- DL manuals

- E-TON

- Offroad Vehicle

- ATV6A 90

- Service Manual

E-TON ATV6A 90 Service Manual

Summary of ATV6A 90

Page 1

Service manual atv6a 90 viper 90 e-ton power.

Page 2

Viper 90 service manual 2009 by e-ton power tech co., ltd. First edition, may 2009 all rights reserved. Any reproduction or unauthorized use without the written permission of e-ton power tech co., ltd. Is expressly prohibited..

Page 3: Important

Important this manual was produced by the e-ton power tech co primarily for use by e-ton dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one man- ual, so it is assumed that anyone who uses this book to perform maintenance and repairs on e-ton m...

Page 4: How to Use This Manual

How to use this manual manual organization this manual consists of chapters for the main categories of subjects. (see “symbols”) 1st title : this is the title of the chapter with its symbol in the upper right corner of each page. 2nd title : this title indicates the section of the chapter and only a...

Page 5: Spec

Symbols the following symbols are not relevant to every machine. Symbols to indicate the subject of each chapter. General information specifications periodic checks and adjustments engine carburetor chassis electrical troubleshooting symbols to indicate the following. Serviceable with engine mounted...

Page 6: Table of Contents

Table of contents specifications 2 periodic checks and adjustments 3 engine 4 carburetor 5 chassis 6 electrical – + 7 general information 1 troubleshooting 8.

Page 7: Chapter 1

Chapter 1 general information machine identification........................................................................... 1-1 vehicle identification number ..................................................... 1-1 engine serial number...............................................................

Page 8: Chapter 2

General specifications ........................................................................ 2-1 engine specifications ............................................................................ 2-4 chassis specifications ........................................................................ 2...

Page 9: Chapter 3

Introduction............................................................................................ 3-1 periodic maintenance chart for the............................................ 3-1 emission control system general maintenance and lubrication chart.......................... 3-1 handlebar, s...

Page 10: Chapter 4

Engine ...........................................................................................................4-1 exhaust pipe/muffler, breather hose and leads ................ 4-1 engine mounting bolts ................................................................... 4-2 removing the engine ....

Page 11

Belt drive ................................................................................................ 4-31 crankcase cover............................................................................. 4-31 kickstarter.................................................................................

Page 12: Chapter 5

Carburetor................................................................................................ 5-1 disassembling the carburetor................................................... 5-4 checking the carburetor ............................................................. 5-4 assembling the ...

Page 13: Chapter 6

Front and rear wheels ...................................................................... 6-1 front wheels .................................................................................... 6-1 rear wheels ......................................................................................6-2...

Page 14

Steering system ..................................................................................... 6-28 handlebar........................................................................................... 6-28 removing the handlebar grips.................................................. 6-30 rem...

Page 15: Chapter 7

Electrical components........................................................................ 7-1 checking the switchs ............................................................................ 7-3 wiring diagram ........................................................................................

Page 16: Chapter 8

Starting failure/hard starting ....................................................... 8-1 fuel system.......................................................................................... 8-1 electrical system............................................................................. 8-1 comp...

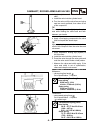

Page 17: Gen

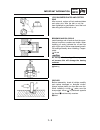

Gen info general information machine identification vehicle identification number the vehicle identification number is stamped into the left side of the frame. Machine identification 1 - 1 the engine serial number is stamped on the engine. Engine serial number 1.

Page 18: Gen

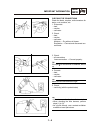

Important information preparation for removal and disassembly 1.Before removal and disassembly add, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. 3. When disassembling always keep mated parts together. This includes gears, cylin- ders, pistons ...

Page 19: Gen

Lock washers/plates and cotter pins after removal, replace all lock washers/plates and cotter pins. After the bolt or nut has been tightened to specification, bend the lock tabs along a flat of the bolt or nut. Bearings and oil seals install bearings and oil seals so that the manu- facturer’s marks ...

Page 20: Gen

Checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector 2. Check: • lead • coupler • connector moisture dry with an air blower. Rust/stains connect and disconnect sev- eral times. 3. Check: • all connections loos...

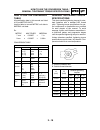

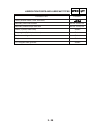

Page 21: Spec

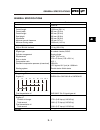

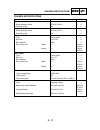

2 2 - 1 general specifications spec spec general specifications item standard model code dimensions overall length 1,500 mm (59.1 in) overall width 850 mm (33.5 in) overall height 900 mm (35.4 in) seat height 680 mm (26.8 in) wheelbase 930 mm (36.6 in) minimum ground clearance 120 mm (4.7 in) minimu...

Page 22: Spec

2 - 2 general specifications spec spec item standard fuel type unleaded gasoline 92 octane fuel tank capacity plastic 4.5 l (0.99 lmp gal, 1.19 us gal) 3.6 l (0.79 lmp gal, 0.95 us gal) fuel reserve amount plastic lron 1.0 l (0.22 imp gal, 0.26 us gal) 0.5 l (0.11 lmp gal, 0.13 us gal) carburetor ty...

Page 23: Spec

2 - 3 general specifications spec spec item standard brake front brake type drum brake operation right hand operation rear brake type single disc brake operation left hand operation suspension front suspension single a-arm / independent rear suspension swing arm shock absorber front shock absorber c...

Page 24: Spec

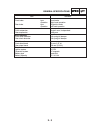

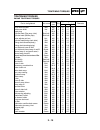

Engine specifications 2 - 4 engine specifications spec spec item standard limit cylinder head warp limit 0.05 mm (0.002 in) cylinder bore size 47.000 mm (1.8504 in) 7.00 ~ 7.40 cm 3 (0.43 ~ 0.45 cu.In) 47.10 mm (1.8543 in) taper limit ---- 0.05 mm (0.002 in) maximum out-of-round ---- 0.01 mm (0.0004...

Page 25: Spec

2 - 5 engine specifications spec spec rocker arm/rocker arm shaft rocker arm inside diameter 10.000 ~ 10.015 mm (0.3937 ~ 0.3943 in) rocker arm shaft outside diameter 9.972 ~ 9.987 mm (0.3926 ~ 0.3932 in) rocker-arm-to-rocker-arm-shaft clearance 0.013 ~ 0.043 mm (0.0005 ~ 0.0017 in) valve, valve sea...

Page 26: Spec

2 - 6 engine specifications spec spec stem-to-guide clearance in 0.010 ~ 0.037 mm (0.0004 ~ 0.0015 in) 0.08 mm (0.0031 in) ex 0.025 ~ 0.052 mm (0.0010 ~ 0.0020 in) 0.10 mm (0.0039 in) stem runout limit ---- 0.02 mm (0.0008 in) valve seat width in 0.8 ~ 1.1 mm (0.0315 ~ 0.0433 in) 1.6 mm (0.0630 in) ...

Page 27: Spec

2 - 7 engine specifications spec spec 0.10 mm (0.0039 in) (0.0004 ~ 0.0016 in) 46.970 ~ 46.990 mm (1.8492 ~ 1.8500 in) (0.5119 ~ 0.5121 in) 13.040 mm (0.5134 in) (0.5117 ~ 0.5118 in) 12.960 mm (0.5102 in) limit standard item direction of winding ---- counterclockwise counterclockwise in (top view) -...

Page 28: Spec

2 - 8 engine specifications spec spec ---- barrel 1.0 × 2.1 mm (0.0394 × 0.0827in) ---- 0.10 ~ 0.25 mm (0.0039~0.0098in) 0.45 mm (0.0177in) 0.015 ~0.055 mm (0.0006~0.0022in) 0.09 mm (0.0035in) ---- taper 1.0 × 2.0 mm (0.0394 × 0.0787in) ---- 0.25 ~ 0.40 mm (0.0098~0.0157in) 0.55mm (0.0217in) 0.015 ~...

Page 29: Spec

2 - 9 engine specifications spec spec automatic centrifugal clutch type 4.0 mm clutch shoe thickness clutch shoe spring free length clutch housing inside diameter compression spring free length 87.9 mm (3.46 in) weight outside diameter 2110±140r/min clutch-in revolution 2350±150 r/min clutch-stall r...

Page 30: Spec

2 - 10 oil pump ---- trochoid oil pump type inner-rotor-to-outer-rotor-tip clearance (0.0016 ~ 0.0047 in) 0.15 mm (0.006 in) outer-rotor-to-oil-pump-housing clearance (0.0055 ~ 0.0083 in) 0.28 mm (0.0110 in) oil-pump-housing-to-inner-rotor-and-outer- rotor clearance 0.06 ~ 0.11 mm 0.14 ~ 0.21 mm 0.0...

Page 31: Spec

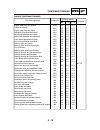

Chassis specifications 2 - 11 chassis specifications spec spec item standard limit front suspension shock absorber travel 35 mm (1.38 in) ---- optional spring no ---- rear suspension shock absorber travel 40 mm (1.57 in) ---- optional spring no ---- front wheel type panel wheel ---- rim size 8 x 5.5...

