- DL manuals

- EarthLinked

- Air Conditioner

- Prime Series

- Quick Start Instructions

EarthLinked Prime Series Quick Start Instructions

Summary of Prime Series

Page 1

Psc-qs (10/16) ©2016 earthlinked technologies, inc. Prime series psc geothermal heating and cooling system quick-start instructions.

Page 2: Table Of Contents

Psc-qs (10/16) page 2 table of contents list of figures ................................................................................................................................... 3 list of revisions ...............................................................................................

Page 3: List of Figures

Psc-qs (10/16) page 3 list of figures figure 1. Matching component model numbers ................................................................................... 7 figure 2. General layout of system components ............................................................................... 8 figur...

Page 4: List of Revisions

Psc-qs (10/16) page 4 figure 35. System troubleshooting chart .......................................................................................... 48 list of revisions corrected piping and internal flow schematic revised electrical drawings and electric box revised charging method due to elimi...

Page 5: M Odel Nomenclature

Psc-qs (10/16) page 5 m odel nomenclature disclaimer proper installation and servicing of the earthlinked ® heat pump is essential to its reliable performance. All earthlinked ® systems must be installed and serviced by an eti trained and authorized technician. Installation and service must be made ...

Page 6: Safety

Psc-qs (10/16) page 6 safety warning, caution and important notices appear throughout the manual. Read these items carefully before attempting installation, servicing or troubleshooting the equipment. Equipment m anuals the following is a listing of the equipment installation manuals that are provid...

Page 7: Installation

Psc-qs (10/16) page 7 installation 1) component matching upon receipt of the equipment, carefully check the component model numbers by referencing figure 1, to ensure that all components of the system match. Prime compress. Unit 1 air handler cased coil hybrid cooling module earth loop 2 eti four sp...

Page 8

Psc-qs (10/16) page 8 figure 2. General layout of system components 2) compressor unit placement earthlinked ® compressor units may be located inside or outside. If outside, place compressor unit on a standard hvac outdoor unit pad. If inside, place it on a level, hard surface. If the compressor uni...

Page 9

Psc-qs (10/16) page 9 figure 3. Compressor unit bracket installation figure 4. Compressor unit clearance placement instructions for other pieces of equipment that make up the earthlinked ® system are included with those pieces of equipment and are listed in this manual under equipment manuals. 3) re...

Page 10

Psc-qs (10/16) page 10 port function type of connection compressor unit model connection size, inches -025 -030 -036 -040 -050 -060 a electrical, power 1- 1/4” hole 1 1 1 1 1 1 b electrical, control 7/8” hole 3/4 3/4 3/4 3/4 3/4 3/4 1 ah/cc/hwm liquid braze 1/2 1/2 1/2 1/2 1/2 1/2 3 el liquid* braze...

Page 11

Psc-qs (10/16) page 11 caution! Refrigerant piping connections refrigerant joints are to be brazed with 15% silver content brazing alloy, utilizing the nitrogen brazing process. Nitrogen brazing process purpose: utilize the nitrogen brazing process on all brazed refrigerant piping connections. This ...

Page 12

Psc-qs (10/16) page 12 the compressor unit has factory installed service valves on the earth loop vapor and liquid stubouts outside the compressor cabinet. For the installation of system components requiring refrigeration connections, refer to figure 6 for line set sizes and the appropriate installa...

Page 13

Psc-qs (10/16) page 13 4) system applications and electrical the psc compressor unit electrical box major components and electric data for all compressor sizes are shown in figure 7. The psc series compressor units are equipped with a nano-plc (programmable logic controller) to provide a range of fu...

Page 14

Psc-qs (10/16) page 14 compressor unit model compressor model voltage/phase/ hz voltage lra rla mca mfs min. Max. -025-1c zps26k5e-pfv 230-1-60 207 253 73.0 14.6 18.0 30 -025-2c zps26k5e-tf5 230-3-60 207 253 58.0 9.6 12.0 20 -030-1c zps30k5e-pfv 230-1-60 207 253 83.0 17.0 21.0 35 -030-2c zps30k5e-tf...

Page 15

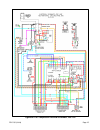

Psc-qs (10/16) page 15 figure 8a. Psc compressor electrical schematic, 230-1-60

Page 16

Psc-qs (10/16) page 16 figure 8b. Psc compressor unit electrical schematic, 230-3-60

Page 17

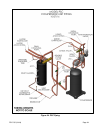

Psc-qs (10/16) page 17 figure 9. Psc air heating/cooling system application.

Page 18

Psc-qs (10/16) page 18 figure 10. Psc air heating/cooling system field wiring diagram.

