- DL manuals

- Earlex

- Paint Sprayer

- HV4901

- Instruction Manual

Earlex HV4901 Instruction Manual

Summary of HV4901

Page 1

Instruction manual spraystation hv4901 i-spray 1300 perfect spray 800 en/fr/es/it.

Page 2: 5/6

Hv4901 1 3 4 5/6 6 5 4 2 7 14 1 + testposter 20-30 cm + – 0 - 10% materialnr. 233 0627 ebss a b c d e f cover up ! 2 4 3 3 3 1 1 4 - 1 3 1 2330627_testposter_w565.Indd 1 11.06.12 10:01 9 11 10 12 instruction manual spraystation hv4901 i-spray 1300 perfect spray 800 en/fr/es/it 2 8.

Page 3

Hv4901 b a 3 ➟ a b 4 5.

Page 4

Hv4901 6 2 1 10 7 a b c 1 8 a b 9.

Page 5

Hv4901 13 a 14 a b c 15 a 11 a c 20-30 cm b 12.

Page 6

Hv4901 1 2 3 4 5 17 19 2 3 4 5 4 18 6 1 2 3 16 20

Page 7

Hv4901 a b 1 2 7 8 3 4 5 6 9 1 2 3 4 5 6 7 8 9 10 1 22 21 24 23.

Page 8: ........

Hv4901 en ..........................................................................9 - 27 ........ ........................................................................Xx - xx ........................................................................Xx - xx ...........................................

Page 9: Contents

En 9 hv4901 contents 1. Explanation of symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2. General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 3. Sa...

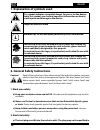

Page 10: 1. Work Area Safety

En 10 hv4901 1. Explanation of symbols used this symbol indicates a potential danger for you or for the device. Under this symbol you can find important information on how to avoid injuries and damage to the device. Danger of electrical shock i indicates tips for use and other particularly useful in...

Page 11: 3. Personal Safety

En 11 hv4901 any form. Do not use adaptor plugs together with protective-earthed tools. Unmodified plugs and suitable sockets reduce the risk of an electric shock. B) avoid physical contact with earthed surfaces such as pipes, heating elements, stoves and refrigerators. The risk through electric sho...

Page 12: 4. Power Tool Use and Care

En 12 hv4901 d) remove setting tools or wrenches before switching on the power tool. A tool or wrench that is in a rotating tool part can lead to injuries. E) avoid an unnatural posture. Ensure that you are standing securely and have your balance at all times. This ensures that you can control the t...

Page 13: 5. Service

En 13 hv4901 5. Service a) have your tool repaired only by qualified specialist personnel and only with original spare parts. This ensures that the tool safety is maintained. B) if the supply cord is damaged, it must be replaced by the manufacturer or it’s service agent or a similarly qualified pers...

Page 14: 5. Field of Application

En 14 hv4901 • cover areas that are not to be sprayed. When working keep in mind that wind, for example, may transport paint mist over great distances and cause damage. • the units may only be used with a functional valve. If paints rises in the ventilating hose (fig. 1, item 18) do not operate the ...

Page 15

En 15 hv4901 6. Coating materials suitable for use interior wall paint (dispersions and latex paint) water- and solvent-based paints, finishes, primers, 2-component paints, clear finishes, automotive finishes, staining sealers and wood sealer-preservatives. 7. Coating materials not suitable for use ...

Page 16: 10. Start-Up

En 16 hv4901 i spraystation hv4901 has been developed for use with all conventional paints in their undiluted form. If the surface is smooth and the paint you are using is very thick and gel-like, dilute it by 10%. Dilution can be necessary if the atomisation is coarse or if the flow rate is too low...

Page 17: 11.

En 17 hv4901 11. Selecting the spray setting (perfect spray 800 spray attachment) warning! Danger of injury! Never pull the trigger guard while adjusting the air cap. With the union nut (fig. 6, 1) slightly unscrewed, turn the air cap (2) to the desired spray setting position (arrow). Then tighten t...