Page 32: Spec

2 - 12 chassis specifications spec spec brake lever brake lever free play (pivot) front 4.0 ~ 6.0 mm (0.16 ~ 0.24 in) ---- rear 0 ~ 1.5 mm (0 ~ 0.06 in) ---- throttle lever free play 1.0 ~ 3.0 mm (0.04 ~ 0.12 in) ---- 53.0 ~ 57.0 mm (2.09 ~ 2.24 in) rear disc brake type disc outside diameter × thick...

Page 33: Spec

Electrical specifications 2 - 13 electrical specifications spec spec item standard limit voltage 12 v ---- ignition system ignition timing (b.T.D.C.) 13.0 ° ± 1 ° /1,700 r/min ---- advanced timing (b.T.D.C.) 28.5 ° ± 1 ° /4,000 r/min ---- advancer type electrical (digital) ---- c.D.I. Magneto model/...

Page 34: Spec

2 - 14 electrical specifications spec spec electric starter system ---- constant mesh type starter motor ---- c1200-a26-9000/sy model/manufacturer ---- ---- 0.35 kw output armature coil resistance 0.014 ~ 0.019 at 20 °c (68 ° ---- f) 3.5 mm 7.0 mm (0.28 in) 1.0 ~ 3.0 n brush overall length (0.14 in)...

Page 35: Spec

Tightening torques engine tightening torques 2 - 15 tightening torques spec spec part to be tightened part name thread size q’ty tightening torque remarks nm m · kg ft · lb cylinder head (muffler pipe) stud bolt m6 2 9 0.9 6.5 cylinder head (pipe assy, inlet) stud bolt cover head cylinder m6 4 12 1....

Page 36: Spec

Chassis tightening torques 2 - 16 tightening torques spec spec part to be tightened thread size tightening torque nm m · kg ft · lb m10 rear shock absorber and frame m10 rear shock absorber and swingarm m10 front shock absorber and frame m10 steering stem and frame m14 steering stem and tie-rod ball...

Page 37: Spec

2 - 17 tightening torques spec spec 1. Before tightening the nuts, apply locking agent (loctite ® ) to rear axle threads. 2. Tighten the inside nut to 60 nm (6.0 m · kg, 43.4 ft · lb). . T u n e d i s n i e h t g n i d l o h e li h w ) b l · t f 3 2 1 , g k · m 0 . 7 1 ( m n 0 7 1 o t t u n e d i s ...

Page 38: Spec

How to use the conversion table all specification data in this manual are listed in si and metric units. Use this table to convert metric unit data to imperial unit data. Conversion table general tightening torque specifications this chart specifies tightening torques for stan- dard fasteners with a...

Page 39: Spec

Lubrication point lubricant ls ls e m ls e ls ls e e e e e e e m m m e e e ls ls oil seal lips o-ring (except v-belt drive unit) cylinder head tightening nut mounting surface cylinder head stud bolt thread cylinder head gasket dowel pin crankshaft pin outside surface connecting rod piston outside an...

Page 40: Spec

Bel-ray asembly lube bel-ray asembly lube sealant sealant sealant sealant sealant lubrication point lubricant ls primary sheave inside, collar, solid bush, secondary fixed inner surface secondary sheave torque cam ditch gasket (cylinder head cover) stopper guide (cylinder head cover) crankcase matin...

Page 41: Spec

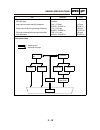

Oil flow diagrams camshaft crankshaft oil pump oil filter 1 2 3 4 2 - 21 oil flow diagrams spec spec.

Page 42: Spec

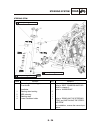

Cable routing rear brake hose throttle cable oil catch hose air filter case check hose wire harness carburetor air vent hose front brake cables handlebar switch lead rear brake switch lead fuel overflow choke cable 0 fuel hose fuel tank breather hose a crankcase breather hose b throttle valve hose 2...

Page 43: Spec

A pass the front brake cables, throttle cable and choke cable through the hose guide. B fasten the choke cable, handlebar switch lead and rear brake switch lead with a plastic band. Insert the fuel tank breather hose into the hole in the handlebar cover. C e f d fasten the fuel overflow hose and car...

Page 44: Spec

G h brake fuel tube with a clip. 2 - 24 cable routing spec spec route the parking brake cable under the cross pipe and left of the steering column as shown in the illustration..

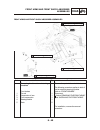

Page 45: Spec

Wire harness 0 fuel drain hose rear brake hose throttle cable front brake cables parking brake cable air filter case check hose a positive starter motor lead b positive battery lead c negative battery lead d starter motor e generator lead f main switch lead g h ignition coil i rectifier/regulator ne...

Page 46: Spec

A pass these leads through rear fender. B fasten the wire harness, main switch lead, heater control switch lead and with a plastic band. C fasten the wire harness, negative battery lead and starter motor lead with a plastic band. D fixed the negative battery lead and negative starter motor lead by a...

Page 47: Spec

Rear brake switch lead rear brake hose front brake cable (right) front brake cable (left) fuel tank breather hose positive battery lead choke cable handlebar switch throttle cable negative battery lead 1 12 13 2 3 4 5 6 battery 7 8 9 10 11 main fuse 2 - 27 cable routing spec spec parking brake cable.

Page 48: Spec

Connect the negative battery lead to the battery so that the lead is routed to the side of the battery. Connect the positive battery lead to the battery so that the lead contacts the battery case. Fasten the handlebar switch lead , rear brake switch lead and choke cable with a plastic band. To start...

Page 49: Spec

Rear brake switch lead rear brake hose choke cable handlebar switch lead throttle cable 1 2 3 4 5 6 7 fasten the handlebar switch lead , rear brake switch lead and choke cable with a plastic band. A front brake cable (right) front brake cable (left) a ignition coil 2 - 29 cable routing spec spec par...

Page 50: Chk

Periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer service life. The need for costly overhaul work w...

Page 51: Chk

10 * shock absorber assemblies check operation and correct if necessary. Check for oil leakage and replace if necessary. 11 * front knuckle piv- ots lubricate with lithium-soap-based grease. 12 * steering shaft lubricate with lithium-soap-based grease. 13 * steering system check operation and repair...

Page 52: Chk

Handlebar, seat, fenders and fuel tank for installation, reverse the removal pro- cedure. Order job/part q’ty remarks removing the handlebar remove the parts in the order listed. Refer to “installing the rear brake master cylinder”. 3 front brake cable 2 4 parking brake cable 1 5 choke cable 1 6 rea...

Page 53: Chk

Order job/part q’ty remarks removing the seat, front panel and footrest boards remove the parts in the order listed. For installation, reverse the removal pro- cedure. 1 seat 1 pull back the seat lock lever, than pull up on the rear of the seat. 2 front panel 1 3 footrest board (l) 1 4 footrest boar...

Page 54: Chk

Front fender order job/part q’ty remarks removing the front fender remove the parts in the order listed. Seat and front panel refer to “seat and front panel”. 1 front body cover 1 2 front fender (l) 1 3 front fender (r) 1 4 air cleaner joint clamp screw 1 loosen. For installation, reverse the remova...

Page 55: Chk

Rear fender and battery order job/part q’ty remarks removing the rear fender and battery remove the parts in the order listed. Front fender refer to “front fender”. Seat and front panel refer to “seat and front panel”. Refer to “ handlebar ”. Handlebar 1 wire harness and main fuse 1 2 negative batte...

Page 56: Chk

3 footrest bar 2 4 footrest bear bar 2 order job/part q’ty remarks removing the fuel tank and footrest bars remove the parts in the order listed. Seat and front panel refer to “seat and front panel”. Front fender refer to “front fender”. 1 fuel hose 2 disconnect. Before disconnecting the fuel hose, ...

Page 57: Chk

1. Remove: valve clearance (cold) intake valve 0.07 ~ 0.10 mm (0.003~ 0.004 in) 0.07 ~ 0.10 mm (0.003~ 0.004 in) exhaust valve • • • c.D.I. Magneto cover • cylinder head cover refer to “cylinder head” in chapter 4 . Engine adjusting the valve clearance the following procedure applies to all of the v...

Page 58: Chk

C. Measure the valve clearance using a thick- ness gauge . Out of specification adjust 3. Adjust: • valve clearance a. Loosen the locknut . B. Insert a thickness gauge between the adjuster end and the valve end. C. Turn the adjuster clockwise or counter- clockwise with the tappet adjusting tool unti...

Page 59: Chk

Adjusting the engine idling speed 1. Start the engine and let it warm up for sev- eral minutes. 2. Attach: • engine tachometer (to the spark plug lead) 3. Measure: • engine idling speed engine idling speed 1,600 ~ 1,800 r/min 4. Adjust: • engine idling speed a. Turn the throttle stop screw in or out...

Page 60: Chk

Adjusting the throttle lever free play engine idling speed should be adjusted prop- erly before adjusting the throttle lever free play. 1. Measure: • throttle lever free play out of specification adjust. 2. Adjust: • throttle lever free play a. Pull back the adjuster cover . B. Loosen the locknut on...