Page 19

Psc-qs (10/16) page 19 5) earthlinked® diagnostic and monitoring system (edm) the earthlinked® diagnostic and monitoring system (edm), as shown in figure 7, provides real-time remote monitoring and tracks pressures, temperatures, power consumption and thermostat signals. It connects via internet, bl...

Page 20

Psc-qs (10/16) page 20 the air zoning o ption kit is designed to use the damper override “d” terminal signal of the compressor unit to force open the largest zone while the earthlinked system is in maintenance mode. The kit isolates the zone control and air handler power supplies and ensures system ...

Page 21

Psc-qs (10/16) page 21 7) surestart features surestart is a factory installed soft starter that reduces light flicker caused at start-up by scroll compressor motors. This control has the following features: 60 to 70% reduction in direct in-rush current under voltage protection motor reversal protect...

Page 22

Psc-qs (10/16) page 22 if the run capacitor is faulty or has failed, surestart will shut down the compressor for 3 minutes before initiating a restart. Figure 12. Surestart mode of operation.

Page 23

Psc-qs (10/16) page 23 flash codes – single phase led flash codes a red led indicator will flash under the following conditions. [note: led fault indicator is turned off in normal running mode.] a) rapid flash (10 / sec) : low voltage b) triple flash every three seconds (3 / 3 secs): lockout on thre...

Page 24

Psc-qs (10/16) page 24 flash codes – three phase a red led indicator will flash under the following conditions. [note: led fault indicator is turned off in normal running mode.] a) reverse phase: (1 / 2 secs) b) fault mode/cycle delay: (1 / 4 secs) c) low voltage/over voltage: 2 / 2 secs) flash code...

Page 25

Psc-qs (10/16) page 25 earth loop protection system 1) anode wire installation prior to this, the below grade installation of the direct axxess® earth loop system, including the earth loop protection system anode and anode wire has been completed per the earth loop protection kit manual, and at this...

Page 26

Psc-qs (10/16) page 26 figure 14. Disassembled plug connector.

Page 27

Psc-qs (10/16) page 27 strip the insulation from the multi-strand anode wire back approximately ¾ inch from the end and while keeping the strands together, push the anode wire through the gland nut, gland cage, gland and plug body as shown in figure 15. Loosen one of the two screw terminals on the p...

Page 28

Psc-qs (10/16) page 28 figure 16. Install the plug insert slide the gland forward on the anode wire until it is firmly seated in the plug body as shown in figure 17. Next, slide the gland cage over the gland, and slide the gland nut firmly against the gland cage, with the gland nut against the plug ...

Page 29

Psc-qs (10/16) page 29 once the gland nut has been hand tightened into the plug body, use two adjustable wrenches to further tighten the gland nut until it is snug in the plug body as shown in figure 18 and the anode wire is held firmly in the plug body and will not slip out. Do not over-tighten the...

Page 30

Psc-qs (10/16) page 30 2) eps operation and service reference figure 20 for the eps components in the compressor unit electric box. Figure 20. Electric box with eps components with power on, and viewing the eps module (under the edm system in the compressor unit electric box), the eps green light sh...

Page 31

Psc-qs (10/16) page 31 3) current verification if it is necessary to verify the current flow through the eps system, it can be checked with a digital dc ammeter set on the milliampere scale. The correct electrical currents for nominal system capacities are listed in figure 21. Nominal system capacit...

Page 32: Start-Up Process

Psc-qs (10/16) page 32 start-up process 1) system leak check after all indoor and outdoor refrigerant bearing components of the system have been installed and joints have been nitrogen brazed, pressurize the system prior to evacuation to leak test the system. Do not exceed 150 psig when pressure tes...

Page 33

Psc-qs (10/16) page 33 figure 23. Psc internal flow schematic.

Page 34

Psc-qs (10/16) page 34 figure 24. Psc piping.

Page 35

Psc-qs (10/16) page 35 2) evacuation refer to figure 25 and the following procedure: 1. Carefully vent any pressurized nitrogen charge from the compressor unit and system.. 2. After venting the pressurized system, use a good quality gauge manifold and a non-permeable hose set as shown in figure 25. ...

Page 36

Psc-qs (10/16) page 36 figure 25. Evacuation of psc system.

Page 37

Psc-qs (10/16) page 37 3) initial charge 1. Disconnect the vacuum pump and isolate the digital vacuum gauge. Connect the refrigerant container to the charging hose of the manifold gauge set as shown in figure 26. 2. Place the refrigerant container upside down (or oriented to deliver liquid refrigera...

Page 38

Psc-qs (10/16) page 38 figure 26. Initial charge of psc system.

Page 39

Psc-qs (10/16) page 39 4) final charge 1. Remove the schrader core tool from the hose just taken off of the initial charging port. 2. Crack open the lp valve on the manifold gauge set so that a small amount of refrigerant gas flows to purge the hose. Connect the hose to the final charging port, show...

