- DL manuals

- E-TON

- Scooter

- Matrix R4-150

- Service Manual

E-TON Matrix R4-150 Service Manual

Summary of Matrix R4-150

Page 1

Eton america matrix r4-150 service manual covers: matrix r4-150 (pn2i) scooter.

Page 2

Contents 1. Information .............................................................................................................. 4 1.1 safety ........................................................................................................................ 4 1.2 notes ......................

Page 3

9.6 rear shock absorber drawing .................................................................... 64 10. Plastic parts ..................................................................................................... 65 10.1 front fender ..........................................................

Page 4: 1. Information

1. Information 1.1 safety ● gasoline is extremely flammable and is explosive under certain conditions. Do not smoke or allow sparks or flames in your work area. ● never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead t...

Page 5

1.3 serial number the frame serial number is stamped on the front of the frame, just at the front of footrest plate. The engine serial number is stamped on the left side of the engine crankcase. Frame serial number engine serial number.

Page 6

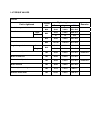

1.4 torque values frame part to tightened thread size tightening torque remarks n-m kg-m ft.Lb handlebar upper holder bolt m10 30-40 3.0-4.0 22.1-29.5 front fork nut upper m25 55-65 5.5-6.5 40.6-47.9 below 14 1.4 10.3 front axle nut m10 30-40 3.0-4.0 22.1-29.5 rear axle nut m20 110-130 11.0-13.0 81....

Page 7

Engine part to tightened thread size tightening torque remarks n-m kg-m ft.Lb spark plug m10 10-12 1.0-1.2 7.4-8.9 cylinder head bolts m6 10-14 1.0-1.4 7.4-10.3 tappet adjusting nut m5 7-11 0.7-1.1 5.2-8.1 oil drain bolt m12 20-30 2.0-3.0 14.8-22.1 clutch outer nut m10 55 5.5 40.6 drive face nut m12...

Page 8: 2. Maintenance

2. Maintenance 2.1 maintenance data specifications spark plug gap 0.6-0.7 mm recommended spark plugs ngk cr7hsa throttle lever free play 5-10 mm idle speed 1700-1 900 rpm brake lever free play 15-25 mm engine oil sae 15w-40 gear lubrication oil sae 80w-90 gear oil 2.2 maintenance schedule the mainte...

Page 9: Wp-0027

Maintenance schedule four stroke vehicles wp-0027 scheduled maintenance 300km every 1000km every 3000km every 6000km every 12000km 200 miles 600 miles 2000 miles 3700 miles 7500 miles new 1 month 3 months 6 months 1 year 1 air cleaner element i * c * r (paper) r (sponge) 2 air cleaner i 3 oil filter...

Page 10

2.3 fuel tube inspect the fuel lines for deterioration, damage, or leaking, and replace if necessary. 2.4 throttle operation inspect the hand grip for smooth full opening and automatic full closing in all steering positions. Inspect for deterioration, damage, or kinking in the throttle cable, and re...

Page 11

2.6 air cleaner unscrew the air cleaner cover screws. Pull out the air filter from the air cleaner case. Wash the component in non-flammable solvent and squeeze out the solvent thoroughly. Let it dry completely. Soak the filter in gear oil and then squeeze out the excess oil. Install the component i...

Page 12

Inspect the rear and brake lever and cable for excessive play or other damage. Replace or repair if necessary. Measure the free play of the brake lever at the end of the brake lever. The standard free play in those two-brake levels are 15-25 mm. 2.10 wheels and tires inspect the tire surfaces for cu...

Page 13

2.12 engine stop switch 2.13 upper – lower beam controller this controller is located beside right handle bar. This controls the headlight. The engine stop switch is located on left handle bar. When the engine must be stopped quickly, push the switch with your left hand thumb and the engine will sto...

Page 14

3. Engine removal and installation 3.1 engine removal remove the seat, helmet box, and body cover. Disconnect the oil tube, fuel tube, and vacuum tube. Disconnect the ac generator and starter motor..

