- DL manuals

- EarthQuake

- Tiller

- CRT series

- Operator's Manual

EarthQuake CRT series Operator's Manual

Summary of CRT series

Page 1

Crt rototiller operator’s manual includes model 5055 om5055 rev. 2/4/04 © copyright 2004 ardisam, inc. All rights reserved. Printed in usa..

Page 2

2 ardisam.

Page 3: Model Identification

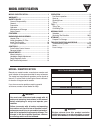

Ardisam 3 model identification model identification ........................................... 3 warranty ................................................................. 4 safety rules ......................................................... 5 owner's responsibility ................................

Page 4: Warranty

4 ardisam warranty thank you . . . For purchasing an earthquake ® counter-rotating-tine rototiller. We guarantee that this rear tine rototiller conforms to applicable north american safety standards, and have worked to ensure that it will meet your exacting standards for usability and durability. Wi...

Page 5: Safety Rules

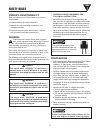

Ardisam 5 safety rules owner's responsibility safe and effective use of the rototiller is the owner's responsibility. 1. Read and follow all safety instructions. 2. Maintain the tiller according to directions and schedule included. 3. Ensure that anyone who uses the tiller is familiar with all contr...

Page 6: Safety Rules

6 ardisam safety rules operation • never operate the tiller without guards, covers, and hoods in place. • never start the engine or operate the tiller with the wheels in the free-wheel position. Make sure the wheel lockpins are engaged through the wheel hubs and wheel axle. Disengage wheel lockpins ...

Page 7: Safety Rules

Ardisam 7 part no. Lbl516f free hand here bumper guard decal part no. Lbl821b warning instructions hood decal part no. Lbl516c warning belt cover decal part no. Lbl516e tines danger hood flap decal part no. Lblcrta operating instructions hood decal safety rules safety decals this rototiller unit has...

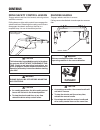

Page 8: Features

8 ardisam features all crt models drive safety control lever drag bar forward cable detent pin reverse cable recoil start serial number plate wheel lockpin r r belt guard.

Page 9: Unpacking and Assembly

Ardisam 9 unpacking and assembly your rototiller comes fully assembled except for a few parts. The following instructions will help you unpack your tiller and assemble and adjust your tiller’s depth regulator lever, cable tension and handlebar height. You will need 2- 9/16” wrenches. Unpack tiller 1...

Page 10: Unpacking and Assembly

10 ardisam install the drag bar 1. Install the depth regulator lever into the top of the depth regulator bracket with handle facing rearward. 2. Insert detent pin through depth regulator bracket and top hole of depth regulator lever--tines should clear the ground. Note: the rototiller is now in the ...

Page 11: Controls

Ardisam 11 controls reverse handle engages wheels and tines in reverse. Pulling reverse handle back towards operator reverses tiller. V as a safety precaution, the reverse handle will not lock in reverse. V to stop the wheels and tines at any time, release the reverse handle. V do not operate both t...

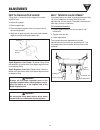

Page 12: Adjustments

12 ardisam wheel lockpins place wheels in tilling position. 1. Remove lockpin. Align hole in axle with hole in wheel hub. 2. Insert lockpin through holes, fold lockpin ring to secure pin to axle. 3. Wheel and axle should be firmly locked together before tilling. 4. Repeat for other wheel. Note: alwa...

Page 13: Adjustments

Ardisam 13 adjustments depth regulator lever tilling depth is controlled by the height of the depth regualtor lever. To adjust tilling depth. 1. Remove detent pin. 2. Raise the depth regulator lever to position tines at chosen tilling depth. 3. Align hole in depth regulator lever with hole in depth ...

Page 14: Operation

14 ardisam operation pre-start inspection 1. Make sure all safety guards are in place and all nuts and bolts are secure. 2. Check oil level in engine crankcase. See your engine manual for procedure and specifications. 3. Inspect air cleaner for cleanliness. See your engine manual for procedure. 4. C...

Page 15: Operation

Ardisam 15 operation shutting down tilling 1. Adjust the depth regulator lever to desired tilling depth. Note: raise depth regulator lever up one hole at a time, testing tiller operation after each raise. Raising depth regulator lever too high can result in loss of control of tiller! 2. Move the thr...

Page 16: Tips

16 ardisam tips tilling tips the key to successful tilling is to begin with a shallow cut on the first pass, and then work an inch or two deeper on each successive pass. ✮ tilling depth will vary with ground conditions. ✮ when beginning to till in unbroken ground or in extremely hard soil, set the d...

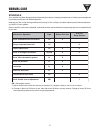

Page 17: Normal Care

Ardisam 17 normal care schedule your rototiller has been designed and produced by the industry's leading manufacturer of outdoor power equipment to provide you with years of reliable operation. Keeping your tiller in top running condition will prolong its life, and help you obtain optimum performanc...

Page 18: Normal Care

18 ardisam normal care servicing the rototiller general the following information will help you make the necessary checks and perform the procedures required to follow the normal care recommendations made for your rototiller unit. If you prefer, your local authorized dealer can make these checks and...

