- DL manuals

- E-COMPACT

- Boiler

- 15

- Installation & Operation Manual

E-COMPACT 15 Installation & Operation Manual

Summary of 15

Page 1

Installation & operation manual e-compact 18 slim / e-compact 15 wood pellet boiler woodenergysolutions.Co.Uk v.1.0 09/13.

Page 3

Contents contents ecompact slim page 1 1. Introduction 2 2. Warnings and guarantee / warranty information 3 2.1 safety instructions 3 2.2 operating warnings 4 2.3 guarantee / warranty information 4 2.3.1 limitations 5 2.3.2 exclusions 5 2.4 the clean air act 1993 6 3. Pre-installation considerations...

Page 4

1. Introduction dear customer, we wish to thank you for choosing this ecompact pellet boiler product from wood energy solutions (wes). In order to get the best performance from your appliance we recommend that you read this booklet carefully before lighting the appliance for the first time. While th...

Page 5

2. Warnings and guarantee /warranty information 2.1. Safety instructions • installation of the boiler, making the electrical connections, checking its operation, and maintenance are all tasks which should be carried out by qualified and authorised personnel. • install the boiler in accordance with t...

Page 6

2.2. Operating warnings • shut the appliance down in the event of a breakdown or bad running. • pellets must not be fed manually into the burner. • accumulated un-burnt pellets in the burner after repeated failed ignitions must be removed before re-lighting. • do not wash the inside of the heat exch...

Page 7

Date on which the commissioning took place. The guarantee is conditional on the commissioning report being filled in and returned to the manufacturer within 10 days, and requires that the product be installed and commissioned by an approved wes installer according to the detailed instructions given ...

Page 8

Ecompact slim page 6 warnings & guarantee conditions © wood energy solutions woodenergysolutions.Co.Uk “the clean air act 1993 and smoke control areas” under the clean air act local authorities may declare the whole or part of the district of the authority to be a smoke control area. It is an offenc...

Page 9

3. Pre-installation considerations 3.1. Pellets wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the working of natural dried wood. The compactness of the material comes from the lignin which is contained in the wood itself, and allows the production of pell...

Page 10

Wes recommends using certified fuel in its appliances to enplus-a1. The use of fuel of inferior quality or not conforming to the specification given above compromises the running of your appliance and can therefore lead to the termination of the guarantee and of the manufacturer's responsibility for...

Page 11

3.3 operating area for proper functioning, the appliance should be positioned in a location where it is able to take in the air necessary for combustion of the pellets (about 40 m3/h must be available), as laid down in the standard governing the installation and in accordance with local national sta...

Page 12

3.4. Connection of the flue wes recommend that the therminox range of stainless steel insulated flue pipe is used with this product. A full range of straight, offset, elbow and ‘t’ elements is available to overcome any obstruction which the flue should avoid. The proper draught conditions in the flu...

Page 13

3.5. How the e-compact overcomes issues caused by draught defects in the flue of all the weather and geographical conditions which affect the operation of a flue pipe (rain, fog, snow, exposure to sunlight, direction of facing), the wind is unquestionably the most decisive. In fact, along with therm...

Page 14

3.6 plumbing connections important! The connection of the boiler to the plumbing system must be carried out only by specialized personnel who are capable of carrying out installation properly, in compliance with current standards in the country of installation. If installation of the boiler will inv...

Page 15

4.1. Unpacking the ecompact slim pellet boiler will come packaged on a single pallet. The flue will be packaged separately. The materials which make up the packaging are 100% re- cyclable. Their storage or recycling are therefore the responsibility of the final user, in compliance with local regulat...

Page 16

4.2. Preparing the base careful planning at an early stage will greatly help the installation process and make sure that all the required clearances are adhered to for servicing and that any potential issues with the routing of the flue can be resolved. The ecompact pellet boiler should be positione...

Page 17

4.3 electrical connections electrical installations should only be carried out by suitably qualified and certified electricians. If in doubt on any issue relating to the electrical connections on the appliance contact wes technical support or your local dealer for guidance before carrying out any co...

Page 18

4.4 boiler control panel schematic ecompact slim page 16 installation & assembly © wood energy solutions only authorised wes personnel may open the control board. Any tampering with the pcb will immediately invalidate the warranty. Woodenergysolutions.Co.Uk.

Page 19

4.5 water connections the diagram below indicates the plumbing connections at the rear of the boiler. The return connection is factory fitted with a 25/6 standard pump. The boiler can be plumbed into either an open vented system (the maximum static head of water permissible is 90 ft. (27.44 meters) ...