Page 61: Chk

Adjusting the speed limiter the speed limiter keeps the carburetor throttle from becoming fully-opened even when the throttle lever is applied to the maximum posi- tion. Screwing in the adjuster stops the engine speed from increasing. 1. Measure: • speed limiter length out of specification ĺ adjust....

Page 62: Chk

Checking the spark plug 1. Remove: • spark plug 2. Check: • spark plug type incorrect ĺ change. 3. Check: • electrode wear/damage ĺ replace. • insulator abnormal color ĺ replace. Normal color is a medium-to-light tan color. 4. Clean: • spark plug (with a spark plug cleaner or wire brush) standard sp...

Page 63: Chk

Checking the ignition timing engine idling speed and throttle cable free play should be adjusted properly before checking the ignition timing. 1. Remove: • shroud cap 2. Attach: • engine tachometer • timing light (to spark plug lead) 3. Check: • ignition timing a. Warm up the engine and keep it at t...

Page 64: Chk

Measuring the compression pressure insufficient compression pressure will result in a loss of performance. 1. Measure: • valve clearance out of specification ĺ adjust. Refer to “adjusting the valve clearance”. 2. Start the engine, warm it up for several min- utes, and then turn it off. 3. Disconnect...

Page 65: Chk

A. Set the main switch to “on”. B. With the throttle wide open, crank the engine until the reading on the compression gauge stabilizes. To prevent sparking, ground the spark plug lead before cranking the engine. C. If the compression pressure is above the maximum specification, check the cylinder he...

Page 66: Chk

Checking the engine oil level 1. Place the machine on a level surface. 2. Check: • engine oil level oil level should be between the maximum mark and minimum mark. Oil level low ĺ add oil to the proper level. Do not screw the dipstick in when checking the oil level. A. Warm up the engine for several ...

Page 67: Chk

Changing the engine oil 1. Start the engine, warm it up for several min- utes, and then turn it off. 2. Place a container under the engine oil drain bolt. 3. Remove: • dipstick • engine oil drain bolt (along with the o-ring, spring and oil filter screen) 4. Drain: • engine oil (completely from the c...

Page 68: Chk

Cleaning the air filter elements there is a check hose at the bottom of the air filter case. If dust and/or water collects in this hose, clean the air filter elements and air fil- ter case. 1. Remove: • air filter case covers 2. Loosen: • bolt 3. Remove: • • • air filter element holders • sponge mat...

Page 69: Chk

B. Squeeze the excess solvent out of the spo- nge materials and let it dry. Do not twist or wring out the sponge materials. Could damage the sponge materials. C. Apply yamaha foam air filter oil or other quality foam air filter oil to the sponge materials. D. Squeeze out the excess oil. The sponge m...

Page 70: Chk

C. Tap the tailpipe lightly with a soft-face ham- mer or suitable tool, then use a wire brush to remove any carbon deposits from the spark arrester portion of the tailpipe and the inner contact surfaces of the muffler. D. Insert the spark arrester into the muffler and align the screw holes. E. Inser...

Page 71: Chk

Chassis before adjusting the front brake, the front brake linings should be checked. Proper lever free play is essential to avoid excessive brake drag. 1. Measure: • front brake lever free play out of specification ĺ adjust. 2. Adjust: • front brake lever free play front brake lever free play 4 ~ 6 ...

Page 72: Chk

3 - 23 adjusting the parking brake chk adj adjusting the parking brake 1. Check: • parking brake cable end length out of specification o adjust. Parking brake cable end length 53.0 ~ 57.0 mm (2.09 ~ 2.24 in) 2. Adjust: • parking brake cable end length a. Loosen the locknut and adjusting bolt . B. Lo...

Page 73: Chk

2. Check: • brake fluid level below the minimum level mark ĺ add the recommended brake fluid to the proper level. • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same type of brake flui...

Page 74: Chk

• rear brake hose cracks/wear/damage ĺ replace. 3. Check: • brake hose clamps loosen ĺ tighten. 4. Hold the machine in an upright position and apply the rear brake. 5. Check: • brake hose apply the brake lever times. Fluid leakage ĺ replace the hose or pipe. Refer to “rear brake” in chapter 6. 6. In...

Page 75: Chk

• be careful not to spill any brake fluid or allow the brake master cylinder reservoir or brake fluid reservoir to overflow. • when bleeding the hydraulic brake system, make sure there is always enough brake fluid before applying the brake. Ignoring this pre- caution could allow air to enter the hyd...

Page 76: Chk

Changing the final transmission oil 1. Place the machine on a level surface. 2. Place a receptacle under the final transmission case. 3. Remove: • final transmission oil drain plug 4. Drain: • final transmission oil 5. Install: • final transmission oil drain plug check the gasket(drain plug). If it ...

Page 77: Chk

1. Measure: • drive chain slack out of specification ĺ adjust. 2. Adjust: • drive chain slack the drive chain slack is adjusted by the rota- tion of the rear axle hub. A. Loosen the rear axle pinch bolts . B. Loosen the locknut . C. To tighten the drive chain, turn the drive chain adjusting nut in d...

Page 78: Chk

Checking the steering system 1. Place the machine on a level surface. 2. Check: • steering shaft bushings and bearings move the handlebar up and down, and/or back and forth. Excessive play ĺ replace the steering shaft bushings and or bearings. Refer to “steering system” in chapter 6. 3. Check: • tie...

Page 79: Chk

Adjusting the toe-in 1. Place the machine on a level surface. 2. Measure: • toe-in out of specification ĺ adjust. Toe-in 10 mm (0.40 in) before measuring the toe-in, make sure that the tire pressure is correct. A. Mark both front tire tread centers. B. Face the handlebar straight ahead. C. Measure t...

Page 80: Chk

Checking the front and rear shock absorbers 1. Place the machine on a level surface. 2. Check: • damper rod bends/damage ĺ replace the front/rear shock absorber assembly. • oil leakage excessive oil leakage ĺ replace the front/ rear shock absorber assembly. • cylinder damage ĺ the front/rear shock a...

Page 81: Chk

B b a adjusting the shock absorbers always adjust the spring preload of both front shock absorbers to the same setting. Uneven adjustment can result in poor han- dling and loss of stability. 1. Adjust: • spring preload a. Turn the adjusting ring in direction or with the spanner wrench . Direction sp...

Page 82: Chk

Checking the tires this model is equipped with low pressure tires. It is important that they be inflated correctly and maintained at the proper pressures. • tire characteristics 1) tire characteristics influence the han- dling of atvs. The tires listed below have been approved by e-ton power tech co...

Page 83: Chk

1. Measure: • tire pressure out of specification ĺ adjust. • the low-pressure tire gauge is included as standard equipment. • if dust or the like is stuck to this gauge, it will not provide the correct readings. Therefore, take two measurements of the tire’s pressure and use the second reading. Unev...

Page 84: Chk

2. Check: • tire surfaces wear/damage ĺ replace. It is dangerous to ride with a worn-out tire. When tire wear is out of specification, replace the tire immediately. Tire wear limit front and rear: 3 mm (0.12 in) checking the wheels 1. Check: • wheel damage/bends ĺ replace. Always balance the wheel w...

Page 85: Chk

Checking and lubricating the cables warning a damaged cable sheath may cause corro- sion and interfere with the cable move- ment. An unsafe condition may result so replace a damaged cable as soon as possi- ble. 1. Check: • cable sheath damage ĺ replace. 2. Check: • cable operation unsmooth operation...

Page 86: Chk

Electrical system checking and charging the battery batteries generate explosive hydrogen gas and contain electrolyte which is made of poisonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: • wear protective eye gear when handling or working near batteries. •...

Page 87: Chk

Since vrla (valve regulated lead acid) batteries are sealed, it is not possible to check the charge state of the battery by measuring the specific gravity of the electrolyte. Therefore, the charge of the battery has to be checked by measuring the voltage at the battery terminals. 1. Remove: • seat •...

Page 88: Chk

Example c. Open-circuit voltage = 12.0 v d. Charging time = 6.5 hours e. Charge of the battery = 20 ~ 30% 5. Charge: • battery (refer to the appropriate charging method illustration) do not quick charge a battery. • never remove the vrla (valve regulated lead acid) battery sealing caps. • do not use...

Page 89: Chk

• as shown in the following illustration, the open-circuit voltage of an vrla (valve regulated lead acid) battery stabilizes about 30 minutes after charging has been completed. Therefore, wait 30 minutes after charging is completed before measuring the open-circuit voltage. 3 - 40 checking and charg...

Page 90: Chk

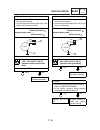

Charging method using a variable-current (voltage) charger measure the open-circuit voltage prior to charging. Connect a charger and ammeter to the battery and start charging. Is the amperage higher than the standard charg- ing amperage written on the battery? Adjust the voltage to obtain the standa...

Page 91: Chk

Charging method using a constant voltage charger measure the open-circuit voltage prior to charging. Connect a charger and ammeter to the battery and start charging. Charge the battery until the charging voltage reaches 15 v. Leave the battery unused for more than 30 minutes before measuring its ope...

