- DL manuals

- E.C.A.

- Boiler

- Fortius

- Service manual

E.C.A. Fortius Service manual

Summary of Fortius

Page 1

24 kw open flued gas combination boiler (bithermic type) 24 kw room sealed fan assisted gas combination boiler (bithermic type) 24 kw room sealed fan assisted gas combination boiler (monothermic type) 28 kw room sealed fan assisted gas combination boiler (monothermic type) service manual.

Page 2: Contents

Contents product product notation safety systems technical data main components operating functions gas type conversion gas pressure adjustments replacement of the burner injectors jumper adjustment adjustments service setting mode chimney sweep push-button pb4 fault & failure 1.

Page 3

Product product notation table 1 notation description fo 24 bb f ortius 24 kw open flued gas combination boiler (bithermic type) fo 24 hb f ortius 24 kw room sealed fan assisted gas combination boiler (bithermic type) fo 24 hm f ortius 24 kw room sealed fan assisted gas combination boiler (monotherm...

Page 4

3 table 2 fo 24 bb fo 24 hb fo 24 hm fo 28 hm unit gas category* boiler type type of gas performances p min , min. Heat output p maks , max. Heat output p %80 , heat output q min , min. Thermal load q maks , max. Thermal load q %80 , thermal load gas consumption** natural gas (max. Load) natural gas...

Page 5

Main components table 3a fo 24 bb fo 24 hb 1 microcontroller board bitermic (main board) microcontroller board bitermic (main board) 2 user interface user interface 3 gas valve gas valve 4 burner (13 blade) burner (13 blade) 5 24 kw heat exchanger (bithermic) 24 kw heat exchanger (bithermic) 6 hydro...

Page 6

5 table 3b fo 24 hm fo 28 hm 1 microcontroller board monotermic (main board) microcontroller board monotermic (main board) 2 user interface user interface 3 gas valve gas valve 4 burner (13 blade) burner (15 blade) 5 24 kw heat exchanger (monothermic) 28 kw heat exchanger (monothermic) 6 hydroblock ...

Page 7

Microcontroller board (main board) 1 the main board operates on 230 vac, 50 hz and drives gas valve, fan, pump and (in monothermic types) 3 way electric valve. Dynamic air pressure test takes place before every ignition cycle. Limit thermostat ensures extra safety level. Flame in the burner is check...

Page 8

Wiring diagrams 7 fig. 1a.

Page 9

8 fig. 1b.

Page 10

9 fig. 1c.

Page 11

10 tablo 4 technical and functional specifications general power supply range: 230 vac -15% +10% power supply frequency: 50 hz ± % 2 power consumption: 5 va max. Admitted humidity: 90% @ 40 °c (non condensing) working temperature range: -20 °c … 60 °c electrical rating fusing: 2a fan output: 230 vac...

Page 12

Tablo 4 technical and functional specifications timing pre purge time: 0 sec waiting time: 0 sec pre ignition time: 2 sec safety time: 7 sec number of retrials: 5 flame failure response time: 1 sec post ignition time: 0,4 sec post purge time: 0,8 sec pump over-run time: a) for dhw - monothermic&wint...

Page 13

Tablo 4 technical and functional specifications other specifications nr. Of electrodes: 2 for flame ignition and one for detection flame sensing cable and spark cable: max. 0,5 m external components (except heat demand): max 0,5 m remote reset: max. Of 5 reset in 15 minutes ch water set temperature ...

Page 14

13 fig. 2 gas valve burner 3 the gas coming from the gas valve is fired in the burner. 13 blade burners are used in 24 kw boilers while 15 blade burners are used in 28 kw boilers. Some of the common specifications of these two burners are shown in the table below. Table 6 burner injector (nozzle) di...

Page 15

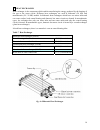

Heat exchanger 4 heat exchanger is the component which enables transferring the energy produced by the burning of the gas to the water circuit. Different heat exchangers are used in bithermic (24 kw) and monothermic (24 / 28 kw) models. In bithermic heat exchangers which have two water inlets and tw...

