- DL manuals

- Eaton

- Inverter

- ETN1000

- Installation And Operation Manual

Eaton ETN1000 Installation And Operation Manual - 1. Overview

7

1. Overview

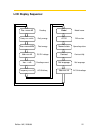

1.0 kW / 2.0kW Design Overview

Front View

Bottom View

Parts Description

Display information switch

Operation LED,

Green , normal

Operation LED,

Red, fault status

Solar panel input

RS232 cover

Optional communications

slot: RS232 & others

Utility (AC) connection:

Terminal Black

LCD Display: Showing

the inverter status

Summary of ETN1000

Page 1

Eaton etn1000 / etn2000 grid pv-inverter installation and operation manual version 1.6 e 2010.06.

Page 2

1 before you start….................................................................................................... 3 safety instructions ................................................................................................... 4 limited warranty...........................................

Page 3

Edition 1.6e, 2010/06 2 front panel ............................................................................................. 20 lcd display sequence: ......................................................................... 22 maximum power point tracking (mppt) ...................................

Page 4: Before You Start…

3 before you start… congratulations on choosing eaton etn1000 / etn2000 grid pv-inverter, a product from eaton grid pv-inverter is a highly reliable product due to its innovative design and perfect quality control. Such an inverter is used in high demand, grid-linked pv systems. T t h h i i s s m m ...

Page 5: Safety Instructions

Edition 1.6e, 2010/06 4 safety instructions z risk of electric shock 1. Do not remove the casing. Inverter contains no user serviceable parts. Refer servicing to qualified service personnel. B b o o t t h h a a c c a a n n d d d d c c v v o o l l t t a a g g e e s s o o u u r r c c e e s s a a r r e...

Page 6

5 z hot surfaces although designed to meet all safety requirements, some parts and surfaces of inverter are still hot during operation. To reduce the risk of injury, do not touch the heat sink at the back of the pv-inverter or nearby surfaces while inverter is operating..

Page 7: Limited Warranty

Edition 1.6e, 2010/06 6 limited warranty inverter comes with a limited warranty. This warranty includes all defects of design, components and manufacturing. Excluded from warranty are damages due to: z breaking the product seal (opening the casing) z improper transportation and delivery z unqualifie...

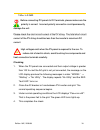

Page 8: 1. Overview

7 1. Overview 1.0 kw / 2.0kw design overview front view bottom view parts description display information switch operation led, green , normal operation led, red, fault status solar panel input rs232 cover optional communications slot: rs232 & others utility (ac) connection: terminal black lcd displ...

Page 9: 2. Features

Edition 1.6e, 2010/06 8 2. Features z very high conversion efficiency (up to 96%) z mppt (maximum power point tracking) z higher power capacity than similar products of the same size. Z embedded lcd display showing complete status information z natural convection cooling. Quiet, fan-less design z st...

Page 10: 3. Installation

9 3. Installation instructions opening the package after opening the package, please check the contents of the box. It should contain the following: 1. One inverter 2. One instruction manual 3. One mounting frame 4. 4 mounting screws 5. 2 safety-lock screws 6. One cable gland and tb cover for ac cab...

Page 11

Edition 1.6e, 2010/06 10 i i n n v v e e r r t t e e r r c c a a n n b b e e i i n n s s t t a a l l l l e e d d a a n n d d o o p p e e r r a a t t e e d d a a t t l l o o c c a a t t i i o o n n s s w w h h e e r r e e t t h h e e a a m m b b i i e e n n t t t t e e m m p p e e r r a a t t u u r r...

Page 12

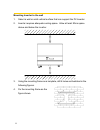

11 mounting inverter to the wall 1. Select a wall or solid vertical surface that can support the pv-inverter. 2. Inverter requires adequate cooling space. Allow at least 20cm space above and below the inverter. 3. Using the mounting frame as a template, drill 4 holes as illustrated in the following ...

Page 13

Edition 1.6e, 2010/06 12 5. Hang the inverter on the mounting frame s s e e l l e e c c t t t t h h e e i i n n s s t t a a l l l l a a t t i i o o n n l l o o c c a a t t i i o o n n s s o o t t h h a a t t t t h h e e s s t t a a t t u u s s d d i i s s p p l l a a y y c c a a n n b b e e e e a a ...

Page 14

13 b) check the upper straps of pv-inverter and ensure it fits on to the bracket c) insert safety-lock screws to the bottom leg to secure the inverter c c h h e e c c k k t t h h e e s s e e c c u u r r e e m m o o u u n n t t i i n n g g o o f f t t h h e e p p v v - - i i n n v v e e r r t t e e r...

Page 15

Edition 1.6e, 2010/06 14 connecting to the grid (ac utility) 1. Measure grid (utility) voltage and frequency. It should be 230vac (or 220vac), 50/60hz, and single phase. 2. Open the breaker or fuse between pv-inverter and utility. 3. For inverter, connect ac wires as follows: z insert utility wires ...

Page 16

15 z twist the gland, attached screws in order to seal the ac gland cover. T t o o p p r r e e v v e e n n t t r r i i s s k k o o f f e e l l e e c c t t r r i i c c s s h h o o c c k k , , e e n n s s u u r r e e t t h h e e g g r r o o u u n n d d w w i i r r e e i i s s p p r r o o p p e e r r l...