Page 92: Chk

6. Install: • battery 7. Connect: • battery leads (to the battery terminals) first, connect the positive battery lead , and then the negative battery lead . 8. Check: • battery terminals dirt ? Clean with a wire brush. Loose connection ĺ connect properly. 9. Lubricate: • battery terminals 10.Install...

Page 93: Chk

Checking the fuses the following procedure applies to all of the fuses. To avoid a short circuit, always set the main switch to “off” when checking or replac- ing a fuse. 1.Remove: • seat refer to “seat, fenders and fuel tank”. 2.Check: • fuse a. Connect the pocket tester to the fuse and check the c...

Page 94: Chk

Never use a fuse with an amperage rating other than that specified. Improvising or using a fuse with the wrong amperage rat- ing may cause extensive damage to the electrical system, cause the lighting and ignition systems to malfunction and could possibly cause a fire. 4. Install: • seat refer to “s...

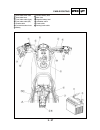

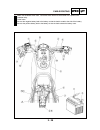

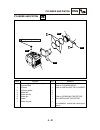

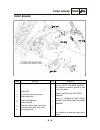

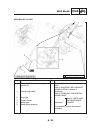

Page 95: Engine

Engine engine exhaust pipe/muffler, breather hose and leads order job/part q’ty remarks removing the exhaust pipe/muffler, breather hose and leads remove the parts in the order listed. Rear fender refer to “seat, fenders and fuel tank” in chapter 3. 2 exhaust pipe/muffler 1 3 exhaust pipe gasket 1 4...

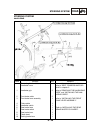

Page 96: Eng

Refer to “removing the engine”. Engine mounting bolts order job/part q’ty remarks removing the engine mounting bolts remove the parts in the order listed. Carburetor refer to “carburetor” in chapter 5. 1 drive chain 1 2 lower engine mounting nut/bolt 1/1 3 upper engine mounting nut/bolt 1/1 refer to...

Page 97: Eng

Removing the engine installing the engine 1. Install: • upper engine mounting bolt/nut • lower engine mounting bolt/nut do not fully tighten the bolts and nuts. The master link clip must be installed with the rounded end facing the direction of travel. 2. Tighten: • upper engine mounting nut • lower...

Page 98: Eng

Cylinder head order job/part q’ty remarks removing the cylinder head remove the parts in the order listed. Carburetor assembly refer to “carburetor” in chapter 5. Exhaust pipe/muffler refer to “engine”. 2 spark plug 1 8 gasket, carb. Insulator 1 7 insulator carburetor 1 6 pipe assy, inlet 1 5 carb. ...

Page 99: Eng

14 head comp cylinder 1 15 gasket cylinder head 1 order job/part q’ty remarks 11 holder cam shaft 1 10 cover assy head cylinder 1 for installation, reverse the removal procedure. 16 guide cam chain 1 12 pin, dowel 4 13 cam shaft comp. 1 17 guide tension cam chain 1 refer to “removing the cylinder he...

Page 100: Eng

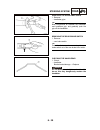

Removing the cylinder head 1. Align: • “t” mark on the rotor (with the stationary pointer on the crank- case) a. Turn the crankshaft clockwise with a wrench. B. Align the “t” mark on the rotor with the stationary pointer on the crankcase. When the “t” mark is aligned with the sta- tionary pointer, t...

Page 101: Eng

Checking the timing chain tensioner assembly 1. Check: • lifter comp tensioned wear/damage ĺ replace. 3. Remove: cam shaft comp. Cyl. Head assy. Fasten a safety wire to the timing chain to prevent it from falling into crankcase. Checking the camshaft sprocket 1. Check: • camshaft sprocket more than ...

Page 102: Eng

Checking the cylinder head 1. Eliminate: • combustion chamber carbon deposits (with a rounded scraper) do not use a sharp instrument to avoid damag- ing or scratching: • spark plug bore threads • valve seats 2. Check: • cylinder head damage/scratches ĺ replace. 3. Measure: • cylinder head warpage ou...

Page 103: Eng

Installing the cylinder head 1. Install: cyl. Head assy. 1 cam shaft comp. Cap, camshaft • • • • • tighten the nuts in two stages and a crisscross pattern. 2. Install: • cam shaft comp. A. Rotate the camshaft to align the round h- ole in camshaft sprocket away from t- he cylinder head. B.Turn the cr...

Page 104: Eng

I. If the marks are aligned, temporarily tighten the camshaft sprocket bolt. If the marks are not aligned, change the meshing position of the camshaft sprocket and timing chain. 3. Install: bolt, flg. (small head) tensioner assy. Always use a new gasket. 4. Adjust: • timing chain tensioner 5. Check:...

Page 105: Eng

Camshaft, rocker arms and valves refer to “removing the rocker arms and camshaft” and “installing the camshaft and rocker arms”. Refer to “removing the valves and valve springs” and “install- ing the valves and valve springs”. For installation, reverse the removal pro- cedure. 1 4 4 5 5 2 3 12 13 11...

Page 106: Eng

Removing the rocker arms and camshaft 1. Loosen: • locknuts • screw, valve adjusting 2. Remove: • shaft in rocker arm • shaft ex rocker arm • intake rocker arm • exhaust rocker arm tip remove the rocker arm shafts with the slide hammer bolt and weight . 3. Remove: • camshaft comp. Removing the valve...

Page 107: Eng

2. Remove: • valve cotters tip attach a valve spring compressor and attachment between the valve spring retainer and the cylinder head to remove the valve cotters. Checking the camshaft 1. Check: • cam lobes pitting/scratches/blue discoloration ĺ replace. 2. Measure: • cam lobe dimensions and out of...

Page 108: Eng

2. Check: • rocker arm shaft blue discoloration/excessive wear/pitting/ scratches ĺ replace or check the lubrica- tion system. 3. Check: • camshaft lobe excessive wear ĺ replace the camshaft. 4. Measure: • rocker arm inside diameter out of specification ĺ replace. Rocker arm inside diameter 10.1 mm ...

Page 109: Eng

Checking the valves and valve springs 1. Measure: • stem-to-guide clearance • out of specification ĺ replace the cylinder head ass'y. Stem-to-guide clearance = valve guide inside diameter – valve stem diameter stem-to-guide clearance intake 0.010 ~ 0.037 mm (0.0004 ~ 0.0015 in) : 0.08 mm (0.0031 in)...

Page 110: Eng

2. Check: • valve face pitting/wear ĺ grind the face. • valve stem end mushroom shape or diameter larger than the body of the stem ĺ replace. 3. Measure: • margin thickness out of specification ĺ replace. Margin thickness intake 0.5 ~ 0.9 mm (0.0197 ~ 0.0354 in) exhaust 0.6 ~ 1.0 mm (0.0236 ~ 0.0394...

Page 111: Eng

7. Measure: • valve seat width out of specification ĺ reface the valve seat. A. Apply mechanic’s blueing dye (dykem) to the valve face. B. Install the valve into the cylinder head. C. Press the valve through the valve guide and onto the valve seat to make a clear pattern. D. Measure the valve seat w...

Page 112: Eng

B. Apply molybdenum disulfide oil to the valve stem. C. Install the valve into the cylinder head. D. Turn the valve until the valve face and valve seat are evenly polished, then clean off all of the compound. Tip for best lapping results, lightly tap the valve seat while rotating the valve back and ...

Page 113: Eng

11.Measure: • spring tilt out of specification ĺ replace. Spring tilt limit inner 2.0°/1.1 mm(2.0°/0.04 in) installing the valves and valve springs 1. Apply: • molybdenum disulfide oil (onto the valve stem and valve stem seal) 2. Install: • valve spring seats • valve stem seals • valves • valve spri...

Page 114: Eng

Installing the camshaft and rocker arms 1. Install: • camshaft comp. Tip be sure to align the round hole in camshaft 2. Apply: • engine oil (onto the rocker arm shafts) 3. Install: • rocker arms • rocker arm shafts tip use a slide hammer bolt to install the rocker arm shaft. Sprocket away from the c...

Page 115: Eng

Cylinder and piston order job/part q’ty remarks removing the cylinder and piston remove the parts in the order listed. Refer to cylinder head “cylinder head”. Refer to 1 cylinder “installing the cylinder”. 1 2 cylinder gasket 2 3 dowel pin 2 4 piston pin clip refer to “removing the piston” and “inst...

Page 116: Eng

Removing the piston 1. Remove: • piston pin clips • piston pin • piston • before removing the piston pin clip, cover the crankcase opening with a clean rag to prevent the piston pin clip from falling into the crankcase. • before removing each piston pin, deburr the clip groove and pin hole area. If ...

Page 117: Eng

B. If out of specification, rebore or replace the cylinder, and replace the piston and piston rings as a set. C. Measure piston skirt diameter “p” with the micrometer. 5 mm (0.20 in) from the bottom edge of the pis- ton d. If out of specification, replace the piston and piston rings as a set. E. Cal...

