- DL manuals

- E-TON

- Scooter

- EV3 E-MO

- Service Manual

E-TON EV3 E-MO Service Manual

Summary of EV3 E-MO

Page 1

Service manual e v 3 e - m o e-ton power.

Page 2

E-mo 2009 by e-ton power tech co., ltd. First edition, april 2009 all rights reserved. Any reproduction or unauthorized use without the written permission of e-ton power tech co., ltd. Is expressly prohibited. Service manual.

Page 3: Important

Important this manual was produced by the e-ton power tech co., ltd., primarily for use by e-ton dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on e-ton vehicl...

Page 4: Table of Contents

Table of contents specifications periodic checks and adjustments controller system battery/ charger troubleshooting general information chassis chk adj gen info chas electrical system elec – + trbl shtg cont spec bat cha.

Page 5: Chapter 1

Chapter 1 general information general information 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Frame serial number 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motor seri...

Page 6: General Information

Identification of scooter 1-1 general information scooter identification frame serial number the frame serial number is stamped on the chassis. Motor serial number the serial number of the motor is stamped on the portion of the left section of the motor box. Tip the fourth to the sixth digits of the...

Page 7: Important Information

Important information 1-2 important information replacement parts 1. Use only genuine e-ton parts for all replacements. Use the oil and/or grease recommended by e-ton for assembly and adjustment. Gaskets, oil seals and o-rings 1. Replace all gaskets, seals and o-rings when overhauling the rim. All g...

Page 8: Gen

Important information 1-3 checking the connections gen info check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector 2. Check: • lead • coupler • connector moisture dry with an air blower. Rust/stains connect and disconnect sev- eral time...

Page 9: Gen

1-4 se3200-5ba0-0fa1 sa6100-a26-0fa1 sa6100-a26-0fa2 sd4712-egc2-0fa1 sd4711-egc2-0fa1 tool no. Tool name: six legs socket function: to disassemble and assemble the nut of front fork component. Tool name / function tool name: bearing inner puller set function: to disassemble the bearing of front whe...

Page 10: Gen

Special tools 1-5 sc9003-egc2-0000 tool name: function: sc9004-egc2-0000 tool name: function: sc130a-egc2-0fg1 tool name: function: sc7200-egc2-0fg1 tool name: function: gen info tool no. Tool name / function picture motor checking tool testing the hall data of motor. Testing interface software test...

Page 11: Chapter 2

Chapter 2 specifications specifications 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . General specifications 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mainten...

Page 12: Specifications

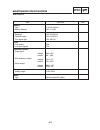

General specifications 2-1 specifications general specifications dimensions overall length 1,550 mm (61.0 in) overall width 650 mm (25.6 in) overall height 1,000 mm (39.4 in) wheelbase 1,050 mm (41.3 in) minimum ground clearance 115 mm (4.5 in) minimum turning radius 1,600 mm (63.0 in) basic weight ...

Page 13: Spec

Maintenance specifications 2-2 chassis front suspension front fork travel 50 mm (1.97 in) rear suspension shock absorber travel 30 mm (1.18 in) front wheel rim size 1.4 x 14" rim material rim runout limit aluminum rear wheel rim size 1.4 x 14" rim material aluminum front drum brake leading, trailing...

Page 14: Spec

Maintenance specifications 2-3 electricity battery type battery capacity li-ion mn battery 48.0 v/ 10ah lights x number headlight 12v 35/ 35w x1 tail/ brake light fuse fuse (main) fuse (turn signal) 12v 21/ 5w x1 turn signal light 12v 10w x4 30a 10a controller system charger power input dc transform...

Page 15: Spec

2-4 spec conversion table all specification data in this manual are listed in si and metric units. Use this table to convert metric unit data to imperial unit data. Conversion table general tightening torque specifications this chart specifies tightening torques for stan- dard fasteners with a stand...

