diagnostic aids if an intermittent problem is evident, follow the guide- lines below. Preliminary checks before using this section you should have already per- formed the “euro on-board diagnostic (eobd) ...

Page 116

1f – 18 engine controls daewoo m-150 bl2 maa1f010 euro on-board diagnostic (eobd) system check circuit description the euro on-board diagnostic (eobd) system check is the starting point for any driveability complaint diagno- sis. Before using this procedure, perform a careful visu- al/physical check...

Page 117

Engine controls 1f – 19 daewoo m-150 bl2 euro on-board diagnostic (eobd) system check step action value(s) yes no 1 1. Turn the ignition on with the engine off. 2. Observe the malfunction indicator lamp (mil). Is the mil on? – go to step 2 go to “no malfunction indicator lamp” 2 1. Turn the ignition...

Page 118

1f – 20 engine controls daewoo m-150 bl2 ecm output diagnosis circuit description the engine control module (ecm) controls most com- ponents with electronic switches which complete a ground circuit when turned on. These switches are ar- ranged in groups of 4 and 7, and they are called either a surfa...

Page 119

Engine controls 1f – 21 daewoo m-150 bl2 multiple ecm information sensor dtcs set circuit description the engine control module (ecm) monitors various sensors to determine engine operating conditions. The ecm controls fuel delivery, spark advance, transaxle op- eration, and emission control device o...

Page 120

1f – 22 engine controls daewoo m-150 bl2 multiple ecm information sensor dtcs set step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the check complete. – go to step 2 go to “euro on-board diagnostic system check” 2 1. Turn the ignition off and disconnect the e...

Page 121

Engine controls 1f – 23 daewoo m-150 bl2 multiple ecm information sensor dtcs set (cont’d) step action value(s) yes no 12 locate and repair the short to voltage in the tp sensor signal circuit. Is the repair complete? – go to step 19 – 13 locate and repair the short to voltage in the iat sensor sign...

Page 122

1f – 24 engine controls daewoo m-150 bl2 maa1f020 engine cranks but wil l nut run.

Page 123

Engine controls 1f – 25 daewoo m-150 bl2 engine cranks but will not run caution: use only electrically insulated pliers when handling ignition wires with the engine running to prevent an electrical shock. Caution: do not pinch or restrict nylon fuel lines. Damage to the lines could cause a fuel leak...

Page 124

1f – 26 engine controls daewoo m-150 bl2 engine cranks but will not run (cont’d) step action value(s) yes no 12 check for an open or short in the wires between ckp sensor connector and ecm connector and repair as need. Is the repair complete? – go to step 2 – 13 1. Disconnect electronic ignition (ei...

Page 125

Engine controls 1f – 27 daewoo m-150 bl2 engine cranks but will not run (cont’d) step action value(s) yes no 21 1. Check for any damages or poor connection in ignition wires and repair as needed. 2. Connect the ei system ignition coil connector and ecm connector. 3. Check for the presence of spark f...

Page 126

1f – 28 engine controls daewoo m-150 bl2 engine cranks but will not run (cont’d) step action value(s) yes no 33 replace the fuel pump sender, the in-tank fuel filter, and/or the fuel coupling hoses as needed. Is the repair complete? – go to step 2 – 34 1. Turn the ignition off. 2. Disconnect the ele...

Page 127

Engine controls 1f – 29 daewoo m-150 bl2 engine cranks but will not run (cont’d) step action value(s) yes no 42 1. Turn the ignition off. 2. Connect test light between fuel injector harness connector 2 and battery positive. 3. Crank the engine. 4. Repeat step 2 and 3 for each of the remaining fuel i...

Page 128

1f – 30 engine controls daewoo m-150 bl2 maa1f030 no malfunction indicator lamp circuit description when the ignition is turned on, the malfunction indica- tor lamp (mil) will be turned on and remain on until the engine is running, if no diagnostic trouble codes (dtcs) are stored. Battery voltage is...

Page 129

Engine controls 1f – 31 daewoo m-150 bl2 no malfunction indicator lamp step action value(s) yes no 1 attempt to start the engine. Does the engine start? – go to step 2 go to “engine cranks but will not run” 2 1. Turn the ignition off. 2. Disconnect the engine control module (ecm) connector. 3. Turn ...

Page 130

1f – 32 engine controls daewoo m-150 bl2 maa1f030 malfunction indicator lamp on steady circuit description when the ignition is turned on, the malfunction indica- tor lamp (mil) will be turned on and remain on until the engine is running, if no diagnostic trouble codes (dtcs) are stored. Battery vol...

