779 washington st., buffalo, n.Y. 14203-1396 u.S.A. • (716) 856-2200 • fax (716) 856-1140 or (716) 856-2068 website: www.Eastmancuts.Com eastman ® blue streak ® ii model 629xs auto-stop brute model 627xs auto-stop instruction manual and parts list blue streak ii model 629xs auto-stop brute model 627...

Eastman form c-1572 limited warranty. Eastman warrants to the buyer that the blue streak ii and brute shall be free from defects in materials or workmanship for a period of 18 0 days commencing on the date of invoice. Any goods or parts claimed by the buyer to be defective must be returned to eastma...

Form c-1572 table of contents safety information ........................................ 1 general safety precautions ..................................... 1 operation ...................................................... 2 initial set up ..............................................................

Eastman form c-1572 figure 22. Single phase motor assembly (exploded view).......................................... 23 figure 23. Three-phase motor assembly (assembled view) ....................................... 24 figure 24. Three-phase motor assembly (exploded view)................................

Form c-1572 safety and indemnification during the life of the machine, the purchaser agrees to pro- vide to all machine users (including its own employees and independent contractors) all relevant safety information, in- cluding warning labels and instruction manuals. The pur- chaser also agrees to ...

Eastman form c-1572 operation before operating the machine, read these instructions care- fully. Familiarize yourself with all the functions and adjust- ments of the machine. Caution operating this machine from an incorrect electrical supply may damage it. 2. Check that the machine has been lubricat...

Form c-1572 7.3 with your right hand, hold the operating handle and press the start button. Allow the motor to gather full speed and then release the release lever. This automatically returns the sharpener to the locked position. Caution turn the motor on and off a few times before running the machi...

Eastman form c-1572 turning off the machine when you have finished using your machine: 1. Position the power switch to off. 2. Make sure the knife guard/pressure foot is lowered to the baseplate by depressing the pressure foot lever (figure 2, r). 3. Disconnect the attachment plug from the power sou...

Form c-1572 2. Remove the plug (figure 2, p) and insert a grease tube. Squeeze an amount of grease approximately the size of a pea into the opening. Warning routinely check the tightness of the operating handle to ensure a secure connection. Sharpening the knife sharpen the knife at frequent interva...

Eastman form c-1572 5. Press the lever (figure 3, e) to a neutral position and raise the sharpener to the top (original) position. 6. Remove the four hold-down nuts (figure 3, v), unplug solenoid cord and remove the sharpener. Note: if you press the sharpener lever (figure 3, e) down too far (beyond...

Form c-1572 adjusting the belt sharpener note: you can obtain all the special tools you will require for adjusting the sharpener by ordering tool kit #820c2. O rear pulley t front pulley s slide with pulley u sharpener shoe figure 5. Changing the sharpener belts warning failure to unplug the attachm...

Eastman form c-1572 checking the extreme down position of the sharpener the correct down position is with the tip of the knife at the center of the belt on the shoe (figure 6, 12). The belt should be in the most downward position, and the knife should be in the most upward position. If the belts are...

Form c-1572 5. When the spacer is adjusted, use the pin to hold the spacer in position, reassemble, and tighten the locknut (figure 6, 15). 6. Replace the plastic cap. Checking the stop screw on the sharpener shoe 1. With new belts on the carrier, insert .010 feeler gauge #141c1-27 between the stop ...

Eastman form c-1572 changing the knife (continued) warning unplug the attachment plug from power source. 1. Make sure the sharpener is in the locked position. 2. Lay the machine on a table, as shown in figure 7. 3. Raise the pressure foot (figure 7, x on page 9) to the top position. 4. Press in the ...

Form c-1572 straight knife selection chart carbon steel high-speed steel special process knife straight saw wave straight round angle saw wave straight size front tooth edge front tip tip tooth edge front 4 80c4 80c4-14 80c4-19 80c4hs 80c4-14hs 80c4-19hs 5 80c5 80c5-14 80c5-19 80c5hs 80c5hs-r 80c5-3...

