- DL manuals

- E.C.A.

- Boiler

- SCOT SC 24 HM

- Installation And User Manual

E.C.A. SCOT SC 24 HM Installation And User Manual

Summary of SCOT SC 24 HM

Page 1

High efficiency condensing boiler scot sc 24 hm installation and user’s operating instructions e.C.A. Call center 444 0 322.

Page 2: İçindekiler

İÇİndekİler preface ...........................................................................................................................................................................................................................................................................................

Page 3: Introduction

1 introduction e.C.A. Scot 24 kw condensing boilers have been designed for an efficient, safe and comfortable central heating and domestic hot water requirement. Scot 24 kw condensing boilers have the ability to operate with natural gas or lpg. The assembly and usage information of 24 kw scot conden...

Page 4

2 safety instructions and precautions safety instructions when a gas leak is found or suspected; - turn off the gas valve of the boiler and the valves of all other devices operating with gas. - shut off the stove, oven and similar appliances to put their flame out. - do not light matches, lighter et...

Page 5: Product

3 escaping into the installation room. • after boiler start up, you should request information about operating the boiler and safety precautions from qualified person. Usage and maintenance • read carefully instructions and precautions in this manual against wrong usage which causes unsafe condition...

Page 6

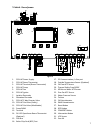

4 1. Stainless steel exchanger 2. Air / gas manifold 3. Frequency controlled fan 4. Pump 5. Hydraulic circuit – flow manifold 6. Gas valve 7. Water pressure sensor 8. Central heating outlet ntc temperature sensor 9. Central heating return ntc temperature sensor 10. Turbine 11. Air/gas mixer 12. Manu...

Page 7

5 notations of product notasyon açıklama sc 24 hm e.C.A. Scot high efficiency condensing boiler - 24 kw central heating output (60/80 0 c) - 26 kw domestic hot water output (60/80 0 c) technical data scot high effieciency condensing boilers are suitable for only room sealed (c type) operation. C typ...

Page 8

6 sc 24 hm unit gas category ii 2h 3b/p type c13(x), c33(x), c43(x), c53(x). C63(x). C83(x) gas type g20 g30/g31 central heating ch min. Heat output (80/60 0 c) 4,8 4,8 kw ch max. Heat output (80/60 0 c) 24,1 24,1 kw ch min. Heat output (50/30 0 c) 5,3 5,4 kw ch max. Heat output (50/30 0 c) 26,6 26,...

Page 9

7 elektrik devre Şeması 6 7 m 9 v1 v2 1 2 4 5 3 8 10 11 12 14 13 17 13 18 20 19 15 16 21 22 23 24 25 26 27 28 29 30 31 32 x1a x1b x2a x2b x2c x3a x3b x4a x4b x4d x4c x5 x6 x7 x8a x8b x8c x8d x8e x8f mv sr/ys kh mv pm by gr sr tr sy kr kr tr tr kr ys ys mv mv kh kh pm gr sr kr sy by n l n l n l n l n...

Page 10: Boiler Packaging

8 the pieces required for the assembly of the device (wall bracket, 5 gaskets for water and gas connections, screws) are placed on the top styrofoam. The other parts which seen in the fig 2b are optional. Optional parts are. • mounting bracket • ch connecting pipes (3/4’’, 2 units) • dhw connecting ...

Page 11

9 1. 90° concentric elbow 2. Flue gas plug 3. Air inlet plug 4. Sealing ring Ø 60 5. Sealing ring Ø 100 6. Extension pipe 7. Screws 8. Flange 9. Bolt and nut 10. Flat sealing ring 11. Concentric terminal (Ø 60/ Ø 100) 12. Inner flange (epdm) 13. Outer flange (plastic) - hermetic flue set is delivere...

Page 12: Installation

10 installation selection of the boiler location the boiler must be installed in accordance with gas safety regulations and relevant standards. Additionally, the clearance around the boiler should be as shown in fig 4. In order to make service, maintenance and usage easier. Figure 4: indicates the m...

Page 13

11 c type (hermetic) devices are not suitable for external environment installation. It should be within in the building. The air/flue terminal must be exposed to the external air and allow free passage of air cross it at all times. • the flue ducts are always wet. • under cold or excessive humid we...

Page 14

12 mounting the boiler having determined the boiler location, • the points of lock screws of wall bracket and assembly bracket are marked by using the assembly template inside installation and user’s operating instructions of the device (pages 40-41). The mounting bracket is an optional part. • afte...

Page 15: Connections

13 connections condensate connection • all condensing boilers generate condensing discharge. The amount of the condensate water depends on the working conditions of your appliance. This can be up to 1.7 litres condensate water an hour. - the plastic pipe should be fixed to the outlet pipe of the sip...

