- DL manuals

- Eaton

- Indoor Furnishing

- LINX

- Installation Manual

Eaton LINX Installation Manual

Summary of LINX

Page 1

Modular furniture linx ™ modular furniture installation manual.

Page 2: Linx

2 linx installation manual linx installation manual eaton.Com/linx disclaimer of warranties and limitation of liability the information, recommendations, descriptions and safety notations in this document are based on eaton corporation’s (“eaton”) experience and judgment and may not cover all contin...

Page 3: Linx

3 linx installation manual linx installation manual eaton.Com/linx linx ® modular furniture i n s ta l l at i o n m a n u a l table of contents introduction linx/worksurface assembly ........................................................................................................................

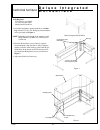

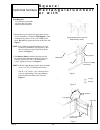

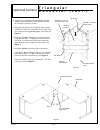

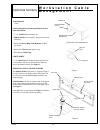

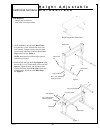

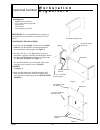

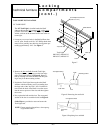

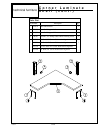

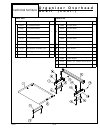

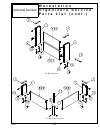

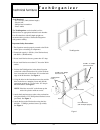

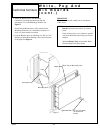

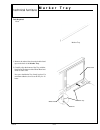

Page 4: L I N E A R

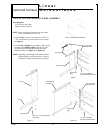

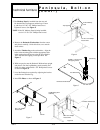

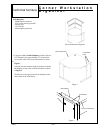

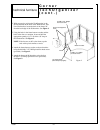

L i n e a r w o r k s u r f a c e s 84567 fully assembled worksurface figure 2 figure 2a tools required -1/4” hex key (provided) -phillips head screwdriver note : due to packaging restrictions, the foot is not factory assembled to the 40” leg. 1. Attach a foot to each 40” leg using two 5/16”-18 x 1-...

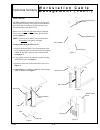

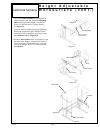

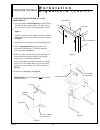

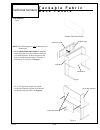

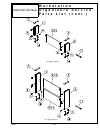

Page 5: L I N E A R

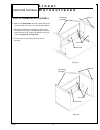

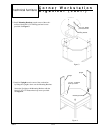

L i n e a r w o r k s u r f a c e s 84567 1. Remove the worksurface from the carton and place it carefully, finish side down, on a smooth clean surface. 2. Place the assembled legs and modesty panel on the worksurface and align its pre-drilled holes with those in the panel and legs. Attach with the ...

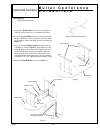

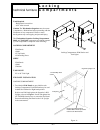

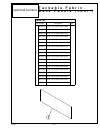

Page 6

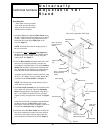

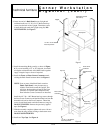

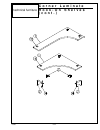

J e t t y w o r k s u r f a c e 84251 jetty worksurface figure 1 glide foot technical furniture a-3 tubular leg #10ab x 1.00 pan head self tapping screws pre-drilled holes jetty worksurface leg/modesty panel assemblies glide foot 2. Attach the tubular leg to the worksurface. Align the holes in the m...

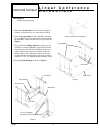

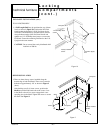

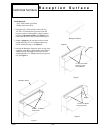

Page 7

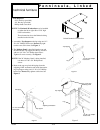

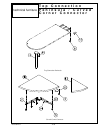

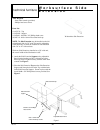

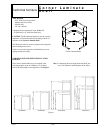

C o r n e r w o r k s t a t i o n ( f r e e s t a n d i n g ) 84568 tools required -5/32” hex key (provided) -1/4” hex key (provided) -phillips head screwdriver 1. Attach the leg/modesty panel assemblies to the rear leg with the 1/4”-20 x 3/4” phillips pan head machine screws provided. See figure 1 ...

