- DL manuals

- Eagle

- Tractor

- TT10 AWD

- Operation Manual

Eagle TT10 AWD Operation Manual

Summary of TT10 AWD

Page 1

Operations manual vehicle types: all tt models eagle tugs.

Page 3: 0-1

Safety warning read this manual in it’s entirety before putting your eagle tow tractor into service. This manual contains important safety instructions. Improper usage or a failure to follow the safety require- ments listed in this manual could result in severe injury or death. 0-1.

Page 4: 1-1

Table of contents 1-1 0-1 safety warning 1-1 table of contents 2-1 revision sheet 3 introduction 3-1 welcome 3-2 contact info 3-3 warranty 3-4 proper use 3-5 vehicle weights, performance, and specifications 4 putting the tow tractor into service 4-1 unpacking/setting up 4-2 fuel requirements 5 instr...

Page 5: 1-1

Table of contents 1-1 8 instructions for safe maintenance 8-1 maintenance operator requirements 8-2 general safety guidelines 8-3 daily operator responsibilities proper fluid checks 8-4 filter guide 8-5 preventative maintenance schedules.

Page 6: 2-1

Revision sheet 2-1 revision history rev number description affected section(s) date r00 initial release all 1/11/09.

Page 7: 3-1

Welcome welcome to the growing family of eagle tractor operators. The tractor was built with the operator's safety, comfort and ease of operation in mind. We hope you agree and enjoy your eagle experience. Purpose & use of manual this manual is designed as a quick guide to familiarize you with the c...

Page 8: 3-2

Contact information corporate offices sales, support, customer service eagle industrial truck 26111 northline rd taylor, mi 48180 usa (734) 442-1000 — (800) 671-0431 global sales office sales maple house high street potters bar herts, en6 5bs uk +44 (0) 208 363 9528 web-site www.Eagletugs.Com contai...

Page 9: 3-3

Introduction 3-3 warranty please read warranty information carefully. Before contacting eagle industrial truck for any warranty issue please have the following information ready: all information can be found on the data plate located beside the driver seat with the exception of the hours which can b...

Page 10: 3-3

3-3 introduction warranty registration vehicles powered by a yanmar engine should register the engine by entering the required information into the customer registration screen found on yanmar’s website at http://www.Yanmar.Co.Jp. Vehicles powered by a wisconsin motors tme27 engine should contact ea...

Page 11: 3-3

Introduction 3-3 this warranty does not apply to any eagle tow tractor, or component part(s) that have been subjected to misuse, accident or improper handling, maintenance or application; nor does it extend to the eagle machine and/or parts which have been repaired or altered outside of eagle's plan...

Page 12: 3-4

Introduction proper use of tt series tow tractors the tt line of tow tractors is designed to be an aircraft tow tractor. When used prop- erly in this application, the tt line of tow tractors will provide years of safe operation. The following activities fall within the approved and anticipated usage...

Page 13: 3-5

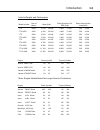

Introduction vehicle weights and performance 3-5 model number year of manuf. Mass (lb/n) rated draw bar pull, dbp (lb/n) rated vertical hitch load (lb/n) tt4 2008 6,700 29,800 4,000 17,800 500 2,200 tt4 awd 2008 4,500 20,000 4,000 17,800 500 2,200 tt5 2008 8,300 36,900 5,000 22,200 500 2,200 tt5 awd...

Page 14: 3-5

Operator vibration level data the operator interface vibration levels on the tt-series tug were tested by iso / iec 17025 accredited testing lab kolano and saha engineers, inc. Of waterford, mi, usa. Introduction 3-5.

Page 15: 3-5

Sound level data the tt-series tow tractor emits the following sound levels: the sound level test was performed in a open area on a flat asphalt surface. Readings were taken at the operator workstation, approximate ear height. The following are the test conditions: spl meter: tandy, model 33-2055 am...

Page 16: 4-1

Unpacking and setting up the following directions specify the correct steps that should be taken once you receive delivery of your tt series tow tractor. These steps will ensure that the tow tractor will operate safely. 1. Read this entire manual, paying close attention to the safety requirements la...

Page 17: 4-2

Putting the tow tractor into service 4-2 fuel requirements only use the fuels specified below. Failure to use the indicated fuels could lead to poor performance or unwarranted damage to engine components. As fuel capabilities are subject to change, please refer to www.Eagletugs.Com for the latest up...

Page 18: 5-1

General usage 5-1 general safety the following safety recommendations are not intended to address every possible safety aspect of operating this vehicle, but rather serve as a guide. Eagle has taken extensive measures to make sure the all vehicles are designed and tested to be safe when they leave t...

Page 19: 5-1

General usage 5-1 • your tractor's seat/s are equipped with retractable seat belts for your safety. Fasten your seat belt and adjust the seat before starting the engine. Be sure the seat belt is fitted snugly around the hips, not around the waist as failure to do so may cause injury in the event of ...