Page 16: Spec

Tightening torques chassis tightening torques 2-5 spec see chapter 3 “adjusting the steering head” 35 35 25 50 3.5 3.5 2.5 5.0 nm m•kg ft•lb m10 m10 m8 m25 1 1 4 2 10 1.0 m6 4 10 1.0 m6 1 10 1.0 m6 1 4 0.4 m6 24 4 0.4 m6 4 80 8.0 m14 m6 2 3 4 0.4 m6 2 4 0.4 35 3.5 m10 1 25 2.5 m8 2 10 1.0 m6 1 4 0.4...

Page 17: Spec

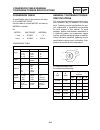

1 2 3 4 5 6 7 8 9 10 11 a b c d 1 3 4 5 6 7 a b c d 12 13 14 15 16 6 15 16 2 2-6 8 9 10 11 12 13 14 cable routing spec wire harness cable brake, rear main switch lead horn lead wire clamp turn signal lead 12 pin connector emi coil starter controller lead dc 12v connecter 6 pin connecter positive bat...

Page 18: Spec

1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 8 9 3 2 1 7 8 9 10 10 10 2-7 cable routing spec right turn light lead right brake lead cable brake, front throttle lead headlight lead meter connector horn lead left brake lead cable brake, rear left turn light lead.

Page 19: Chapter 3

Chapter 3 periodic checks and adjustments introduction/ periodic maintenance/ lubrication 3-1 . . . . . . . . . . . . . . . . . . . . . Removing and installing rear bottom cover/ rear fender 3-5 . . . . . . . . . Adjustment front/rear brake free play 3-6 . . . . . . . . . . . . . . . . . . . . . . ....

Page 20: Chk

3-1 this chapter includes all information necessary to perform recommended checks and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable motorcycle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This informati...

Page 21: Chk

1 2 2 1 3 1 4 1 3-2 1 2 3 (x2) 4 1 (x4) (x3) (x6) (x2) (x2) (x2) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) side cover/ body cover/ headlight/ meter remove and install removing the side c...

Page 22: Chk

1 1 2 1 3 1 4 1 5 1 6 1 3-3 5 (x4) (x4) (x2) (x2) t r . . 25 nm (2.5 m • kg, 18.08 ft • ib) 1 2 3 4 6 t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 6 nm (0.6 m • kg, 4.3 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) 7 t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) 7 1 side cover/ body cover/ headlight/...

Page 23: Chk

1 1 2 1 3 1 4 1 5 1 3-4 1 2 4 5 3 (x3) (x2) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) side cover/ body cover/ headlight/ meter remove and install chk adj removing headlight/ meter/ meter side cover removing headlight/ meter/ ...

Page 24: Chk

1 1 2 1 3 2 4 2 5 1 3-5 1 2 3 4 5 3 4 (x4) t r . . 25 nm (2.5 m • kg, 18.1 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 35 nm (3.5 m • kg, 25.3 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) 6 1 6 removing and installing rear bottom cover/ rear fender chk adj removing rear bottom cover/ ...

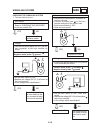

Page 25: Chk

A (a) (b) (a) (b) 3-6 adjusting the front/rear brake checking the brake shoes chk adj chassis front brake adjusting nut rear brake adjusting nut adjusting nut dowel pin 1. Check • clockwise (a) revolving will reduce free play. • counterclockwise (b) revolving will increase free play. Before adjustin...

Page 26: Chk

3-7 adjusting the front/rear brake checking the brake shoes chk adj checking the brake shoes 1. Operate the brake. 2. Check • brake shoes wear indicators reaches the wear limit line ĺ replace the brake shoes as a set. Refer to “rear brake” in chapter 7. Wear limit line wear indicator wear limit line...

Page 27: Chk

Checking the steering head chk adj 4. Remove • front cap a. Remove the upper ring nut . B. Loosen the lower ring nut . Checking the steering head 1. Stand the scooter on a level surface. Warning • please support by main stand. 2. Use a support put in the buttom of vehicle and raise the front wheel. ...

Page 28: Chk

3-9 checking the front fork 1. Stand the scooter on a level surface. 2. Check • front fork 6fudshgdpdjhĺuhsodfh 3. Operation push down hard on the handlebar several times and check if the front fork rebounds smoothly. Rough movement ĺ replace warning • securely support the scooter so that there is n...