Page 19: Normal Care

Ardisam 19 normal care belt replacement part #’s: 727a (forward) 730 (reverse) change forward/reverse belt 1. Turn off engine. Engine must be cool. 2. Remove spark plug wire and secure from spark plug. 3. Remove belt guard. ✮ remove the forward belt from the forward engine pulley: - gently pull the ...

Page 20: Normal Care

20 ardisam normal care adapted from briggs & stratton corporation, form no. 274263-10/99. Engine is shipped from factory without oil. You must add engine oil before starting engine. Check or fill engine crankcase 1. Add oil according to engine manual. Do not overfill. Use a clean, high quality deter...

Page 21: Normal Care

Ardisam 21 normal care check tire pressure recommended tire pressure is 20 psi. If tires do not have equal pressure, tiller will pull to one side. Lubrication proper lubrication of moving mechanical parts of your rototiller is a very important part of care and maintenance. You should oil the moving ...

Page 22: Storage

22 ardisam storage prepare for storage follow the steps below to prepare your tiller for storage. Read your engine manual for detailed instructions on preparing the engine for storage. 1. Protect wheels and axles from rust: - remove lockpin and slide wheel off hub. - coat the axles lightly with axle...

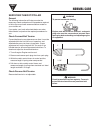

Page 23: Troubleshooting and Repair

Ardisam 23 troubleshooting and repair troubleshooting guide while normal care and routine maintenance will extend the life of your rototiller, prolonged or constant use may eventually require that service be performed to allow it to continue operating properly. The troubleshooting guide below lists ...

Page 24: Troubleshooting and Repair

24 ardisam troubleshooting and repair problem remedy/action belts squeal in neutral and/or reverse belts squeal in forward operation excessive heat build up in transmission/tine area during tilling • adjust forward belt guide: - turn engine off and allow muffler to cool - disconnect spark plug wire ...

Page 25: Notes

Ardisam 25 notes ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ _______________________________...

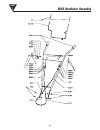

Page 26: 5055 Handlebar Assembly

26 ardisam 5055 handlebar assembly.

Page 27: 5055 Handlebar Assembly

Ardisam 27 5055 handlebar assembly part # qty. Description 60g56 1 nut-bi-way lock, 5/16-18 199 2 handle grip-drive control lever 318 1 handlebar assembly 1401 1 bolt-hex hd, 5/16-18 x 1-1/4” 1424 1 bushing-pivot, 5/16" 2102 4 bolt-hex hd, 3/8-16 x 1”, grade 5 2104 4 nut-hex, 3/8-16 53530 1 spring-b...

Page 28: 5055 Tines & Hood Assembly

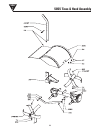

28 ardisam 5055 tines & hood assembly.

Page 29: 5055 Tines & Hood Assembly

Ardisam 29 5055 tines & hood assembly part # qty. Description 60g56 2 nut-bi-way lock, 5/16-18 394 1 bracket-depth regulator, black, 2-holes 401crt 1 depth regulator lever, black, 4-holes 417 2 bolt-hex hd, 5/16-18 x 1/2", grade 5 504 2 lockwasher-spring, 5/16" 509 2 bolt-hex hd, 1/4-20 x 1/2" 719 2...

Page 30: 5055 Motor Mount Assembly

30 ardisam 5055 motor mount assembly.

Page 31: 5055 Motor Mount Assembly

Ardisam 31 5055 motor mount assembly part # qty. Description 60g56 12 nut-bi-way lock, 5/16-18 311 4 bracket-motor mount, right 504 4 lockwasher-spring, 5/16" 507a 1 bracket-motor mount, left 508b 1 weight-complete 719 1 lockwasher-spring, 3/8” 727a 1 belt-forward 730 1 belt-reverse 731 1 pulley-2 g...

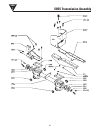

Page 32: 5055 Transmission Assembly

32 ardisam 5055 transmission assembly.

Page 33: 5055 Transmission Assembly

Ardisam 33 part # qty. Description 60g56 4 nut-bi-way lock, 5/16-18 311 1 bracket-motor mount, right 394 1 bracket-depth regulator, black, 2-holes 494l 1 tiller transmission casting 507a 1 bracket-motor mount, left 1500crt1 1 transmission assembly, lockpin (replacement only) 1501 14 bolt-hex flange ...

Page 34

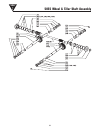

34 ardisam 5055 wheel & tiller shaft assembly.

Page 35

Ardisam 35 5055 wheel & tiller shaft assembly part # qty. Description 1506 4 seal-tiller housing 1508 1 cap-rear bearing 1514 1 cap-front bearing 1515 1 oil seal-drive shaft 1600lc1 1 main drive shaft, lh 1601 2 bearing-tapered (includes cone & race) 1700a 1 wheel shaft assembly, lockpin 1701 2 key ...

Page 36

Ardisam, inc. 1690 elm street, cumberland, wisconsin 54829 (715)822-2415 • fax (715)822-4180 1-800-345-6007 www.Ardisam.Com.