Page 131

Engine controls 1f – 33 daewoo m-150 bl2 malfunction indicator lamp on steady step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the check complete. – go to step 2 go to “euro on-board diagnostic system check” 2 1. Turn the ignition off. 2. Install the scan too...

Page 132

1f – 34 engine controls daewoo m-150 bl2 fuel system diagnosis circuit description the fuel pump is an in-tank type mounted to a fuel send- er assembly. The fuel pump will remain on as long as the engine is cranking or running and the engine control module (ecm) is receiving reference pulses from th...

Page 133

Engine controls 1f – 35 daewoo m-150 bl2 fuel system pressure test (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 8 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁ...

Page 134

1f – 36 engine controls daewoo m-150 bl2 maa1f040 fuel pump relay circuit check circuit description when the ignition switch is turned on, the engine con- trol module (ecm) will supply battery voltage to activate the fuel pump relay and run the in-tank fuel pump. The fuel pump will operate as long a...

Page 135

Engine controls 1f – 37 daewoo m-150 bl2 fuel pump relay circuit check (cont’d) step action value(s) yes no 3 1. Check for an open circuit between fuel pump test connector and ground g401, and repair as needed. 2. Check for the fuel cut-off switch and reset or replace the fuel cut off switch. Is the...

Page 136

1f – 38 engine controls daewoo m-150 bl2 maa1f050 main relay circuit check circuit description when the ignition is turned on or to the start position, the main relay is energized. The main relay then supply voltage to the engine fuse block fuse ef25 and ef26. The electronic ignition (ei) system ign...

Page 137

Engine controls 1f – 39 daewoo m-150 bl2 main relay circuit check step action value(s) yes no 1 1. Turn the ignition off. 2. Disconnect the engine fuse block fuse ef26. 3. Turn the ignition on. 4. With a test light connected to the ground, probe the fuse terminals nearest the main relay for fuse ef1...

Page 138

1f – 40 engine controls daewoo m-150 bl2 maa1f060 manifold absolute pressure check circuit description the manifold absolute pressure (map) sensor measure the changes in the intake manifold pressure which result from engine load (intake manifold vacuum) and rpm changes. The map sensor converts these...

Page 139

Engine controls 1f – 41 daewoo m-150 bl2 manifold absolute pressure check step action value(s) yes no 1 1. Turn the ignition off. 2. Connect a scan tool to the data link connector (dlc). 3. Turn the ignition on. 4. Compare the manifold absolute pressure (map) sensor voltage reading from scanner with...

Page 140

1f – 42 engine controls daewoo m-150 bl2 maa1f070 idle air control system check circuit description the engine control module (ecm) controls the engine idle speed with the idle air control (iac) valve. To in- crease the idle speed, the ecm pulls the iac pintle away from its seat, allowing more air t...

Page 141

Engine controls 1f – 43 daewoo m-150 bl2 idle air control system check step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “euro on-board diagnostic system check” 2 1. Turn the ignition off. 2. Remove idle air control (...

Page 142

1f – 44 engine controls daewoo m-150 bl2 maa1f080 ig ni t io n syst em c h eck.

Page 143

Engine controls 1f – 45 daewoo m-150 bl2 ignition system check circuit description the electronic ignition (ei) system uses a waste spark method of spark distribution. In this type of ei system, the crankshaft position (ckp) sensor is mounted to the oil pump near a slotted wheel that is a part of th...

Page 144

1f – 46 engine controls daewoo m-150 bl2 ignition system check (cont’d) step action value(s) yes no 9 check for an open in the wire from ei system ignition coil connector terminal 2 to the engine control module (ecm) connector terminal 1. Is the problem found? – go to step 7 go to step 11 10 1. Repl...

Page 145

Engine controls 1f – 47 daewoo m-150 bl2 ignition system check (cont’d) step action value(s) yes no 21 measure the voltage between the ckp sensor connector terminal 2 and ground. Is the voltage within the value specified? 0.95–1.10 v go to step 18 go to step 22 22 check the wire between the ckp sens...

Page 146

1f – 48 engine controls daewoo m-150 bl2 maa1f090 engine cooling fan circuit check circuit description the engine cooling fan circuit operates the cooling fan. The cooling fan is controlled by the engine control mod- ule (ecm) based on input from the coolant temperature sensor (cts) and the a/c on/o...

Page 147

Engine controls 1f – 49 daewoo m-150 bl2 engine cooling fan circuit check step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “euro on-board diagnostic system check. 2 1. Check the fuses ef3 and ef10 in engine fuse bloc...

