- DL manuals

- EarthLinked

- Water System

- AVS-0030-A

- Quick Start Instructions

EarthLinked AVS-0030-A Quick Start Instructions

Summary of AVS-0030-A

Page 1

Sd-410-qs (h) (06/15) copyright 2015 earthlinked technologies, inc. Classic series sd (h) geothermal heating and cooling system quick-start instructions.

Page 2

Sd-410-qs (h) (06/15) page 2 table of contents model nomenclature .......................................................................................................................... 5 safety .........................................................................................................

Page 3

Sd-410-qs (h) (06/15) page 3 list of figures figure 1. Matching component model numbers .................................................................................. 7 figure 2. General layout of system components .............................................................................. 8 ...

Page 4

Sd-410-qs (h) (06/15) page 4 figure 32. Suction pressure and temperature measurements (sc system shown) ......................... 45 figure 33. Many bubbles-inline sight glass ..................................................................................... 46 figure 34. Clear-inline sight glass...

Page 5

Sd-410-qs (h) (06/15) page 5 model nomenclature disclaimer proper installation and servicing of the earthlinked ® heat pump is essential to its reliable performance. All earthlinked ® systems must be installed and serviced by a technician authorized by earthlinked technologies. Installation and serv...

Page 6

Sd-410-qs (h) (06/15) page 6 safety warning, caution and important notices appear throughout the manual. Read these items carefully before attempting installation, servicing or troubleshooting the equipment. Equipment manuals the following is a listing of the equipment installation manuals that are ...

Page 7

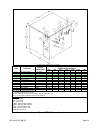

Sd-410-qs (h) (06/15) page 7 installation component matching upon receipt of the equipment, carefully check the component model numbers by referencing figure 1, to ensure that all components of the system match. Heat/cool applications compress. Unit 1 air handler 3 var. Speed cased coil txv kit mode...

Page 8

Sd-410-qs (h) (06/15) page 8 figure 2. General layout of system components compressor unit placement earthlinked ® compressor units may be located inside or outside. If outside, place compressor unit on a standard hvac outdoor unit pad. If inside, place it on a level, hard surface. If the compressor...

Page 9

Sd-410-qs (h) (06/15) page 9 figure 3. Compressor unit bracket installation figure 4. Compressor unit clearance placement instructions for other pieces of equipment that make up the earthlinked ® system are included with those pieces of equipment and are listed in this manual under equipment manuals...

Page 10

Sd-410-qs (h) (06/15) page 10 port function type of connection compressor unit model connection size, inches -024 -030 -036 -042 -048 -054 -060 a 1 electrical, power 1- 1/4” hole 1 1 1 1 1 1 1 b 1,2 electrical, control 7/8” hole 3/4 3/4 3/4 3/4 3/4 3/4 3/4 1 ah/cc liquid braze 1/2 1/2 1/2 1/2 1/2 1/...

Page 11

Sd-410-qs (h) (06/15) page 11 compressor units are shipped from the factory with a low pressure nitrogen holding charge. Carefully relieve the holding charge when the compressor unit is being prepared to connect refrigerant system piping. Caution! This compressor unit is equipped with poe lubricant....

Page 12

Sd-410-qs (h) (06/15) page 12 the compressor unit package contains a service valve kit and an adapter kit. The two service valves are to be installed on the earth loop vapor and liquid connections of the compressor unit, using the adapters to right-size to the proper earth loop line set. Installatio...

Page 13

Sd-410-qs (h) (06/15) page 13 system applications and electrical the sd(h) compressor unit electrical box major components and electric data for all compressor sizes are shown in figure 7. The surestart module is a factory installed component that (1) reduces compressor starting current and (2) redu...

Page 14

Sd-410-qs (h) (06/15) page 14 compressor unit model compressor model voltage/phase/ hz voltage lra rla mca mfs min. Max. -024-1c zp25k6e-pfv 230-1-60 207 253 72.5 15.0 18.0 30 -024-2c zp25k63-tf5 230-3-60 207 253 61.4 9.8 12.0 20 -030-1c zp31k5e-pfv 230-1-60 207 253 78.0 18.6 23.0 35 -030-2c zp31k5e...