Page 16

14 flue connection 3 different types fo air/flue system can be designed for scot high efficiency condensing boiler. In a) the air/flue system is designed by horizontal concentric ducts b) the air/flue system is designed by vertical concentric ducts c) the air/flue system is designed by two separate ...

Page 17

15 figure 8 • lubricate the internal part of the seals before the assembling. Oils and greases are not suitable for the “epdm”. A correct lubrication using silicon – substances is advised. If the length of the flue is insufficient, additional flue accessories should be ordered through qualified serv...

Page 18

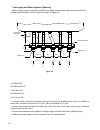

16 total length of horizontal air/flue system set shouldn’t exceed b=13m for sc 24 hm. Furthermore, each extra 90° concentric elbow or two pieces of 45° concentric elbow decreases the maximum length 1 m. Figure 9 l 1 l 2 l 3 l max =l 1+ l 2+ l 3 =b-1 lmax = b l max = l 1 +l 2 = b - 1 l 1 l 2 a) b) c...

Page 19

17 b) connection by vertical concentric ducts -the standard vertical air/flue kit is showed in figure 10. A) concentric vertical adapter with flange (Ø60/100 mm) 7006951718 - flat sealing ring - sealing ring epdm (Ø60 mm) - seal ring epdm (Ø100 mm) b) vertical concentric terminal (Ø60/100 mm) 700695...

Page 20

18 l 1 l 2 m in .3 70 m m l max =l 1 +l 2 =c-0,5 if the air/flue kit length is insufficient, additional flue accessories can be ordered. - vertical air/flue kit accessories (Ø60/100 mm) a) concentric extension l=500 mm (Ø60/100 mm) 7006951561 - concentric extension l= 1000 mm (Ø60/100 mm) 7006951562...

Page 21

19 figure 13 c) connection by two separate ducts (twin pipe) - there are two different standard twin air/flue kits: the twin air/flue kit - 1: air inlet flue gas outlet terminals through the wall (figure 13). 7006951727 a) twin adapter with sampling point (with measurement plug) (Ø 80 - Ø 80 mm) - 2...

Page 22

20 the twin air/flue kit - ii: air inlet duct through the wall and flue gas outlet through the roof (figure 16). A) double flue adaptor (Ø 80 - Ø 80mm) - two units of seal epdm (Ø mm) b) air inlet terminal l= 939 mm (Ø80 mm) c) flue gas outlet terminal l= 1380 mm (from Ø 80 mm to Ø 80/125) d) 90° co...

Page 23

21 if the length of the flue set is insufficient, additional flue accessories should be ordered from qualified services. Do not use flue set parts of different brands and types. - the twin kit accessories (figure 16) a) concentric extension l= 500 mm. Ø80 mm 7006951285 concentric extension l= 1000 m...

Page 24

22 gas supply and water systems (optional) - water and gas supply connections between the boiler and the mounting bracket can be fixed with the optional pipes and the nipples as shown in figure 18. A) ch flow 3/4’’ b) dhw outlet 1/2’’ c) gas inlet 3/4’’ d) dhw inlet 1/2’’ e) ch return 3/4’’ - a suit...

Page 25

23 electrical connection electrical installation should be made according to the national and local instructions. The boiler must be earthed and a standard 230 v ac – 50 hz supply is required. Room thermostat (optional) one of the optional room thermostats compatible with you device may be used in o...

Page 26

24 • cancel the bridge on the other side on room thermostat connection. • only the room thermostats deemed to be appropriate by authorized services of e.C.A. Should be used on your boiler. Otherwise, it may cause the malfunction of your device. Responsibility is not undertaken under such conditions....

Page 27: Commissioning

25 • having completed the installation and connections (condensate, flue, electricity supply, gas supply and water circuits) of the boiler according to the authorized gas company regulations and relevant standards, the final checks and operations must be carried out by qualified person. 1)filling th...

Page 28

26 caution: in order to prevent the calcification of the exchanger, it is recommended for you to use well water, natural spring water etc except the mains water. 2) open hot water tap to check dhw circuit. Check any leakage in water pipes. 3) check whether flue kit is comprised of original parts or ...

Page 29: Bar

27 1) dhw temperature control potantiometer the dhw knob has two functions: • to turn on/off to the boiler • to set dhw temperature between 35°c to 60°c. 2) display panel: a lcd display having white symbols on black background has been used on the display panel. • lcd display: operations modes, actu...

Page 30

28 3) central heating circuit water temperature potantiometer the ch knob has two functions: • to select summer/winter mode • to set ch temperature between 35°c to 80°c. 4) buttons a) reset button has two functions: - to reset locking the system. - to cancel or exit existing operations. (esc) b) i b...