Page 118: Eng

Checking the piston rings 1. Measure: • piston ring side clearance out of specification ĺ replace the piston and piston rings as a set. Before measuring the piston ring side clear- ance, eliminate any carbon deposits from the piston ring grooves and piston rings. 2. Install: • piston ring (into the ...

Page 119: Eng

Checking the piston pin 1. Check: • piston pin blue discoloration/grooves ĺ replace the piston pin and then check the lubrication system. 2. Measure: • piston pin outside diameter out of specification ĺ replace the piston pin. Piston pin outside diameter 12.996 ~ 13.000 mm (0.5117 ~ 0.5118 in) : 12....

Page 120: Eng

120 Û 120 Û 120 Û b c a d e f f new installing the piston 1. Install: • piston rings (onto the piston) tip • be sure to install the piston rings so that the manufacturer’s marks or numbers are located on the upper side of the rings. • lubricate the piston and piston rings liberally with engine oil. ...

Page 121: Eng

Installing the cylinder 1. Install: • cylinder install the cylinder with one hand while com- pressing the piston rings with the other hand. • be careful not to damage the timing chain damper during installation. • pass the timing chain through the timing chain cavity. Eng 4 - 27 cylinder and piston ...

Page 122: Eng

For installation, reverse the removal pro- cedure. Removing the c.D.I. Magneto duct inlet assy. Fan c.D.I. Magneto rotor stator coil assembly c.D.I. Magneto remarks order job/part q’ty 1 2 3 1 1 1 1 disassemble the parts in the order listed. Refer to “cylinder head”. Disconnect the c.D.I. Magneto le...

Page 123: Eng

Removing the c.D.I. Magneto rotor 1. Remove: nut plate washer 1 1 checking the pickup coil/stator assembly 1. Check: • pickup coil/stator assembly damage ĺ replace. Tip while holding the c.D.I. Magneto rotor with the holding tool , loosen the c.D.I. Mag- neto nut . Do not allow the sheave holder to ...

Page 124: Eng

Installing the c.D.I. Magneto rotor 1. Install: c.D.I. Magneto rotor tip clean the tapered portion of the crankshaft and the magneto rotor hub. When installing the magneto rotor, make sure the woodruff key is properly seated in the keyway of the crankshaft. 2. Tighten: nut tip while holding the c.D....

Page 125: Eng

Remarks order job/part q’ty 1 2 3 1 1 2 belt drive crankcase cover removing the belt drive arm comp kick starter cover l side dowel pin remove the parts in the order listed. For installation, reverse the removal pro- cedure. T r . . 12 nm (1.2 m • kg, 8.7 ft • ib) eng 4 - 31 belt drive.

Page 126: Eng

Remarks order job/part q’ty 4 5 2 1 3 6 7 9 8 1 1 1 1 1 1 1 1 1 remove the parts in the order listed. Refer to “crankcase cover “. Refer to “installing the kickstarter“. For installation, reverse the removal pro- cedure. Kickstarter removing the kickstarter crankcase, cover circlip washer gear comp ...

Page 127: Eng

Installing the kickstarter 1. Install: boss kick spindle spindle comp kick start spring kick starter 2. Hook: spring kick starter tip hook the spring end on the spindle comp kick start as shown, and hook the other end on the projection . 3. Install: plain washer circlip 4. Install: kgear comp starte...

Page 128: Eng

Remarks order job/part q’ty 1 2 3 4 5 6 8 9 10 11 12 13 1/1 1 1 1 1 1 1 1 1 1 1/6 3 1 remove the parts in the order listed. Refer to “ removing the face assy, movable drive “. Refer to “ removing the plate sub assy driven and v-belt “. For installation, reverse the removal pro- cedure. Removing the ...

Page 129: Eng

Remarks order job/part q’ty 1 1 3 1 1 3 1 2 2 1 disassemble the parts in the order listed. Refer to “ plate sub assy driven and v-belt “. For assembly, reverse the disassembly procedure. Disassembling the plate sub assy drive nut hex clutch comp spring clutch spring driven face collar spring pin gui...

Page 130: Eng

Removing the primary sheave 1. Remove: primary sheave nut plate washer primary fixed sheave - 1 while holding the primary fixed sheave with the rotor holding tool , loosen the primary fixed sheave nut. Removing the secondary sheave and v-belt 1. Remove: secondary sheave nut clutch housing primary fi...

Page 131: Eng

Disassembling the secondary sheave 1. Remove: clutch carrier nut tip install the clutch spring holder and clutch spring holder arm onto the secondary sheave as shown. Then, compress the spring, and re- move the clutch carrier nut . Checking the clutch shoe 1. Measure: clutch shoe scratches 3 glaze u...

Page 132: Eng

Checking the v-belt 1. Check: v-belt cracks/damage/wear replace. Grease/oil clean the primary and sec- ondary sheave. 2. Measure: v-belt width out of specification replace. V-belt width 18.0 mm (0.709 in) : 17.0 mm (0.669 in) checking the drive pulley 1. Check: face movable drive face driver cracks/...

Page 133: Eng

Checking the piece slider 1. Check: piece slide damage/wear replace checking the driven pulley 1. Check: face comp, driven face comp, movable driven cracks/damage/wear replace the face comp, driven and face comp, movable driven as a set. 2. Check: torque cam groove damage/wear replace the face comp,...

Page 134: Eng

Assembling the primary sheave 1. Clean: face driver face movable drive boss drive face roller weights 3. Install: piece slide face movable drive plate ramp tip use thinner to clean up grease, dirt on the pri- mary sliding sheave cam side . 2. Install: roller weights boss drive face 2 2 2 2 2 2 3 3 1...

Page 135: Eng

Assembling the secondary sheave 1. Lubricate: face comp, movable driven’s inner surface face comp, driven’s inner surface torque cam groove oil seals bearings (with the recommended lubricant) 2. Install: face comp, movable driven install the face comp, movable driven onto the face comp, driven with ...

Page 136: Eng

2 1 5. Install: face comp, driven spring clutch comp attach the clutch spring holder and clutch spring holder arm onto the secondary sheave as shown. Then, compress the spring, and tighten the clutch nut hex . Installing the belt drive 1. Install: v-belt plate sub assy drive 1 do not allow grease to...

Page 137: Eng

2. Install: clutch nut hex tip while holding the clutch carrier with the rotor holding tool , tighten the clutch carrier nut with the locknut wrench . 3. Install: outer clutch nut tip tighten the secondary sheave nut with the sheave holder . 4. Position: v-belt tip position the v-belt in the face mo...

Page 138: Eng

Starter clutch and starter motor remarks order job/part q’ty 1 2 3 4 1 1 1 1 1 1 1 1 1 1 1 disassemble the parts in the order listed. Refer to “ removing the primary sheave “ for installation, reverse the removal pro- cedure. Removing the starter clutch and starter motor primary sheave 5 6 7 8 9 10 ...

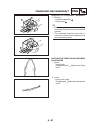

Page 139: Eng

Checking the starter wheel gear 1. Check: starter wheel gear idle gear burrs/chips/roughness/wear replace 1 2 eng 4 - 45 starter clutch and starter motor 2. Check: starter clutch operation 1 2 a b a. Install the starter wheel gear onto the idle gear and hold the starter clutch. B. When turning the s...

Page 140: Eng

Oil pump 3 6 8 7 4 1 13 12 2 ls 5 9 10 e 11 remarks order job/part q’ty 1 2 3 4 5 6 7 8 9 10 11 12 13 1 2 1 2 1 1 1 1 1 1 1 1 1 disassembling the oil pump c.D.I. Magneto cover o-ring oil seal dowel pin nut oil pump driven gear dowel pin oil pump body outer rotor inner rotor oil pump shaft oil pump h...

Page 141: Eng

Checking the oil pump 1. Check: oil pump driven gear cracks/damage/wear replace the de- fective part(s). 2. Measure: inner-rotor-to-outer-rotor-tip clearance outer-rotor-to-oil-pump-housing clear- ance oil-pump-housing-to-inner-rotor-and- outer-rotor clearance out of specification replace the oil pu...

Page 142: Eng

Installing the oil pump 1. Install: o-ring new oil pump assembly oil pump bolt after tightening the bolts, make sure the oil pump turns smoothly. 3. Check: oil pump operation rough movement repeat steps (1) and (2) or replace the defective part(s). 2 1 new 2 1 t r . . 12 nm (1.2 m • kg, 8.7 ft • ib)...

Page 143: Eng

Crankcase and crankshaft remarks order job/part q’ty 1 2 3 4 5 6 7 8 9 1 2 1 1 1 1 1 1 1 remove the parts in the order listed. Refer to “ engine “. Refer to “cylinder head “. Refer to “cylinder and piston “. Refer to “v-belt, clutch, drive and driven pulley “. Refer to “starter clutch and starter mo...

Page 144: Eng

Separating the crankcase 1. Remove: • crankcase bolt 2. Remove: • right crankcase tip tap on one side of the crankcase with a soft- face hammer . Tap only on reinforced portions of the crankcase, not on the crankcase mating surfaces. Work slowly and carefully and make sure the crankcase halves separ...