Page 15

Disconnect the carburetor and throttle cable wires. Remove the spark plug cap. Remove the muffler by removing the retaining bolts..

Page 16

Remove the air cleaner by removing the retaining bolts as shown. Remove the bolt at the bottom of the rear shock absorber. Remove the rear disc brake caliper bolts. Remove the rear brake tube bolt..

Page 17

Remove engine hanger nut. Remove the engine from the frame. 3.2 engine installation install engine in reverse order of disassembly. Torque value: m8 nut: 20-30 n-m m10 nut: 30-40 n-m m12 nut: 50-60 n-m after the engine is installed, check these parts: wires and connections carburetor and throttle ca...

Page 18: 4. Cylinder Head and Valves

4. Cylinder head and valves 4.1 service information general this section describes maintenance for the cylinder head, valves, camshaft, and related parts. The engine must be removed from the frame to service cylinder head. Camshaft lubrication oil is fed to the cylinder head through an oil orifice i...

Page 19

4.2 trouble shooting engine top-end problems usually affect engine performance. These problems can be diagnosed by a compression test, or by tracing engine noise to the top end with a sounding rod or stethoscope. Valve incorrect valve adjustment worn or damaged valve seats burned or bent valve...

Page 20

Remove the air cleaner and carburetor. Remove the inlet pipe assembly. Remove the shroud compositions. Loosen the cam chain adjuster screw. Remove the screw and o-ring and tighten the cam chain adjusting bolt in the clockwise direction. Remove the nuts and washers. Remove the camshaft holder and dow...

Page 21

Inspection inspect the cam lobes surface and height of cam lobes for wear or damage. Service limit: in 29.395 mm ex 29.160 mm inspect the camshaft and bearings for wear or damage and replace them if necessary. Screw a 5mm bolt into the rocker arm shaft threaded end. Pull on the bolt to remove the sh...

Page 22

4.4 cylinder head removal remove the flange bolts and cylinder head. Remove the cylinder head gasket and dowel pins. Remove the cam chain guide. Measure the i.D. Of each rocker arm. Service limit: 10.10 mm measure the o.D. Of each rocker arm shaft. Service limit: 9.91 mm.

Page 23

Cylinder head disassembly remove the valve cotters, spring retainers and valve springs with a valve spring compressor. Inspection clean off all carbon deposits from the combustion chamber. Check the spark plug hole and valve area for cracks. Measure the cylinder head diagonally for waring with a str...

Page 24

Inspect each valve for turning, burning, scratches or abnormal stem wear. Check the valve movement in the guide. Measure and record each valve stem o.D. Service limits: 4.90 mm measure and record the valve guide i.D. Service limits: in / ex 5.30 mm calculate the stem-to-guide clearance. Service limi...

Page 25

Installation install the new gasket and dowel pins. Install the cam chain guide. Install the cylinder head. Camshaft composition installation install the rocker arms and rocker arm shafts into the camshaft holder..

Page 26

Align the “t” mark on the flywheel with the index mark on the alternator cover by turning the flywheel counter- clockwise. Position the camshaft gear with cam chain so that its“i” mark aligns with the cylinder head surface and the circle hole forwards front. Install the dowel pins and camshaft holde...

Page 27

Loosen the cam chain-adjusting bolt with counter clockwise direction and install the o-ring and screw. Install the cylinder head cover..

Page 28: 5. Lubrication

5. Lubrication 5.1 service information general this section describes inspection and replacement of the engine oil, oil filter screen and assembly of the oil pump. Fill the oil pump with clean oil when reassembling the pump. Specification engine oil capacity 1.0 liter at disassembly (0.9 liter at dr...

Page 29

Oil drain bolt 20-30 n.M 5.2 troubleshooting oil level too low normal oil consumption. external oil leaks. oil not changed often enough. worn piston rings. faulty heat gasket. Oil contamination worn piston rings. faulty heat gasket. oil or filter not changed often enough. 5.3 engine ...