Eastman form c-1572 adjusting bevel bloc ® shoes (continued) if you need to adjust the bevel on the knife edge to a differ- ent length, proceed as follows: 1. Disconnect the machine from the power source. 2. Lower the knife to the bottom of the stroke with the machine turning knob (figure 2, f on pa...

Form c-1572 subassembly 743c3-1 includes: 20c13-63 screw, set 103c2-36 shoe, sharpener l.H. 766c1-1 bevel bloc assembly l.H. 308c10-1 screw, socket 6/32" x 5/16" (2 required) part no. Description 4c2-63 l.H. Nut (2 required) 715c1-16 lower gear bracket complete 5"-10" knife 715c1-18 lwr. Gear bracke...

Eastman form c-1572 problem solution machine does not a. Surface of cutting table not move easily on table smooth b. Rubber mounted rollers com- pressed causing baseplate to drag on table no bevel on one side a. Broken torsion spring of blade b. Band plates do not pivot freely sharpener belt cut a. ...

Form c-1572 15 figure 12. Electrical configuration.

Eastman form c-1572 freeing frozen guides 3 screw 7 oiler tube 4 connecting rod 8 crosshead 5 hole 10 washer 6 set screw 11 notch figure 13. Freeing frozen guides to free frozen guides, proceed as follows: 1. Remove the machine from the power source. 2. Remove the sharpener from the machine, see rem...

Form c-1572 figure 14. Available metal mesh glove styles ordering details all gloves are available with three or five fingers. Note: all gloves are shipped with left hand configuration. For a right hand configuration reverse the wrist snap fas- tener. Ordering reference description left-hand (see no...

Eastman form c-1572 the 250x microphotographs (figure 16) show four different edges, as produced by eastman’s four abrasive belt grits. Fine belt fine edge slices thru synthetics and blends, for knitted or loosely woven cloths, and for silks, high-pile fabrics, quilting, etc. Blue 181c2-5 medium bel...

Form c-1572 specialty machines plastic master model 627xspm/629xspm eastman's plastic master has been specifically designed by eastman's engineering group to eliminate the fusing of synthetic materials such as plastics, pvc, vinyl, and rein- forced vinyl. Exclusively formulated plastic master fluid ...

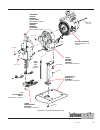

Eastman form c-1572 illustrated parts list your eastman straight knife has been carefully designed to provide many hours of trouble-free operation. The com- prehensive exploded parts illustrations have been carefully prepared to enable you to easily order replacement parts. Replacement parts for thi...

Form c-1572 sharpener housing assembly (front view) see pages 28 and 29 sharpener housing assembly (rear view) see pages 30 and 31 standard and baseplate assembly see pages 34 and 35 for replacement belts see pages 17 and 18 motor assemblies see pages 22, 23, 24 and 25 front bearing housing assembly...

Eastman form c-1572 part no. No. Req'd description 52c5-238 1 1 switch base 52c5-239 1 1 fuse base 53c7-35 1 1 fan cover 73c7-121 1 1 terminal wire tubing 79c2-82 1 0 label, safety warning 79c2-84 0 1 label, safety warning 90c1-146 1 1 rear bearing housing 90c6-46 1 1 rear ball bearing 236c-177 1 1 ...

Form c-1572 figure 22. Single phase motor assembly (exploded view) note: l.H. Indicates left- hand thread. All others are right-hand. Warning attach ground wire to ground terminal “e” on terminal block. Failure to ground terminal block may result in electrocution or other serious personal injuries. ...

Eastman form c-1572 three-phase motor assemblies figure 23. Three-phase motor assembly (assembled view) note: please specify model and serial number of machine when ordering parts. Part no. No. Req'd description 1c4-8 1 1 sleeve, cutout 4c1-145 1 1 shaft lock nut 4c2-87 1 1 nut, clutch 10c1-41 1 1 r...