Page 15

Sd-410-qs (h) (06/15) page 15 figure 8a. Sd(h) compressor unit electrical ladder diagram, 230-1-60

Page 16

Sd-410-qs (h) (06/15) page 16 figure 8b. Sd(h) compressor unit electrical schematic diagram, 230-1-60

Page 17

Sd-410-qs (h) (06/15) page 17 figure 9a. Sd(h) compressor unit electrical ladder diagram, 230-3-60

Page 18

Sd-410-qs (h) (06/15) page 18 figure 9b. Sd(h) compressor unit electrical schematic diagram, 230-3-60

Page 19

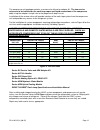

Sd-410-qs (h) (06/15) page 19 figure 10a. Sd(h) air heating/cooling, hydronic heating and water heating application.

Page 20

Sd-410-qs (h) (06/15) page 20 figure 10b. Sd(h) air heating/cooling, hydronic heating and water heating field wiring diagram.

Page 21

Sd-410-qs (h) (06/15) page 21 plumbing a typical primary hydronic plumbing circuit for an sd(h) system is illustrated in figure 11. Figure 11. Typical sd(h) primary hydronic circuit plumbing the components are as follows: 1. Flowmeter : model eti-a1-116000-1 hydronic water/antifreeze solution flowme...

Page 22

Sd-410-qs (h) (06/15) page 22 4. Storage water heater: the gste series storage water heaters are available from eti in 60, 80 and 119 us gallon capacities, and are designed for use with the earthlinked ® geothermal systems. They are equipped with a 4.5 kw supplemental heater which satisfies the eti ...

Page 23

Sd-410-qs (h) (06/15) page 23 antifreeze protection when hwm hydronic water modules are applied to radiant panel hydronic heating and/or cooling systems, the water circulating system must be protected from potential damage due to freeze-up by utilizing an adequate antifreeze solution. The antifreeze...

Page 24

Sd-410-qs (h) (06/15) page 24 general guidelines for introducing propylene glycol into the water circulating system follow. The manufacturer’s specific instructions and industry standards always take precedence when introducing propylene-glycol to the system. Calculate the quantity of inhibited prop...

Page 25

Sd-410-qs (h) (06/15) page 25 internal heat recovery system the sd(h) compressor unit has a built-in heat recovery system for the purpose of providing supplemental water heating during heating and/or cooling operation. The heat recovery system does not replace the standard storage water heater sized...

Page 26

Sd-410-qs (h) (06/15) page 26 figure 13a. Gste storage water heater - service connections figure 13b. Gste storage water heater – tank top view.

Page 27

Sd-410-qs (h) (06/15) page 27 the sd(h) compressor unit desuperheater contains a water high temperature control. It is factory set to 140°f. The desuperheater also contains a refrigerant low temperature limit switch, which is factory set to 125°f. Also, a freeze protection control is designed to ope...

Page 28

Sd-410-qs (h) (06/15) page 28 earth loop protection system anode wire installation prior to this, the below grade installation of the direct axxess® earth loop system, including the earth loop protection system anode and anode wire has been completed per the earth loop protection kit manual , and at...

Page 29

Sd-410-qs (h) (06/15) page 29 figure 15. Disassembled plug connector.

Page 30

Sd-410-qs (h) (06/15) page 30 strip the insulation from the multi-strand anode wire back approximately ¾ inch from the end and, while keeping the strands together, push the anode wire through the gland nut, gland cage, gland and plug body as shown in figure 16. Loosen one of the two screw terminals ...

Page 31

Sd-410-qs (h) (06/15) page 31 figure 17. Install the plug insert slide the gland forward on the anode wire until it is firmly seated in the plug body as shown in figure 18. Next, slide the gland cage over the gland, and slide the gland nut firmly against the gland cage, with the gland nut against th...

Page 32

Sd-410-qs (h) (06/15) page 32 once the gland nut has been hand tightened into the plug body, use two adjustable wrenches to further tighten the gland nut until it is snug in the plug body as shown in figure 19 and the anode wire is held firmly in the plug body and will not slip out. Do not over-tigh...