Page 17

Edition 1.6e, 2010/06 16 10a dc in 2.0kw. B b e e f f o o r r e e c c o o n n n n e e c c t t i i n n g g p p v v p p a a n n e e l l s s t t o o d d c c t t e e r r m m i i n n a a l l s s , , p p l l e e a a s s e e m m a a k k e e s s u u r r e e t t h h e e p p o o l l a a r r i i t t y y i i s ...

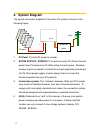

Page 18: 4. System Diagram

17 4. System diagram the typical connection diagram for the entire pv system is shown in the following figure. 1. Pv panel: provide dc power to inverter. 2. Eaton etn1000 / etn2000 pvinverter converts dc (direct current) power from pv panel(s) to ac (alternating current) power. Because inverter is g...

Page 19: 5. Operating

Edition 1.6e, 2010/06 18 5. Operating your pv-inverter modes of operation there are 3 different modes of operation. 1. Normal mode: in this mode, inverter works normally. Whenever the supplied power from pv panel is sufficient (voltage>150vdc), inverter converts power to the grid as generated by the...

Page 20

19 front panel arrangement led there are 2 led’s on inverter, one is green and the other is red. Normally, only the green led switches on during operation. Their indicated status is explained as follows: 1. Power on (green led): it lights to indicate that inverter is running. 2. Fault (red led): ill...

Page 21

Front panel operating inverter is quite easy. During normal operation, inverter runs automatically. However, to achieve maximum conversion efficiency of inverter, please read through the following information: 1. Automatic on-off: inverter starts up automatically when dc-power from the pv panel is s...

Page 22

Repeatedly press the function key until the desired display is reached. Release the key and press again for more than 2 second until you see “lock”, release the key; the information remains on the display. To change the display again, please press the key as indicated in above section 3. Change disp...

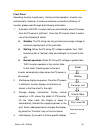

Page 23: Lcd Display Sequence:

Lcd display sequence: pac =xxxx.Xw eac=xxxxxxkwh vdc=xxx.Xv iac= x.Xa frequency=xx.Xhz model a1.00 normal state contrast set language feeding total energy dc-pv voltage feeding current etoday=xxx.Xxkwh daily energy ac-grid freq. Model name fw version operating status contrast adj. Set language vac=x...

Page 24

Maximum power point tracking (mppt) a good pv inverter must be able to convert the maximum power from any pv panel. Due to its advanced design, inverter pv-inverter can track the maximum power from your pv panel in any condition. When the displayed power on the lcd output does not change dramaticall...

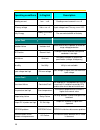

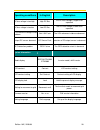

Page 25: 6. Inverter Status

6. Inverter status inverter is designed to be user-friendly. Therefore, the status of the inverter can be easily understood by reading the information that shown on the front panel display. All possible messages are shown in the following table. Display information operating conditions in english de...

Page 26

Operating conditions in english description feeding current iac = x.Xa feeding current amount in xx.X a pv array voltage vdc = xxx.X v input voltage from pv array, xxx.X vdc daily energy etoday=xxx.Xxkw h the accumulated kwh of that day system fault isolation failure isolation fault earth fault of t...

Page 27

Operating conditions in english description dc bus voltage is too high high dc bus the dc bus voltage is higher than expected dc bus voltage is too low low dc bus the dc bus voltage is lower than expected 2.5v reference voltage inside problem ref 2.5v fault the 2.5v reference inside are abnormal out...

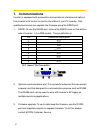

Page 28: 7. Communications

7. Communications inverter is equipped with a powerful communications interface and options. Use inverter’s ez control to monitor the status of your pv-inverter. Also, qualified personnel can upgrade the firmware using the rs232 port. 1. Rs232: to use the rs232 port, remove the rs232 cover on the bo...

Page 29

Eaton contact information telephone: 1300 3 eaton web: http://www.Eatonelectric.Com.Au/ t t o o p p r r e e v v e e n n t t r r i i s s k k o o f f d d a a m m a a g g e e i i t t i i s s r r e e c c o o m m m m e e n n d d e e d d t t h h a a t t o o n n l l y y a a u u t t h h o o r r i i z z e e ...

Page 30: 8. Trouble Shooting

8. Trouble shooting in most situations, the inverter requires very little service. However, if inverter is not able to work perfectly, please refer to the following instructions before calling your local dealer. Z should any problems arise, the red (fault) led on the front panel turns on and the lcd...

Page 31

Over temperature 1. The internal temperature is higher than specified normal value 2. Find a way to reduce the ambient temperature. 3. Or move the inverter to a cooler environment 4. If it is not effective, please contact eaton. Relay failure dc inj high eeprom failure sci failure high dc bus low dc...

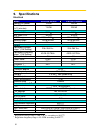

Page 32: 9. Specifications

9. Specifications electrical model eaton etn1000 eaton etn2000 nominal ac power 1000w 2000w max. Ac power (in 10 minutes) 1100w 2200w input nominal dcv 360v dc 360v dc max. Open dcv 500v dc 500v dc mppt range 150 to 450v dc 150 to 450v dc working range 100 to 500v dc 100 to 500v dc max. Input curren...

Page 33

∗product specifications are subject to change without notice edition 1.6e, 2010/06 32.