Page 40

Psc-qs (10/16) page 40 figure 27. Final charge of psc system.

Page 41

Psc-qs (10/16) page 41 figure 28. Charging to the middle sight glass (heat only units) figure 29. Final charging to the top sight glass (heat/cool units).

Page 42

Psc-qs (10/16) page 42 temperature (°f) pressure (psig) temperature (°f) pressure (psig) -20 26.1 70 199.2 -15 30.8 75 216.1 -10 35.9 80 234.0 -5 41.5 85 253.0 0 47.5 90 273.0 5 54.1 95 294.1 10 61.2 100 316.4 15 68.8 105 339.9 20 77.1 110 364.6 25 86.0 115 390.5 30 95.5 120 417.7 35 105.7 125 446.3...

Page 43

Psc-qs (10/16) page 43 figure 31. Start-up process.

Page 44: Troubleshooting

Psc-qs (10/16) page 44 troubleshooting if you experience difficulties with the earthlinked ® system, please review the appropriate section of the manual. It may be helpful to have another professional hvac or eti approved refrigeration service person review and check it with you. Time and expense ca...

Page 45

Psc-qs (10/16) page 45 figure 32. Compressor unit voltage information the following compressor checklist is provided to analyze the compressor and determine if it is operating properly or if it is faulty: 1. Electrical service panel – turn power off. A. Check circuit terminal connections for tightne...

Page 46

Psc-qs (10/16) page 46 if the compressor draws a high amperage and does not start (amperage is approximately locked rotor amperage – lra (see figure 7)), the compressor is locked mechanically and should be removed from the system and replaced. Verify before removing! 7. Motor circuit testing using a...

Page 47

Psc-qs (10/16) page 47 8. Grounded windings test the compressor motor for a grounded winding. The check should be made using an ohmmeter capable of measuring very high resistance on a vom. The resistance between windings and the housing is one million to three million ohms for an ungrounded winding....

Page 48

Psc-qs (10/16) page 48 2) system problem / symptom likely cause(s) correction a. System does not run. Note: some digital thermostats have a built-in five- minute time delay. 1. Thermostat fault. 1. Adjust thermostat settings. / replace thermostat. 2. Power supply problem (ahu / compressor unit). 2. ...

Page 49

Psc-qs (10/16) page 49 c. System blows fuses or trips circuit breaker (con’t) 4. Excessively high or low supply voltage or phase loss (3 only). 4. Note voltage range limitations specific to the compressor. 5. Faulty run capacitor or soft start components. 5. Replace as necessary. D. Air handler fan ...

Page 50

Psc-qs (10/16) page 50 g. Uncomfortable temperature. (not enough heat/cold air) (cont’d) 7. Refrigerant undercharged. 7. Check for refrigerant level in acc.(heating mode only). Level at top sight glass @ saturation. Repair leak, evacuate and recharge the system. Check in-line sight glass in cooling ...

Page 51: Commissioning Document

Psc-qs (10/16) page 51 commissioning document the document that follows (lit-170) enables verification and documentation of system component model numbers, location of underground system components and system performance for air and hydronic heating and cooling..

Page 52

Psc-qs (10/16) page 52.

Page 53

Psc-qs (10/16) page 53.

Page 54

Psc-qs (10/16) page 54.

Page 55

Psc-qs (10/16) page 55.

Page 56

Psc-qs (10/16) page 56.

Page 57

Psc-qs (10/16) page 57.

Page 58: Tools And Equipment

Psc-qs (10/16) page 58 tools and equipment the purpose of the following list is to highlight key pieces of equipment, tools and materials necessary for the installation, maintenance and servicing of earthlinked ® heating and cooling system hvac (above ground) equipment. The professional hvac technic...

Page 59: Triple Evacuation

Psc-qs (10/16) page 59 triple evacuation triple evacuation is implemented to evacuate a system to a deep vacuum. It is accomplished by evacuating a system to a vacuum of 1500 microns, and then bleeding a small amount of dry nitrogen into the system. The nitrogen is then blown out to the atmosphere. ...

Page 60: Models)

Psc-qs (10/16) page 60 appendix: functions of the nano-plc (for air-only models) programmable logic controllers (nano-plc) come standard in all prime series units as well as in the classic sdh, scw and scwd. The nano-plc is programmed to ensure different functions depending on the units, you can fin...

Page 61

Psc-qs (10/16) page 61 5) zone control: if the system is air zoned, the zone override terminal “d” should be used and will send 24 volts out during the 5-minute maintenance cycle (see 4) only. The 24 volt signal can be used to open zones to prevent high static pressure and noise from the duct system...