Page 20: 5-2

General usage 5-2 operator requirements the tt series tow tractor is a piece of industrial equipment and has inherent safety risks. As such, the operator of the tow tractor is expected to have a fork truck or similar license, or be otherwise trained in the usage of material handling equipment. The o...

Page 21: 5-3

General usage 5-3 pre-operation inspection checklist the following inspections should be conducted each day prior to the first operation of the tractor. Additional inspections may be required due to unusual operating conditions walk-a-round inspection - look for evidence around and under tractor for...

Page 22: 5-3

General usage 5-3 cab inspection if the tractor is equipped with a cab: - check that all mirrors are properly adjusted and clean. - test windshield wiper . - check all windows for cracks or chips. Be sure windows are clean for best visibility - check that heater and heater fan are functioning correc...

Page 23: 5-4

General usage 5-4 tt digital control panel: the tt line of tow tractors equipped with yanmar 4tnv98 engines also feature an h30 digital control panel provided by houston street technologies. The h30 panel provides many useful features and benefits to the operator. Below, you will find standard opera...

Page 24: 5-4

Operation screen: the operation screen is the main screen and provides gauge and other engine/truck operating information. The operation screen is set by default to show the fuel level (large center gauge), oil pressure (upper right), and coolant temperature (upper left) as the three large analog ga...

Page 25: 5-4

4) operation screen setup: the operation screen setup menu allows the user to change the display of the gauges on the operation screen. The large gauge, upper left, and upper right can be se- lected by using the up and down buttons and changed us- ing the right and left buttons to any of the availab...

Page 26: 5-4

3) controller settings auto contrast adjust the contrast based on tempera- ture conditions. Contrast allows the user to set their own contrast level. This can help in circumstance where the display is difficult to read. Power save turns off the h30 after a period of inactiv- ity. Language changes th...

Page 27: 5-5

Oil pressure gauge the gauge will vary within the normal operating range of 10-50 psi (69-345 kpa) for gasoline engines (tme27, h153, 6g72, lrg725 and esg642) and 20-60 psi (138- 414 kpa) for diesel engines (4tnv98, 4tnv98t, tmd27, tmdt27, 4jb1, 4jg1 and 4jg1t. If the value drops below the normal ra...

Page 28: 5-5

General usage 5-5 temperature gauge this gauge indicates the temperature of the engine coolant. The temperature will rise to the normal range as the engine warms. If the value moves above the normal range of 225°f (107°c), the engine is overheating. Check for proper airflow through the ra- diator an...

Page 29: 5-6

General usage 5-6 controls ignition switch (all models without h30) your tractor is equipped with either a keyless or keyed ignition switch. Both switches are three-position switches-off, on and start (crank). • on position - the fuel pump, electrical system, accessories and fuel- temperature-voltag...

Page 30: 5-7

Starting & shut-down procedures never start the tractor's engine while standing on the ground. Start the engine from the operator's seat with the transmission in neutral or park and the parking brake in the "on" position. Your tractor's seat(s) is/are equipped with retractable seat belts for your sa...

Page 31: 5-7

General usage 5-7 diesel engine (4tnv98) be sure the transmission is in "park" or "neutral". 1. Turn ignition switch (if equipped) to the "on" position. 2. See “starting the unit” in section 5.6. 3. Allow the engine to run at idle speed approximately 6 minutes (1/10 of an hour on the hour meter) to ...

Page 32: 5-8

General usage 5-8 transmission operation the transmission is controlled by a "lever type" gearshift located in the instrument panel or console. The control has six selector positions- p (park), r (reverse), n (neutral), d (drive), 2 (second) and 1 (first). In entering or leaving a gear position, the...

Page 33: 5-9

General usage 5-9 your tractor is equipped with both front and rear wheel brakes. The front and rear brakes operate on a dual system-- if one set should fail the operation of the other set will continue. The system has an emergency back up of up to three hard applications of the brakes should both s...

Page 34: 6-1

Moving loads maximum capacity towing or pushing of loads shall be done with the transmission selector lever in 1(first) or rev (reverse) gears. 6-1 instructions for safe towing/pushing load load towing safety if towing a load, check to see that: • the towed load is securely connected to the hitch of...

Page 35: 7-1

Handling 7-1 emergency towing if it should be necessary to tow the tractor to a location for maintenance service, be sure the following procedures are followed: • make sure the parking brake is released and the transmission gearshift lever is in the "n" (neutral) position. • "all wheel drive" tracto...

Page 36: 7-2

Handling 7-2 tie down procedure for long distance travel, the tt-series tow tractor can be transported by trailer. When transporting the tow tractor, please use the following tie-down procedure. This will ensure that the tractor is securely fastened and will prevent damage to the tractor. 1) positio...

Page 37: 8-1

Maintenance 8-1 maintenance operator requirements only trained and qualified mechanics familiar with ground support equipment should undertake repairs on the tt series tow tractor. The maintenance operator should read the operator’s manual and the service manual fully before performing maintenance o...