Page 148

1f – 50 engine controls daewoo m-150 bl2 engine cooling fan circuit check (cont’d) step action value(s) yes no 12 1. Turn the ignition on. 2. Connect a test light between terminals 86 and 30 of low speed cooling fan relay and ground. Does the test light on for both case? – go to step 14 go to step 1...

Page 149: Blank

Engine controls 1f – 51 daewoo m-150 bl2 blank.

Page 150

1f – 52 engine controls daewoo m-150 bl2 maa1f010 data link connector diagnosis circuit description the provision for communicating with the engine con- trol module (ecm) is the data link connector (dlc). It is located under the instrument panel. The dlc is used to connect the scan tool. Battery pow...

Page 151

Engine controls 1f – 53 daewoo m-150 bl2 data link connector diagnosis step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “euro on-board diagnostic system check. 2 with a test light connected to the ground, probe the d...

Page 152

1f – 54 engine controls daewoo m-150 bl2 fuel injector balance test a fuel injector tester is used to energize the injector for a precise amount of time, thus spraying a measured amount of fuel into the intake manifold. This causes a drop in the fuel rail pressure that can be recorded and used to co...

Page 153

Engine controls 1f – 55 daewoo m-150 bl2 diagnostic trouble code diagnosis clearing trouble codes notice: to prevent engine control module (ecm) dam- age, the key must be off when disconnecting or recon- necting the power to the ecm (for example battery cable, ecm pigtail connector, ecm fuse, jumper...

Page 154

1f – 56 engine controls daewoo m-150 bl2 diagnostic trouble codes (cont’d) dtc function error type illuminate mil p0336 58x crankshaft position sensor extra/missing pulse e yes p0337 58x crankshaft sensor no signal e yes p0341 camshaft position sensor rationality e yes p0342 camshaft position sensor...

Page 155

Engine controls 1f – 57 daewoo m-150 bl2 diagnostic trouble codes (cont’d) dtc function error type illuminate mil p1660 malfunction indicator lamp(mil) high voltage e yes p1661 malfunction indicator lamp(mil) low voltage e yes.

Page 156

1f – 58 engine controls daewoo m-150 bl2 maa1f060 diagnostic trouble code (dtc) – p0107 manifold absolute pressure sensor low voltage circuit description the engine control module (ecm) uses the manifold ab- solute pressure (map) sensor to control the fuel deliv- ery and the ignition timing. The map...

Page 157

Engine controls 1f – 59 daewoo m-150 bl2 if the connections are ok monitor the manifold absolute pressure (map) sensor signal voltage while moving re- lated connectors and the wiring harness. If the failure is induced, the display on the scan tool will change. This may help to isolate the location o...

Page 158

1f – 60 engine controls daewoo m-150 bl2 dtc p0107 – manifold absolute pressure sensor low voltage (cont’d) step action value(s) yes no 10 1. Repair the wire or the connector terminal as needed. 2. Clear any dtcs from the ecm. 3. Perform the diagnostic system check. Is the repair complete? – system ...

Page 159: Blank

Engine controls 1f – 61 daewoo m-150 bl2 blank.

Page 160

1f – 62 engine controls daewoo m-150 bl2 maa1f060 diagnostic trouble code (dtc) – p0108 manifold absolute pressure sensor high voltage circuit description the engine control module (ecm) uses the manifold ab- solute pressure (map) sensor to control the fuel deliv- ery and the ignition timing. The ma...

Page 161

Engine controls 1f – 63 daewoo m-150 bl2 dtc p0108 – manifold absolute pressure sensor high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool ...

Page 162

1f – 64 engine controls daewoo m-150 bl2 dtc p0108 – manifold absolute pressure sensor high voltage (cont’d) step action value(s) yes no 11 1. Replace the manifold absolute pressure sensor. 2. Clear any dtcs from the ecm. 3. Perform the diagnostic system check. Is the replacement complete? – system ...

Page 163: Blank

Engine controls 1f – 65 daewoo m-150 bl2 blank.

Page 164

1f – 66 engine controls daewoo m-150 bl2 maa1f100 diagnostic trouble code (dtc) – p0112 intake air temperature sensor low voltage circuit description the intake air temperature (iat) sensor uses a therm- istor to control the signal voltage to the engine control module (ecm). The ecm supplies a 5 vol...

Page 165

Engine controls 1f – 67 daewoo m-150 bl2 dtc p0112 – intake air temperature sensor low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool to th...

