- DL manuals

- E-Tech

- Water Heater

- WH-100

- Instruction manual

E-Tech WH-100 Instruction manual

Instruction Manual

PRINTED 0114

329360-000

PLACE THESE INSTRUCTIONS ADJACENT TO HEAT PUMP AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

COMMERCIAL ELECTRIC AIR-TO-WATER HEAT PUMP WATER HEATER

MODELS WH-35 to WH-170

SERIES 100

INSTALLATION - OPERATION - SERVICE

MAINTENANCE - LIMITED WARRANTY

820 SW 41st Street

Renton, WA 98057

Read and understand this instruction

manual and the safety messages

herein before installing, operating or

servicing this water heater.

Failure to follow these instructions and

safety messages could result in death

or serious injury.

This manual must remain with the

water heater.

FOR INDOOR INSTALLATION ONLY

Summary of WH-100

Page 1

Instruction manual printed 0114 329360-000 place these instructions adjacent to heat pump and notify owner to keep for future reference. Commercial electric air-to-water heat pump water heater models wh-35 to wh-170 series 100 installation - operation - service maintenance - limited warranty 820 sw ...

Page 3: Table of Contents

Table of contents 3 installation .................................................................................... 16 required tools and materials .......................................................... 16 installation & start up tools ...................................................... 16 ...

Page 4: Approvals

4 safe installation, use and service the proper installation, use and servicing of this commercial heat pump water heater is extremely important to your safety and the safety of others. Many safety-related messages and instructions have been provided in this manual and on your own heat pump water he...

Page 5: General Safety Information

5 grounding instructions this heat pump water heater must be grounded in accordance with the national electrical code and/or local codes. These must be followed in all cases. Failure to ground this water heater properly may also cause erratic control system operation. This heat pump water heater mus...

Page 6: Introduction

Thank you for purchasing this heat pump water heater. Properly installed and maintained, it should give you years of trouble free service. Abbreviations found in this instruction manual include: • hpwh - heat pump water heater • ansi - american national standards institute • asme - american society ...

Page 7

7 8. Ensure the power supply voltage and phase at the job site matches the power requirements on the hpwh rating label before installation begins. Energizing the hpwh with the wrong voltage or phase will cause permanent damage to the unit. Principle of operation the appliances covered by this instru...

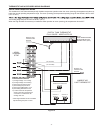

Page 8: Features And Components

Component refrigeration circuit 1) compressor 2) hot gas line 3) condenser / heat exchanger 4) liquid line 5) thermostatic expansion valve (txv) 6) evaporator 7) suction line 8) accumulator refrigerant state gas gas gas to liquid liquid liquid liquid to gas gas gas / liquid component water circuit a...

Page 9

9 table 1 model number performance air volume (cfm) water flow (gpm) dimensions weight (lbs) water heating capacity cooling capacity cop inlet outlet water (fpt) width a depth b height c d kw btu/hr* btu/hr tons wh-35 10.4 35,500 27,500 2.3 3.9 1040 7 1.0” 40” 26” 24.75” 7" 315 wh-55 17.0 58,000 45,...

Page 10: Installation Requirements

10 installation requirements read all installation requirements in this manual before installation begins. The installation must conform to these instructions and all local and national code authority having jurisdiction. Costs to diagnose, perform service and repair damage caused by installation er...

Page 11: Caution

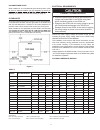

Table 2 model volts/phase/hz compressor blower motor pump (230 vac 1Ø)* mca mfs rla lra mcc fla hp fla hp wh-35 208-230/1/60 18.60 100.00 29.00 3.60 1/2 0.88 1/8 28 45 wh-35 208-230/3/60 10.90 77.00 17.00 2.40 1/2 0.88 1/8 17 25 wh-35 460/3/60 5.40 39.00 8.50 1.20 1/2 0.88 1/8 9 12 wh-55 208-230/1/6...

Page 12

12 table 2 on page 11 provides the mca (minimum circuit ampacity) and mfs (maximum fuse size). Use mca to select the minimum field wires size to power the unit and mfs to select the maximum fuse size for over current protection as follows: mca = c x 1.25 + m + p mfs = c x 2.25 + m + p where: c - com...

Page 13

13 closed water systems water supply systems may, because of code requirements or such conditions as high line pressure, among others, have installed devices such as pressure reducing valves, check the water system to be a closed system. Thermal expansion as water is heated, it expands (thermal expa...