Page 29: Chk

2.25-14 27b 2.25-14 27b c-109r-x c-109r-x maxxis maxxis 3-10 t r . . Upper bolt, 35 nm (3.5 m • kg, 25.3 ft • lb) t r . . Lower bolt, 35 nm (3.5 m • kg, 25.3 ft • lb) • tire characteristics manufacturer size type front rear warning ride conservatively after installing a tire to allow it to seat itse...

Page 30: Chk

3-11 tip it is dangerous to ride with a worn-out tire. When tire wear is out of specification, replace the tire immediately. Checking the tires/ checking the wheels chk adj 2. Check: • tire surfaces 'dpdjhzhduĺ5hsodfhwkhwluh 7kuhdgghswk 6lghzdoo :hdulqglfdwru minimum depth of thread of tires 0.8 mm ...

Page 31: Chk

3-12 replacing the headlight bulb chk adj replacing the headlight bulb 1. Remove • headlight . Refer to " removing and installing the cover". • opening the headlight bulb holder cover . • remove headlight coupler . • loosen the screw of bulb fixer and the fixer will open. 1 1 2 2 4 4 3 3.

Page 32: Chk

3-13 replacing the headlight bulb/ replacing the front/ rear turn lights chk adj warning • headlight bulb. Replacing the froent/ rear turn light bulb • lens . • turn light holder site . • bulb . 2. Replace • bulb (burned). • counterclockwise revolving the bulb will take it out. Tip tip notice since ...

Page 33: Chk

3-14 warning since the light bulb gets extremely hot, keep flammable products and your hands away from the bulb until it has cooled down. Warning since the light bulb gets extremely hot, keep flammable products and your hands away from the bulb until it has cooled down. New tip replacing the tail li...

Page 34: Chapter 4

Chapter 4 controller system motor 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Check and troubleshooting 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Re...

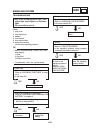

Page 35: Cont

4-1 sc130a-egc2-0fg1 motor cont check and troubleshooting • when the rider control motor speed via acceleration handle, and if the motor can’t run and smoothly and the instrument panel sends out a warning signal, it is necessary to check the motor. • it is necessary to confirm relevant motorcycle co...

Page 36: Cont

Cover l . Remove the bolts and rear bottom Ԧʳʳ bolt . 1 2 1 2 2 2 1 2 1 1 cover r . Remove the bolts and rear bottom Ԧʳʳ 2 1 remove the rear fender bolt . Ԧʳʳ remove the band and rear fender Ԧʳʳ 2 1 and rear fender . Remove the rear fender bracket bolt Ԧʳʳ 1 4-2 motor cont removing the motor 1 2 1.

Page 37: Cont

1 1 1 1 2 3 2 1 4-3 motor cont • remove brake cable. Warning 1 2 3 1 2 • remove brake cable set nut to rear end. • adjust the adjusting nut to loosening position and fix the groove across the brake drum. • remove brake cable adjusting bolt . • loosen set nuts on left and right motor and frame as ill...

Page 38: Cont

4-4 motor cont dowel pin regulator motor installation warning • reverse the removal procedure for installation. • it is necessary to confirm whether the regular and dowel pin are fastened tightly during brake cable installation. Clearance to maintain at 5~10mm. • it is necessary to check and adjust ...

Page 39: Cont

48 v ± 10 v 0 a ~ 30 a 12 v ± 1 v 7 a ± 0.5 a 48 v ± 10 v 25 a ± 1 a driver cont specification power input electric current voltage check and troubleshooting • if an avometer displays “ ”, please replace the fuse. Check installation turn the main switch to “off”. • install a new fuse of the same spe...

Page 40: Cont

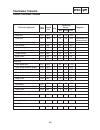

1 & 2 6 3k ~10k 3k~10k 3k~10k 120k~140k 3 4 5 6 7 8 9 10 12 13 14 16 4-6 driver cont 2. Remove out wiring assembly after testing the 3. Remove out wiring assembly after testing the 4. Remove out wiring assembly after testing the when failed, the precise circuits and electronic driver accordi...