Page 33

Sd-410-qs (h) (06/15) page 33 eps operation and service reference figure 21 for the eps components in the compressor unit electric box. Figure 21. Electric box with eps components with power on , and viewing the eps module in the compressor unit electric box, the eps green light should be illuminate...

Page 34

Sd-410-qs (h) (06/15) page 34 current verification if it is necessary to verify the current flow through the eps system, it can be checked with a digital dc ammeter set on the milliampere scale. The correct electrical currents for nominal system capacities are listed in figure 22. Nominal system cap...

Page 35

Sd-410-qs (h) (06/15) page 35 system start-up evacuation prior to system start-up, evacuation of the system is accomplished through the compressor unit. All of the refrigerant containing components in the compressor unit are illustrated in figures 24 and 25. The evacuation and charging process will ...

Page 36

Sd-410-qs (h) (06/15) page 36 figure 25. Sd(h) piping refer to figure 26 and the following procedure: 1. Carefully vent any pressurized charge from the compressor and system.. 2. After venting the pressurized system, connect the gage block and hoses as shown in figure 26. Lp and hp valves are fully ...

Page 37

Sd-410-qs (h) (06/15) page 37 figure 26. Evacuation of sd(h) system 4. Initiate the system evacuation. Evacuate the system down to 400 microns as read on the digital micron gage. After 400 microns has been achieved, turn off the lp and hp valves and turn off the vacuum pump. Reading the digital micr...

Page 38

Sd-410-qs (h) (06/15) page 38 initial charge 1. Close the lp and hp valves on the gage block. Disconnect and isolate the vacuum pump and digital micron gage. Connect the refrigerant container (on the scale) to the gage block utility hose as shown in figure 27. Warning! Inhalation of high concentrati...

Page 39

Sd-410-qs (h) (06/15) page 39 figure 27. Initial charge of sd(h) system 2. Open the refrigerant container valve and inject liquid refrigerant into the initial charging port as shown in figure 27. 3. Charge with liquid refrigerant until 3 pounds of refrigerant per ton of system capacity, has entered ...

Page 40

Sd-410-qs (h) (06/15) page 40 final charge it is critical to control the conditions under which the compressor unit operates while final charging the system. Final charging must be done in heat mode. Air handler systems the return air to the air handler during final charging is to be maintained in t...

Page 41

Sd-410-qs (h) (06/15) page 41 1. Re-connect the red hp hose, after purging with a trickle of refrigerant, (from the initial charging port in figure 27) to the access port as shown in figure 28. Continue measuring the refrigerant charge weight as shown in figure 28. 2. Be sure that air entering the a...

Page 42

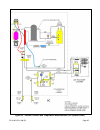

Sd-410-qs (h) (06/15) page 42 for air systems: in figure 30, locate the evaporating temperature on the horizontal axis. The corresponding condensing temperature reading should fall between the upper and lower parallel lines in figure 30. The temperature profile in figure 30 is valid for the air hand...

Page 43

Sd-410-qs (h) (06/15) page 43 figure 31. Hydronic system performance parameters 8. Check the suction saturation temperature to verify that it is within ±3°f for the measured suction pressure. The suction temperature should be approximately 15 to 20°f lower than the local earth temperature. Cool mode...

Page 44

Sd-410-qs (h) (06/15) page 44 these following steps describe the procedure for system start-up in the cooling mode. This is illustrated in the process flow chart, figure 38. Be sure the cooling mode for the system is enabled. 1. Close the hp valve on the gage block. Turn the system on in cool mode ,...

Page 45

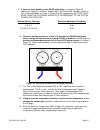

Sd-410-qs (h) (06/15) page 45 figure 32. Suction pressure and temperature measurements (sc system shown).

Page 46

Sd-410-qs (h) (06/15) page 46 figure 33. Many bubbles-inline sight glass 6. When suction pressure reaches 120 psig , observe the inline sight glass. If it is either clear as shown in figure 34, or has a trickle of bubbles as shown in figure 35, no additional refrigerant charge is required. Go to ste...