Page 145: Eng

Removing the crankshaft assembly 1. Remove: crankshaft assembly timing chain tip before removing the crankshaft assembly, remove the timing chain from the crankshaft sprocket. The crankshaft assembly cannot be re- moved if the timing chain is attached onto the crankshaft sprocket. Checking the timin...

Page 146: Eng

Checking the crankshaft and con- necting rod 1. Measure: crankshaft runout out of specification replace the crank- shaft, bearing or both. Tip turn the crankshaft slowly. Maximum crankshaft runout 0.04 mm (0.0016 in) 2. Measure: big end side clearance out of specification replace the big end bearing...

Page 147: Eng

5. Check: crankshaft journal scratches/wear replace the crank- shaft. Installing the crankshaft 1. Install: crankshaft assembly crankcase timing chain to avoid scratching the crankshaft and to ease the installation procedure, lubricate the oil seal lips with lithium-soap-based grease and each bearin...

Page 148: Eng

Assembling the crankcase 1. Thoroughly clean all the gasket mating sur- faces and crankcase mating surfaces. 2. Install: (onto the crankcase mating surfaces) 3. Install: dowel pins timing chain 4. Install: crankshaft crankcase (right ) 5. Tighten: crankcase tip install the timing chain so it is not ...

Page 149: Eng

Transmission 8 7 remarks order job/part q’ty 1 2 3 4 5 6 1 1 2 1 1 1 removing the lock washer, drive sprocket, and circlip transmission oil crankcase cover belt drive driven pulley cover mission gasket, mission cover dowel pin shaft drive counter shaft comp final shaft comp 7 8 1 1 sprocket drive pl...

Page 150: Eng

Checking the transmission 1. Measure: counter shaft runout (with a centering device and dial gauge ) out of specification replace the counter shaft. Counter shaft runout limit 0.08 mm (0.0031 in) 2. Measure: drive shaft runout (with a centering device and dial gauge ) out of specification replace th...

Page 151: Carburetor

Carburetor carburetor order job/part q’ty remarks removing the carburetor remove the parts in the order listed. 1 fuel overflow hose 1 2 air vent hose 1 3 fuel hose 1 7 spring 1 8 manual starter comp 1 5 plate 1 4 carburetor assembly 1 6 plunger assay, starter 1 for installation, reverse the removal...

Page 152: Carb

Order job/part q’ty remarks disassembling the carburetor remove the parts in the order listed. Before disassembling the carburetor, make sure to note the number of times the pilot screw is turned out from the seated position to its set position. Cover 1 1 spring 1 piston valve 1 jet needle 1 1 1 pil...

Page 153: Carb

Order job/part q’ty remarks disassembling the carburetor remove the parts in the order listed. Needle valve spring 1 float pin 1 main jet 1 1 needle jet holder 1 needle jet 1 pilot jet 1 plug 1 1 float for assembly, reverse the disassembly procedure. New 1 2 3 4 5 6 8 9 7 10 11 12 13 14 15 17 18 16 ...

Page 154: Carb

Disassembling the carburetor tip before disassembling the carburetor, make sure to note the number of times the pilot screw is turned out from the seated position to its set position. • float tang checking the carburetor 1. Check: • carburetor body • float chamber cracks/damage replace. • fuel passa...

Page 155: Carb

4. Check: 5. Check: 6 . Check: 8 . Check: • piston valve damage/scratches/wear replace. • piston valve diaphragm cracks/tears replace. • vacuum chamber cover • piston valve spring cracks/damage replace. • jet needle • main jet • needle jet holder • pilot jet bends/damage/wear replace. Obstruction cl...

Page 156: Carb

Assembling the carburetor before assembling the carburetor, make sure to turn out the pilot air screw the same number of times, as noted before disassembly, from the seated position to the set position. • before assembling the carburetor, wash all of the parts in a petroleum-based sol- vent. • alway...

Page 157: Carb

Installing the carburetor 1. Adjust: • engine idling speed engine idling speed 1,600 ~ 1,800r/min refer to “adjusting the engine idling speed” in chapter 3. 2. Adjust: • throttle cable free play throttle cable free play (at the flange of the throttle grip) 1 ~ 3 mm (0.04 ~ 0.12 in) refer to “adjusti...

Page 158: Carb

Measuring and adjusting the fuel level 1. Measure: • fuel level out of specification ĺ adjust. A. Stand the machine on a level surface. B. Install the fuel level gauge onto the fuel drain pipe . C. Loosen the fuel drain screw . D. Hold the fuel level gauge vertically next to the line on the float ch...

Page 159: Chassis

Chassis front and rear wheels front wheels order job/part q’ty remarks removing the front wheels remove the parts in the order listed. Place the machine on a level surface. Securely support the machine so there is no danger of it falling over. The following procedure applies to both of the front whe...

Page 160: Chas

Rear wheels order job/part q’ty remarks removing the rear wheels remove the parts in the order listed. Place the machine on a level surface. Securely support the machine so there is no danger of it falling over. The following procedure applies to both of the rear wheels. 1 cotter pin 1 refer to “ins...

Page 161: Chas

Checking the wheels the following procedure applies to both of the front and rear wheels. 1. Check: • wheel 2. Measure: • wheel runout over the specified limit ĺ replace the wheel or check the wheel bearing play . 3. Check: • wheel balance out of balance ĺ adjust. After replacing the tire, ride cons...

Page 162: Chas

Eye protection is recommended when using striking tools. C. To install the wheel bearings, reverse the above sequence. Use a socket that matches outside diameter of bearing outer race to drive in bearing. Do not strike the center race or balls of the bearing. Contact should be made only with the out...

Page 163: Chas

Installing the front wheels the following procedure applies to both of the front wheels. 1. Install: • wheel tip the arrow mark on the tire must point in the direction of rotation of the wheel. 2. Tighten: • nuts a installing the rear wheels the following procedure applies to both of the rear wheels...

Page 164: Chas

Front brakes order job/part q’ty remarks removing the front brakes remove the parts in the order listed. Refer to “front and rear wheels”. The following procedure applies to both of the front brakes. 1 brake shoe 2 refer to “installing the front brakes”. 2 front brake cable (drum side) 1 3 brake sho...

Page 165: Chas

Removing the front brakes the following procedure applies to each brake. 1. Remove: • brake camshaft lever • brake camshaft when removing the brake camshaft lever, mark the position on the brake camshaft lever where it is aligned with the punch mark in the brake camshaft. Checking the front brake sh...

Page 166: Chas

2. Check: • brake shoe lining surface glazed areas ĺ remove. Use coarse sandpaper. Tip after using sandpaper, wipe off the polished particles with a cloth. 3. Measure: • brake shoe lining thickness out of specification ĺ replace. Measuring points tip replace the brake shoes as a set if either is fou...

Page 167: Chas

2. Check: • brake drum inner surface oil/scratches ĺ remove. Installing the front brakes the following procedure applies to both of the front brakes. Reverse the “removal” procedure. Note the following points. 1. Lubricate: • brake camshaft • pivot pin during installation, lightly grease the brake c...

Page 168: Chas

3. Install: • brake shoe plate when installing the brake shoe plate, align the groove of the brake shoe plate with the pro- jection of the steering knuckle. 4. Install: • front brake cable (drum side) • brake shoes check that the brake shoes are properly posi- tioned. 5. Check: • brake camshaft oper...

Page 169: Chas

Rear axle and rear axle hub order job/part q’ty remarks removing the rear axle and rear axle hub remove the parts in the order listed. Rear wheels/rear wheel hubs refer to “front and rear wheels”. 1 nut 2 2 brake caliper 1 do not apply the brake lever and do not use the parking brake when the brake ...

Page 170: Chas

Order job/part q’ty remarks 4 rear axle 1 refer to “removing the rear axle”. 6 driven sprocket/sprocket bracket 1/1 refer to “installing the driven sprocket”. 7 spacer 1 8 chain puller 1 10 bearing/oil seal 11 bearing spacer 1 12 bearing/oil seal 1/1 for installation, reverse the removal procedure. ...

Page 171: Chas

Removing the rear axle 1. Place the machine on a level surface. • nuts • apply the brake lever so that the rear axle does not turn, when loosening the nut. • use the axle nut wrench (36 mm) . 3. Elevate the rear wheels by placing the suit- able stand under the frame. 4. Remove: • rear wheels • wheel...

Page 172: Chas

Checking the rear axle 1. Check: • rear axle runout out of specification ĺ replace. Do not attempt to straighten a bent axle. Checking the driven sprocket 1. Check: • driven sprocket refer to “rear shock absorber, swingarm and drive chain”. Installing the driven sprocket 1. Install: • driven sprocke...

Page 173: Chas

Installing the rear axle 1. Install: • axle clip tip 3. Tighten: • nut tighten the nut with rear axle nut wrench to specification while holding the rear axle. 2 tip 2. Tighten: • nut tighten the nut with rear axle nut wrench to specification while holding the rear axle. 2 t r . . 60 nm (6.0 m • kg, ...