Page 16

Fig. 4b monothermic heat exchanger hydroblock 5 two different types of hydroblocks are used in bithermic and monothermic types. Hydroblock consists of different components depending on the boiler model. The bithermic hydroblock has pump, pressure relief valve (3 bar), discharge tap, filling tap, wat...

Page 17

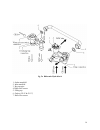

Fig. 5a bithermic hydroblock 1 outlet manifold 2 inlet manifold 3 by-pass pipe 4 water flow sensor 5 filling tap 6 gasket (g3/4” & g1/2”) 7 hall effect sensor 16.

Page 18

Fig. 5b monothermic hydroblock 1 3 way electric valve 2 inlet manifold 3 by-pass pipe 4 water flow sensor 5 filling tap 6 valve motor 7 valve motor clip 8 hall effect sensor 9 bolt 10 oring 11 by-pass pipe clip 17.

Page 19

Pump 6 pump enables the central heating water circulation in monothermic and bithermic types. Also in monothermic types, it enables heating the domestic water passing through the plate heat-exchanger by causing the central heating water short circuit circulation. Pump is located on the hydroblock an...

Page 20

Pressure relief valve (3 bar) 7 pressure relief valve (3 bar) protects the central heating circuit and the appliance against increasing pressure. When the pressure in the central heating circuit is over 3 bars, the relief valve functions and decreases the pressure (the outlet tap of the 3 bar relief...

Page 21

20 fig. 9 water pressure switch plate heat-exchanger 11 plate heat-exchanger is the secondary heat-exchanger used in monothermic types for heating the domestic water. In need of domestic hot water, the 3 way electric valve sends the central heating water from the primary heat-exchanger to the plate ...

Page 22

Fig. 11 water flow sensor central heating and domestic hot water (ntc) temperature sensors 13 the central heating and domestic hot water temperature sensors are ntc (negative temperature coefficient) type. In ntc sensor, temperature and sensor resistance are inversely proportional; the sensor resist...

Page 23

Table 14 the r-t relation of the ntc sensors t ( o c) temperature r ( Ω) resistance α (1/ o c) sensitivity -20 98660 -5,8 % -10 56250 -5,4 % 0 33210 -5,1 % 10 20240 -4,8 % 20 12710 -4,5 % 25 10170 -4,4 % 30 8194 -4,3 % 40 5416 -4,0 % 50 3663 -3,8 % 60 2530 -3,6 % 70 1782 -3,4 % 80 1278 -3,2 % 85 108...

Page 24

Limit thermostat 15 the limit thermostat used is bimetal type. When water ch from the heat-exchanger exceeds 105°c, the limit thermostat opens and cuts the signal sent to the main board and ensures safety. When the water temperature is below 75 °c, the limit thermostat closes enabling the boiler to ...

Page 25

Differential air presssure switch (aps) 17 differential air pressure switch is used in room sealed fan assisted models. It controls the air flow by measuring the pressure differences of the clean air required for burning and flue gas. In case of problems like blockage in the air/flue kit or a strong...

Page 26

25 fig. 17 ttb temperature sensor table 17 the r-t relation of the ttb sensor t ( o c) temperature r ( Ω) resistance α (1/ o c) sensitivity -20 97060 -5,8 % -15 72940 -5,6 % -10 55319 -5,4 % -5 42324 -5,3 % 0 32654 -5,2 % 5 25396 -5,1 % 10 19903 -4,8 % 15 15714 -4,7 % 20 12493 -4,5 % 25 10000 -4,4 %...

Page 27

Fan 19 fan enables taking the clean air required for combustion to the combustion chamber and disposing of flue gas in room sealed fan assisted boilers. Table 18 fan maximum power 55w interior diameter of silicon hose connected to aps 5 mm fig. 18 fan termomanometer 20 termomanometer displays the wa...

Page 28

Modes of operation a) stand-by mode: when there is no heat demand for central heating or domestic hot water. B) domestic hot water (dhw) mode: when there is need for dhw (hot water tap is opened), the hall effect sensor on the water flow sensor detects the water flow and signals the main board for d...

Page 29

- domestic hot water can be obtained between 35°c and 60°c. - domestic hot water safety temperature is 75°c. If the temperature detected by dhw sensor is above 75°c, dhw operation will stop (burner goes off). - dhw operation is possible even if ch anti-cycling time is active. - during dhw operation,...