Page 8

D e l u x e i n t e g r a t e d w o r k s u r f a c e 84567 tools required -5/32” hex key (provided) -1/4” hex key (provided) -phillips head screwdriver 1. Attach the leg/modesty panel assemblies to the rear leg with the 1/4”-20 x 3/4” phillips pan head machine screws provided. See figure 1 . Note :...

Page 9

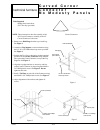

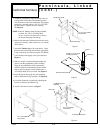

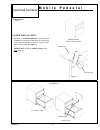

B u l l e t c o n f e r e n c e w o r k s u r f a c e tools required -phillips head screwdriver 1. Remove the worksurface from the carton and place it carefully, finish side down, on a smooth clean surface. 2. Place the leg assemblies on the worksurface and align the pre-drilled holes in the worksur...

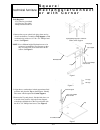

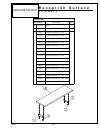

Page 10

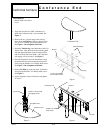

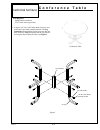

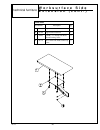

L i n e a r c o n f e r e n c e w o r k s u r f a c e linear conference worksurface 85004 tools required -phillips head screwdriver 1. Remove the worksurface from the carton and place it carefully, finish side down, on a smooth clean surface. 2. Place the leg assemblies on the worksurface and align ...

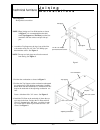

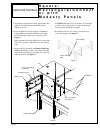

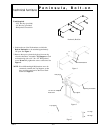

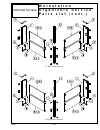

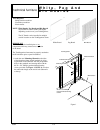

Page 11: J O I N I N G

J o i n i n g w o r k s t a t i o n s 2. Position the workstations as shown in figure 2 . 3. Position the top support on the workstation underneath the worksurface of the adjoining workstation. See fig - ure 2 . Mark and then drill three 1/8” diameter holes 1/2” deep in the underside of the adjoinin...

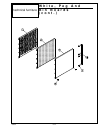

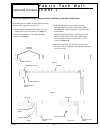

Page 12: S Q U A R E /

S q u a r e / r e c t a n g u l a r c o n n e c t o r w i t h the 30” x 24” and 36” x 30” connectors have only one cable bushing. The longer modesty panel should be installed on this side. See figure 4 . Square/rectangular connector with modesty panels figure 1 figure 2 27” high 29” high tools requi...

Page 13: S Q U A R E /

3. Align the two workstations in their approximate final positions and install the second modesty panel. Tighten all screws. 4. Place the top over the top supports and modesty panels. Make sure that the worksurfaces and edges are flush and adjust the leveler if necessary. See figure 5 . Make sure th...

Page 14: S Q U A R E /

S q u a r e / r e c t a n g u l a r c o n n e c t o r w i t h c o r n e r figure 2 27” high 29” high square/rectangular connector with corner support tools required -5/32” hex key (provided) -1/4” hex key (provided) -phillips head screwdriver 2. Align the two workstations in their approximate final ...

Page 15: S Q U A R E /

5. Remove the top and attach the double faced tape strips to the top supports. Next, remove the backing from the tape strips and carefully lower the top back into position. See figure 4 . Caution! Once the top is in position, do not at- tempt to lift the top to reposition it as it will tear the doub...

Page 16: S Q U A R E /

69735 technical furniture square/rectangular connector with corner support s q u a r e / r e c t a n g u l a r c o n n e c t o r w i t h c o r n e r s u p p o r t.

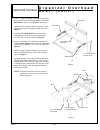

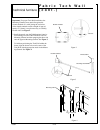

Page 17: T R I A N G U L A R

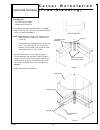

Tools required -electric drill -1/8” dia. Drill bit -5/32” allen wrench triangular connector figure 2 triangular connector modesty panel #10ab x .75 phillips head screws note : two people are required for some steps in the installation procedure. 1. Remove three plastic hole plugs from one leg of ea...

Page 18: T R I A N G U L A R

T r i a n g u l a r c o n n e c t o r ( c o n t . ) 4. Align the two workstations in their approximate final positions. With the modesty panel installed, position the triangular connector in place. 5. Engage the side flanges on the modesty panel with the extended 1/4”-20 x 1/2” button head screws in...