Page 38: 8-2

8-2 general safety guidelines • always stop the tractor, turn the engine off, put in "park" and apply the parking brake when making any adjustments or servicing the unit. • never refuel the tractor when the engine is running. • do not smoke when refueling. • do not over fill the fuel tank. Do not fi...

Page 39: 8-2

Maintenance 8-2 warnings the following list contains some general warnings that you should follow when you work on equipment: • always wear safety glasses for eye protection. • use safety stands whenever a procedure requires you to be under the equipment. • be sure that the battery is disconnected f...

Page 40: 8-3

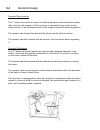

8-3 maintenance daily operator responsibilities proper fluid checks engine oil check engine oil with the unit on a level surface, the key in the “off” position (if equipped), the h30 display off (if equipped), the shifter position in “park” and parking brake applied. Open side access door or hood de...

Page 41: 8-4

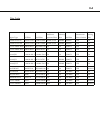

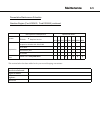

8-4 engine type oil filter fuel filter fuel/water seperater filter lubricity filter air filter transmission filter & gasket power steering filter yanmar 4tnv98 129150‐35153 119802‐55801 129242‐55730 fs20000 p601437 85705 n/a yanmar 4tnv98t 129150‐35153 123907‐55801 129242‐55730 fs20000 p601437 85705...

Page 42: 8-5

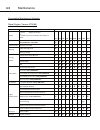

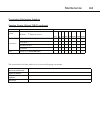

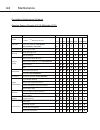

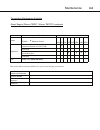

8-5 preventative maintenance schedule diesel engine (yanmar 4tnv98) maintenance description of check/service system x ‐ check * requires service ** contact your local yanmar distributor or dealer daily 50 250 500 750 1000 1250 1500 2000 engine oil engine oil and filter *first 50 and every 250 hours ...

Page 43: 8-5

Maintenance 8-5 this section below has been added to for your record keeping convenience date service performed tug serial number tug hours technician description of check/service system x ‐ check * requires service ** contact your local yanmar distributor or dealer daily 50 250 500 750 1000 1250 15...

Page 44: 8-5

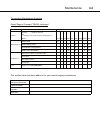

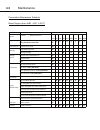

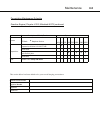

Preventative maintenance schedule gasoline engine (wiscon tme27) 8-5 maintenance description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 engine oil engine oil and filter *first 50 and every 250 hours thereafter x * * * * * * * transmission transmission fl...

Page 45: 8-5

Maintenance 8-5 description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 suspension u‐bolts 110‐120 ft lbs * drive axles * * * * axle shaft u‐joint * * * * driveshaft * * * * * * tires rotate tires *every 500 hours * * * * suspension operational hours this...

Page 46: 8-5

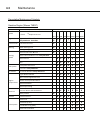

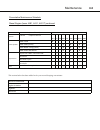

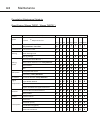

8-5 maintenance description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1250 1500 2000 engine oil engine oil and filter *first 50 and every 100 hours thereafter x * * * * * * * * transmission transmission fluid x * power steering fluid x steering linkage x x x x co...

Page 47: 8-5

Maintenance 8-5 this section below has been added to for your record keeping convenience date service performed tug serial number tug hours technician description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1250 1500 2000 brake fluid x brake pads (front) x x x x dr...

Page 48: 8-5

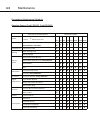

8-5 maintenance preventative maintenance schedule gasoline engine (ford lrg425, ford esg642) description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 engine oil engine oil and filter *first 50 and every 250 hours thereafter x * * * * * * * transmission tra...

Page 49: 8-5

Maintenance maintenance 8-5 description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 suspension u‐bolts 110‐120 ft lbs * drive axles * * * * axle shaft u‐joint * * * * driveshaft * * * * * * tires rotate tires *every 500 hours * * * * suspension operationa...

Page 50: 8-5

8-5 maintenance preventative maintenance schedule gasoline engine (chrysler h153 & mitsubishi 6g72) description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 engine oil engine oil and filter *first 50 and every 250 hours thereafter x * * * * * * * transmiss...

Page 51: 8-5

Maintenance 8-5 preventative maintenance schedule gasoline engine (chrysler h153, mitsubishi 6g72) continued description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 suspension u‐bolts 110‐120 ft lbs * drive axles * * * * axle shaft u‐joint * * * * drivesh...

Page 52: 8-5

8-5 maintenance preventative maintenance schedule diesel engine (wiscon tmd27, wiscon tmdt27 ) description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 engine oil engine oil and filter *first 50 and every 250 hours thereafter x * * * * * * * transmission t...

Page 53: 8-5

Maintenance 8-5 preventative maintenance schedule diesel engine (wiscon tmd27, wiscon tmdt27) continued description of check/service system x ‐ check * requires service daily 50 250 500 750 1000 1500 2000 suspension u‐bolts 110‐120 ft lbs * drive axles * * * * axle shaft u‐joint * * * * driveshaft *...