Page 31: Bar

29 2) starting up the appliance and adjustment of domestic hot water (dhw) position: to start up the boiler, turn dhw knob to requested dhw set temperature. Lcd display will turn on and power on sequence will be monitored for several seconds. While the central heating circuit is closed and the domes...

Page 32: Bar

30 4) position of central heating circuit: in order to activate winter position, in other words the central heating circuit on the boiler, you can set the temperature of exiting water in between 30-80°c through the adjustment knob. The set value is seen on the lcd display, the ignition operation aut...

Page 33: Bar

31 6) service position: when it is set to service position by the authorized service, the service icon on the display panel indicates its activation through blinking. - it becomes activated when it is pressed for 5 seconds on the “eco” and “reset” button on the control panel of your device. - when t...

Page 34

32 8) pump and 3 way valve blockage protection function: blockage protection protects the pump against blockage in cases when the pump is not in use for a long period. This function enables the pump to be operated for a few seconds in ch position when the pump is not operated within the recent 24 ho...

Page 35: Gas Conversion

33 figure 30 gas conversion gas conversion operation from lpg to natural gas or from natural gas to lpg should be performed by authorized service. If the user requests gas transformation after purchase of the device, it is subject to a fee. Gas conversion operation consists of two main operations. 1...

Page 36

34 danger: after conversion, gas conversion label should be affixed near the information label of the product. Danger: as there is the danger of fire, explosion, severe injury or death as the result of gas leakage, the gas leakage test after conversion operation should be performed by authorized ser...

Page 37

35 gas leakage test: • apply the foam obtained by soapy water on all the gas pipe connections. Arise of bubbles indicates gas leakage on the connection. • in case of determination of gas leakage, tighten that connection, and recheck it by applying foam on the connections. • if the gas leakage persis...

Page 38

36 error code error type possible cause solution reaction error type er 03 flue temperature lockout if the flue temperature sensor (ntc) course an over temperature regarding the parameters swe03 overheat flue temperature (lock-out) / swe04 overheat flue temperature (blocking). (the limit temperature...

Page 39

37 scot er 61 ion control deviation press on reset button. If error is continuing after reset inform e.C.A. Authorized service. Warning er 62 scot actuators press on reset button. If error is continuing after reset inform e.C.A. Authorized service. Warning er 63 scot system error internal scot syste...

Page 40

38 er 64 er 65 er 66 er 74 calibration error press on reset button. If error is continuing after reset inform e.C.A. Authorized service. Locking er 67 ion base value invalid ion base value outside factory limits or saved incorrectly. Press on reset button. If error is continuing after reset inform e...

Page 41: Standards / Instructions

39 standards / instructions in addition to the warnings and instructions regarding the installation and usage of the device which is described in this manuel, it should be conformed to all laws, regulations, standards and instructions of local gas company regarding the devices operating with gas. Al...

Page 42: Mounting Template

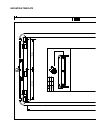

187.5mm 187.5mm 3/4" 3/4" 3/4" 1/2" 1/2" 65 mm 195 mm 65 mm 65 mm 65 mm 187.5mm a b 65mm 187.5mm b a ( ) 100 mm 125 mm 181 mm 166 mm ( ) 840 mm optional mounting template.

Page 43

187.5mm 187.5mm 3/4" 3/4" 3/4" 1/2" 1/2" 65 mm 195 mm 65 mm 65 mm 65 mm 187.5mm a b 65mm 187.5mm b a ( ) 100 mm 125 mm 181 mm 166 mm ( ) 840 mm optional.

Page 44

42.

Page 45

Seller company product’s title : ...................................................................................... Address : ...................................................................................... ......................................................................................

Page 46

Production emas makİna sanayİ a.Ş. Organize sanayi bölgesi 3. Kısım mustafa kemal bulvarı no: 13 45030 manİsa phone : +90 236 213 00 21 fax : +90 236 213 08 59 email: emas@emas.Com.Tr www.Emas.Com.Tr sales emas makİna sanayİ a.Ş. Yalı mah. Ziya gökalp cd. No:3 34844 maltepe / İstanbul phone : +90 21...

Page 47

Production emas makİna sanayİ a.Ş. Organize sanayi bölgesi 3. Kısım mustafa kemal bulvarı no: 13 45030 manİsa phone : +90 236 213 00 21 fax : +90 236 213 08 59 email: emas@emas.Com.Tr www.Emas.Com.Tr sales emas makİna sanayİ a.Ş. Yalı mah. Ziya gökalp cd. No:3 34844 maltepe / İstanbul phone : +90 21...

Page 48: Certifica

Provided that the e.C .A. Combi boilers are used as specified in the user’s guide; 1- the warranty period starts as from the date of delivery of product, and it is 3 years . 2- all the product inc luding all its parts are under the warranty of our compan y. 3- in case of malfunction of the product wi...