- DL manuals

- E.C.A.

- Boiler

- Proteus Plus

- Installatio And User's Operating Instructions

E.C.A. Proteus Plus Installatio And User's Operating Instructions

Summary of Proteus Plus

Page 1

Plus 23,3 kw room sealed fan assisted gas combination boiler (monothermic type) installation and user’s operating instructions.

Page 2

...-- .I contents preface guarantee & service symbols' definitions safety instructions and warnings product general specifications product notation technical data l j boiler packaging installation selection of the boiler location mounting the boiler connections flue connection gas supply & water sys...

Page 3

Preface proteus plus 23,3 kw room sealed fan assisted gas combination boilers have been designed for providing efficient, safe and comfortable central heating (ch) and domestic hot water (dhw). The boilers are supplied for use with either natural gas or lpg. This manual contains installation and use...

Page 4

Safety instructions and precautions this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person re...

Page 5

Boiler start-up boiler start-up must be performed certainly by qualified person. gas type (natural gas/lpg), gas supply pressure (mbar), maximum dhw operating water presure (bar) and electricity supply voltage (v) data which are detailed on the information plate must be suitable with mains suppl...

Page 6

Plate heat exchanger makes hot water more efficient in monothermic types. The safety systems in your appliance provide entire safety for you and your appliance. The safety systems are: flue gas safety system flame failure safety system over-heat safety system (105 0 c) dhw (domestic hot water) over-...

Page 7

Kw kw kw m 3 /h o c o c watt kg for gas consumption calculation ; natural gas: hu=9,59 kwh/m 3 lpg: hu=12,793 kwh/kg *the following gas categories can also be used 6 prp 24 hm gas categories ii 2h 3b/p ii 2e 3b/p ii 2e+ 3+ table 2.2 prp 24 hm unit gas category * boiler type type of gas performances ...

Page 8: Prp 24Hm

D wi r i ng di agram prp 24hm i ill f el 12 1 15 l_, i i c n s . 8 e::::::::l c::::::::j cn1 4 . . . . T n f 22 1 2 3 4 5 ma i n board supply cable electr i c 3 way valve gasvalve fan pump 9 outs de temp e rature sensor (optio n al ) 10 dhw f l ow se n s or 11 dhw temperatur e s e nsor 1 2 d i ffere...

Page 9

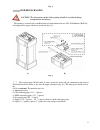

Fig. 1 boiler packaging caution: the instructions on the boiler package should be considered during transportation and storage. - the product is covered with a cardboard box of which dimensions are 867x 470x400 mm (hxwxl) and supported by upper and lower styrofoams (fig. 2a). A) b) fig. 2 the requir...

Page 10

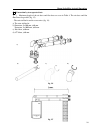

- for room sealed fan assisted operation, apart from the boiler package, concentric air/flue kit ( 60/100) is given with a cardboard box. Air/flue kit consists of the following parts: a) flat sealing ring b) flange c) 90 0 concentric elbow d) screws e) fixing collar f) sealing ring, epdm g) concen...

Page 11

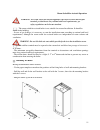

Installation selection of the boiler location the boiler must be installed in accordance with gas safety regulations and relevant standards. Additionally, the clearances around the boiler should be as shown in fig. 4 in order to make service, maintenance and usage easier. fig. 4 indicates minumum ...

Page 12

Room sealed fan assisted operation warning: for room sealed fan assisted appliance, the boiler location and air/flue terminal position must obey national and local requirements, gas safety regulations and relevant standarts. The room sealed fan assisted boiler is not suitable for external installati...

Page 13

Fig. 7 connections flue connection 3 different types of air/flue system can be designed for 23,3 kw room sealed fanned assisted boilers: a) the air/flue system is designed by horizontal concentric ducts. B) the air/flue system is designed by two separate ducts. C) the air/flue system is designed by ...

Page 14

Fig. 9 room sealed fan assisted operation fig. 10 if the air/flue kit length is insufficient, additional flue accessories qualified service. Do not use any other type / brand name of flue parts. Should be ordered through - horizontal air/flue kit accessories (fig 11): a) concentric extension, l=500 ...

Page 15

Room sealed fan assisted operation the total length of horizontal air/flue system must not exceed 3 m. Furthermore, each extra 90 0 concentric elbow or two pieces of 45 0 concentric elbow decreases the maximum length 1m (fig. 12). The maximum number of 90 0 elbow to be used is 3. A) b) c) fig. 12 14.

Page 16

Room sealed fan assisted operation mounting the restrictor: the restrictor should be mounted on the fan outlet according to the length of the air/flue connection to provide efficient combustion and suitable combustion products. Table 3 (mm) fig. 13 15 product elbow l (m) l max (m) restrictor prp 24 ...