Form c-1572 note: l.H. Indicates left- hand thread. All others are right-hand. Attachment plug terminal block see back cover 30c1-8 l.H. 10c1-41 4c2-87 l.H. L.H. 4c1-145 53c7-35 34c1-51 301c8-1 13c1-9 300c12-3 1c4-8 67c1-10 73c7-121 90c1-146 783c1-3 305c10-1 12c1-32 12c1-12 90c6-46 513c3-240 513c3-2...

Eastman form c-1572 part no. No. Req'd description 4c1-111 1 1 operating handle lock nut 4c1-132 1 1 crank ball bearing lock nut 4c1-190 1 1 lock nut for shaft 4c2-91 3 3 nut for guide screw 4c2-110 1 1 stop nut 4c3-8 3 3 guide adjustment nut 11c12-92 1 1 shaft for ball bearing 12c1-21 2 2 shakeproo...

Form c-1572 figure 25. Front bearing housing with oiler assembly (exploded view) notes: l.H. Indicates left-hand thread. All others are right-hand. Slip large lug over switch before replacing switch base. Secure switch to base tightly to ensure positive ground. Note: certain 220 volt machines will u...

Eastman form c-1572 sharpener housing assembly (front view) note: please specify model and serial number of machine when ordering parts. Figure 26. Sharpener housing assembly (assembled, front view) for both 627 & 629 part no. No. Req'd description 4c1-149 1 nut, elastic 4c2-112 1 r.H. Nut for screw...

Form c-1572 figure 27. Sharpener housing assembly (exploded, front view) note: l.H. Indicates left-hand thread. All others are right-hand. *these parts sold only in assemblies as follows. 713c4-4 screw shaft with extension, r. & l. Hand nuts 5"-8" 713c4-5 screw shaft with extension, r. & l. Hand nut...

Eastman form c-1572 part no. No. Req'd description 4c2-2 1 lock nut for shaft 4c2-85 1 r.H. Follower nut 4c2-86 1 l.H. Follower nut 11c12-58 1 r.H. Square shaft 5"-8" knife 11c12-59 1 r.H. Square shaft 9"-10" knife 11c12-81 1 r.H. Square shaft 11-1/2" knife 11c12-85 1 r.H. Square shaft 13" knife 11c...

Form c-1572 figure 29. Sharpener housing assembly (exploded, rear view) note: l.H. Indicates left-hand thread. All others are right-hand. Note: for special shoes, if the machine is not an 1800 rpm or a dual-speed unit, it must be equipped with a #584c3-14 slow-speed driver, including the following p...

Eastman form c-1572 note: please specify model and serial number of machine when ordering parts. Figure 30. Lower gear bracket assembly (assembled view) lower gear bracket assembly illustrated parts list complete sharpener assembly numbers: 637c10-* machine stroke 1-1/8" 1-1/4" 1-1/2" 1-3/4" -20, -2...

Form c-1572 figure 31. Lower gear bracket assembly (exploded view) 33 note: l.H. Indicates left-hand thread. All others are right-hand..

Eastman form c-1572 standard and baseplate assembly note: please specify model and serial number of machine when ordering parts. Figure 32. Standard and baseplate assembly (assembled view) part no. No. Req'd description for both 627 & 629 12c1-35 4 lock washer, #8 12c15-77 1 washer for micro fog sta...

Form c-1572 figure 33. Standard and baseplate assembly (exploded view) instructions for removing worn plate roller shell figure 34. Removing a worn plate roller shell caution do not oil the plate roller shells or you may dam- age them. Place the plate on blocks and press out the roller shell from th...

Form c-1572 © 1996 eastman machine company printed in u.S.A. 9/2007 electrical connections please specify voltage when ordering parts description part no. Attachment plug 523c1-99 523c1-100 523c1-101 523c1-102 523c1-103 cord sleeve 1c13-27 1 1 1 1 1 u-lock sleeve 20c13-103 4 4 3 3 3 spring 34c10-170...