Page 174: Chas

Rear brake order job/part q’ty remarks removing the rear brake pads remove the parts in the order listed. The following procedure applies to both of the rear brake calipers. Rear wheel refer to “front and rear wheels”. 1 brake pad 2 2 brake pad spring 1 for installation, reverse the removal procedur...

Page 175: Chas

Disc brake components rarely require dis- assembly. Do not: • disassemble components unless abso- lutely necessary; • use solvents on internal brake compo- nents; • use spent brake fluid for cleaning; (use only clean brake fluid) • allow brake fluid to come in contact with the eyes, as this may caus...

Page 176: Chas

5. Check: • brake lever or brake pedal operation soft or spongy feeling ĺ bleed the brake system. Refer to “bleeding the hydraulic brake system” in chapter 3. C. Tighten the brake caliper bleed screw. D. Install a new brake pad spring and new brake pads. 3. Install: • brake caliper • brake caliper m...

Page 177: Chas

Rear brake master cylinder order job/part q’ty remarks removing the rear brake master cylinder remove the parts in the order listed. Brake fluid drain. Refer to “bleeding the hydraulic brake system” in chapter 3. 1 brake fluid reservoir cap 1 2 brake fluid reservoir diaphragm 1 3 front brake light s...

Page 178: Chas

Checking the master cylinder 1. Check: • brake master cylinder wear/scratches ĺ replace the brake mas- ter cylinder assembly. • brake master cylinder body cracks/damage ĺ replace. • brake fluid delivery passage (brake master cylinder body) blockage ĺ blow out with compressed air. 2. Check: • rear br...

Page 179: Chas

Installing the rear brake master cylinder 1. Install: • brake master cylinder • the “up” mark on the brake master cylinder bracket should face up. • install the brake master cylinder so that the gaps between the brake master cylinder and the brake master cylinder bracket are equal. 2. Install: • cop...

Page 180: Chas

3. Fill: • brake fluid reservoir brake fluid may damage painted surfaces or plastic parts. Always clean up spilled brake fluid immediately. • use only the designated quality brake fluid: other brake fluids may deteriorate the rubber seals, causing leakage and poor brake performance. • refill with th...

Page 181: Chas

Order job/part q’ty remarks removing the rear brake caliper remove the parts in the order listed. Brake fluid drain. Refer to “bleeding the hydraulic brake system” in chapter 3. 2 union bolt 1 parking brake cable 1 3 copper washer 2 4 brake hose 1 disconnect. 5 brake caliper assembly 1 for installat...

Page 182: Chas

Chas 6 - 24 order job/part q’ty remarks remove the parts in the order listed. For assembly, reverse the disassembly procedure. Rear brake t r . . 8 nm (0.8 m • kg, 6.5 ft • ib) disassembling the rear brake caliper adjusting bolt 1 locknut 1 parking brake arm 1 bracket brake bracket 1 parking brake c...

Page 183: Chas

Checking the rear brake caliper recommended brake component replacement schedule brake pads as required caliper ass'y every two years brake hoses every four years brake fluid replace when brakes are disassembled. 1. Check: • brake caliper body cracks/damage ĺ replace. • brake fluid delivery passage ...

Page 184: Chas

Installing the rear brake caliper 1. Install: • brake caliper assembly • brake caliper mounting bolts • brake hose • copper washers • union bolt brake caliper mounting bolt 35 nm (3.5 m•kg, 25.3 ft•lb) union bolt 28 nm (2.8 m•kg, 20.3 ft•lb) when installing the brake hose on the brake caliper, make ...

Page 185: Chas

• use only the designated quality brake fluid: other brake fluids may deteriorate the rubber seals, causing leakage and poor brake performance. • refill with the same type of brake fluid: mixing brake fluids may result in a harm- ful chemical reaction and lead to poor brake performance. • be careful...

Page 186: Chas

Steering system handlebar order job/part q’ty remarks removing the handlebar remove the parts in the order listed. Handlebar cover refer to “seat, fenders and fuel tank” in chapter 3. 1 handlebar grip 2 refer to “removing the handlebar grips” and “installing the han- dlebar grips”. 2 front brake cab...

Page 187: Chas

Order job/part q’ty remarks 11 upper handlebar holder 2 refer to “installing the handle- bar”. 12 handlebar 1 for installation, reverse the removal pro- cedure. 6 - 29 chas steering system (x4) (x2) (x2).

Page 188: Chas

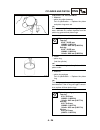

Removing the handlebar grips 1. Remove: • handlebar grips blow compressed air between the handlebar and handlebar grip, and gradually push the grip off the handlebar. Removing the rear brake switch 1. Remove: • rear brake switch push the fastener when removing the rear brake switch out of the rear b...

Page 189: Chas

Installing the handlebar 1. Install: • handlebar • upper handlebar holders • install the handlebar, please align the punch mark and the gap at handlebar holder . • the upper handlebar holders should be installed with the flange forward . First tighten the bolt on the rear side of the handlebar holde...

Page 190: Chas

Installing the rear brake master cylinder 1. Install: • handlebar switch tip • installing the rear brake master cylinder, make sure the handlebar switch , handlebar grip , and brake master cylinder are in the positions shown in the illustration. Installing the front brake lever assembly 1. Install: ...

Page 191: Chas

Installing the parking brake lever 1. Install: • parking brake lever • parking brake cable • damper • parking brake lever plate • parking brake lever bracket tip 2. Adjust: • parking brake refer to “ adjusting the parking brake” in chapter 3. A b install the parking brake cable lever, please align t...

Page 192: Chas

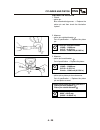

Steering stem order job/part q’ty remarks removing the steering stem remove the parts in the order listed. Front fender refer to “seat, fenders and fuel tank” in chapter 3. Handlebar refer to “handlebar”. 1 steering stem bushing 2 2 brg.,steering 1 3 steering stem 1 4 lower handlebar holder 1 refer ...

Page 193: Chas

Removing the steering stem 1. Remove: • steering stem when loosening each tie-rod end nut , hold the tie-rod ball joint with a 14-mm wrench . Checking the steering stem 1. Check: • steering stem bends ĺ replace. Do not attempt to straighten a bent stem; this may dangerously weaken the stem. 2. Check...

Page 194: Chas

Installing the steering stem 1. Tighten: • steering stem nut • tie-rod end nut tip when tightening each tie-rod end nut , hold the tie-rod ball joint with a 14-mm wrench . Tip the lower handlebar holder and steering stem should be set a right angle when assembling. Installing the lock washer 1. Inst...

Page 195: Chas

Tie-rods and steering knuckles order job/part q’ty remarks removing the tie-rods and steering knuckles remove the parts in the order listed. The following procedure applies to both of the tie-rods and steering knuckles. Refer to “front brakes”. 1 tie-rod refer to “installing the tie-rods”. 1 2 suspe...

Page 196: Chas

Removing the tie-rods the following procedure applies to both of the tie-rods. The following procedure applies to both of the steering knuckles . 1. Remove: • tie-rod tip when removing the tie-rod, hold each tie-rod ball joint with a 14-mm wrench and then loosen the tie-rod end nut. Checking the tie...

Page 197: Chas

Installing the tie-rods the following procedure applies to both of the tie-rods. 1. Install: • tie-rod tip • the tie-rod side which must be installed on the outside has grooves . • when installing the tie-rod, hold each tie-rod ball joint with a 14-mm wrench and then tighten the tie-rod end nut. 2. ...

Page 198: Chas

Front arms and front shock absorber assemblies order job/part q’ty remarks removing the tie-rods and steering knuckles remove the parts in the order listed. The following procedure applies to both of the tie-rods and steering knuckles. Refer to “front brakes”. 1 tie-rod 1 disconnect. 1 1 1 front bra...

Page 199: Chas

2 1 a b removing the front arms 1. Check: • front arm free play a. Check the front arm side play by moving it from side to side. If side play is noticeable, check the bush- ings. B. Check the front arm vertical movement by moving it up and down. If the vertical movement is tight or rough, or if ther...

Page 200: Chas

Checking the ball joints the following procedure applies to both of the front arm ball joints. 1. Check: • ball joint damage/pitt lqjĺ replace the front arm. Free pla \ĺ replace the front arm. Turns roug ko\ĺ replace the front arm. Installing the front arms the following procedure applies to both of...

Page 201: Chas

Rear shock absorber, swingarm and drive chain order job/part q’ty remarks removing the rear shock absorber, swingarm and drive chain remove the parts in the order listed. Seat/rear fender/air filter case refer to “seat, fenders and fuel tank” in chapter 3. Rear axle hub refer to “rear axle and rear ...

Page 202: Chas

Order job/part q’ty remarks 9 drive chain case 1 1 10 lock washer 1 11 drive sprocket 1 12 drive chain 1 13 dust cover 15 bushing 1 16 spacer 2 for installation, reverse the removal procedure. Refer to “installing the drive sprocket”. 2 14 drive chain guide 2 t r . . 35 nm (3.5 m • kg, 25.3 ft • ib)...