Page 14

14 connected to the storage tank. If more than one water heating appliance is connected to the storage tank the aggregate total of all heating input ratings of all connected appliances must be factored when choosing a t&p valve for the storage tank. The pressure rating of the t&p valve should always...

Page 15

15 potentially harmful fumes and vapors could be introduced into occupied spaces. See unit placement on page 16. Storage & handling heavy object! All heat pump water heaters (hpwhs) covered by this manual are beyond the safe lifting weight for one person. Use proper conveyance equipment to move the ...

Page 16: Installation

Installation required ability installation and service of the hpwh unit requires ability equivalent to that of a qualified agency in the field involved. Plumbing, ducting and electrical work are required. See qualifications on page 6. General the installation must conform with these instructions and...

Page 17: Caution

Electrical connections correct power supply! Ensure the power supply at the job site matches the voltage and phase listed on the hpwh rating label before connecting power to the hpwh unit. • damage caused to the hpwh as the result of applying the wrong voltage or phase is not covered under the limit...

Page 18

15. All components in the hot water supply system must be adequately sized to meet peak water flow requirement 16. When the hpwh unit is installed above the storage tank install a tee fitting at a high point in the outlet water line leaving the unit. Install a purge valve, or if required by local co...

Page 19

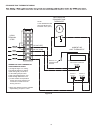

19 digital tank thermostat installation 1. Mount the thermostat on the storage tank jacket when or at a suitable location close to the storage tank, see figure 10. 2. Install three conductor low voltage wiring between the thermostat’s terminal strip and the hpwh unit’s terminal strip as shown in the...

Page 20: Danger

20 negative pressure ducting supply air only to an alternate location, such as the outdoors, may cause excessive negative air pressure inside the building envelope. Excessive negative pressure inside the building structure may result in cold or hot air from outdoors being drawn inside the building a...

Page 21

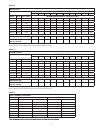

21 table 6 metal duct duct size (inches) 6 8 10 12 14 16 18 20 22 24 model cfm ext (in wg) maximum equivalent length (feet) wh-35 1040 0.35 3 14 41 102 208 417 wh-55 1650 0.35 6 17 41 90 173 308 wh-75 2150 0.35 3 10 25 52 105 188 313 wh-100 3200 0.35 6 14 31 59 107 180 292 wh-115 3200 0.35 5 12 26 4...

Page 22: Installation Checklist

The list below represents some of the most critical installation requirements that, when overlooked, often result in operational problems, down time and needless parts replacement. This is not a complete list. Before performing any troubleshooting procedures use the list below to check for installat...

Page 23: Start Up

Start up 23 flow is decreased the temperature rise will increase and as water flow is increased the temperature rise will decrease. Because of this relationship between temperature rise and flow rate this test can be useful to determine if the flow rate through the heat exchanger is adequate. Other ...

Page 24

Digital tank thermostat set output mt -5 11 r i up button set button factory supplied digital tank thermostat - model mt511ri led display down button figure 11 operation when the water temperature in the storage tank as sensed by the digital tank thermostat’s temperature sensor reaches the tank temp...

Page 25: Maintenance And Service

25 routine maintenance warning: when possible, disconnect all power to the unit and follow t he prescribed lock - out/tag - out procedure to prevent accidental electrocution. Should the unit have to be serviced with live electricity, only trained and qualified technicians should carry out the servic...

Page 26

26 cleaning internal insulation inspect the internal insulation on a yearly basis for any microbial growth. The insulation never has to be cleaned unless microbial growth is detected. If microbial growth is detected, follow the removal steps below: 1. Disconnect all power to the unit and follow the ...

Page 27: Troubleshooting

27 troubleshooting problem possible causes corrections heat pump is too noisy. 1. Sheet metal fasteners are loose. 2. Operating vibration is transferring to floor or building structure. 3. 3. Blower pulley assembly loose or out of alignment. Tighten fasteners. Place vibration dampeners underneath un...

Page 28

Checking refrigerant charge servicing of the refrigeration circuit must only be performed by agencies or individuals possessing type ii or universal this hpwh unit is factory charged with 134a refrigerant. See the rating label on the hpwh unit and table 9 for refrigerant charge by weight. It should ...

Page 29: Control System

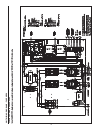

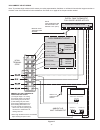

Control system 29 control board the heart of the control system is the control board which is a printed circuit board (pcb) installed inside the control box. See figure 13 below, figure 14 on page 30 and the wiring diagrams on pages 32 to 36. The control board is powered by 24 vac from the transform...