Page 41: Cont

4-7 ᛀྒྷտ૿൷ᙰ ᛀྒྷտ૿൷ᒵ Ꮪ।൷ᙰ ᦀ೯ᕴ൷ᙰ usb ൷ᙰ driver cont 1. Testing: lev interface (testing interface) testing interface software panel connector list the all possible causes according to trouble- shooting and be sure to check and confirm all other causes shall be excluded before testing driver according to ...

Page 42: Cont

4-8 driver cont • fill in lev in the selected frame for connecting to the com port of the computer, such as filling 3 for com 3 after clicking com created . The com port position has gotten by click my frpsxwhuĺfolfnuljkwnh\erdugĺclick contents ĺfolfnkdugzduhĺghylfhnhhshudiwhulqvwdoo wkhwhvwlqjlqwhu...

Page 43: Cont

4-9 driver cont • the controller will report the system status as • if it is necessary to leave interface testing software after completing testing, please click on the selected frame com release , and click on com release ,and the switch off the software and pull off the plug to avoid software cras...

Page 44: Cont

4-10 ˄ ˈ ˆ ˇ ˉ ˅ driver cont • operate according the testing interface operation status: unable to starting computer booting (there is no display on the panel instrument or beep tone continues). Steps. If the illustration in the left still doesn’t appear, the driver shall be replaced. Status: if ele...

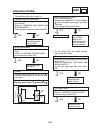

Page 45: Cont

88 888888 odo km/h mph trip 8888.8 8888 p ow x no yes push 00 888888 odo km/h trip 8888.8 1 ʳ 4-11 88 888888 odo km/h mph trip 8888.8 8888 p ow x no yes ˄ˇ ˄ˈ ˄˃ ˌ ˄˄ ˄˅ ˄ˆ ˄ˇ ˋ ˉ ˈ ˇ ˆ ˅ ˄ ˊ ˄ instrument panel cont how to read instrument check and troubleshooting panel total mileage vehicle speed u...

Page 46: Cont

4-12 ˢˡʳ ˢ˙˙ʳ ˢˡ˂ʳˢ˙˙ʳ ˖˟˘˔˥ʳˢ˗ˢʳ instrument panel cont b. After the instrument panel check tools are connected instrument panel can’t function regularly, the panel wiring 12 v functions irregularly, check the main c. If the panel instrument can function regularly, use the electricity meter to measu...

Page 47: Cont

20 888888 km/h trip 8888.8 20 888888 odo km/h trip 8888.8 odo 4-13 00 888888 odo km/h trip 8888.8 instrument panel cont testing steps 2. Switch on a turn signal in riding screen. The icon “eye” and turn signal indicator led shall flash. Failure status 1 • switch on turn signal in the riding screen, ...

Page 48: Cont

X no yes 4-14 00 888888 odo km/h trip 8888.8 instrument panel cont testing steps 4. There will sound beeper tone upon pressing button a or button b in the riding screen. Failure status 1 • the button tone doesn’t sound upon pressing the left or right button in the riding screen. A. Restart the booti...

Page 49: Chapter 5

Chapter 5 battery/charger battery 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . How to check battery residual capacity 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Charger 5-4 . . . . ....

Page 50: Bat

1 1 5-1 battery how to check battery residual capacity read the battery residual capacity indicator or observe the indicator light on the battery box. From the battery residual capacity indicator in the display turn the main switch to on. The battery re- sidual capacity icon in the display will ligh...

Page 51: Bat

5-2 e. Remove the battery to observe the indicator light on the battery box as illustrated in the following list. One of the e-mo features is li-ion mn battery and its performance (electric capacity) will reduce gradually. The performance reduction speed will depend on usage. Repeating charging and ...

Page 52: Bat

5-3 1 1 testing charging 1. Plug on the charger plug and make the charger be off. Switch on the charger and observe whether the charger indicator light illumi- !!!! Nates in red. 2 2 1 discharge 1. Press battery residual power display button and observe whether led light !!! Is on. If led is not on,...

