- DL manuals

- E.H. Wachs

- Saw

- WS-8460

- User Manual

E.H. Wachs WS-8460 User Manual

Diamond Wire Saw

User’s Manual

Copyright © 2010 E.H. Wachs. All rights reserved.

This manual may not be reproduced in whole or in part

without the written consent of E.H. Wachs.

E.H. Wachs

600 Knightsbridge Parkway

Lincolnshire, IL 60069

www.ehwachs.com

E.H. Wachs Part No. 10-010-MAN

Rev. 1-0310, March 2010

Revision History:

Original

March 2010

Summary of WS-8460

Page 1

Diamond wire saw user’s manual copyright © 2010 e.H. Wachs. All rights reserved. This manual may not be reproduced in whole or in part without the written consent of e.H. Wachs. E.H. Wachs 600 knightsbridge parkway lincolnshire, il 60069 www.Ehwachs.Com e.H. Wachs part no. 10-010-man rev. 1-0310, ma...

Page 2

Diamond wire saw user’s manual part no. 10-010-man, rev. 1-0310 e.H. Wachs.

Page 3

Table of contents e.H. Wachs part no. 10-010-man, rev. 1-0310 i table of contents chapter 1: about the diamond wire saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 purpose of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

Diamond wire saw user’s manual ii part no. 10-010-man, rev. 1-0310 e.H. Wachs chapter 4: maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Chapter 1

Chapter 1, about the diamond wire saw e.H. Wachs part no. 10-010-man, rev. 1-0310 1 chapter 1 about the diamond wire saw p urpose of t his m anual this manual explains how to operate and maintain the dia- mond wire saw. It includes instructions for set-up, opera- tion, and maintenance. It also conta...

Page 6

Diamond wire saw user’s manual 2 part no. 10-010-man, rev. 1-0310 e.H. Wachs s ymbols and w arnings the following symbols are used throughout this manual to indicate special notes and warnings. They appear in the out- side column of the page, next to the section they refer to. Make sure you understa...

Page 7

Chapter 1, about the diamond wire saw: manual updates and revision tracking e.H. Wachs part no. 10-010-man, rev. 1-0310 3 a note provides supple- mentary information or oper- ating tips. M anual u pdates and r evision t racking current versions of e.H. Wachs company manuals are also available in pdf...

Page 8

Diamond wire saw user’s manual 4 part no. 10-010-man, rev. 1-0310 e.H. Wachs • cutting drive: operates the drive wheel that drives the cutting wire. • feed drive: operates the bow holding the wire drive sys- tem, to feed the wire through the pipe and retract the bow when finished cutting. • clamp dr...

Page 9

Chapter 1, about the diamond wire saw: equipment description e.H. Wachs part no. 10-010-man, rev. 1-0310 5 the ws-8460 has an addi- tional idler wheel next to the drive wheel. Figure 1-1. The photo shows the cutting wire drive system components. The drive wheel is operated by the hydraulic drive mot...

Page 10

Diamond wire saw user’s manual 6 part no. 10-010-man, rev. 1-0310 e.H. Wachs the ws-8460 has four feed rails, as shown below. The other models have three rails. Figure 1-2. The saw bow moves on three feed rails on the frame. The feed screw along the center rail drives the bow. Figure 1-3. The feed s...

Page 11

Chapter 1, about the diamond wire saw: equipment description e.H. Wachs part no. 10-010-man, rev. 1-0310 7 figure 1-4. Use the manual feed nut to move the saw bow if it cannot be operated using hydraulic power. Turn the nut clockwise to retract the bow away from the workpiece. The feed system has a ...

Page 12

Diamond wire saw user’s manual 8 part no. 10-010-man, rev. 1-0310 e.H. Wachs clamping system an adjustable clamping system allows you to configure the machine for pipe sizes within each model’s range. The two clamping arms are attached to the main frame with two- pronged forked pins that are removab...

Page 13

Chapter 1, about the diamond wire saw: equipment description e.H. Wachs part no. 10-010-man, rev. 1-0310 9 figure 1-7. The photo shows the clamping cylinder extended and the clamp arm secured against the pipe. The frame of the machine has clamp shoes attached that the machine rests upon when install...