Page 19: C O N N E C T O R

1. Remove two hole plugs from the top of each leg. See figure 1 . 2. Assemble a top support to each workstation using the 1/4”-20 x 3/8” button head cap screws provided. See figure 1 . 3. Position the two linx workstations in their required positions for the corner connector being installed. Next, p...

Page 20: C O N N E C T O R

84253 corner connector c u r v e d c o r n e r c o n n e c t o r n o m o d e s t y p a n e l s technical furniture.

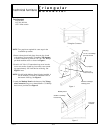

Page 21

Tools required - phillips head screw driver - level 1. Align and level the two linx workstations to which the conference end is to be installed. See figure 1 . 2. Remove the two top hole plugs from each leg. Next, attach the bracket to the legs using the four 1/4”-20 x 3/4” phillips pan head machine...

Page 22

P e n i n s u l a , b o l t - o n 1. Position the two linx workstations to which the bolt-on peninsula is to be attached approximately 30” apart. See figure 1 . 2. Remove the top two plastic hole plugs from one leg of each workstation. Assemble a top support to each workstation leg with a 1/4”-20 x ...

Page 23: ( C O N T . )

3. The modesty panel is installed from the rear and fits between the top supports and the legs. Fasten it with four 1/4”-20 x 3/4” phillips head screws. Tighten all screws. See figure 4 . Note : if the 26” modesty panel is being installed, use six 1/4”-20 x 3/4” phillips head screws. 4. Remove the p...

Page 24

84913 bolt-on peninsula p e n i n s u l a , b o l t - o n technical furniture.

Page 25

P e n n i n s u l a , l i n k e d 84569 tools required -5/32” hex key (provided) -1/4” hex key (provided) -phillips head screwdriver note : the peninsula worksurface may be installed on either the left or right side of a 29” high linx worksurface. These instructions show the peninsula being installe...

Page 26: ( C O N T . )

84569 5. Attach the leg/modesty panel assembly to the ad- joining linx workstation. The modesty panel in- stalls from the rear and fits between the top support and the leg. Attach it with two 1/4”-20 x 3/4” phil- lips head screws. Tighten all screws securely. See figure 4 . Note : if the 26” modesty...

Page 27: C O N N E C T I O N

Tools required -phillips head screwdriver -electric drill -1/8” drill bit note : the peninsula is provided with the top con- nection bracket/stiffener and the die cast leg mounting plate factory installed. The height adjustable leg provides the ability to install the peninsula to a 29” to 30” high w...

Page 28

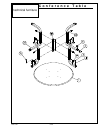

C o n f e r e n c e t a b l e tools required -phillips head screwdriver -5/32” allen wrench (provided) conference table 81071 technical furniture a-22 1. Using the 1/4”-20 x 2.00” button head cap screws and lock washers provided, assemble the base. The leg connector has tapped holes. Insert the scre...

Page 29: ( C O N T . )

81071 c o n f e r e n c e t a b l e ( c o n t . ) technical furniture 2. Remove the conference table top from the carton and place it carefully, finished side down, on a smooth clean surface. 3. Place the base assembly upside down on the top, aligning the holes in the base with the holes in the top....

Page 30: ( C O N T . )

81071 c o n f e r e n c e t a b l e ( c o n t . ) technical furniture parts list description qty. 2176x round conference table top, 36” 1 2177x round conference table top, 42” 1 2178x round conference table top, 48” 2 2255x “c” leg 4 3 59103 #10ab x .75 phillips pan head thread forming screw 8 4 542...

Page 31

Selecting a location positioning the posting shelf to the extreme left or right is recommended for all workstations. On 24” deep surfaces, the cable port will be blocked when in the extreme position. You may wish to move in 2” to clear it. Hook-on surfaces (lms), 72” in length, have a formed stiffen...

Page 32

Tools required -5/32” hex key -phillips head screwdriver storage shelf 1. Remove the two lower plastic hole plugs located on the inside of each leg. See figure 1 . 2. Loosen the two lower rear phillips head screws located on the inside of each leg. See figure 1 . 3. Install the storage shelf by hook...