Page 17

Room sealed fan assisted operation connection by two separate ducts maximum length of the air ducts and flue ducts are seen in table 4. The air ducts and flue ducts must be parallel (fig. 15). - the twin air/flue kit and its accessories (fig. 14): a) the twin air/flue kit b) extension, l=500 mm, 80...

Page 18

Room sealed fan assisted operation table 4 (mm) connection by vertical concentric ducts vertical flue connection can be designed by 60/100 mm or 80/125 mm concentric ducts. The total length is 3 m for 60/100 mm vertical air/flue system and 8 m for 80/125 mm vertical air/flue system. Furthermore,...

Page 19

Room sealed fan assisted operation table 5 the restrictors for 60/100 mm concentric ducts (mm) in the use of 80/125 mm concentric ducts, - up to 2 m length, the same restrictors (shown in table 5) should be used - between 2m and 8m, no restrictor should be used. A) b) c) sample connections by 60/...

Page 20

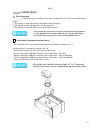

Gas supply & water systems (optional) - water & gas connections between the boiler and the mounting bracket can be fixed with the optional pipes and the nipples as shown in fig. 18. 1\!Iou n ting bracket nipp l e (3 / 4" t b t c t e t d a fig. 18 a) ch flow 3/4" b) dhw outlet 1/2" c) gas inlet 3/4" ...

Page 21

Electricity supply electrical installation should be made according to the national and local instructions. The boiler must be earthed and a standard 230 v ac - 50 hz supply is required. Warning: disconnect power supply to prevent electrical shock before connecting the electricity supply. Warning: i...

Page 22

Boiler start-up final checks and operations : having completed the installation and connections (flue, electricity supply, gas supply and water circuits) of the boiler according to the authorized gas company regulations and relevant standards, the final checks and operations must be carried out by q...

Page 23

2 ) the filling tap is not available in some models based on national and local regulations. Ii control panel the control panel shown in fig. 20 consists of the following parts as detailed below. Fault & error led manometer status potentiometer central heating potentiometer fig.20 domestic hot water...

Page 24

[!] error i reset mode - error code and error led will be flashing countinusly if the errors cause a lock out condition, tum to status (pl) to reset" e "position and hold it for 5 sec. To get to the normal operation (winter or summer) mode again. [!] monometer ch operating water pressure can be read...

Page 25

- in case of failed ignition, automatic ignition sequence is repeated 5 times. If all ignition trials are failed, flame failure lockout happens. Error led (red) will turn on and blink to indicate this error condition (fig.22). Turn status ’s knob to the reset “ ” position and hold it for 5 sec. To g...

Page 26

- rotate the ch to minumum position. The summer mode will be active and the system will go back to stand-by mode again. Frost protection the appliance goes on and off automatically depending on actual water temperature values measured by the sensors for protecting water circuits against freezing. Th...

Page 27

Fig. 21 programming the unit - set the right sliding button to p. - see the program number that you want to set while pressing p button. (if the program to be set is startup program, sign will appear. 1,3,5,7,9,11,13,15 are startup programs; 2,4,6,8,10,12,14,16 are shutdown programs) - set the day o...

Page 28

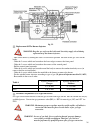

Gas pressure adjustments the operating pressure varies depending on the type of gas. Therefore, minumum and maximum operating gas pressure must be set by means of the adjusment screws that are on top of the gas valve. The heat output directly depends on the operating pressure. When the operating gas...

Page 29

Fig. 22 replacement of the burner injectors warning:keep the gas valve on the boiler and electricity supply closed during replacement of the burner injectors. - shut off the boiler by turning the status to off-reset position and turn off the gas valve on the boiler. - undo the 2 screws which are loc...

Page 30

.. Gas leak test );- apply a rich soap and water solution to the surface of all pipe connections. Bubbles indicate a gas leak );- );- );- in case of gas leak, tighten the pipe connection. Check the pipe connection again for gas leak. Replace the part/parts if gas leak can not be stopped. A caution: ...

Page 31

Table 11 cc: when the power supply is switched on “ ” showed on lcd display means outside temp. Sensor correctly disconnected and the function enabled. Oc: when the power supply is switched on “ ” showed on lcd display means outside temp. Sensor correctly connected and the function enabled. 30 fault...

Page 32

Maintenance - the boiler should be checked and serviced for general maintenance once a year. Maintenance and service operations must be carried out only by qualified person. - only a damp cloth should be used for cleaning the outer space of the boiler and then the surfaces should be dried completely...

Page 33

23,3 kw gas combination boilers’ capacity & operating gas pressure diagrams for (lpg) propan all rights reserved product specifications are subject to change without notice. Manufacturer : emas makİna sanayi a.Ş. Organize sanayi bölgesi mustafa kemal bulvarı no:13 manİsa pbx: +90 236 213 00 21 fax: ...