Page 14

Diamond wire saw user’s manual 10 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 1-9. The photo shows the controls on the top- side control unit. (the fourth circuit, to the far right, is not used with the subsea wire saw.) rigging the machine a rigging instruction label is attached to the top o...

Page 15

Chapter 1, about the diamond wire saw: equipment description e.H. Wachs part no. 10-010-man, rev. 1-0310 11 lifting for vertical cut attach the machine to the lifting device using chains on the top lift hooks. Tip the machine up to a vertical position, then pick it up. Make sure the chains are the a...

Page 16

Diamond wire saw user’s manual 12 part no. 10-010-man, rev. 1-0310 e.H. Wachs rigging the ws-8460 you can lift the ws-8460 saw vertically, or in either hori- zontal orientation. See the following figures for lift points. Figure 1-13. Use the lift points indicated to lift the machine horizontally or ...

Page 17

Chapter 1, about the diamond wire saw: operating envelope e.H. Wachs part no. 10-010-man, rev. 1-0310 13 clean and dry the machine thoroughly, then cover it with a waterproof cover. You can leave the wire installed on the machine during stor- age. Keep normal tension on the wire to hold it in place....

Page 18

Diamond wire saw user’s manual 14 part no. 10-010-man, rev. 1-0310 e.H. Wachs a b c.

Page 19: Chapter 2

Chapter 2, safety e.H. Wachs part no. 10-010-man, rev. 1-0310 15 chapter 2 safety the e.H. Wachs company takes great pride in designing and manufacturing safe, high-quality products. We make user safety a top priority in the design of all our products. Read this chapter carefully before operating th...

Page 20

Diamond wire saw user’s manual 16 part no. 10-010-man, rev. 1-0310 e.H. Wachs properly maintaining the machine can greatly decrease the chances for injury. • always read placards and labels. Make sure all placards, labels, and stickers are clearly legible and in good condition. You can purchase repl...

Page 21

Chapter 2, safety: safety labels e.H. Wachs part no. 10-010-man, rev. 1-0310 17 protective equipment requirements for additional information on eye and face protection, refer to federal osha regulations, 29 code of federal regula- tions, section 1910.133., eye and face protection and american nation...

Page 22

Diamond wire saw user’s manual 18 part no. 10-010-man, rev. 1-0310 e.H. Wachs.

Page 23: Chapter 3

Chapter 3, operating instructions e.H. Wachs part no. 10-010-man, rev. 1-0310 19 chapter 3 operating instructions t ensioning the c utting w ire you should have the wire installed according to the mainte- nance instructions in chapter 4. 1. At the tension wheel fixture, check the start lines on the ...

Page 24

Diamond wire saw user’s manual 20 part no. 10-010-man, rev. 1-0310 e.H. Wachs 2. Tighten the drive wheel tensioning knob, as shown in figure 3-2, until you can see the line on the spring- loaded driver wheel, figure 3-3. Figure 3-2. Turn the tension knob on the drive wheel fixture to increase the te...

Page 25

Chapter 3, operating instructions: adjusting clamp arms for the pipe size e.H. Wachs part no. 10-010-man, rev. 1-0310 21 figure 3-4. When you push the wire to deflect it, the actuator rod will extend. A djusting c lamp a rms for the p ipe s ize the clamp arms are attached to the main frame using for...

Page 26

Diamond wire saw user’s manual 22 part no. 10-010-man, rev. 1-0310 e.H. Wachs ws-3012 pipe size settings table 2 and figure 3-5 describe the pipe size settings for the ws-3012 model. Figure 3-5. The photo shows the size stamps on the ws-3012 model. The pin is in the 26-30” position. Table 2: pipe si...

Page 27

Chapter 3, operating instructions: adjusting clamp arms for the pipe size e.H. Wachs part no. 10-010-man, rev. 1-0310 23 ws-3616 pipe size settings table 3 and figure 3-6 describe the pipe size settings for the ws-3616 model. Figure 3-6. The photo shows the size stamps on the ws-3616 model. The pin ...

