- DL manuals

- Dimplex

- Heat Pump

- SI 100ZS

- Installation And Operating Instructions Manual

Dimplex SI 100ZS Installation And Operating Instructions Manual

Summary of SI 100ZS

Page 1

Installation and operating instructions brine-to-water heat pump for indoor installation ce order no.: 452234.67.01 fd 8511 si 50zs / si 75zs / si 100zs.

Page 2

2 contents 1 read immediately 3 1.1 important information 1.2 legal provisions and guidelines 1.3 energy-efficient use of the heat pump 2 purpose of heat pump 4 2.1 application 2.2 principle of operation 3 scope of delivery 4 3.1 baseline unit 4 accessories 5 4.1 connecting flanges 5 transport 5 6 i...

Page 3: Caution!

3 read immediately 1.1 important information any work on the heat pump may only be performed by an authorised and qualified customer service. The transport securing devices must be removed after the transport. The heat pump must not be tilted more than max. 45 ° (in either direction). Flush the heat...

Page 4

4 3 purpose of heat pump scope of delivery purpose of the heat pump 2.1 application the brine-to-water heat pump is designed for use in existing or newly built heating systems. Brine is used as the heat carrier in the heat source system. Ground coils, ground collectors or similar systems can be used...

Page 5: Caution!

5 transport 5 accessories transport caution! Caution! 4 accessories 4.1 connecting flanges the use of flat-sealing connecting flanges allows the unit, as an option, to be connected by means of flanges. For the transport by means of a hand truck or boiler trolley, position the latter under the front ...

Page 6: Caution!

6 6 7 installation mounting installation 6.1 general information as a rule, the unit must be installed indoors on a level, smooth and horizontal surface. The entire base frame should make full contact with the surface in order to ensure adequate sound insulation. Failing this, additional sound insul...

Page 7: Caution!

7 mounting 7.3 connection on heat source side the following procedure must be observed when making the connection: connect the brine line to the flow and return pipe of the heat pump. The supplied strainer must be fitted in the heat source inlet of the heat pump in order to protect the evaporator ag...

Page 8: Caution!

8 commissioning 8 caution! Commissioning 8.1 general information to ensure proper commissioning it should be carried out by a customer service authorised by the manu- facturer. Only then can an extended warranty period of 3 years in total be granted (cf. Warranty service). 8.2 preparatory steps prio...

Page 9: Caution!

9 care/cleaning 9.3 cleaning of heat source side the supplied strainer is to be install- ed in the heat source inlet of the heat pump in order to protect the evaporator against conta- mination. The filter screen of the strainer should be cleaned one day after commissioning, thereafter every week. If...

Page 10: Caution!

10 11 decommissioning 11.1 summer shutdown a heating-only system can be shut down in summer (no domestic water heating). This can be effected by means of the mode selector switch of the heat pump controller. Please follow the instructions contained in the controller's in-stallation and operating man...

Page 11

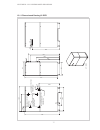

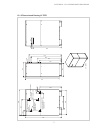

11 appendix 12 appendix 12.1 dimensioned drawings 12.1.1 dimensioned drawing si 50zs 12 12.1.2 dimensioned drawing si 75zs 13 12.1.3 dimensioned drawing si 100zs 14 12.2 equipment data 15 12.3 diagrams 12.3.1 characteristic curves si 50zs 16 12.3.2 characteristic curves si 75zs 17 12.3.3 characteris...

Page 12

12 appendix: 12.1 dimensioned drawings 12.1.1 dimensioned drawing si 50zs ( 1 : 20 ) 18 91 2 56,5 928 1348 1 290 68 2 10 0 11 30 ,5 11 2 17 7 17 70 74 9 690 11 42 12 55 15 98 17 03 20 ca . 15 00 108 31 5 2 1 /2" internal / external thread heat source heat pump inlet 1 1 /2" internal / external threa...

Page 13

13 appendix: 12.1 dimensioned drawings 12.1.2 dimensioned drawing si 75zs ( 1 : 20 ) 11 30 ,5 11 42 12 55 15 98 17 03 20 ca. 690 749 17 70 82 8 256 ,5 13 48 18 91 10 0 17 7 11 2 68 2 12 90 15 00 108 315 2 1/2" internal / external thread heat source heat pump inlet 2 1/2" internal / external thread h...