Page 30

- when there is ch demand, ignition starts and ignition state continues until flame is present. - when the ignition state is over, the boiler will operate in normal modulation and reach the set point within the time defined with slope (°c/min). After that, modulation continues. - if the central heat...

Page 31

- bithermic & winter mode: pump runs for the defined over run time (3sec). This is for transferring the remaining energy to the ch circuit. - bithermic & summer mode: if the temperature detected by the ch temperature sensor is more then 75°c, the pump will run for 1 sec., otherwise it will not run. ...

Page 32

Gas type conversion : gas type conversion from lpg to natural gas or from natural gas tolpg must be carried out only by qualified person. - gas type conversion can be divided in 3 sections: gas pressure adjustments, replacement of the burner injectors and jumper adjusment. Gas pressure adjustments t...

Page 33

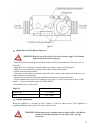

Fig. 19 replacement of the burner injectors warning:keep the gas valve on the boiler and electricity supply closed during replacement of the burner injectors. - shut off the boiler by turning the on/off switch to off position and turn off the gas valve on the boiler. - undo the 2 screws which are lo...

Page 34

Warning: in case of gas leak, fire or explosion hazard, property damage, severe injury or death can happen. Therefore, gas leak test must be performed by qualified person after gas type conversion. ¨ gas leak test ¾ apply a rich soap and water solution to the surface of all pipe connections. Bubbles...

Page 35

Adjustments led’s have 6 different signals. The definitions: • on • off • slow blink: 0.75 sec on - 0.75 sec off • fast blink: 0.10 sec on - 0.40 sec off • change blink: 0.75 sec on - 0.25 sec off (it seen when adjusting service setting parameters) • update blink: 0.15 sec on - 0.15 sec off (it seen...

Page 36

Table 22 7 segment display 1st 2nd after pressing pb3 twice after pressing pb2 progressively description 88 1 st press:flame current 88 2 nd press: modulation level 88 3 rd press: dhw flow frequency 88 4 th press: flue temperature (for room sealed type, it's fixed as 25) 88 5 th press: ttb calculate...

Page 37

36 - after the 11 th press pb2, the display goes back to “ l 2 ” . - if pb3 is pressed continuously more than 5 seconds, all led blink three times and the parameters are set to the factory defaults (minimum power, maximum power, ignition power, anti-cycling time, dhw on-off flow rate, otc curve foot...

Page 38

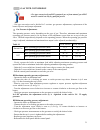

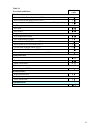

Table 24 parameters no definition range default 1 ch water set temperature range ( o c) 40 – 80 - 2 dhw set temperature range ( o c) 35 – 60 - 3 minimum power (%) 0 – 30 3 4 maximum power (%) 80 – 100 100 5 ignition power (%) 20 – 70 50 6 anti-cycling time (min) 0 – 15 3 f1: on=3 off= 2,5 - 7 dhw on...

Page 39

Chimney sweep push-button pb4 chimney sweep push-button pb4 has two functions: a) to activate the chimney sweep mode, b) to activate the minimum and maximum running mode without modulation. Chimney sweep mode a - if the push-button pb4 is pressed more than 3 seconds and less than 5 seconds, chimney ...

Page 40

Running mode selection is active. L1 l2 l3 7 segment display l7 l8 l9 on off 88 fast blink off fast blink or running mode selection is active. L1 l2 l3 7 segment display l7 l8 l9 on off 88 off fast blink fast blink fig. 22a - turn the ch potentiometer the minimum position, led l7 and l9 start blinki...

Page 41

Fig. 22e fault & failure stand – by l1 l2 l3 7 segment display l7 l8 l9 on off off 88 off off off several checks are included to protect the boiler and its environment. In case of error condition, the error code is displayed by 7 segment display (table 26), and heat demands will be disabled. ¨ error...

Page 42

Table 26 error/fault definitions error/fault codes flue gas circuit break in flue safety device (ntc) t 6. Short circuit in flue safety device (ntc) t 6 flue safety device (ntc) shuts system off because of flue gas leakage t 2 air flow aps open e 4 aps closed e 5 temperatures over-temperature failur...