Page 30

30 phase monitor some of the higher capacity models are equipped with phase monitor and compressor overload modules that interface with the control board. See table 12 on page 31. • if all 3 phases of power are present and in sequence, the normally open contacts (y/y-out) will close when 24 volts is...

Page 31: Wiring Diagrams

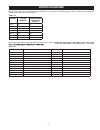

Wiring diagrams not all models are factory equipped with phase monitors or compressor overload modules. Table 12 shows which models will include these components from the factory. Table 12 model phase monitor compressor overload module wh-35 no no wh-55 no no wh-75 no no wh-100 yes no wh-115 yes no ...

Page 32

U n it w ir in g d ia g ra m s - f u se siz es 208/230 v ac - single phase - 60 hz 32.

Page 33

U n it w ir in g d ia g ra m s - f u se siz es 208/230 v ac - three phase - 60 hz : wh-35, wh-55 and wh-75 only . 33.

Page 34

U n it w ir in g d ia g ra m s - f u se siz es 208/230 v ac - three phase - 60 hz only . 34.

Page 35

U n it w ir in g d ia g ra m s - f u se siz es 460 v ac - three phase - 60 hz 35.

Page 36

U n it w ir in g d ia g ra m s - f u se siz es 460 v ac - three phase - 60 hz only . 36.

Page 37

Thermostat and accessory wiring diagrams digital tank thermostat wiring this ambient air limit thermostat temporarily disables compressor operation when the return (entering) air temperature is above or below the normal operating temperature range. The return (entering) air temperature operating ran...

Page 38

Standard tank thermostat wiring 38 figure 16 remote air temperature sensor field supplied standard tank thermostat note: tank temperature setting must not exceed 140°f (60°c) (24 vac com) (24 vac hot) hpwh terminal strip ambient air limit thermostat ambient air limit thermostat configuration notes: ...

Page 39

High ambient air kit wiring note: to purchase high ambient air kit contact your sales representative, distributor or call the toll free technical support number on the back cover of this manual for further assistance. See table 14 on page 40 for the part number needed. 39 figure 17 digital tank ther...

Page 40

Thermostat and accessory wiring diagrams building recirculation pump wiring diagram circulating pump wiring diagram for building recirculation to storage tank field supplied line temperature control installed in the circulating loop return line circ pump motor l1 hot l2 neutral 120 vac power note: u...

Page 41

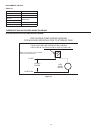

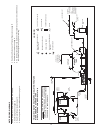

4. See closed systems and thermal expansion on page 13 5. See w ater connections on page 17. 6. If a building recirculation loop is present the circulation pump must be controlled by a thermostat. See figure 1 8 on page 4 0 for wiring. W ate r pipi n g d ia g ram s before installation of water pipin...

Page 42

4. See closed systems and thermal expansion on page 13 5. See w ater connections on page 17. 6. If a building recirculation loop is present the circulation pump must be controlled by a thermostat. See figure 1 8 on page 4 0 for wiring. W ate r pipi n g d ia g ram s before installation of water pipin...

Page 43

4. See closed systems and thermal expansion on page 13 5. See w ater connections on page 17. 6. If a building recirculation loop is present the circula tion pump must be controlled by a thermostat. See figure 1 8 on page 4 0 for wiring. W ate r pipi n g d ia g ram s before installation of water pipi...

Page 44

4. See closed systems and thermal expansion on page 13 5. See w ater connections on page 17. 6. If a building recirculation loop is present the circulation pump must be controlled by a thermostat. See figure 1 8 on page 4 0 for wiring. W ate r pipi n g d ia g ram s before installation of water pipin...

Page 45

4. See closed systems and thermal expansion on page 13 5. See w ater connections on page 17. 6. If a building recirculation loop is present the circula tion pump must be controlled by a thermostat. See figure 1 8 on page 4 0 for wiring. W ate r pipi n g d ia g ram s before installation of water pipi...

Page 46

46 limited warranty models awh, wh, ww, cph commercial heat pump water heaters a. O. Smith corporation, the warrantor, extends the following limited warranty to the owner of this commercial heat pump water heater subject to the terms, conditions and disclaimers stated below: 1. Compressor if within ...

Page 47

47 model no. Serial no. Date installed dealer’s name dealer’s address phone no. City and state zip fill in the following for your own reference. Keep it. Registration is not a condition of warranty. The model and serial number are found on the heater’s rating label..

Page 48

500 tennessee waltz parkway, ashland city, tn 37015 technical support: 800-527-1953 • parts: 800-433-2545 • fax: 800-644-9306 www.Hotwater.Com.