Eaton Char-Lynn 110 Repair Manual - Disassembly

110, 230, and 450 Series Steering Control Units

6

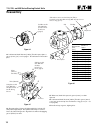

17 Remove two bearing races and needle thrust bearing and seal from

spool and sleeve assembly.

18 Tip housing onto port face. Remove spool and sleeve assembly

from 14 hole end of housing (Figure 10).

Attention: Do not bind spool and sleeve in housing. Rotate spool and

sleeve assembly slowly when removing it from housing.

19 Push pin from spool and sleeve assembly.

20 Push spool partially from control end of sleeve, then carefully

remove centering springs from spool by hand (Figure 11). Low input

torque unit uses four centering springs and two spacers. Standard

input torque unit uses six centering springs.

21 Remove seal from housing (see figure 12).

22 Remove manual steering check valve from housing (when appli-

cable) by removing set screw with 1/4 in. hex key.

Bearing Race

Needle Thrust Bearing

Seal

Check Ball Seat

Check Ball

Set Screw

O-ring 9,3 mm [.36 in.] ID

O-ring 7,7 mm [.30 in.] ID

Check Ball Retainer

Manual Steering

Check Valve –

Early Design

Shown Here

Standard Input Torque

Low Input Torque

Spring/Spacer Package

Disassembly

Figure 9

Figure 10

Figure 11

Figure 12

Pin

Warning: Pin may slide

outward from spool and

sleeve locking these

parts into housing, please

follow instructions.