Page 33

Tools required -5/32” allen wrench (provided) -phillips head screwdriver 1.Remove the two lower plastic hole plugs located on the inside of each leg and replace them with the two 1/4”- 20 x 3/8” button head cap screws provided. See figure 1 . 2. Loosen the two lower rear phillips head screws located...

Page 34: M A N A G E M E N T

W o r k s t a t i o n c a b l e m a n a g e m e n t tools required - none cable management is an intergral element of each linx workstation. * 2” x 2” cable ports in laminate tops * modesty panels with “stepped” design for horizontal cable runs. * removable power ring cable retainers in mod- esty pa...

Page 35

W o r k s t a t i o n c a b l e m a n a g e m e n t ( c o n t . ) figure 4 wire cover modesty panel leg figure 6 wire cover leg exit from modesty panel cable figure 5 cable port bottom of wire cover wire covers the wire covers are attached to the rear of each work- station leg and vertically route c...

Page 36: N O V A

R e t r o f i t k i t n o v a 86270lx please read these instructions carefully and follow the installation steps in sequence. Note : the trim ring provided with the nova01 and nova06 kits can not be used with linx worksurfaces. Please discard trim ring. Tools required -phillips head screwdriver note...

Page 37: R E T

86270lx 3. Turn the assembly upright and position it underneath the viewport cutout in the worksurface. Align the holes in the top rails with the corresponding holes in the worksurface and attach with the #14ab x 3/4” screws provided. See figure 3 . 4. Attach the tracks to the to the underside of th...

Page 38: R E T

86270lx r e t r o f i t k i t n o v a ( c o n t . ) technical furniture 7. Attach the adjustable mousing surface to the key- board drawer using the pre-drilled holes and four #10ab x 5/8” phillips head screws provided. See figure 7 . Note : the mousing surface can be attached to either the right han...

Page 39: R E T

R e t r o f i t k i t n o v a ( c o n t . ) 86270lx monitor support installation note : the monitor support adjusts three ways - for height, angle and forward/backward. Adjust it so that you have a comfortable viewing angle of the monitor when you’re in a normal work- ing position. 1. The monitor su...

Page 40: R E T

R e t r o f i t k i t n o v a ( c o n t . ) 86270 parts list description qty. 1 5001818-02 side assembly 2 2 5001818-03 cross brace 2 3 keyboard drawer 1 4 5001818-06 monitor support 1 5 5001818-07 viewport glass 1 6 5001818-08 leveler 4 7 5001818-11 #14ab x 3/4” screw (cross braces, legs and worksu...

Page 41: R E T

R e t r o f i t k i t n o v a ( c o n t . ) 86270 technical furniture a- 34.

Page 42: M O N I T O R

S e m i r e c e s s e d m o n i t o r 87522 please read these instructions carefully and follow the installation steps in sequence. Tools required -phillips head screwdriver fasteners that you will be using: technical furniture #66714 #10-24 x 3/8” phillips pan head thread forming screw #66250 #10ab...

Page 43

S e m i r e c e s s e d m o n i t o r ( c o n t . ) 87522 technical furniture 2. Install the monitor shelf by hooking the front and rear tabs into the desired slot location on the frame. See figure 3 . Note : when the tabs are positioned in the same slots front and back, the shelf will provide the 2...

Page 44

S e m i r e c e s s e d m o n i t o r ( c o n t . ) 87522 parts list part number description qty. 1 8867x frame, standard monitor 1 8868x frame, large monitor 2 8869x shelf, standard monitor 1 8870x shelf, large monitor 3 8572x monitor stop 1 technical furniture a-37.

Page 45

A d j u s t a b l e c p u h o l d e r , n o v a 86320 please read these instructions carefully and follow the installation steps in sequence. Tools required -none 1. Install the cpu holder as shown in figures 1 and 2 . 2. The cpu holder can be adjusted as shown in figure 3 . #nova04 adjustable cpu h...