Page 18: 15. Interruption Of Work

En 18 hv4901 i important: start at the edge of the area to be sprayed. Start the spray movement first of all, and then press the trigger. Avoid interruptions within the area to be sprayed. • the spray movement should come from the arm, not just from the wrist. This ensures that a uniform distance is...

Page 19: Spray Attachment

En 19 hv4901 container. 2) divide the spray gun. Press the hook (fig. 5 "click") slightly downwards. Turn the gun front part and gun rear part against each other and take them apart. 3) unscrew the container. Empty any remaining coating material back into the material tin. 4) preclean the container ...

Page 20: Assembly

En 20 hv4901 assembly the unit may only be operated with a diaphragm fitted (fig. 14, c). 1) place the diaphragm (fig. 14, c) with the pin facing upwards on the bottom section of the valve. Also see the marking on the gun body. 2) place on the valve cover (fig. 14, b) and screw it closed. 3) place t...

Page 21: 19. Maintenance

En 21 hv4901 of the valve. Also see the marking on the gun body. 2) place on the valve cover (fig. 14, b) and screw it closed. 3) place the ventilating hose (fig. 14, a) on the valve cover and on the nipple at the gun body. 4) push the nozzle seal (fig. 18, 5) over the needle (6); the groove (slot) ...

Page 22: Spare Parts List (Fig. 25)

En 22 hv4901 spare parts list i-spray attachment (fig. 24) pos. Designation order no. Spray attachment complete with 1300 ml container 2352 129 1 spray jet adjustment ring 2352 366 2 union nut 2352 362 3 air cap 2352 360 4 nozzle 2328 908 5 nozzle seal (2 pcs.) 2304 433 6 o-ring of spray attachment ...

Page 23: 22. Environmental Protection

En 23 hv4901 accessories (not included in the delivery) brilliant spray attachment incl. 600 ml container optimised nozzle and air guidance for brilliant paint results 0417 932 perfect spray 800 spray attachment incl. 800 ml. Container for a rapid paint change. For medium- and large-scale objects an...

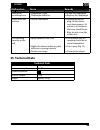

Page 24: Malfunction

En 24 hv4901 24. Correction of malfunctions malfunction cause remedy no coating material emerges from the nozzle • nozzle clogged • material volume setting turned too far to the left (-) • no pressure build-up in container • container empty • feed tube loose • feed tube clogged • ventilating bore (f...

Page 25: Malfunction

En 25 hv4901 malfunction cause remedy paint in the ventilating hose • diaphragm soiled • diaphragm defective ➞ clean the diaphragm ➞ replace the diaphragm device does not function • device overheated ➞ unplug the power plug, let the device cool down approx. 30 minutes, do not bend the hose, check th...

Page 26: 2 Years Guarantee

En 26 hv4901 warning if the supply cord of this appliance is damaged, it must only be replaced by a repair shop appointed by the manufacturer, to avoid a hazard because special purpose tools are required. Warning! Do not connect the blue or brown wire to the earth terminal of the plug! The wires in ...

Page 27

En 27 hv4901 ec declaration of conformity we declare under sole responsibility that this product conforms to the following relevant stipulations: 2006/42/ec; 2004/108/ec; 2011/65/eu; 2002/96/ec applied harmonised norms: en 60335-1:2012; en 50580:2012; en 55014-1:2006 + a1:2009 + a2:2011; en 55014-2:...

Page 28

En 28 hv4901.

Page 29

En 29 hv4901 part. No. L2401 12/14 © copyright earlex ltd www.Earlex.Com not responsible for errors and changes. Sous réserves d’erreurs et de modifications. Errores y modificaciones reservados con riserva di errori e modifiche. Nl wsb finishing equipment bv de heldinnenlaan 200 3543 mb utrecht +31/...