Page 53: Bat

5-4 terminal charging plug power outlet charger power switch charging outlet battery warning power switch charging outlet electricity voltage switch 230 power cable input terminal charger +v -v led installation steps 1. Make sure the charger is switched off. Connect the battery to output terminal. S...

Page 54: Bat

5-5 maintenance and testing steps 1. Set the dc voltage of ammeter to over 100v. 2. The charger shall not be connected with the battery. Switch on the charger and the charger shall illuminate in green. 3. Use the red probe of the ammeter to contact the positive pole (p1) and the black probe to conta...

Page 55: Bat

5-6 troubleshooting if the troubleshooting still can’t be attained after conducting the steps as in the following list, please contact the e-ton co., ltd. Or the authorized dealer. Select wire of proper diameter status possible cause solution no output electricity voltage turn to on position power s...

Page 56

Chapter 6 electrical electrical components 6-1 ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ checking the bulbs and bulb sockets 6-5 ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ checking switch continuity ...

Page 57: Electrical System

Electrical components 6-1 electrical system electrical components main switch controller battery fuse throttle handle switch horn meter 8 9 10 turn signal relay 11 charge 5 1 6 5 7 2 2 3 4 motor 6 7 – + elec 9 10 11 4 1 3 8.

Page 58: Elec

6-2 wiring diagram – + elec on of f on of f r push l r pu sh 10a 30a y/b b /w b/w y/b b/w gr b/w gr br/b y/g g/y g/y g/y g/y g/y y/br g/b br/b y/br g/b br/w y/g g/y br/w b/y lg lg l/y l/y l/y l/y b/y lg lg lg lg br br lg br br br br br br/y br/y br/y y/r b/y y/r br/y br/y br/y br/y r b b r r/w b/y b...

Page 59: Elec

Checking switch continuity 6-3 a b br lg y/r checking switch continuity check each switch for continuity with the poc- ket tester. If the continuity reading is incorrect, check the wiring connections and if necessary, replace the switch. Never insert the tester probes into the cou- pler terminal slo...

Page 60: Elec

Checking the switches 6-4 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the terminals. Refer to “checking switch con- tinuity”. Damage/wear repair or replace. Improperly connected properly connect. Incorrect continuity reading replace...

Page 61: Elec

Checking the bulbs and bulb sockets 6-5 checking the bulbs and bulb sockets check each bulb and bulb socket for damage or wear, proper connections, and also for con- tinuity between the terminals. Damage/wear repair or replace the bulb, bulb socket or both. Improperly connected properly connect. No ...

Page 62: Elec

Checking the bulbs and bulb sockets 6-6 2. Check: • bulb (for continuity) (with the pocket tester) no continuity replace. Tip before checking for continuity, set the pocket tester to “0” and to the “ x 1” range. A. Connect the positive tester probe to termi- nal and the negative tester probe to ter-...

Page 63: Elec

Lighting system 6-7 lighting system circuit diagram – + elec on of f on of f l r pu sh 10a 30a y/b b /w b/w y/b b/w gr b/w gr br/b y/g g/y g/y g/y g/y g/y y/br g/b br/b y/br g/b br/w y/g g/y br/w b/y lg lg b/y lg lg lg lg br br lg br br br br br br/y br/y br/y y/r b/y y/r br/y br/y br/y br/y r b b r...

Page 64: Elec

Lighting system 6-8 troubleshooting check: 1. Main fuse 2. Battery 3. Main switch tip • before troubleshooting, remove the follo- wing part(s): • troubleshoot with the pocket tester. Any of the following fail to light: head- light, and meter light. 4. Headlight switch 5. Wiring connections 1. Main f...

Page 65: Elec

Lighting system 6-9 checking the lighting system 1. The headlight fail to come on. 1. Headlight bulb and socket • check the headlight bulb and socket for continuity. Refer to “checking the bulbs and bulb sockets” • are the headlight bulb and socket ok? 2. Voltage • connect the pocket tester (dc 20 v...