Page 203: Chas

Checking the rear shock absorber 1. Check: • shock absorber oil leaks ĺ replace the rear shock absorber assembly. • shock absorber rod bends/damage ĺ replace the rear shock absorber assembly. • spring fatigue ĺ replace the rear shock absorber assembly. Move the spring up and down. Removing the rear ...

Page 204: Chas

C. Check the swingarm vertical movement by moving it up and down. If vertical movement is tight or rough, or if there is binding, check the spacer, bearings and frame pivot. 2. Remove: • pivot shaft nut • pivot shaft • swingarm checking the swingarm 1. Check: • swingarm bends/cracks/damage ĺ replace...

Page 205: Chas

Checking the drive chain 1. Measure: • 15-link section of the drive chain out of specification ĺ replace the drive chain. Tip • while measuring the 15-link section, push down on the drive chain to increase its ten- sion. • measure the length between drive chain roller and as shown. • perform this me...

Page 206: Chas

4. Check: • drive chain rollers damage/wear ĺ replace the drive chain. • drive chain side plates cracks/damage/wear ĺ replace the drive chain. 5. Lubricate: • drive chain 6. Check: • drive sprocket • driven sprocket more than 1/4 tooth wear ĺ replace the drive chain sprockets as a set. Bent teeth ĺ ...

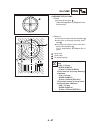

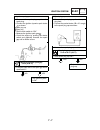

Page 207: Elec

7 - 1 electrical components electrical components elec main switch brake switch cdi unit starter relay fuse rectifier/regulator battery starter motor c.D.I. Magneto ignition coil spark plug 5 1 2 3 4 6 7 8 9 10 11 3 7 11 1 2 4 6 8 9 10 5.

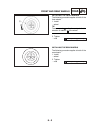

Page 208: Elec

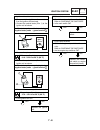

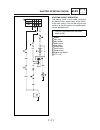

7 - 2 wiring diagram elec main s witch c .D .I. Magneto rectifier/regulator batter y main fuse batter y (+) lead batter y (-) lead wire lead star ter rela y star ter motor c .D .I. Unit ignition coil star t s witch br ak e s witch engine stop s witch 5 1 2 3 4 6 7 8 9 14 10 12 13 11 15 color cod b b...

Page 209: Elec

7 - 3 checking the switches checking the switches check each switch for damage or wear, proper connections, and also for continuity between the terminals. Refer to “checking switch con- tinuity”. Damage/wear repair or replace. Improperly connected properly connect. Incorrect continuity reading repla...

Page 210: Elec

7 - 4 checking switch continuity checking switch continuity check each switch for continuity with the pocket tester. If the continuity reading is incor- rect, check the wiring connections and if nec- essary, replace the switch. Never insert the tester probes into the cou- pler terminal slots . Alway...

Page 211: Elec

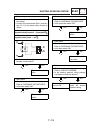

7 - 5 ignition system ignition system elec circuit diagram main switch c.D.I. Magneto battery main fuse c.D.I. Unit ignition coil 5 1 2 4 12 11 off st ar t st eng stop sw ar t sw 7.5a 12v 5ah br r b r r r r l/y l/y y/r l/y r g/y g/y g/y b r/w r/w r b b b g/y mo t o r 5 4 6 7 8 9 10 14 13 off on r r/...

Page 212: Elec

7 - 6 ignition system troubleshooting check: 1. Spark plug 2. Ignition spark gap 3. Spark plug cap resistance 4. Ignition coil resistance 5. Main switch 7. Wiring connections (of the entire ignition system) tip • before troubleshooting, remove the following part(s): 1. Seat 2. Front fender 3. Fuel t...

Page 213: Elec

7 - 7 ignition system no yes yes no 2. Ignition spark gap • disconnect the spark plug cap from the spark plug. • connect the ignition dynamic spark tester as shown. Spark plug cap spark plug • set the main switch to “on”. • measure the ignition spark gap . • crank the engine by pushing the starter s...

Page 214: Elec

7 - 8 ignition system yes no yes no yes no 4. Ignition coil resistance • disconnect the ignition coil connectors from the ignition coil terminals. • connect the pocket tester ( × 1) to the ignition coil as shown. Positive tester probe ĺ black terminal negative tester probe ĺ green terminal • measu...

Page 215: Elec

7 - 9 ignition system yes no yes a.C.G. A.C.G. No yes no 7. Pickup coil resistance • disconnect the c.D.I. Magneto coupler from the wire harness. • connect the pocket tester ( 100) to the pickup coil terminal as shown. Positive tester probe white/red terminal negative tester probe black terminal • m...

Page 216: Elec

7 - 10 electric starting system electric starting system elec circuit diagram off st ar t st eng stop sw ar t sw 7.5a 12v 5ah br r b r r r r l/y l/y y/r l/y r g/y g/y g/y b r/w r/w r b b b g/y mo t o r 5 4 6 7 8 9 10 14 13 off on r r/b b r b check off on main sw 1 br w/r br r b r/b w/b b/w b/w 2 ww ...

Page 217: Elec

7 - 11 electric starting system starting circuit operation battery main fuse main switch brake switch starter motor engine stop switch • you pull in the brake lever (the brake switch is on). 7 5 1 2 3 4 8 9 9 10 7 10 6 c.D.I. Unit safety switch start switch starter relay check off on r r r c/y r/w m...

Page 218: Elec

7 - 12 electric starting system troubleshooting check: 1. Main fuse 2. Battery 3. Starter motor 4. Starter relay 5. Main switch 6. Brake switch 7. Start switch 8. 9. 10. Wiring connections (of the entire starting system) tip • before troubleshooting, remove the following part(s): 1. Seat 2. Front fe...

Page 219: Elec

7 - 13 electric starting system yes no yes no yes no yes no 4. Starter relay • disconnect the starter relay coupler from the coupler. • connect the pocket tester ( × 1) and bat- tery (12 v) to the starter relay coupler as shown. Positive battery terminal ĺ yellow/red negative battery terminal ĺ gr...

Page 220: Elec

7 - 14 starter motor starter motor order job/part q’ty remarks removing the starter motor remove the parts in the order listed. 1 starter motor lead 1 2 ground lead 1 3 starter motor 1 for installation, reverse the removal pro- cedure. Disassembling the starter motor remove the parts in the order li...

Page 221: Elec

7 - 15 starter motor checking the starter motor 1. Check: • commutator dirt ĺ clean with 600-grit sandpaper. 2. Measure: • commutator diameter out of specification ĺ replace the starter motor. 3. Measure: • mica undercut out of specification ĺ scrape the mica to the proper measurement with a hacksaw...

Page 222: Elec

7 - 16 starter motor 5. Measure: • brush length out of specification ĺ replace the brushes as a set. 6. Measure: • brush spring force out of specification ĺ replace the brush springs as a set. 7. Check: • gear teeth damage/wear ĺ replace the gear. 8. Check: • bearing • oil seal • o-rings damage/wear...

Page 223: Elec

7 - 17 charging system charging system elec circuit diagram off st ar t st eng stop sw ar t sw 7.5a 12v 5ah br r b r r r r l/y l/y y/r l/y r g/y g/y g/y b r/w r/w r b b b g/y mo t o r 5 4 6 7 8 9 10 14 13 off on r r/b b r b check off on main sw 1 br w/r br r b r/b w/b b/w b/w 2 ww y/r y/r bb w w r w...

Page 224: Elec

7 - 18 charging system troubleshooting check: 1. Main fuse 2. Battery 3. Charging voltage 4. Charging coil resistance 5. Wiring connections (of the entire charging system) tip • before troubleshooting, remove the following part(s): 1. Seat 2. Rear fender • troubleshoot with the following special too...

Page 225: Troubleshooting

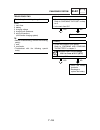

Troubleshooting tip the following troubleshooting does not cover all the possible causes of trouble. It should be helpful, however, as a guide to troubleshooting. Refer to the relative procedure in this manual for check, adjustment and replacement of parts. Starting failure/hard starting fuel system...

Page 226: Trbl

Compression system cylinder and cylinder head • loose spark plug • loose cylinder head or cylinder • broken cylinder head gasket • broken cylinder gasket • worn, damaged or seized cylinder valve, camshaft and crankshaft • improperly sealed valve • improperly contacted valve and valve seat • improper...

Page 227: Trbl

Faulty gear shifting/clutch slipping/ dragging/overheating faulty clutch engine operates but vehicle will not move v-belt • bent, damaged or worn v-belt • slipping v-belt plate ramp and piece slide • damaged or worn plate ramp • damaged or worn piece slide clutch spring(s) • damaged clutch spring tr...

Page 228: Trbl

Faulty brake/shock absorber malfunction/ unstable handling faulty brake poor braking effect front drum brake • worn brake shoe lining • worn brake drum • oily or greasy brake shoe lining • oily or greasy brake drum • improperly adjusted brake lever free play • improper brake cam lever position • imp...