Page 20

Once the plumbing has been completed the system should be fully flushed to clear any debris which may have become lodged in the pipework. The system should generally be filled from the lowest point on the system to force any air to the highest point where it can be vented. The flow pipe on the boile...

Page 21

Control system ecompact slim page 19 5. Control system © wood energy solutions woodenergysolutions.Co.Uk.

Page 22

Ecompact slim page 20 control system © wood energy solutions woodenergysolutions.Co.Uk errors description display error activation safety thermostat high voltage er01 water over-temperature er04 exhaust over-temperature er05 water pressure low er09 water pressure high er10 real time clock error er11...

Page 23

Ecompact slim page 21 control system © wood energy solutions 5.1 error codes in the unlikely event that the appliance fails to start or shuts down unexpectedly, then the error code show on the display will give an indication as to the potential cause of the problem. Some of the errors can be cleared...

Page 24

Ecompact slim page 22 commissioning © wood energy solutions woodenergysolutions.Co.Uk 6. Commissioning commissioning of the e-compact range of boilers can be divided into 3 sections : pre-commissioning checks auger calibration & fire-up client handover pre-commissioning checks pre-commissioning chec...

Page 25

Ecompact slim page 23 © wood energy solutions woodenergysolutions.Co.Uk before we can carry out the auger calibration we must temporarily disconnect the boiler door switch as we will have the boiler door open during this procedure. This can be done by turning off all electrical power to the boiler a...

Page 26

Ecompact slim page 24 © wood energy solutions woodenergysolutions.Co.Uk check the auger on value for power 7 in : system menu > auger > c09 this value is the auger on time for power 7 on each cycle. Enter the auger capacity menu : system menu > outputs test > augercapacity this menu gives the option...

Page 27

Ecompact slim page 25 © wood energy solutions woodenergysolutions.Co.Uk allow the counter to run for 360 seconds then press esc (key p1) to stop the simulation. Collect all the fuel into a bowl of a known weight taking care not to leave any behind. Weigh the quantity of fuel then run the following c...

Page 28

Ecompact slim page 26 © wood energy solutions woodenergysolutions.Co.Uk first fire-up hold the on/off key (p2) for 3 seconds until ‘ignition started’ appears on the display. The system will go through each stage for the specified time as per the graph below. The various stages can be observed from t...

Page 29

Ecompact slim page 27 © wood energy solutions woodenergysolutions.Co.Uk customer handover after every commissioning the customer must be provided with training by the commissioning engineer. The following is a list of items which should be covered during the product induction with the customer : pro...

Page 30

7 boiler operation & maintainance the ecompact slim has been developed to ensure that the user is able to carry out the most basic functions in a safe and convenient manner. Once the installation has been successfully carried out the user interaction is quiet simple from a regular inspection on the ...

Page 31

Always allow boiler to cool down before opening the combustion chamber door. Unscrew the two fixing knobs on the ash pan. Carefully remove the ash pan and dispose of the ash into a metal container. Ecompact slim page 29 boiler operation & maintenance © wood energy solutions woodenergysolutions.Co.Uk.

Page 32

Emptying the ash pan • the boiler contains an ash area where ash needs to be removed at regular intervals. • the ash pan is located in the main combustion chamber. The frequency of emptying the ash pan is determined by the length of time the boiler has been running and under what load conditions. On...

Page 33

Filling with fuel • the boiler will indicate when the level of pellets reaches a low level. The system will shut down and will wait for the hopper to be refilled. • open the pellet hopper lid and carefully pour approved pellets into the hopper. • never fill the hopper above the guard mesh across the...

Page 34

7. Technical data technical data ecompact 15 / slim 18 nominal output kw 4.6 –15/ 18 nominal heatinput kg/hr 5.0 – 18.2/19.8 efficiency nominal output (en 303-5) % 89/90.7 smoke temperature at nominal power °c 120-140 smoke temperature at reduced power °c 70-90 min. Required draft pa 10 exhaust gas ...

Page 35

Flue height determined on site ecompact slim page 33 boiler operation & maintenance © wood energy solutions woodenergysolutions.Co.Uk 1071mm 495mm 1135mm.

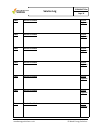

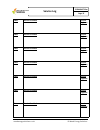

Page 36

Ecompact slim page 34 service log © wood energy solutions date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date ser...

Page 37

Ecompact slim page 35 service log © wood energy solutions date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date service provided service engineer date ser...

Page 38

© wood energy solutions wood energy solutions donaskeigh, tipperary, co. Tipperary, ireland booths hall, chelford rd., knutsford, england wa16 8gs. Info@woodenergysolutions.Co.Uk www.Woodenergysolutions.Co.Uk woodenergysolutions.Co.Uk.