Page 166

1f – 68 engine controls daewoo m-150 bl2 maa1f100 diagnostic trouble code (dtc) – p0113 intake air temperature sensor high voltage circuit description the intake air temperature (iat) sensor uses a therm- istor to control the signal voltage to the engine control module (ecm). The ecm supplies a 5 vo...

Page 167

Engine controls 1f – 69 daewoo m-150 bl2 dtc p0113 – intake air temperature sensor high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool to t...

Page 168

1f – 70 engine controls daewoo m-150 bl2 dtc p0113 – intake air temperature sensor high voltage (cont’d) step action value(s) yes no 11 1. Replace the ecm 2. Perform the diagnostic system check. Is the repair complete? – go to step 12 – 12 check if any additional dtcs are set. Are any dtcs displaced...

Page 169: Blank

Engine controls 1f – 71 daewoo m-150 bl2 blank.

Page 170

1f – 72 engine controls daewoo m-150 bl2 maa1f110 diagnostic trouble code (dtc) – p0117 engine coolant temperature sensor low voltage circuit description the engine coolant temperature sensor (ect) uses a thermistor to control the signal voltage to the engine control module (ecm). The ecm supplies a...

Page 171

Engine controls 1f – 73 daewoo m-150 bl2 dtc p0117 – engine coolant temperature sensor low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool t...

Page 172

1f – 74 engine controls daewoo m-150 bl2 maa1f110 diagnostic trouble code (dtc) – p0118 engine coolant temperature sensor high voltage circuit description the coolant temperature sensor (ect) uses a thermis- tor to control the signal voltage to the engine control module (ecm). The ecm supplies a vol...

Page 173

Engine controls 1f – 75 daewoo m-150 bl2 dtc p0118 – engine coolant temperature sensor high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool ...

Page 174

1f – 76 engine controls daewoo m-150 bl2 maa1f120 diagnostic trouble code (dtc) p0122 throttle position sensor low voltage circuit description the engine control module (ecm) supplies a 5 volt ref- erence voltage signal and a ground to the throttle posi- tion (tp) sensor. The tp sensor sends a volta...

Page 175

Engine controls 1f – 77 daewoo m-150 bl2 dtc p0122 – throttle position sensor low voltage step action value(s) yes no 1 perform an on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “on-board diagnostic system check” 2 1. Install a scan tool to the data link conne...

Page 176

1f – 78 engine controls daewoo m-150 bl2 dtc p0122 – throttle position sensor low voltage (cont’d) step action value(s) yes no 12 1. Using the scan tool, clear the diagnostic trouble codes (dtcs). 2. Start the engine and idle at normal operating temperature. 3. Operate the vehicle within the conditi...

Page 177: Blank

Engine controls 1f – 79 daewoo m-150 bl2 blank.

Page 178

1f – 80 engine controls daewoo m-150 bl2 maa1f120 diagnostic trouble code (dtc) p0123 throttle position sensor high voltage circuit description the engine control module (ecm) supplies a 5 volt ref- erence voltage signal and a ground to the throttle posi- tion (tp) sensor. The tp sensor sends a volt...

Page 179

Engine controls 1f – 81 daewoo m-150 bl2 dtc p0123 – throttle position sensor high voltage step action value(s) yes no 1 perform an on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “on-board diagnostic system check” 2 1. Install a scan tool to the data link conn...

Page 180

1f – 82 engine controls daewoo m-150 bl2 dtc p0123 – throttle position sensor high voltage (cont’d) step action value(s) yes no 13 check if any additional dtcs are set. Are any dtcs displayed that have not been diagnosed? – go to applicable dtc table system ok.

Page 181: Blank

Engine controls 1f – 83 daewoo m-150 bl2 blank.

Page 182

1f – 84 engine controls daewoo m-150 bl2 maa1f130 diagnostic trouble code (dtc) – p0131 oxygen sensor low voltage circuit description the engine control module (ecm) supplies a voltage of about 450m volts between the ecm terminals 44 and 13. The oxygen (o 2 ) sensor varies the voltage within a range...

Page 183

Engine controls 1f – 85 daewoo m-150 bl2 dtc p0131 – oxygen sensor low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool to the data link conn...

Page 184

1f – 86 engine controls daewoo m-150 bl2 dtc p0131 – oxygen sensor low voltage (cont’d) step action value(s) yes no 12 check if any additional dtcs are set. Are any dtcs displaced that have not been diagnosed? – go to applicable dtc table system ok.

Page 185: Blank

Engine controls 1f – 87 daewoo m-150 bl2 blank.

