Summary of E-Flat

Page 1

European audio team instructions for use e.A.T. E-flat.

Page 2

2 dear music lover, welcome! Congratulations on your purchase of our e.A.T. E-flat turntable. Your e.A.T. E-flat was handcrafted by our skilled technicians here at the european audio team. It has been rigorously tested and is ready and waiting for your enjoyment. Please take the time to read this ma...

Page 3

3 contents product illustrations and key 4-5 setup 1. Protective covers, sub-platter and drive belt installation 6 2. Platter installation 7 3. Tonearm assembly 8 a) tonearm installation 9 b) cartridge installation 10 c) vertical tracking force setting (vtf) 10 d) tonearm output connection 11 e) ver...

Page 4

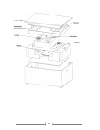

4.

Page 5

5 key: controls, features and connections 1. Platter with bonded vinyl mat 2. Record clamp 3. Chassis 4. Tonearm counterweight 5. Tonearm lift lever 6. Tonearm rest 7. Rca output 8. Power supply connector 9. Anti-skating mechanism 10. Headshell with finger lift 11. Speed control panel 12. Drive belt...

Page 6: Setup

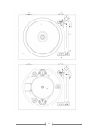

6 setup 1. Protective covers, sub-platter and drive belt installation the main bearing shaft (18) and housing in the sub-platter (13) are protected by special plastic covers. These covers shield against dust and dirt and keep the bearing shaft and housing sufficiently lubricated. If necessary, lubri...

Page 7

7 2. Platter installation tha platter (1) has a threaded shaft for the record clamp (2). To install the platter on the sub- platter, first screw the record clamp onto the platter. Once you have screwed the record clamp onto the platter, double-check to make sure that the clamp is holding the platter...

Page 8

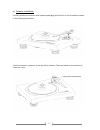

8 3. Tonearm assembly see the next steps to set up your tonearm..

Page 9

9 a) tonearm installation carefully remove the tonearm from separate packaging and install it on the turntable as shown in the following illustrations. Screw the tonearm connector on the top of the tonearm. Take care about correct position of connector’s pins..

Page 10

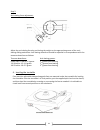

10 b) cartridge installation install the cartridge into the aluminium headshell, using the appropriate hardware included with your cartridge. Connect the cartridge as indicated below: • white left channel l+ • red right channel r+ • green right channel r- • blue left channel l- for correct cartridge...

Page 11

11 d) tonearm output connection connect the tonearm cable provided with the accessories to the rca connectors that is located at the rear of the turntable, behind the tonearm. E) vertical tracking angle setting (vta) to set the vertical tracking angle, first put a record on the platter. When the nee...

Page 12

12 f) anti-skating assembly and adjustment the anti-skating mechanism is shipped partially disassembled to avoid damage during transport. For correct installation, please follow the steps below. Step 1: prepare all parts supplied from the accessories bag: • anti-skating sliding mechanism with anti-s...

Page 13

13 step 3: the anti-skating sliding mechanism is supplied with a pre-mounted anti-skating weight and anti- skating thread. Put the eye of the anti-skating thread around the hole for the hook screw and screw the hook screw into the tonearm through the eye of the anti-skating thread as shown in the il...

Page 14

14 step 5: anti-skating force adjustment: adjust the anti-skating force by positioning the weight on the appropriate groove of the anti- skating sliding mechanism. Anti-skating downforce should be adjusted in correspondence with the tonearm downforce as follows: tonearm downforce: anti-skating groov...

Page 15

15 5. Using the clamp, starting the motor, changing the speed using the clamp – after placing a record on the platter, place the record clamp on the spindle and record. Do not screw down the clamp for playback – this function of the clamp is used only when removing or replacing the platter. Controli...

Page 16

16 6. Technical specifications e.A.T. E-flat model e-flat nominal speed 33/45 rpm, driven by microprocessor, lighted control buttons speed variance 33rpm: ± wow and flutter 33rpm: ± signal to noise s/n ratio (mechanical noise): - 40 db s/n ration (electrical noise): -70 db downforce range 0 - 30 mn ...

Page 17

17 troubleshooting the platter doesn’t turn although the unit is switched on: • the unit is not connected to the mains power supply (the building’s electrical system). • no mains power is being delivered at the socket. • the drive belt is not fitted properly or has slipped off. No signal through one...

Page 18

18.