Page 28

Diamond wire saw user’s manual 24 part no. 10-010-man, rev. 1-0310 e.H. Wachs ws-5230 pipe size settings table 4 and figure 3-7 describe the pipe size settings for the ws-5230 model. Figure 3-7. The photo shows the size stamps on the ws-5230 model. The pin is in the 46-52” position. Ws-8460 pipe siz...

Page 29

Chapter 3, operating instructions: adjusting clamp arms for the pipe size e.H. Wachs part no. 10-010-man, rev. 1-0310 25 figure 3-8. The photo shows the size stamps on the ws-8460 model. The pin is in the 78-84” position. Positioning the clamp arms do not attempt to change the clamp arm positions wh...

Page 30

Diamond wire saw user’s manual 26 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 3-9. Remove the spring clips from both ends of the forked pin, then pull the pin out from the other side. 2. Slide the clamp arm assembly so that the mounting holes line up with the appropriate hole pair for the pip...

Page 31

Chapter 3, operating instructions: connecting the hydraulic hoses e.H. Wachs part no. 10-010-man, rev. 1-0310 27 make sure both clamping arms are set at the same position. If they are not the same, the machine may not clamp securely on the pipe. Damage to the machine could result. 5. Set the positio...

Page 32

Diamond wire saw user’s manual 28 part no. 10-010-man, rev. 1-0310 e.H. Wachs m ounting the m achine on the p ipe lift the machine only on the lifting eyes provided. Lifting on any other component could damage the machine. See “rigging the machine” in chapter 1 for instructions on lifting the machin...

Page 33

Chapter 3, operating instructions: performing the cut e.H. Wachs part no. 10-010-man, rev. 1-0310 29 p erforming the c ut the cutting wire spins at very high speed. If the wire breaks, segments of the wire can fragment and be thrown from the machine at danger- ous speeds. Make sure all personnel are...

Page 34

Diamond wire saw user’s manual 30 part no. 10-010-man, rev. 1-0310 e.H. Wachs the larger the pipe size, the longer it will take to feed the cutting wire close to the pipe. This is because smaller pipes fit closer between the mount- ing shoes. 3. Visually monitor the position of the cutting wire as t...

Page 35

Chapter 3, operating instructions: performing the cut e.H. Wachs part no. 10-010-man, rev. 1-0310 31 figure 3-15. Push the cutting speed knob up to increase the drive wheel speed. 6. Push the feed flow lever down to start feeding the wire into the pipe. The feed speed knob should be at 2.5 gpm. 7. A...

Page 36

Diamond wire saw user’s manual 32 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 3-16. Push the feed flow lever up to 0 and pull the feed flow lever up to turn off the feed drive. 11. Pull the cutter flow lever up to turn off the cutter drive. Figure 3-17. Pull the cutter flow lever up to turn o...

Page 37

Chapter 3, operating instructions: performing the cut e.H. Wachs part no. 10-010-man, rev. 1-0310 33 r emoving the m achine 1. Set the feed direction knob on the tcp to reverse. Figure 3-18. Set the feed direction knob to reverse. 2. Push the feed flow lever down to open the feed circuit. Figure 3-1...

Page 38

Diamond wire saw user’s manual 34 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 3-20. Push the feed speed knob down to the maximum setting. It will take about 30 minutes to retract the feed drive on a 36 inch pipe. 4. When the saw bow is back at its home position, pull the feed flow lever up to...

Page 39

Chapter 3, operating instructions: performing the cut e.H. Wachs part no. 10-010-man, rev. 1-0310 35 figure 3-22. Set the clamping direction knob to retract. 7. Push both clamping flow levers down simultaneously until the clamp arms are fully open. The right (return pressure) gauge reading will equa...

Page 40

Diamond wire saw user’s manual 36 part no. 10-010-man, rev. 1-0310 e.H. Wachs.

Page 41: Chapter 4

Chapter 4, maintenance e.H. Wachs part no. 10-010-man, rev. 1-0310 37 chapter 4 maintenance l ubrication every time you use the machine, lubricate the following components. 1. Slowly pump multi-purpose no. 2 ep marine grease into the grease fittings on each of the 4 wheel hubs. (do not use aqualube ...