Page 30

Remove the oil filter cap, spring and oil filter screen. Check the o-ring for damage or fatigue. Install a new oil filter screen and spring then install the cap. Install the oil drain bolt with sealing washer. Torque: 20-30 n-m fill the crankcase with recommended oil. Engine oil capacity: 0.9 liter ...

Page 31

Remove the cooling fan assembly. Remove the ac generator assembly. Remove the right crankcase cover. Remove the starting clutch outer and gear assy..

Page 32

Remove the flange bolts and oil separator. Remove the oil pump chain and oil pump driven sprocket. Remove the oil pump assy. Disassemble the oil pump..

Page 33

Inspection measure the oil pump rotor-to-body clearance. Service limit: 0.12 mm install the oil pump shaft and measure the pump rotor tip clearance. Service limit: 0.12 mm. Remove the oil pump shaft and measure the pump end clearance. Service limit: 0.2 mm. Oil pump assembly / installation install t...

Page 34

Install the oil pump assembly. Install the oil separator. Install the starting clutch outer and gear assembly. Oil separator install the oil pump driven sprocket and oil pump chain. Ps: the tighten torque of driven sprocket nut is 8-12 n-m oil pump driven sprocket.

Page 35

Install the new gasket, dowel pins, and right crankcase cover. Install the ac generator assembly and cooling fan composition..

Page 36: 6. Cylinder / Piston

6. Cylinder / piston 6.1 service information general camshaft lubrication oil is fed to the cylinder head through an oil orifice in the cylinder head and engine case. Before installing the cylinder head, make sure the orifice is not clogged and the gasket, o-ring, and dowel pins are in place. Item s...

Page 37

6.3 cylinder removal remove the cylinder head. Remove the cylinder. Remove the cylinder gasket and dowel pins. Clean off any gasket materials from the cylinder surface. Note: be careful not to damage the gasket surface. Cylinder cylinder hea cylinder surface gasket dowel.

Page 38

6.4 piston removal stuff a shop towel into the crankcase. Remove the piston pin clip with needle nose pliers. Note: do not allow the clip fall into the crankcase. Remove the piston pin from the piston. Remove the piston. Spread each piston ring and remove it by lifting up at a point opposite the gap...

Page 39

Measure and record the cylinder i.D. At three levels in both an x and y-axis. Take the maximum reading to determine the cylinder wear. Service limit: 57.50 mm calculate the piston-to-cylinder clearance. Take the maximum reading to determine the clearance. Service limit: 0.10 mm calculate cylinder ta...

Page 40

Inspect the piston for wear or damage. Insert each piston ring into the cylinder and measure the ring end gap. Note: push the rings into the cylinder with the top of the piston to be sure they are squarely set in the cylinder. Service limits: top 0.5 mm second 0.5 mm measure the piston pin o.D. Serv...

Page 41

Calculate the piston-to-piston pin clearance. Service limit: 0.02 mm measure the connecting rod small end i.D. Service limit: 15.06 mm 6.5 piston installtion piston ring installation clean the piston ring grooves thoroughly and install the piston rings with the marks facing up. Note: don’t interchan...

Page 42

Piston installation install the piston with it’s “in“ mark on the intake valve side. Install the piston pin with new pin clips. Do not align the piston pin clip end gap with the piston cutout. Note: do not allow the clip to fall into the crankcase. 6.6 cylinder installation clean any gasket material...

Page 43

Coat the cylinder bore and piston rings with engine oil and install the cylinder. Note: avoid piston rings damage cylinder bore during installation. Do not allow the cam chain fall into the crankcase. Install the cylinder head..

Page 44

7. Transmission / kick starter 7.1 service information if the drain tube assembly fills with water, the tube should be drained. Specifications mm item standard service limit driven belt width 19.8 - 20.2 19.0 weight roller o.D. 17.9 - 18.1 17.40 movable drive face i.D. 27.98 – 28.0 28.03 drive face ...

