- DL manuals

- Eaton

- Switch

- COOPER POWER SERIES

- Installation And Operation Instructions Manual

Eaton COOPER POWER SERIES Installation And Operation Instructions Manual

Summary of COOPER POWER SERIES

Page 1

Dc motor operator control installation and operation instructions cooper power series padmounted switchgear mn285018en effective may 2017 supersedes october 1994 (s285-80-1).

Page 2

I operation instructions mn285018en may 2017 disclaimer of warranties and limitation of liability the information, recommendations, descriptions and safety notations in this document are based on eaton corporation’s (“eaton”) experience and judgment and may not cover all contingencies. If further in...

Page 3

Contents disclaimer of warranties and limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I safety for life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ii...

Page 4

The instructions in this manual are not intended as a substitute for proper training or adequate experience in the safe operation of the equipment described. Only competent technicians who are familiar with this equipment should install, operate, and service it. A competent technician has these qual...

Page 5

Product information introduction service information mn285018en provides installation and operating instructions for eaton’s cooper power series dc motor operator control. Before installing and operating this control, carefully read and understand the contents of this manual. Additional information ...

Page 6

Control power the control requires a 120 vac (104-127 vac) to operate the battery charger. An additional 120 vac input with a flip-flop relay will be provided for preferred/alternate voltage sources (see figures 2 and 3). Figure 2 . Ac supply and battery charger board description of control control ...

Page 7

Control operation-local mode the operator panel is located inside, and at the top, of the control cabinet. The operator panel contains the power toggle switch, the scada toggle switch, the motor select knob, the operation switches, and the status indicators. (see figure 4). Local mode operation stat...

Page 8

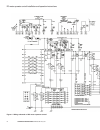

Figure 4 . Wiring schematic of dc motor operator control 4 operation instructions mn285018en may 2017 dc motor operator control installation and operation instructions.

Page 9

Otee: n this is a typical schematic diagram for standard motor operator control. Refer to the schematic diagrams supplied with your control for specific information on accessories or special modifications that were supplied at the time of manufacture. Dashed wires indicate customer-made connections....

Page 10

Instructions for local mode operation for dc motor operator control wiring and outline information, refer to figure 5 and 8. 1 . Power switch must remain on for normal operation . Power off disables both control and motors . The power switch is a 5-amp, dc breaker which will operate in 1 to 3 second...

Page 11

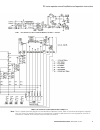

Figure 5 . Scada terminal block extended control accessory the dc motor operator control can be operated via a separate portable control when equipped with the appropriate accessory components. The extended control accessory components include the portable control, the control cable, and modificatio...

Page 12

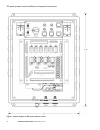

Figure 7 . Outline diagram of dc motor operator control 8 operation instructions mn285018en may 2017 dc motor operator control installation and operation instructions.

Page 13

Scada terminal block connection procedures scada terminal block connection can be completed via side-entry or front-entry connection. The maximum wire size to be used is #14. The minimum wire size to be used is #26. To connect the scada terminal block, use the screwdriver provided in the dc motor op...

Page 14

Maintenance information warning this equipment requires routine inspection and maintenance to ensure proper operation . If it is not maintained it may fail to operate properly . Improper operation can cause equipment damage and possible personal injury . G105 .1 maintenance program a routine mainten...

Page 15

This page intentionally left blank. 11 operation instructions mn285018en may 2017 dc motor operator control installation and operation instructions.

Page 16

Eaton 1000 eaton boulevard cleveland, oh 44122 united states eaton.Com eaton’s power systems division 2300 badger drive waukesha, wi 53188 united states eaton.Com/cooperpowerseries © 2017 eaton all rights reserved printed in usa publication no. Mn285018en may 2017 ka2048-0406 rev01 eaton is a regist...