Page 46

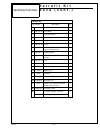

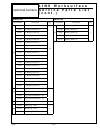

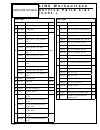

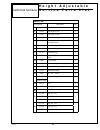

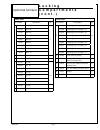

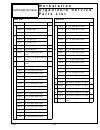

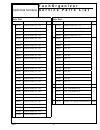

84567 parts list description qty. 1249x leg - l.H., 29” high 1250x leg - l.H., 27” high 1779x leg - l.H., 40” high 6810x leg - r.H., 36” high 1247x leg - r.H., 29” h 1248x leg - r.H., 27” h 1778x leg - r.H., 40” h 6811x leg - r.H., 36” h 1 6723x leg - l.H., 29” h x 36” d 1 6812x leg - l.H., 36” h x ...

Page 47: ( C O N T . )

84567 l i n x w o r k s u r f a c e s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture a-40 parts list description qty. 5107x 26” modesty panel, 24” 5108x 26” modesty panel, 30” 5109x 26” modesty panel, 36” 5110x 26” modesty panel, 42” 5111x 26” modesty panel, 48” 5112x 26” modesty pa...

Page 48: ( C O N T . )

84567 parts list description qty. 5946x 26” modesty panel, 90° connector 30”-30” 5947x 12” modesty panel, 45° connector 24”-24” 5948x 26” modesty panel, 45° connector 24”-24” 31 5949x 12” modesty panel, 45° connector 30”-30” 1-2 5950x 26” modesty panel, 45° connector 30”-30” 6720x 12” modesty panel,...

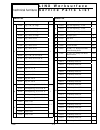

Page 49: ( C O N T . )

84567 parts list description qty. 5338x top, 24” x 24” corner connector 44 5339x top, 24” x 30” corner connector 1 5340x top, 30” x 30” corner connector 2180x top, 90° connector, 30” l-24” r 4042x top, 90° connector, 24” l-30” r 45 2181x top, 90° connector, 30”-30” 1 2185x top, 90° connector, 24”-24...

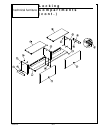

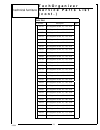

Page 50: S U R F A C E S

84567 linx worksurfaces conference worksurfaces l i n x w o r k s u r f a c e s / c o n f e r e n c e w o r k - s u r f a c e s technical furniture a-43.

Page 51: T R I A N G U L A R

84571 triangular connector t r i a n g u l a r c o n n e c t o r technical furniture a-44.

Page 52: S Q U A R E /

84570/69735 square/rectangular connector with corner support technical furniture s q u a r e / r e c t a n g u l a r c o n n e c t o r w i t h m o d e s t y p a n e l s square/rectangular connector with modesty panels a-45.

Page 53

84252/85217 conference end c o n f e r e n c e e n d technical furniture a-46.

Page 54

84569/84913 l i n k e d p e n i n s u l a / b o l t - o n p e n i n s u l a technical furniture a-47 linked peninsula bolt-on peninsula.

Page 55

80752/84253 top connection peninsula curved corner connector t o p c o n n e c t i o n p e n i n s u l a / c u r v e d c o r n e r c o n n e c t o r technical furniture a-48.

Page 56

81071-b c o n f e r e n c e t a b l e technical furniture a-49.

Page 57

84085 posting shelf p o s t i n g s h e l f technical furniture a-50

Page 58

81046 storage shelf s t o r a g e s h e l f technical furniture a-51.

Page 59

84566 cable management components w o r k s t a t i o n c a b l e m a n a g e m e n t ( c o n t . ) technical furniture a-52.

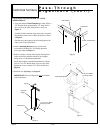

Page 60: S T A N D

U n i v e r s a l l y a d j u s t a b l e v d t s t a n d tools required - 4mm allen wrench (provided) -5mm allen wrench (provided) -6mm allen wrench (provided) -phillips head screwdriver 1. Attach the feet to the adjustable base frame using the m8 x 1.00”(25mm) socket head screws and lock washers. ...

Page 61: E X T E N S I O N

W o r k s u r f a c e s i d e e x t e n s i o n tools required -5mm allen wrench (provided) -phillips head screw driver parts list (1) #5377x - top (1) #2519x - support (1) #59103 - #10ab x 3/4” phillips head screw (6) #81718 - m-8 x 16mm flat socket head cap note : the side extension may be install...