Page 42

Diamond wire saw user’s manual 38 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 4-2. Grease the feed components shown at the top of the feed system. 3. Pump aqualube into the grease fitting on the feed screw mount at the bottom of the screw. Figure 4-3. Grease the fitting at the bottom of the f...

Page 43

Chapter 4, maintenance: replacing the cutting wire e.H. Wachs part no. 10-010-man, rev. 1-0310 39 figure 4-4. Both clamping cylinders have a grease fit- ting on the rod end. R eplacing the c utting w ire start with the saw bow retracted all the way to the top of the frame. See special instructions a...

Page 44

Diamond wire saw user’s manual 40 part no. 10-010-man, rev. 1-0310 e.H. Wachs 3. Different brands of wire have different markings to indicate cutting direction. Look at the new wire closely to determine direction. Figure 4-6. This wire has molded arrows indicating the cutting direction. Figure 4-7. ...

Page 45

Chapter 4, maintenance: replacing the cutting wire e.H. Wachs part no. 10-010-man, rev. 1-0310 41 5. Turn the drive wheel tension knob until the wire starts to tighten and stays on the wheels. 6. To prepare the machine for a new cut, set the wire ten- sion as described in the operating instructions ...

Page 46

Diamond wire saw user’s manual 42 part no. 10-010-man, rev. 1-0310 e.H. Wachs r eplacing the m ounting s hoes you may have to replace the mounting shoes if they are damaged or worn. Four screws attach each shoe to the frame. Figure 4-10. The four screws indicated hold the shoe to the machine frame. ...

Page 47

Chapter 4, maintenance: replacing the wheel liners e.H. Wachs part no. 10-010-man, rev. 1-0310 43 tension and idler wheels remove the cutting wire before taking off any of the wheels. 1. Remove the nut on the end of the hub bolt and pull the bolt out of the wheel mounting fixture. Some models have c...

Page 48

Diamond wire saw user’s manual 44 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 4-12. Remove the screws from the side plate to take it off. 4. Remove the side plate. 5. Remove the old wheel liner. You may have to pry it loose with a screwdriver. Figure 4-13. Pull the liner off the wheel. You ma...

Page 49

Chapter 4, maintenance: replacing the wheel liners e.H. Wachs part no. 10-010-man, rev. 1-0310 45 6. Place the new liner on the wheel and press it down into place. Figure 4-14. Put the new wheel liner on the wheel. 7. If you removed the shaft, replace it through the center of the wheel. Figure 4-15....

Page 50

Diamond wire saw user’s manual 46 part no. 10-010-man, rev. 1-0310 e.H. Wachs 9. Fasten the side plate with the 12 screws. Snug each screw, then tighten them in a criss-cross pattern to secure the wheel evenly. Figure 4-16. Replace the screws in the side plate. 10. Replace the wheel into its mountin...

Page 51

Chapter 4, maintenance: replacing the wheel liners e.H. Wachs part no. 10-010-man, rev. 1-0310 47 figure 4-17. Loosen the set screws in the stop collars to remove the pivot pin. 3. Remove the nut from the bolt holding the wheel assembly to the tension rod, then remove the bolt. The wheel and motor a...

Page 52

Diamond wire saw user’s manual 48 part no. 10-010-man, rev. 1-0310 e.H. Wachs 4. Remove the hub bolt and spacer bolt from the wheel assembly, as shown in figure 4-18. Be careful not to lose the spacer. 5. Pull the top plate off the wheel. 6. Pull the wheel up off the motor shaft. Note the side of th...

Page 53

Chapter 4, maintenance: bleeding the feed tension control e.H. Wachs part no. 10-010-man, rev. 1-0310 49 figure 4-19. Make sure the pivot pin is through both plates, then position the stop collars and tighten the set screws. B leeding the f eed t ension c ontrol if the feed tension control mechanism...