Page 186

1f – 88 engine controls daewoo m-150 bl2 maa1f130 diagnostic trouble code (dtc) – p0132 oxygen sensor high voltage circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 44 and 13. The oxygen (o2) sensor varies the voltage within a range...

Page 187

Engine controls 1f – 89 daewoo m-150 bl2 dtc p0132 – oxygen sensor high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to on, with the e...

Page 188

1f – 90 engine controls daewoo m-150 bl2 maa1f130 diagnostic trouble code (dtc) – p0133 oxygen sensor no activity circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 44 and 13. The oxygen (o 2 ) sensor varies the voltage within a rang...

Page 189

Engine controls 1f – 91 daewoo m-150 bl2 dtc p0133 – oxygen sensor no activity step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Connect the scan tool to the data link conn...

Page 190

1f – 92 engine controls daewoo m-150 bl2 dtc p0133 – oxygen sensor no activity (cont’d) step action value(s) yes no 11 replace the o 2 sensor. Is the repair complete? – go to step 12 – 12 1. Clear any dtcs from the ecm 2. Perform the diagnostic system check is the repair complete – go to step 13 – 1...

Page 191: Blank

Engine controls 1f – 93 daewoo m-150 bl2 blank.

Page 192

1f – 94 engine controls daewoo m-150 bl2 maa1f140 diagnostic trouble code (dtc) – p0137 heated oxygen sensor low voltage circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 44 and 13. The oxygen (o 2 ) sensor varies the voltage within...

Page 193

Engine controls 1f – 95 daewoo m-150 bl2 dtc p0137 – heated oxygen sensor low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to on, with...

Page 194

1f – 96 engine controls daewoo m-150 bl2 dtc p0137 – heated oxygen sensor low voltage (cont’d) step action value(s) yes no 10 check if any additional dtcs are set. Are any dtcs displaced that have not been diagnosed? – go to applicable dtc table system ok.

Page 195: Blank

Engine controls 1f – 97 daewoo m-150 bl2 blank.

Page 196

1f – 98 engine controls daewoo m-150 bl2 maa1f140 diagnostic trouble code (dtc) – p0138 heated oxygen sensor high voltage circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 64 and 13. The heated oxygen (o 2 ) sensor varies the voltag...

Page 197

Engine controls 1f – 99 daewoo m-150 bl2 dtc p0138 – heated oxygen sensor high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to on, wit...

Page 198

1f – 100 engine controls daewoo m-150 bl2 maa1f140 diagnostic trouble code (dtc) – p0140 heated oxygen sensor no activity circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 64 and 13. The oxygen (o 2 ) sensor varies the voltage withi...

Page 199

Engine controls 1f – 101 daewoo m-150 bl2 dtc p0140 – heated oxygen sensor no activity step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Run the engine to above the specifi...

Page 200

1f – 102 engine controls daewoo m-150 bl2 dtc p0140 – heated oxygen sensor no activity (cont’d) step action value(s) yes no 11 1. Turn the ignition switch to lock. 2. Replace the heated o2 sensor. 3. Road tests the vehicle. 4. Perform the diagnostic system check. Is the replacement complete? – go to...

Page 201: Blank

Engine controls 1f – 103 daewoo m-150 bl2 blank.

Page 202

1f – 104 engine controls daewoo m-150 bl2 maa1f140 diagnostic trouble code (dtc) – p0141 heated oxygen sensor heater malfunction circuit description the engine control module (ecm) supplies a voltage of about 450mm volts between the ecm terminals 44 and 13. The oxygen (o 2 ) sensor varies the voltag...

Page 203

Engine controls 1f – 105 daewoo m-150 bl2 dtc p0141 – heated oxygen sensor heater malfunction step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to ...

Page 204

1f – 106 engine controls daewoo m-150 bl2 diagnostic trouble code (dtc) – p0171 fuel trim system too lean system description to provide the best possible combination of driveability, fuel economy, and emission control, a closed loop air/ fuel metering system is used. While in closed loop, the engine...

Page 205

Engine controls 1f – 107 daewoo m-150 bl2 dtc p0171 – fuel trim system too lean step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Install the scan tool to the data link con...

Page 206

1f – 108 engine controls daewoo m-150 bl2 dtc p0171 – fuel trim system too lean (cont’d) step action value(s) yes no 9 1. Visually/physically inspect the following items for vacuum leaks: d intake manifold. D throttle body. D injector o-rings. 2. Repair any leaks found as necessary. Is the repair co...