Page 45

7.3 c.V.T disassembly l crank case cover removal loosen the band screw and remove the c.V.T inlet duct. Disassemble the ground wire as shown. Remove the bolts and l cranks case cover..

Page 46

Remove the gasket and dowel pins. Clean off any gasket material from l crank case surface. Cvt removal loosen the flange nut and remove kick-starter ratchet. Remove the drive face. Loosen the flange nut. Remove the drive pulley assy. And driven belt. Remove the drive face boss and movable driven fac...

Page 47

Remove the ramp plate and weight roller set. Loosen the special nut and remove the driven plate composition and driven face spring. Inspection inspect the driven belt for wear, tears or damage. Measure the width of driven belt. Service limit: 19.0 mm inspect the weight roller for wear or damage and ...

Page 48

Measure the i.D. Of movable driven face. Service limit: 28.03mm inspect the drive face collar for wear or damage. Measure the i.D. Of drive face collar. Service limit: 24.098 mm inspect the drive face boss for wear or damage. Measure the o.D. Of drive face boss. Service limit: 23.92 mm inspect the c...

Page 49

Measure the length of driven face spring. Service limit: 164.0 mm inspect the driven face assy. And replace them if necessary. 7.4 kick starter disassembly remove the l crank case cover. Remove the kick-starter. Remove the ex. Circle-clip and washer from kick-starter spindle composition. Driven face...

Page 50

Rotate the kick-starter spindle composition to remove the kick driven gear and spring. Remove the kick-starter spindle composition and return spring. Remove the kick spindle bush. Inspection inspect the kick starter spindle composition for wear or damage. Inspect the kick return spring for fatigue o...

Page 51

Inspect the machining surface for wear or damage. 7.5 kick starter assembly install the kick spindle bush, return spring and spindle assembly. Install the kick driven gear and spring. Install the kick-starter. 7.6 c.V.T assembly assemble the driven face assembly, spring, and driven plate composition...

Page 52

Assemble the movable driven face composition, weight roller set, and drive face. Install the movable drive face assembly and boss. Install the drive face and kick-starter ratchet. Install the driven belt and driven pulley assembly. Driven belt driven pulley assy. Kick starter ratchet movable drive f...

Page 53

Install the dowel pins and gasket. Install the l crank case cover. Install the gas waste recovery and c.V.T ducts..

Page 54

7.7 electric self-starter mechanism 7.8 kick starter this kick-starter arm is on the left side of engine. When the kick-starter arm is kicked, the starting gear shaft will drive the kick-starter to rotate the crankshaft to start the engine. After the engine is started, the kick-started will stop tra...

Page 55

7.9 removal of cvt system remove the engine clutch cover by unscrewing the fixed bolts. Check the belt for wear. If necessary, replace the belt. Disassemble the front drive pulley and check the six rollers for wear. If necessary, replace the rollers. 7.10 disassembly and inspection of the cvt system...

Page 56: System

8. Front wheel, brakes, and steering system 8.1 troubleshooting steering is heavy damaged steering bearings damaged steering bearing races steering shaft holder too tight damaged tire insufficient tire pressure handlebar positioned improperly bent front fork bent front axle damaged front wheel damag...

Page 57

8.3 replace speedometer cable disassemble the handlebar cover. Unscrew the speedometer cable nut. Unscrew the speedometer cable fixing bolt on the front wheel. Remove the worn speedometer cable. Install the replacement speedometer cable in reverse order of removal. Note: before installing the new sp...

Page 58

Loosen the handlebar fixing nut and bolt on the front fork. Remove the handlebar. Install a new handlebar in reverse order of removal. Locking nut torque: m10 nut: 30-40 n-m 8.5 front wheel release the anti-lock nut at the right side of front wheel. Inspecting the front wheel axle check the axle for...

Page 59

Front wheel axle bearing inspection replacing the front disk brake caliper assembly unscrew the two front disk brake caliper fixing bolts at the front fork. Remove the front disk brake caliper. Reinstall by installing the caliper and reattaching the fixing bolts. Torque value: m8 nut: 24-30 n-m rele...