Page 54

Diamond wire saw user’s manual 50 part no. 10-010-man, rev. 1-0310 e.H. Wachs figure 4-20. The photo shows the locations of the ten- sion control system components on the ws5230 saw model. The assemblies are in the same location on all models of the diamond wire saw. 1. Position the saw so that the ...

Page 55

Chapter 4, maintenance: bleeding the feed tension control e.H. Wachs part no. 10-010-man, rev. 1-0310 51 3. Remove the rod end from the tension control mecha- nism cylinder by removing ¼-28 shcs. Temporarily put the schs back on the cylinder. Note: shcs is item 20 and rod end is item 7 on drawing 10...

Page 56

Diamond wire saw user’s manual 52 part no. 10-010-man, rev. 1-0310 e.H. Wachs 8. Slowly cycle the tension control assembly cylinder (figure 4-22) back and forth 10 times. 9. Open the frame bypass ball valve (item 10 in figure 4-22). 10. Slowly cycle the spring assembly cylinder (figure 4- 21) back a...

Page 57: Chapter 5

Chapter 5, parts list and ordering information e.H. Wachs part no. 10-010-man, rev. 1-0310 53 chapter 5 parts list and ordering information o rdering i nformation to place an order, request service, or get more detailed information on any e.H. Wachs products, call us at one of the following numbers:...

Page 58

Diamond wire saw user’s manual 54 part no. 10-010-man, rev. 1-0310 e.H. Wachs • a description of the problem or the work to be done. Before we perform any repair, we will estimate the work and inform you of the cost and the time to complete it. Warranty information enclosed with the manual is a warr...

Page 59

Chapter 5, parts list and ordering information: drawings and parts lists e.H. Wachs part no. 10-010-man, rev. 1-0310 55 table 1: common assemblies—all ws models drawing number description 10-010-00-412 planetary gear motor 10-010-00-418 tension control mechanism 10-010-00-419 flow divider assembly 1...

Page 60

Diamond wire saw user’s manual 56 part no. 10-010-man, rev. 1-0310 e.H. Wachs table 4: ws-3616 assembly drawings drawing number description 10-010-36-410 frame assembly 10-010-36-411 feed frame 10-010-36-413 lifting tube 10-010-36-420 clamp assembly 10-010-36-421 adjustable clamp with actuator 10-01...

Page 61

10 1/4" a a 16 3 2 7 3" sq. .10 2.00 section a-a 18 8 1 15 14 12 11 5 9 13 17 10 6 ? 1 production release 11/12/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 11-103-00 gearbox, planetary output 1 2 1293k21 1/4-28 tapered grease fitting; ss 1 3 90-500-04...

Page 62

A a 19 15 30 18 17 11 23 19 1 4 3 6 7 20 21 14 13 14 10 12 9 5 8 25 section a-a 22 16 2 27 26 31 24 29 26 28 1 production release 11/25/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-006 cylinder 1 2 10-010-00-007 directional valve 1 3 10-010-0...

Page 63

1 2 2 2 3 4 2 4 1 production release 11/25/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-004 flow divider 1 2 brennan #6400-06-06-o mj-morb straight connector 4 3 brennan #6602-06-06-06 mj-fjs-mj tee 1 4 brennan #6500-06-06 mj-fjs 90-connector...

Page 64

A a c 11 28 25 30 3 32 33 1 15 e e 31 b d section a-a scale 1 : 2 16 6 5 7 4 12 13 9 14 17 38 35 37 8 22 27 20 detail b scale 2 : 1 2 34 detail c scale 1 : 1 26 21 24 detail d scale 2 : 1 19 10 36 39 38 section e-e scale 1 : 2 18 6 4 28 25 29 21 26 23 7 1 production release 11/12/2009 krp rev. Descr...

Page 65

C c 12.98 1.50 section c-c 2 6 2 3 1 4 d d section d-d 7 1 production release 11/12/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-053a wheel, plate 053a 1 2 10-010-00-053 blank wheel, 053 2 3 10-010-00-053d wheel, plate 053d 1 4 10-010-00-053e...