Page 66: Elec

Signaling system 6-10 signaling system circuit diagram – + elec on of f on of f l r pu sh 10a 30a y/b b /w b/w y/b b/w gr b/w gr br/b y/g g/y g/y g/y g/y g/y y/br g/b br/b y/br g/b br/w y/g g/y br/w b/y lg lg b/y lg lg lg lg br br lg br br br br br br/y br/y br/y y/r b/y y/r br/y br/y br/y br/y r b ...

Page 67: Elec

Signaling system 6-11 troubleshooting •any of the following fail to light : turn signal light, brake light or an indicator light. •the horn fails to sound. Check: 1. Main fuse 3. Battery 2. Turn signal fuse 4. Main switch 5. Turn signal switch 6. Wiring connections (of the entire signaling system) t...

Page 68: Elec

Signaling system 6-12 checking the signaling system 1. The horn fails to sound. 1. Horn switch • check the horn switch for continuity. Refer to “checking the switches”. • is the horn switch ok? 2. Voltage • connect the pocket tester (dc 20 v) to the horn connector at the horn terminal as shown. Posi...

Page 69: Elec

Signaling system 6-13 2. The tail/brake light fails to come on. 1. Tail/brake light bulb and socket • check the tail/brake light bulb and socket for continuity. Refer to “checking the bulbs and bulb sockets” • are the tail/brake light bulb and socket ok? 2. Brake light switches • check the brake lig...

Page 70: Elec

Signaling system 6-14 3. Voltage • connect the pocket tester (dc 20 v) to the turn signal relay coupler (wire harness side) as shown. Positive tester probe red/white red/white negative tester probe ground • set the main switch to “on”. • measure the voltage (dc 12 v) on red/white at the turn signal ...

Page 71: Chapter 7

Chapter 7 chassis front wheel / rear wheel 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Front wheel 7-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rear wheel 7-2 . ...

Page 72: Chapter 7

Chapter 7 chassis lower bracket 7-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lower bracket 7-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Re...

Page 73: Chas

1 front wheel / rear wheel front wheel remarks q’ty job/part order removing the front wheel 3 1 1 4 1 hexagon flange bolt 5 2 front wheel 6 2 front brake shoe plate 2 1 collar b 7 1 collar a oil seal bearing 1 3 4 5 6 2 5 6 7-1 chas remove the parts in the order listed. Tip place the scooter on a su...

Page 74: Chas

1 3 1 1 4 1 2 1 5 6 1/1 1 7-2 1 3 4 2 5 6 1 (x4) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 80 nm (8.0 m • kg, 57.9 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) front wheel / rear wheel rear wheel chas remove the parts in the order listed. For installation, reverse the removal pro- cedure. Re...

Page 75: Chas

7-3 2 3 front wheel / rear wheel chas 1. Removing • wheel bearings • collar remove the wheel bearings with a general bearing puller . რ notice securely support the wheel to avoid damaging the brake disk. If the brake disk had damaged, please replace immediately. Checking the front/ rear wheel removi...

Page 76: Chas

7-4 2 3 4 5 2 3 4 t r . . T r . . 35 nm (3.5 m•kg, 25.3 ft•lb) 80 nm (8.0 m•kg, 57.9 ft•lb) 2 3 4 3 4 ˔ ˔ ˕ ˕ 5 3 front wheel / rear wheel chas assemble the front/ rear wheel 1. Install • collar a • collar b • oil seal • bearing 5 • front brake shoe plate tip before tightening the wheel axle nut, pu...

Page 77: Chas

1 3 4 5 6 2 2 1 1 4 1 1 5 1 6 1 7 8 9 1 2 1 3 1 7 8 9 7-5 t r . . 35 nm (3.5 m • kg, 25.3 ft • lb) front brake / rear brake front brake chas remarks q’ty job/part order removing the front brake remove the parts in the order listed. Please refer to " lower bracket " in cheaper 7. For installation, re...

Page 78: Chas

3 4 1 5 1 1 9 8 7 6 1 1 1 2 1 2 1 1 7-6 1 3 2 9 4 5 6 7 8 t r . . 9 nm (0.9 m • kg, 6.5 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) (x4) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) front brake / rear brake rear brake chas remarks q’ty job/part order removing the rear brake remove the parts in the ord...

