- DL manuals

- E-Tech

- Boiler

- S 160

- Installation, Operating And Servicing Instructions

E-Tech S 160 Installation, Operating And Servicing Instructions

Summary of S 160

Page 1

03/02/2005 - 66401700.A excellence in hot water installation, operating and servicing instructions e-tech s 160 / 240 / 290 / 380

Page 2

1 people who should read these instructions these instructions are intended for: - specifying engineers - the installing engineers - end-users - servicing engineers symbols the following symbols are used in these instructions: essential instruction for operating the system correctly. Essential instr...

Page 3

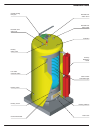

Overview • combination boiler (central heating and domestic hot water) . • tank-in-tank indirect storage type domestic hot water production. • the central heating connections are designed so that they can be connected in all three directions, this means that the boiler can be installed against a wal...

Page 4

3 description domestic hot water return domestic hot water outlet insulation central heating flow pipe primary expansion vessel tank-in-tank heat exchanger drain cock control thermostat primary circuit primary safety valve domestic cold water inlet heating return low water pressure switch heating re...

Page 5

4 dimensions the units are delivered fully assembled, tested and packed on a timber base with shockproof edges and protected by heat-shrunk plastic film. On reception and after unpacking, check the equipment for domage. For transport purposes, refer to the weight and dimensions give below. Technical...

Page 6

5 technical specifications maximum operating conditions maximum operating pressure (tank full of water) - primary circuit: 3 bar - secondary circuit: 10 bar test pressure (tank full of water) - primary circuit: 4.5 bar - secondary circuit: 13 bar operating temperature maximum temperature: 90 °c wate...

Page 7

6 boiler room important • keep vents free at all times. • do not store inflammable products in the boiler room. • do not store corrosive products near the boiler, such as paints, solvents, chlorine, salt, soap and other cleaning products. Accessibility the boiler room must be large enough to allow p...

Page 8

7 installation domestic hot water connection pressure reducer if the water mains pressure is greater than 6 bar, a pressure reducer calibrated to 4.5 bar must be fitted. Safety unit the tank safety unit must be acv approved and calibrated to 7 bar. The valve discharge must be connected to the waste ...

Page 9

8 installation electrical connections control circuit power supply the control circuit is automatically powered from the power circuit. It is also protected by a magneto-thermal circuit breaker. Control wiring diagram it is important to switch the boiler off before carrying out any work. 1 3 4 5 6 7...

Page 10

9 installation e-t ech `s` t ri phase control circuit - with shunt circuit (f actor y wired) cable colour codes bk- black br - br own r- re d w-white y- yellow o - orange b - blue v - violet p - pink gr - gr ey all bold numbers indicate a din rail ter minal connection boiler stat (78 - 53°c) please ...

Page 11

10 connecting the accessories the electrical accessories are connected to the numbered terminals on the control terminal block as shown on the control wiring diagram. Power wiring diagram • for the mono phase model (in top of the page 11) • for the tri phase model (in bottom of the page 11) electric...

Page 12

L n 3 x red 3 x red 3 x blue 3 x blue to boiler body gr een / y ellow stage 1 power relay 1 stage 1 power relay 2 stage 2 power relay 1 to control circuit mcb e-tech single phase power wiring l1 l2 l3 n to control circuit mcb 4 x orange 4 x black 4 x red 4 x blue to boiler body gr een / y e llow sta...

Page 13

12 commissioning filling the domestic hot water and heating circuits 1. Fill the domestic hot water circuit and bring it up to pressure important the hot water tank must be pressurised before the heating circuit is filled. 2. Fill the central heating circuit making sure that any air in the upper par...

Page 14

13 maintenance service intervals acv recommend that boilers should be serviced at least once a year. This servicing work should be carried out by a competent technician. Servicing the boiler 1. Set the on/off switch on the control panel to the off pos tion and switch the power off from the external ...

Page 15

14 7 - safety thermostat when the temperature in the boiler exceeds 103 °c, the manually reset safety thermostat is started up. 8 - boiler shutdown indicator light this light is lit when the safety thermostat starts up or when the water pressure in the boiler is too low. Central heating system gauge...

Page 16

15 boiler shutdown if the red light on the control panel lights up, this indicates an operating fault. 1. Check the boiler pressure, it should be between 1 and 2 bar depending on the height of the building. 2. Once you have checked the pressure, wait until the boiler has cooled down before resetting...