Page 66

A a c c d d b section a-a 3 14 8 18 13 11 5 10 12 4 15 2 6 detail b scale 2 : 1 20 22 19 9 7 21 section c-c 15 section d-d 1 17 16 1 production release 11/12/2009 krp rev. Description date apr. Revision history part number description qty. 1 10-010-00-025 1 2 10-010-00-032 plate, 032 1 3 10-010-00-0...

Page 67

A a section a-a 7 9 8 5 17 16 2 11 1 13 15 14 3 12 10 6 4 1 production release 11/12/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-052 hub, wheel 1 2 10-010-00-054a plate 054a 2 3 10-010-00-054b plate 054b 1 4 10-010-00-055b tube, 055b 1 5 10-...

Page 68

A a 4 11 17 1 3 6 8 9 13 7 10 19 2 b b section a-a 18 5 section b-b 12 16 14 15 1 production release 11/12/2009 krp rev. Description date apr. Revision history part number description qty. 1 10-010-00-005 die spring 1 2 10-010-00-006 1 3 10-010-00-023c rod, 023c 1 4 10-010-00-024 spacer, 024 2 5 10-...

Page 69

30 1/2" a a 29 8 13 4 3 32 d d b b 15 14 11 5 23 22 7 25 1 section d-d scale 1 : 1 32 10 9 12 28 section b-b scale 1 : 1 24 16 c c section a-a scale 1 : 1 27 11 18 6 21 19 26 2 20 31 30 section c-c scale 1 : 1 17 32 27 1 production release 12/29/2009 krp rev. Description date apr. Revision history i...

Page 70

44" 19 3/16" a a 5 6 2 1 3 section a-a 4 8 7 1 production release 1/7/2010 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-252 plate, 252 2 2 10-010-00-254 collar 2 3 90145a583 dowel pin 5/16 x 1" lg, ss 4 4 10-010-16-255 bar, lifting 1 5 10-010-16-25...

Page 71

A a 27 28 29 32 20 24 1 32 19 31 9 14 15 11 12 31 8 26 section a-a 23 17 20 4 3 6 7 21 10 22 18 16 25 13 31 16 1 production release 1/7/2010 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-006 cylinder 1 2 10-010-00-007 directional valve 1 3 10-010-00...

Page 72

1 2 4 4 3 remount modified mounting brackets, det.2 as shown 1 production release ag rev. Description date apr. Revision history part number description qty. 1 10-010-00-004 flow divider 1 2 10-010-16-280 bracket, flow divider 2 3 brennan 6400-06-06-o mj-morb straight connector 4 4 brennan 6602-06-0...

Page 73

15/16" 9/16" 1 3 2 3/16 typ. 5" 4 5 1 production release 12/22/2009 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-16-224 plate, bulkhead 1 2 brennan 2706-08-08 mp-mj bulkhead straight 4 3 brennan 2706-16-16 mp-mj bulkhead straight 2 4 brennan 0306-16 n...

Page 74

Rev. Description date apr. Revision history 1 production release 11/24/2009 krp item no. Part number description qty. 1 10-010-00-027 plate, 027 3 2 10-010-00-027b plate, 027b 2 3 10-010-00-028 plate, 028 1 4 10-010-00-029 plate, 029 2 5 10-010-00-243 plate, 243 1 6 10-010-00-246 plate, 246 1 7 10-0...

Page 75

46 1/2" a a 12 6 25 b b 2 3 13 5 21 15 27 20 11 28 17 c c section a-a scale 1 : 1 31 28 29 14 30 26 22 1 18 23 4 section b-b scale 1 : 1 24 19 section d-d scale 1 : 1 8 9 7 10 15 32 section c-c scale 1 : 1 16 32 1 production release 11/17/2009 krp rev. Description date apr. Revision history item no....

Page 76

5 3 6 7 4 59" 1 2 1 production release 12/16/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-252 plate, 252 2 2 10-010-30-250 tube, lifting 2 3 10-010-36-255 bar, lifting 1 4 6436k76 collar 2 5 90145a583 dowel pin 5/16 x 1" lg, ss 2 6 91831a144 ...