Page 79: Chas

7-7 ʳ 2 3 2 3 2 3 2 3 front brake / rear brake chas the following procedure applies to each brake. Brake and rear brake. Removing the front/ rear brake 1. Removing • brake arm • brake arm cam tip the following procedure applies to each brake. Checking the brake disk 1. Checking • brake disk a • brak...

Page 80: Chas

B 2 2 2 b 7-8 front brake / rear brake chas 3. Measure • brake shoe lining thickness 2xwrivshflilfdwlrqĺuhsodfh measuring points replace the brake shoes as a set if either is found to be worn to the wear limit. Checking the brake drums the following procedure applies to each brake. • brake drum insi...

Page 81: Chas

2 3 t r . . 9 nm( 0.9 m•kg, 6.5ft•lb) 4 ˶ ˷ a 2 3 4 ˶ ˷ 4 ˶ ˷ c b c b 7-9 front brake / rear brake chas 2. Install • brake arm cam • brake arm • install the brake arm cam so its punch mark is positioned as shown. • align the punch mark in the brake arm cam with the mark on the brake arm. A tip • rea...

Page 82: Chas

1 2 3 4 2 2 1/1 1 5 6 7 1 2 1 8 9 1 1 7-10 1 2 3 4 8 9 7 6 6 5 3 1 2 t r . . 25 nm (2.5 m • kg, 18.1 ft • ib) t r . . 35 nm (3.5 m • kg, 25.3 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . 4 nm (0.4 m • kg, 2.9 ft • ib) swingarm swingarm chas remove the parts in the order listed. Remarks q’t...

Page 83: Chas

7-11 35 nm (3.5 m •kg, 25 .3 ft • ib) a a b b swingarm chas remove the swingarm 1. Check • swing arm free play swingarm free play 1.0 mm (0.04 in) b. Check the swingarm side play by moving ing it from side to side. If side play is noticeable, check the spacer, bearings and frame pivot. A. Check the ...

Page 84: Chas

7-12 1 1 1 2 3 1 1 2 2 3 t r . . 35 nm (3.5 m • kg, 25.3 ft • ib) rear shock absorber rear shock absorber chas remove the parts in the order listed. Remarks q’ty job/part order removing the rear shock absorber for installation, reverse the removal pro- cedure. Pin rear shock absorber hexagon flange ...

Page 85: Chas

7-13 35 nm (3.5 m• kg, 25 .3 ft • ib) 35 nm (3.5 m• kg, 25 .3 ft • ib) rear shock absorber chas checking the rear shock absorber 1. Check • shock absorber oil leaks ĺ replace the rear absorber assembly. • shock absorber rod bends/damage ĺreplace the rear absorber assembly. • spring fatigue ĺreplace ...

Page 86: Chas

1 3 1 1 4 1/1 5 1 2 1 1 3 4 2 4 5 7-14 t r . . 45 nm (4.5 m • kg, 32.5 ft • lb) steering system headlebar chas remove the parts in the order listed. Remarks q’ty job/part order for installation, reverse the removal pro- cedure. Front brake cable front cap meter side l/ r headlight meter handle lever...

Page 87: Chas

ϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰ ϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧ 2 t r . . 45 nm( 4.5 m•kg, 32.5 ft•lb) 3 2 3 7-15 steering system chas removing the handlebar grip 1. Remove • handlebar grip • blow compressed air between the handlebar and handlebar grip, and gradually push the grip off the handlebar. Removing step :...

Page 88: Chas

7-16 steering system chas install the handlebar reverse the removal procedure for installation and pay attention the following tips: 1. Clean • if the connection part of steering touch with grease, should be clean. Warning 2. Install • handlebar • securely support the scooter so that there is no dan...

Page 89: Chas

1 1 2 1 3 4 2 5 1 1 6 7 8 1/1 2 2 9 10 1 1 2 3 4 5 6 7 8 9 10 1 9 11 3 8 1 11 7-17 t r . . 50 nm (5.0 m • kg, 36.2 ft • lb) t r . . 12 nm (1.2 m • kg, 8.7 ft • lb) t r . . 45 nm (4.5 m • kg, 32.5 ft • lb) lower bracket chas lower bracket remove the parts in the order listed. Remarks q’ty job/part or...