Page 14

14 appendix: 12.1 dimensioned drawings 12.2.3 dimensioned drawing si 100zs ( 1 : 20 ) 256,5 693 1348 315 10 8 15 00 11 30 ,5 11 2 17 7 68 2 1290 10 0 18 91 20 ca. 17 03 15 98 12 55 11 42 749 17 70 690 3 " internal / external thread heat source heat pump inlet 3 " internal / external thread heat sour...

Page 15

15 appendix: 12.2 equipment data equipment data equipment data for brine-to-water heat pumps for heating purposes 1 type and commercial description ..50zsn ..75zsn ..100zsn 2 model 2.1 enclosure type acc. To en 60 529 ip 21 ip 21 ip 21 2.2 installation site indoors indoors indoors 3 performance data...

Page 16

16 0 10 20 30 40 50 60 70 80 -10 -5 0 5 10 15 20 25 30 35 50 35 50 0 1 2 3 4 5 6 7 8 9 -10 -5 0 5 10 15 20 25 30 35 50 0 2 4 6 8 10 12 14 16 -10 -5 0 5 10 15 20 25 30 50 35 50 35 0 2000 4000 6000 8000 10000 0 2 4 6 8 10 0 5000 10000 15000 20000 25000 30000 35000 0 5 10 15 20 brine inlet temperature ...

Page 17

17 0 20 40 60 80 100 120 -10 -5 0 5 10 15 20 25 30 brine inlet temperature in [°c] heating capacity in [kw] 35 50 water outlet temperature in [°c] 0 5 10 15 20 25 -10 -5 0 5 10 15 20 25 30 brine inlet temperature in [°c] power consumption (incl. Power input to pump) 50 35 50 35 0 1 2 3 4 5 6 7 8 -10...

Page 18

18 0 20 40 60 80 100 120 140 160 -10 -5 0 5 10 15 20 25 30 brine inlet temperature in [°c] heating capacity in [kw] 35 50 water outlet temperature in [°c] 0 5 10 15 20 25 30 -10 -5 0 5 10 15 20 25 30 brine inlet temperature in [°c] power consumption (incl. Power input to pump) 50 35 50 35 0 2 4 6 8 ...

Page 19

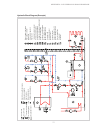

19 12.4.1 control appendix: 12.4 wiring diagrams mains system.

Page 20

20 . 0 ) 0 ; 3( 9 $& +] 1h w] / / 3( / 0 7 7 7 . ) 0 7 7 7 $ $ $ $ 1 1 12.4.2 load appendix: 12.4 wiring diagrams mains system.

Page 21

21 9 $ & + ] ) 3( ,' $7u ) / . $ ) / %& ; 5 % * * - 1 - - 5 % - % - 9'& %& *1' % % - - . Rqw dn wr iih q : 3 j hv shuuw ' lh ) xq nw lrq gh v w hq : ( lv wz lko edu (98 6 sh uu vf kw ] 7 9* 9* - - 63 5 (9 6 7 ,' ,' ,' ,' ,' ,' ,' - & 12 12 12 . $ & 9h ug l 0 0 / 3 ( 9 $ & + ] 1hw ] / ; / / 3( [[[[[...

Page 22

12.4.4 legend appendix: 12.4 wiring diagrams 22 a1 wire jumper across j5-id3>x2 must be inserted if no utility company disable contactor is used a2 wire jumper, must be removed if 2nd disable input is used a7 wire jumper in si 50/-70, in place of f18/f19 b2* pressostat low pressure, brine b3* thermo...

Page 23

23 hydraulic block diagram (example) appendix: 12.5 hydraulic block diagram immersion heater , hot water primary circulating pump heating circulating pump heating circulating pump, heating circuit 2 suppl. Circulating pump hot water circulating pump mixer , heating circuit 3 mixer , heating circuit ...

Page 24: Ec Declaration of Conformity

24 appendix: 12.6 ec declaration of conformity ec declaration of conformity ec declaration of conformity the undersigned glen dimplex deutschland gmbh division dimplex am goldenen feld 18 d-95326 kulmbach / allemagne hereby confirm that the design and construction of the product(s) listed below, in ...

Page 25

25 notes.

Page 26

26 notes.

Page 27

27 notes.

Page 28

28 glen dimplex deutschland gmbh subject to technical modifications division dimplex fax +49 92 21 709-589 am goldenen feld 18 www.Dimplex.De d-95326 kulmbach.