Page 207

Engine controls 1f – 109 daewoo m-150 bl2 diagnostic trouble code (dtc) – p0172 fuel trim system too rich system description to provide the best possible combination of driveability, fuel economy, and emission control, a closed loop air/ fuel metering system is used. While in closed loop, the engine...

Page 208

1f – 110 engine controls daewoo m-150 bl2 dtc p0172 – fuel trim system too rich step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 install the scan tool to the data link connec...

Page 209

Engine controls 1f – 111 daewoo m-150 bl2 dtc p0172 – fuel trim system too rich (cont’d) step action value(s) yes no 12 check the iac valve performance. Refer to “dtc p0506 idle speed rpm lower than desired idle speed” or “dtc p0507 idle speed rpm higher than desired idle speed” in this section and ...

Page 210

1f – 112 engine controls daewoo m-150 bl2 dtc p0172 – fuel trim system too rich (cont’d) step action value(s) yes no 21 1. Using the scan tool, clear the diagnostic trouble codes (dtcs). 2. Start the engine and idle at normal operating temperature. 3. Operate the vehicle within the conditions for se...

Page 211: Blank

Engine controls 1f – 113 daewoo m-150 bl2 blank.

Page 212

1f – 114 engine controls daewoo m-150 bl2 maa1f040 diagnostic trouble code (dtc) – p1230 fuel pump relay low voltage circuit description when the ignition switch is turned on, the ecm will acti- vate the fuel pump relay and run the in-tank fuel pump. The fuel pump will operate as long as the engine ...

Page 213

Engine controls 1f – 115 daewoo m-150 bl2 dtc p1230 – fuel pump relay low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to lock for 10 ...

Page 214

1f – 116 engine controls daewoo m-150 bl2 dtc p1230 – fuel pump relay low voltage (cont’d) step action value(s) yes no 11 1. Repair the wire between the fuel pump relay connector terminal 66 and the ignition key on (ign1). 2. Install the fuel pump relay. 3. Turn the ignition off for 10 seconds. 4. C...

Page 215: Blank

Engine controls 1f – 117 daewoo m-150 bl2 blank.

Page 216

1f – 118 engine controls daewoo m-150 bl2 maa1f040 diagnostic trouble code (dtc) – p1231 fuel pump relay high voltage circuit description when the ignition switch is turned on, the ecm will acti- vate the fuel pump relay and run the in-tank fuel pump. The fuel pump will operate as long as the engine...

Page 217

Engine controls 1f – 119 daewoo m-150 bl2 dtc p1231 – fuel pump relay high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to lock for 10...

Page 218

1f – 120 engine controls daewoo m-150 bl2 dtc p1231 – fuel pump relay high voltage (cont’d) step action value(s) yes no 10 1. Replace the ecm. 2. Turn the ignition off for 10 seconds. 3. Clear any dtcs from ecm. 4. Turn the ignition switch to on. Does the fuel pump operate? 2.55 seconds system ok go...

Page 219: Blank

Engine controls 1f – 121 daewoo m-150 bl2 blank.

Page 220

1f – 122 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0261 injector 1 low voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the inj...

Page 221

Engine controls 1f – 123 daewoo m-150 bl2 dtc p0261 – injector 1 low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 with the engine start? – go to step 3 go to “eng...

Page 222

1f – 124 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0262 injector 1 high voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the in...

Page 223

Engine controls 1f – 125 daewoo m-150 bl2 dtc p0262 – injector 1 high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 with the engine start? – go to step 3 go to “en...

Page 224

1f – 126 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0264 injector 2 low voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the inj...

Page 225

Engine controls 1f – 127 daewoo m-150 bl2 dtc p0264 – injector 2 low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 with the engine start? – go to step 3 go to “eng...

Page 226

1f – 128 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0265 injector 2 high voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the in...

Page 227

Engine controls 1f – 129 daewoo m-150 bl2 dtc p0265 – injector 2 high voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 with the engine start? – go to step 3 go to “en...

Page 228

1f – 130 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0267 injector 3 low voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the inj...

Page 229

Engine controls 1f – 131 daewoo m-150 bl2 dtc p0267 – injector 3 low voltage step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 with the engine start? – go to step 3 go to “eng...

Page 230

1f – 132 engine controls daewoo m-150 bl2 maa1f150 diagnostic trouble code (dtc) – p0268 injector 3 high voltage circuit description the engine control module (ecm) has three individual injector driver circuits, each of which controls an injector. When a driver circuit is grounded by the ecm, the in...

Page 231

Engine controls 1f – 133 daewoo m-150 bl2 the injector resistance tested at the ecm connection is slightly more than it tested directly at the injector be- cause it includes resistance of the harness wires. The normal value is about 13.5 Ω . Dtc p0268 – injector 3 high voltage step action value(s) y...

Page 232

1f – 134 engine controls daewoo m-150 bl2 maa1f160

Page 233

Engine controls 1f – 135 daewoo m-150 bl2 diagnostic trouble code (dtc) – p0300 multiple cylinder misfire system description the engine control module (ecm) monitors the crank- shaft and camshaft positions to detect if the engine is misfiring. The ecm looks for a quick drop in crankshaft speed. This...

Page 234

1f – 136 engine controls daewoo m-150 bl2 dtc p0300 – multiple cylinder misfire (cont’d) step action value(s) yes no 6 1. Turn the ignition on, with the engine off. 2. Review the freeze frame data, and note the parameters. 3. Operate the vehicle within the freeze frame conditions and conditions for ...

Page 235

Engine controls 1f – 137 daewoo m-150 bl2 dtc p0300 – multiple cylinder misfire (cont’d) step action value(s) yes no 18 repair the open or the shorted fuel injector driver circuit. Is the repair complete? – go to step 27 – 19 repair the open ignition feed circuit between the fuel injector harness co...

Page 236

1f – 138 engine controls daewoo m-150 bl2 maa1f160

Page 237

Engine controls 1f – 139 daewoo m-150 bl2 diagnostic trouble code (dtc) – p0300 multiple cylinder misfire system description the engine control module (ecm) monitors the crank- shaft and camshaft positions to detect if the engine is misfiring. The ecm looks for a quick drop in crankshaft speed. This...

Page 238

1f – 140 engine controls daewoo m-150 bl2 dtc p0300 – multiple cylinder misfire (cont’d) step action value(s) yes no 3 perform a visual/physical inspection. Make any repairs that are necessary. Is the repair complete? – go to step 27 go to step 4 4 start the engine and allow it to idle. Are any misf...

Page 239

Engine controls 1f – 141 daewoo m-150 bl2 dtc p0300 – multiple cylinder misfire (cont’d) step action value(s) yes no 16 replace any malfunctioning fuel injectors. Is the repair complete? – go to step 27 – 17 check the affected fuel injector driver circuit at terminals 90, 58, and 89 for an open, sho...

Page 240

1f – 142 engine controls daewoo m-150 bl2 diagnostic trouble code (dtc) – p1320 crankshaft segment period segment adaptation at limit circuit description the 58x reference signal is produced by the crankshaft position (ckp) sensor. During one crankshaft revolu- tion, 58 crankshaft pulses will be pro...

Page 241

Engine controls 1f – 143 daewoo m-150 bl2 dtc p1320 – crankshaft segment period segment adaptation at limit step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “on-board diagnostic system check” 2 attempt to start the e...

Page 242

1f – 144 engine controls daewoo m-150 bl2 diagnostic trouble code (dtc) – p1321 crankshaft segment period tooth error circuit description the 58x reference signal is produced by the crankshaft position (ckp) sensor. During one crankshaft revolu- tion, 58 crankshaft pulses will be produced. The engin...

Page 243

Engine controls 1f – 145 daewoo m-150 bl2 dtc p1321 – crankshaft segment period tooth error step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Was the check performed? – go to step 2 go to “on-board diagnostic system check” 2 attempt to start the engine. Does the ...

Page 244

1f – 146 engine controls daewoo m-150 bl2 maa1f170 diagnostic trouble code (dtc) – p0327 knock sensor circuit fault circuit description the knock sensor(ks) system is used to detect engine detonation, allowing the engine control module(ecm) to retard ignition control spark timing based on the ks sig...

Page 245

Engine controls 1f – 147 daewoo m-150 bl2 dtc p0327 – knock sensor circuit step action value(s) yes no 1 perform an euro on-board diagnostic (eobd ii) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Start the engine. 2. Install a scan tool. 3....

Page 246

1f – 148 engine controls daewoo m-150 bl2 dtc p0327 – knock sensor circuit (cont’d) step action value(s) yes no 12 1. Using the scan tool, clear the dtcs. D start the engine and idle at normal operating temperature. D operate the vehicle within the conditions for setting this dtc as specified in the...

Page 247: Blank

Engine controls 1f – 149 daewoo m-150 bl2 blank.