Page 62

Parts list description qty. 1 5377x top 1 2 2519x support side extension 1 3 59103 #10ab x .75” phillips pan head thread forming screw 4 4 81718 m8 x 12mm flat head socket cap screw 2 part number w o r k s u r f a c e s i d e e x t e n s i o n ( c o n t . ) 81723 technical furniture b-3.

Page 63

H e i g h t a d j u s t a b l e w o r k s u r f a c e 82743 tools required -phillips head screwdriver -6mm allen wrench (provided) 1. Attach the feet to the adjustable base frame using the m-8 x 1.00” socket head screws and lock washers. Tighten securely using the 6mm allen wrench. Install the round...

Page 64

82743 h e i g h t a d j u s t a b l e w o r k s u r f a c e ( c o n t . ) 3. The front crank assembly may be installed on either the right or left side. Fasten the mounting block to the appropriate support using the two #10 x 1/2” pan head screws. Tighten securely. See figure 3a . Insert the crank a...

Page 65

82743 parts list description qty. 1 1934x/1933x base frame 1 2 82741 top support, l.H. 1 3 82740 top support. R.H. 1 4 2518x crank assembly, front 1 5 81717 mounting bracket w/(2) #10 x 1/2” pan head screws 1 6 63526 name plate (provided by wright line) 1 7 82739 square end cap, black 4 8 81716 conn...

Page 66

82743 height ajustable worksurface universally adjustable vdt stand h e i g h t a d j u s t a b l e w o r k s u r f a c e s technical furniture b-7.

Page 67

M o b i l e p e d e s t a l tools required -none caster installation 1. Carefully lay the mobile pedestal on its back. Install a caster at each corner of the bottom by inserting the caster stems into the holes . Push the casters in until they are fully seated. See figure 1 . Important : install the ...

Page 68: O R G A N I Z E R S

W o r k s t a t i o n o r g a n i z e r s 69299 important : it is recommended that the assembly of this product be done on the floor. Assistance may be re- quired. Assembling the organizer 1. Carefully slide the uprights over the ends of the back panel . Be sure that the holes for mounting brackets ...

Page 69

W o r k s t a t i o n o r g a n i z e r s ( c o n t . ) 69299 technical furniture 2. Install a mounting bracket at each corner of the worksurface with the #10 x 3/4” phillips pan head screws provided. See figure 4 . 3. With two people, carefully lift and place the organizer on the worksurface with t...

Page 70

W o r k s t a t i o n o r g a n i z e r s ( c o n t . ) fastening the organizer to non-wright line manufactured worksurfaces if the worksurface to which the organizer is to be in- stalled is not a wright line linx worksurface, locate and drill the four 1/8” diameter x 1/2” deep holes in the rear cor...

Page 71: L O C K I N G

Tools required -phillips head screwdriver -5/32” allen wrench caution : the workstation organizer must be secure- ly attached to a worksurface before proceeding with the installation of any component. Failure to secure the organizer may cause tipping and personal injury. The workstation organizer lo...

Page 72: L O C K I N G

End panel installation (cont.) full length shelf 1. A full length shelf may be positioned at any of three levels as shown in figure 3b . Position the r.H. End panel against the organizer’s r.H. Upright at the de- sired level. The three factory installed screws must be along the bottom edge of the en...

Page 73: L O C K I N G

80954lx top panel installation 1. Be sure the three screws along the top edge of each end panel are backed out 1/8” as shown in figure 4 . 2. Position the top panel above the screws. The receding door mounting holes must face foward. Lower the top panel onto the screws so that the six screws engage ...

Page 74: L O C K I N G

80954lx l o c k i n g c o m p a r t m e n t s ( c o n t . ) technical furniture top panel installation (72” locking compartment) 1. Two top panels are required, installed one at a time. Be sure the three screws along the top edge of each end panel and on both sides of the center panel are backed out...

Page 75: L O C K I N G

80954lx task light installation 24” task light the 24” task light is installed under the shelf either at the extreme left, extreme right, or the center position. If desired, two 24” task lights may be in- stalled, with one at the extreme left and one at the ex- treme right. 1. Locate any two screw h...

Page 76: L O C K I N G

80954lx 48” task light the 48” task light can only be installed in the center position. 1. