Summary of HV4500

Page 1

Spraystation® hv4500 operating manual en.

Page 2

Hv4500 b a a 2 3 b 1 1 3 4 5 spraystation® hv5500 operating manual en 2.

Page 3

Hv4500 4 2 1 7 a c 20-30 cm b 6 5 a b c.

Page 4

Hv4500 1 2 3 10 1 3 2 11 a 12 8 4 1 2 3 4 5 6 9 7 8 9 4.

Page 5: Contents

Us 1 hv4500 many thanks for placing your trust in us we would like to congratulate you on purchasing this earlex product; we are sure that you will enjoy working with it greatly. Please read the operating manual carefully and observe the safety information before starting the tool. Store the operati...

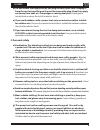

Page 6: 1. Work Area Safety

Us 2 hv4500 1. Explanation of symbols used this symbol indicates a potential danger to you or for the tool. Under this symbol you can find important information on how to avoid injuries and damage to the power tool. Danger of electrical shock i indicates tips for use and other particularly useful in...

Page 7: 3. Personal Safety

En 3 hv4500 d) do not misuse the supply cord by carrying the tool by the cord, hanging it from the cord or by pulling on the cord to remove the plug. Keep the supply cord away from heat, oil, sharp edges or moving tool parts. Damaged or twisted leads increase the risk of an electric shock. E) if you...

Page 8: 4. Power Tool Use and Care

Us 4 hv4500 4. Power tool use and care a) do not overload the tool. Use the power tool designed for the work that you are doing. You work better and safer in the specified performance range if you use the suitable power tool. B) do not use power tools whose switch is defective. A power tool that can...

Page 9

Us 5 hv4500 socket-outlets and plugs must be masked. Risk of an electric shock as a consequence of sprayed material entering the socket-outlet! • do not use the spray guns to spray flammable substances. • the spray guns are not to be cleaned with flammable solvents. • caution against dangers that ca...

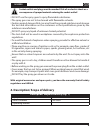

Page 10: 5. Field of Application

Us 6 hv4500 5. Field of application many different coating substances can be processed with this tool. 6. Coating materials suitable for use interior wall paint (dispersions and latex paint) water and solvent-based paints, finishes, primers, clear finishes, staining sealers and wood sealer preservat...

Page 11: Model

Us 7 hv4500 9. Preparation of the coating material • mix the material well in the original container. When using interior wall paint, an agitator is recommended. I the viscosity (thickness) of your paint may need thinning before spraying. Start with a 10% dilution. Stir well. If further thinning is ...

Page 12: 11.

Us 8 hv4500 i spend some time practising on cardboard or a similar surface in order to determine the right flow rate of paint and air for the best spray pattern. Detailed information about these settings can be found in chapter 11- 12. 11. Selecting the spray setting warning! Danger of injury! Never...

Page 13: 14. Interruption Of Work

Us 9 hv4500 fig. 7 a / 7 b: correct even distance to the object. Fig. 7 c: incorrect an uneven distance will result in uneven paint application. • move the spray gun evenly side to side or up-and-down, depending on the spray pattern setting. • an even movement of the spray gun results in an even sur...

Page 14: 17. Maintenance

Us 10 hv4500 16. Cleaning the fluid tip and needle removing the needle 1) carefully unscrew and remove material volume adjuster (fig. 10, 1) at the back of the gun. 2) remove spring (fig. 10, 2). 3) pull back on trigger (fig. 11, 4) to release fluid needle (fig. 10, 3) at the back of the gun. 4) rem...

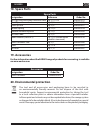

Page 15: 18. Spare Parts

Us 11 hv4500 18. Spare parts spare parts designation reference order no. Air cap, ring and spray direction plate fig. 9, 1+2+3 ear2354075 fluid tip fig. 9, 4 ear2354076 fluid tip seal fig. 9, 5 ear2354077 needle spring fig. 10, 2 ear2353978 material volume adjuster fig. 10, 1 ear2353999 air feed tub...

Page 16: Malfunction

Us 12 hv4500 21. Important note regarding product liability! The manufacturer is liable for this product only if all parts originate from or were approved by the manufacturer and the tools are assembled and operated correctly. The use of other accessories and spare parts can partially or completely ...

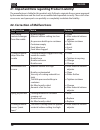

Page 17: Malfunction

Us 13 hv4500 malfunction cause remedy too much fog of coating material (overspray) • distance to the object too large • too much coating material applied, material volume setting too high • amount of air too high ➞ reduce distance ➞ alter material volume adjuster ➞ alter material volume adjuster pai...

Page 18: Warning

Us 14 hv4500 warning this unit is a double-insulated appliance for your protection, no earthing wire is necessary. If the supply cord is damaged, it must be replaced by the manufacturer or its appointed agents to avoid a safety hazard. If you are using an extension lead it must be rated a minimum of...

Page 19: 2 Year Warranty

Us 15 hv4500 2 year warranty the warranty runs for two years, counting from the date of sale (sales slip). It covers and is restricted to free-of-charge rectification of faults which are demonstrably attributable to the use of faulty materials in manufacture, or assembly errors; or free- of-charge r...

Page 20

Us 16 hv4500

Page 21

Us 17 hv4500

Page 22: Wagner Spraytech Corporation

Us 18 hv4500 part. No. L2314 01/15 © copyright wagner spraytech (uk) ltd. Us us wagner spraytech corporation 1770 fernbrook lane plymouth, mn 55447 888-783-2612 www.Earlex.Com not responsible for errors and changes. Sous réserves d’erreurs et de modifications. Errores y modificaciones reservados.