Page 77

21 20 20 22 detail f scale 1 : 1 22 scale 1 : 1 detail e 30 10 23 19 24 30 scale 1 : 1 detail d 19 22 17 34 25 detail a scale 1 : 1 4 30 scale 1 : 1 detail b 26 19 36 37 37 35 38 35 33 detail l scale 1 : 2 28 12 5 1 6 11 25 3/32" 30 39 2 4 10 26 3 m m 13 13 9 8 7 rev. Description date apr. Revision ...

Page 78

9 9 9 a a b b d d 14 23 c c 9 12 8 11 13 10 section a-a scale 1 : 2 1 3 24 section b-b scale 1 : 2 22 4 19 section d-d scale 1 : 2 17 2 section c-c scale 1 : 2 18 20 7 5 24 20 6 16 21 1 production release 11/19/2009 krp rev. Description date apr. Revision history item no. Part number description qty...

Page 79

F f g g 11 10 12 12 14 14 13 b c 15 16 d e e a 1 18 17 18 17 detail a scale 1 : 1 33 24 33 31 21 detail b scale 1 : 2 35 25 29 35 detail c scale 1 : 2 34 30 7 8 detail d scale 1 : 3 9 26 section e-e scale 1 : 2 27 33 33 24 24 31 19 33 33 section f-f scale 1 : 2 2 5 6 view g-g scale 1 : 4 20 4 22 3 1...

Page 80

3 1 2 3/16 6 plc. 5 4 assembly note: align bulkhead fittings as shown, and tightly fasten before welding 1 production release 12/7/09 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-30-224 plate, bulkhead 1 2 brennan 2706-08-08 mp-mj bulkhead straight 4 ...

Page 81

86" c b b d f f g g h h j j k 10 9 23 14 11 6 e 1 a a 15 16 34 18 24 34 18 35 31 5 8 7 6 30 34 12 13 section a-a scale 1 : 2 4 26 19 36 2 detail c scale 1 : 2 9 32 23 section b-b scale 1 : 2 37 20 23 28 35 31 33 29 9 33 28 21 3 detail d scale 1 : 2 33 29 32 detail e scale 1 : 2 34 30 33 28 section f...

Page 82

51 1/2" a a 12 6 26 b b d d 2 3 13 5 22 16 28 21 11 29 18 c c section a-a scale 1 : 1 32 29 30 15 31 4 27 23 1 24 19 section b-b scale 1 : 1 25 20 section c-c scale 1 : 1 17 14 section d-d scale 1 : 1 9 7 8 16 10 14 1 production release 11/12/2009 krp rev. Description date apr. Revision history item...

Page 83

65" 3 2 1 7 4 5 6 1 production release 12/1/2009 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-00-252 plate, 252 2 2 10-010-36-250 tube, lifting 2 3 10-010-36-255 bar, lifting 1 4 90145a583 dowel pin 5/16 x 1" lg 2 5 91831a144 locknut 5/8"-11,ss 4 6 92...

Page 84

32" 36" 56 1/2" 24" 1 a a b b c c d d e e f f 8 8 6 6 5 5 4 4 3 3 2 2 1 1 7 7 size d rev. Dwg. No. 10-010-36-420 drawn by approved by date date scale sheet 1:8 1 of 1 title . 10/21/2009 written permission of e.H. Wachs is prohibited. Unless otherwise specified: sole property of e.H. Wachs. Any repro...

Page 85

B b a a d d 14 24 section b-b scale 1 : 2 4 23 20 section a-a scale 1 : 2 2 18 section d-d scale 1 : 2 1 15 16 3 c c 7 13 8 9 12 section c-c scale 1 : 2 19 21 10 22 5 6 11 17 21 1 production release 11/12/2009 krp rev. Description date apr. Revision history item no. Part number description qty. 1 10...

Page 86

65 1/4" f f h h j 11 12 12 5 6 2 14 15 13 a d d 10 1 50 1/2" c e 17 16 19 18 19 18 19 18 detail a scale 1 : 1 35 37 27 detail c scale 1 : 2 38 28 32 section d-d scale 1 : 2 33 35 37 21 35 detail e scale 1 : 2 8 34 39 7 g b b detail g scale 1 : 2 29 9 view f-f scale 1 : 4 4 3 25 25 23 section h-h sca...