Page 248

1f – 150 engine controls daewoo m-150 bl2 maa1f180 diagnostic trouble code (dtc) – p0335 magnetic crankshaft position sensor electrical error circuit description the 58x reference signal is produced by the crankshaft position (ckp) sensor. During one crankshaft revolu- tion, 58 crankshaft pulses wil...

Page 249

Engine controls 1f – 151 daewoo m-150 bl2 dtc p0335 – magnetic crankshaft position sensor electrical error step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 attempt to start t...

Page 250

1f – 152 engine controls daewoo m-150 bl2 maa1f180 diagnostic trouble code (dtc) – p0336 58x crankshaft position sensor no plausible signal circuit description the 58x reference signal is produced by the crankshaft position (ckp) sensor. During one crankshaft revolu- tion, 58 crankshaft pulses will ...

Page 251

Engine controls 1f – 153 daewoo m-150 bl2 dtc p0336 – 58x crankshaft position sensor no plausible signal step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 attempt to start the...

Page 252

1f – 154 engine controls daewoo m-150 bl2 maa1f180 diagnostic trouble code (dtc) – p0337 58x crankshaft position sensor no signal circuit description the 58x reference signal is produced by the crankshaft position (ckp) sensor. During one crankshaft revolu- tion, 58 crankshaft pulses will be produce...

Page 253

Engine controls 1f – 155 daewoo m-150 bl2 dtc p0337 – 58x crankshaft position sensor no signal step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 attempt to start the engine. D...

Page 254

1f – 156 engine controls daewoo m-150 bl2 maa1f190 diagnostic trouble code (dtc) – p0341 camshaft position sensor rationality circuit description the camshaft position sensor is used to detect cam- shaft position and to have correlation with crankshaft position so that the ecm can determine which cy...

Page 255

Engine controls 1f – 157 daewoo m-150 bl2 dtc p0341 – camshaft position sensor rationality step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to loc...

Page 256

1f – 158 engine controls daewoo m-150 bl2 maa1f190 diagnostic trouble code (dtc) – p0342 camshaft position sensor no signal circuit description the camshaft position sensor is used to detect cam- shaft position and to have correlation with crankshaft position so that the ecm can determine which cyli...

Page 257

Engine controls 1f – 159 daewoo m-150 bl2 dtc p0342 – camshaft position sensor no signal step action value(s) yes no 1 perform an euro on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition switch to lock....

Page 258

1f – 160 engine controls daewoo m-150 bl2 maa1f200 diagnostic trouble code (dtc) – p0351 ignition signal coil a fault circuit description the engine control module (ecm) provides a ground for the electronic spark timing 1 circuit. When the ecm re- moves the ground path of the ignition primary coil, ...

Page 259

Engine controls 1f – 161 daewoo m-150 bl2 d dtc(s) can be cleared by using the scan tool. D disconnecting the ecm battery feed for more than 10 seconds. Diagnostic aids check and correct any abnormal engine noise before using the diagnostic table. Any circuitry that is suspected as causing engine no...

Page 260

1f – 162 engine controls daewoo m-150 bl2 maa1f200 diagnostic trouble code (dtc) – p0352 ignition signal coil b fault circuit description the engine control module (ecm) provides a ground for the electronic spark timing 3 circuit. When the ecm re- moves the ground path of the ignition primary coil, ...

Page 261

Engine controls 1f – 163 daewoo m-150 bl2 d a history dtc will clear after 40 consecutive warm up cycles without a fault. D using the scan tool can clear dtc(s). D disconnecting the ecm battery feed for 10 seconds. Diagnostic aids check and correct any abnormal engine noise before using the diagnost...

Page 262

1f – 164 engine controls daewoo m-150 bl2 maa1f200 diagnostic trouble code (dtc) – p0353 ignition signal coil c fault circuit description the engine control module (ecm) provides a ground for the electronic spark timing 3 circuit. When the ecm re- moves the ground path of the ignition primary coil, ...

Page 263

Engine controls 1f – 165 daewoo m-150 bl2 d a history dtc will clear after 40 consecutive warm up cycles without a fault. D using the scan tool can clear dtc(s). D disconnecting the ecm battery feed for 10 seconds. Diagnostic aids check and correct any abnormal engine noise before using the diagnost...

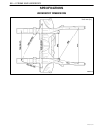

Page 264

1f – 166 engine controls daewoo m-150 bl2 maa1f210 diagnostic trouble code (dtc) – p1382 rough road data invalid (non abs) circuit description the vr sensor is used to detecting the road situation. By sensing difference of wheel rotation duration caused by bumps or potholes in the road, the engine c...

Page 265