Page 47

Sd-410-qs (h) (06/15) page 47 9. If there are many bubbles in the inline sight glass, as shown in figure 33, additional refrigerant is required. Repeat step 7 until the inline sight glass clears or has a trickle of bubbles as shown in figure 34 or 35, respectively, but do not add more than the follo...

Page 48

Sd-410-qs (h) (06/15) page 48 saturation temperature (°f) suction pressure (psig) saturation temperature (°f) suction pressure (psig) -20 26.1 70 199.2 -15 30.8 75 216.1 -10 35.9 80 234.0 -5 41.5 85 253.0 0 47.5 90 273.0 5 54.1 95 294.1 10 61.2 100 316.4 15 68.8 105 339.9 20 77.1 110 364.6 25 86.0 1...

Page 49

Sd-410-qs (h) (06/15) page 49 figure 38. Cooling mode start-up.

Page 50

Sd-410-qs (h) (06/15) page 50 troubleshooting if you experience difficulties with the earthlinked ® system, please review the appropriate section of the manual. It may be helpful to have another professional hvac or refrigeration service person review and check it with you. Time and expense can be s...

Page 51

Sd-410-qs (h) (06/15) page 51 figure 39. Compressor unit voltage information the following compressor checklist is provided to analyze the compressor and determine if it is operating properly or if it is faulty: 1. Electrical service panel – turn power off. A. Check circuit connections for tightness...

Page 52

Sd-410-qs (h) (06/15) page 52 7. Motor circuit testing using a digital volt-ohmmeter (vom), measure the resistance across the compressor windings as shown in figure 40. The power leads to the compressor must be disconnected before taking an electrical measurement. A good rule of thumb for single pha...

Page 53

Sd-410-qs (h) (06/15) page 53 8. Grounded windings test the compressor motor for a grounded winding. The check should be made using an ohmmeter capable of measuring very high resistance on a vom. The resistance between windings and the housing is one million to three million ohms for an ungrounded w...

Page 54

Sd-410-qs (h) (06/15) page 54 system problem / symptom likely cause(s) correction a. System does not run. Note: some digital thermostats have a built-in five- minute time delay . 1. Thermostat fault. 1. Adjust thermostat settings. / replace thermostat. 2. Power supply problem (ahu / compressor unit)...

Page 55

Sd-410-qs (h) (06/15) page 55 c. System blows fuses or trips circuit breaker (con’t) 4. Excessively high or low supply voltage or phase loss (3 only). 4. Note voltage range limitations specific to the compressor. 5. Faulty run capacitor or soft start components. 5. Replace as necessary. D. Air handl...

Page 56

Sd-410-qs (h) (06/15) page 56 g. Uncomfortable temperature. (not enough heat/cold air) (cont’d) 7. Refrigerant undercharged. 7. Check for refrigerant level in acc.(heating mode only) repair leak, evacuate and recharge the system. Check in-line sight glass in cooling mode. 8. Restriction in refrigera...

Page 57

Sd-410-qs (h) (06/15) page 57 commissioning document the document that follows (lit-170) enables verification and documentation of system component model numbers, location of underground system components and system performance for air and hydronic heating and cooling..

Page 58

Sd-410-qs (h) (06/15) page 58.

Page 59

Sd-410-qs (h) (06/15) page 59.

Page 60

Sd-410-qs (h) (06/15) page 60

Page 61

Sd-410-qs (h) (06/15) page 61.

Page 62

Sd-410-qs (h) (06/15) page 62.

Page 63

Sd-410-qs (h) (06/15) page 63.

Page 64

Sd-410-qs (h) (06/15) page 64 tools and equipment the purpose of the following list is to highlight key pieces of equipment, tools and materials necessary for the installation, maintenance and servicing of earthlinked ® heating and cooling system hvac (above ground) equipment. The professional hvac ...

Page 65

Sd-410-qs (h) (06/15) page 65 triple evacuation triple evacuation is implemented to evacuate a system to a deep vacuum. It is accomplished by evacuating a system to a vacuum of 1500 microns, and then bleeding a small amount of dry nitrogen into the system. The nitrogen is then blown out to the atmos...