Page 60

Disassembling front brake disk disassemble the front wheel. Unscrew the three brake disk fixing bolts. Release the brake disk. Torque of these m8 nuts: 30-40 n-m inspecting the brake disk measure the thickness of the brake disk. Standard thickness: 3.5 mm minimum limit: 3.1 mm inspect brake shoes (l...

Page 61

9. Rear wheel and brake system 9.1 troubleshooting bad brake performance worn brake shoes brake adjusted improperly brake linings oily , greasy , or dirty worn brake drum brake arm setting improperly engaged vibration or wobble bent rim damaged tired wheel axle improperly tightened 9.2 maintenance d...

Page 62

9.3 rear wheel removal remove the bolt at the bottom of the rear shock absorber. Unscrew the rear bracket bolt. Unscrew the rear wheel axle nut. Disassemble the rear wheel. Torque value: m16 nut: 60-80 n-m.

Page 63

9.4 inspecting the rear wheel measure the warping or distortion of the rear wheel rim. Replace with a new rim if the distortion is over 2.0 mm. 9.5 rear brake replace the rear disc brake caliper assembly unscrew the two fixing bolts on rear disc brake caliper assembly at the rear bracket. Releasing ...

Page 64

Remove the rear disc brake caliper. When reinstalling the caliper: torque value: m8 nut 24-30 n-m brake disc inspection measure the thickness of the brake disc. Standard thickness: 3.5 mm using limit: 3.1 mm brake shoes (lining) inspection measure the thickness of brake lining. Standard thickness: 4...

Page 65

9.6 rear shock absorber drawing.

Page 66: 10. Plastic Parts

10. Plastic parts 10.1 front fender unscrew the 7 fixing screws between the front fender and leg shield. Remove the front fender. 10.2 body cover unscrew the 4 fixing bolts on the rear carrier. Remove the rear carrier..

Page 67

Open the seat. Unscrew the 4 fixing bolts on the helmet box. Remove the helmet box. Unscrew the upper body cover fixing bolts. Unscrew the fixing bolts between the body cover and middle cover. Remove the middle cover. Unscrew the body cover fixing bolts under the middle cover..

Page 68

Open and remove the fuel tank cap. Unscrew the 2 rear cover fixing bolts near the fuel tank. Unscrew the 2 tail light fixing bolts near the fuel tank. Disconnect the negative pole of battery, then disconnect the positive pole. Remove the battery. Unscrew the two side protection cover fixing bolts..

Page 69

Remove the right and left side protecting covers. Unscrew the 5 leg shield fixing bolts. Unscrew the 6 fixing bolts on the footrest board. Remove the leg shield and footrest board. Reinstalling torque values: m6: 7-11 n-m m5: 3.5-5 n-m.

Page 70

10.3 canister comp removal and installation suggested: change the canister composition every 2 years or 9000 miles (15000km). 3. Carburetor assy. 5. Fuel tank assy. 6. Vapor control 2. Canister comp 4. Fuel petcock 1. Air cleaner assy..

Page 71: 11. Electrical System

11. Electrical system 11.1 troubleshooting engine starts but stops improper ignition timing faulty spark plug no spark at plug engine stop switch at “ off “ faulty ignition coil faulty generator faulty cdi unit pooly connected: o between cdi and ignition coil o between alternator and c...

Page 72

11.2 ignition coil remove the spark plug cap from the spark plug. Disconnect the ignition coil primary wire. Measure the primary coil resistance. Standard: 0.1-0.30(20 11.3 battery inspection the battery is located under the seat. Measure the battery voltage using a voltmeter. Voltage: fully charged...

Page 73

11.4 charging connect the charger’s positive cable to the battery position terminal. Connect the charger’s negative cable to the battery negative terminal. Using a trickle charger, apply 0.9a-charging current for about 5 hours. (normal charging - recommended) or using 4a-charging current, charge for...

Page 74

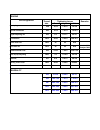

11.6 wiring diagram matrix r4-150