- DL manuals

- Eastwood

- Welding System

- MIG 135

- Assembly & Operating Instructions

Eastwood MIG 135 Assembly & Operating Instructions

Summary of MIG 135

Page 1

Mig 135 welder assembly & operating instructions part #12011.

Page 2

2 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com statement of limited warranty the eastwood company (hereinafter “eastwood”) warrants to the end user (purchaser) of all new welding and cutting equipment (collectively called the “products”) that it will be free of defects in work...

Page 3

To order parts and supplies: 800.345.1178 >> eastwood.Com 3 safety information arc welding can be dangerous. This welding machine must be connected to a power source in accordance with appliance electrical codes. Disconnect from power source before assembling, disassembly or maintenance of the torch...

Page 4

4 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com safety information welding sparks can cause fire or explosion. Do not operate electric arc welder in areas where fl ammable or explosive vapors are present. Always keep a fi re extinguisher nearby while welding. Use welding blanke...

Page 5

To order parts and supplies: 800.345.1178 >> eastwood.Com 5 components and controls 1. Ground cable access hole 2. Mig gun cable access hole 3. Power switch 4. Voltage control 5. Wire speed control 6. Latch 7. Power cord 8. Breaker reset switch 9. Shielding gas inlet 10. Rocker arm 11. Pressure adju...

Page 6

6 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com fig.C fig.C fig. D fig. D fig. B fig. B fig. A fig. A polarity for mig welding polarity for flux-cored welding 1a 2a 2b 3b 1b installation installing the welding gun 1. Open the side door of the welder and loosen the mig gun thumb...

Page 7

To order parts and supplies: 800.345.1178 >> eastwood.Com 7 installing shielding gas supply a shielding gas bottle is not included with your eastwood mig135 but is necessary to use when welding using solid mig wire. A shielding gas bottle can be rented at most local welding supply stores. Eastwood r...

Page 8

8 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com connecting the welder to a power source the eastwood mig135 welder requires a dedicated 120 vac 20 amp grounded outlet protected by a time delay breaker. If using an extension cord, use a 14 awg cord for up to 50 feet and a 12 awg...

Page 9

To order parts and supplies: 800.345.1178 >> eastwood.Com 9 shielding gas flow adjustment after connecting your shielding gas regulator, the gas fl ow rate needs to be adjusted so that the proper amount of shielding gas is fl owing over your weld. If there is too little gas fl ow there will be poros...

Page 10

10 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com operation welding process your eastwood mig135 can be used to form a large number of different joints and welds all of which will require practice and testing before using on an actual project piece. This following welding proces...

Page 11

To order parts and supplies: 800.345.1178 >> eastwood.Com 11 types of weld joints 1. Butt weld is a joint between two pieces that are laying in the same direction. 3. Edge weld is a joint between two pieces where the edges are being joined. 5. Tee weld is a joint between two pieces where one is perp...

Page 12

12 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com sheet metal welding techniques when welding sheet metal a different approach is usually taken to account for how thin the metal is and it’s susceptible to warping it is. The technique most often used is called stitch welding and ...

Page 13

To order parts and supplies: 800.345.1178 >> eastwood.Com 13 duty cycle the rated duty cycle refers to the amount of welding that can be done within an amount of time. It is easiest to look at your welding time in blocks of 10 minutes and the duty cycle being a percentage of that 10 minutes. If weld...

Page 14

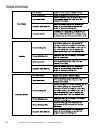

14 eastwood technical assistance: 800.544.5118 >> techelp@eastwood.Com troubleshooting.

Page 15

To order parts and supplies: 800.345.1178 >> eastwood.Com 15 notes.

Page 16

© copyright 2012 easthill group, inc. Instruction part #12011q rev. 9/12 if you have any questions about the use of this product, please contact the eastwood technical assistance service department: 800.544.5118 >> email: techelp@eastwood.Com the eastwood company 263 shoemaker road, pottstown, pa 19...