Page 87

1 3 2 3/16 6-pls. 5 4 assembly note: align bulkhead fittings as shown, and tightly fasten before welding. 1 released for production 12/7/09 krp rev. Description date apr. Revision history item no. Part number description default/ qty. 1 10-010-36-224 plate, bulkhead 1 2 brennan 2706-08-08 mp-mj bulk...

Page 88

5 1 h h f f b b g g j j a a b b c c d d e e f f 8 8 6 6 5 5 4 4 3 3 2 2 1 1 7 7 size d rev. Dwg. No. 10-010-52-410 drawn by approved by date date scale sheet 1:12 1 of 1 title proprietary and confidential: the information contained in this drawing is the sole property of e.H. Wachs. Any reproduction...

Page 89

69 1/2" a a 12 6 26 b b d d 16 22 18 5 13 2 3 29 21 28 11 c c section a-a scale 1 : 1 32 1 23 31 27 15 30 29 4 24 19 section c-c scale 1 : 1 17 14 section b-b scale 1 : 1 25 20 section d-d scale 1 : 1 16 8 7 9 14 10 1 production release 11/12/2009 krp rev. Description date apr. Revision history item...

Page 90

4 1 2 detail b scale 1 : 4 3 5 detail c scale 1 : 4 6 7 1 production release 1/6/2010 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-52-255 bar, lifting 1 2 10-010-52-250 tube, lifting 2 3 10-010-00-254 collar 2 4 10-010-00-252 plate, 252 2 5 90145a583 ...

Page 91

. 1/06/10 . 1 a a b b c c d d e e f f 8 8 6 6 5 5 4 4 3 3 2 2 1 1 7 7 size d rev. Dwg. No. 10-010-52-420 drawn by approved by date date scale sheet clamp, 52"-30" pipe range ag shall apply to all items not specified on drawing. 15 min. E.H. Wachs 1:12 www.Ehwachs.Com title angular sole property of e...

Page 92

A a d d b b 14 24 c c 11 12 7 8 6 section a-a scale 1 : 2 18 1 section d-d scale 1 : 2 15 13 2 16 section b-b scale 1 : 2 20 23 3 section c-c scale 1 : 2 4 21 19 21 17 15 9 10 22 1 production release 11/12/2009 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10...

Page 93

Detail f 9 scale 1 : 2 30 scale 1 : 2 21 34 section k-k 36 38 scale 1 : 2 section j-j 38 31 38 25 28 28 20 28 38 20 section c-c scale 1 : 2 31 38 38 32 16 15 33 scale 1 : 2 detail b 29 39 39 detail d scale 1 : 2 33 39 26 29 section g-g scale 1 : 2 4 24 5 2 6 23 39 scale 1 : 1 detail a 16 25 38 28 36...

Page 94

1 3 2 3/16 6-pls. 5 4 assembly note: align bulkhead fittings as shown, and tightly fasten before welding. 1 production release 12/7/09 ag rev. Description date apr. Revision history item no. Part number description qty. 1 10-010-52-224 plate, bulkhead 1 2 brennan 2706-08-08 mp-mj bulkhead straight 4...

Page 95

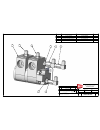

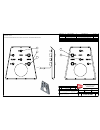

119" 205 1/4" 89" 60" 84" 4 46 1/2" 6 13 14 15 16 19 19 20 19 19 1 2 3 5 7 8 9 10 11 12 17 18 ws-8460 general arrangement - dimensions and features lightweight aluminum plate/spacer frame assemblies 1. Constant tension bow feed frame module 2. Four replaceable clamp contact pads 3. Indexable clamp p...

Page 96

84" clamp configuration #1 (84" - 78" as shown) clamp arm positions size b rev. Dwg. No. 08-031-slo drawn by approved by date date scale sheet 1:30 2 of 3 title proprietary and confidential: the information contained in this drawing is the sole property of e.H. Wachs. Any reproduction in part or as ...