Page 90: Chas

2 3 4 2 7 7 2 2 6 5 3 4 2 6 5 6 5 7-18 lower bracket chas 1. Remove removing the lower bracket • front fender assembly • ring nut • ball race cover • bearing ball • ball race outer • ball race upper • removing the ring nut by the steering nut wrench . • support the front fork safety and firmly, avoi...

Page 91: Chas

ϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰϰ t r . . 7-19 lower bracket chas 1. Install installing the lower bracket • bearing ball • outer bearing race • make sure the bearing ball size is correct. • make sure the site of up and down while installing outer bearing race and upper bearing race. 2. Lubricate • bearing bal...

Page 92: Chas

ϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧϧ 3 2 7-20 lower bracket chas • tighten the ring nut, please refer to "checking steering head " in cheaper 3..

Page 93: Chas

1 2 2 2 3 2 4 2 1 2 3 4 1 2 3 7-21 t r . . 30 nm (3.0 m • kg, 21.7 ft • ib) front fork chas front fork remove the parts in the order listed. Remarks q’ty job/part order for installation, reverse the removal procedure. Remove the front fork. Cap (l / r) bolt (l / r) nut (l / r) front fork (l / r).

Page 94: Chas

ʳ 7-22 front fork chas 1. Remove removing the front fork • cap is no danger of it falling over. Warning • securely support the scooter so that there • bolt • nut (fork) warning • front fork (l/ r) the fork spring would spring, should pay attention when remove the bolt. Disassemble the front fork 1. ...

Page 95: Chas

7-23 front fork chas 1. Check checking the front fork • inner tube :hduvehqgvgdpdjhĺuhsodfh warning do not try to straighten an outer tube or an inner tube as this may dangerously weaken the tube. 2. Measure )runvsulqj $eryhvshflilhgolplwĺuhsodfh fork spring free length 99.0 mm (3.90 in) : 94.0 mm ...

Page 96: Chas

T 30 nm(3.0 m•kg, 21.7 ft•lb) t r . . 30 nm(3.0 m•kg, 21.7 ft•lb) b b 7-24 front fork chas 3. Install • dust seal • circlip couple the circlip correctly on the groove of the outer tube. 4. Check • operation of inner tube 8qvprrwkrshudwlrqĺuhsodfh installing the front fork reverse the disassembly pro...

Page 97

Chapter 8 trouble shooting 8-1 8-1 ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ ˁ lasting meter warning tone light odes n...

Page 98: Trbl

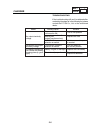

8-1 Ϭʳ warning tone list warning tone o: tone x: no tone vehicle operation main switch on press an operation button password decode wrong password 10% battery residual volume main switch off warning and warning message no operation for 30 seconds troubleshooting tip the following guide for troublesh...

Page 99: Trbl

8-2 poor braking performance faulty front fork legs Ԧʳʳ worn brake shoe lining. Ԧʳʳ incorrect brake lever free play. Ԧʳʳ incorrect brake shoe position. Ԧʳʳ wearing brake camshaft. Ԧʳʳ worn or rusty brake drum. Ԧʳʳ dust or water on the brake drum. Ԧʳʳ oil or grease on the brake drum. Ԧʳʳ worn brake c...

Page 100: Trbl

8-3 the following warning messages might display with a warning tone during riding status. Meter m essage code Ε warning message(warning tone) drawing message code 88 888888 odo km/h trip 8888.8 p ow lowv x message code battery residual capacity warning message (warning tone) ovc2 ov t ov v lowv war...

Page 101: Trbl

8-4 indication code cause action lock fail old new push pres wrong password. Enter the old password. Enter the new password. Spd0 fast over speed warning. Lowb low battery. Lowp re-enter the password. Tps0 (over 52km/hr) operate code lock during riding. Using power mode during low battery residual c...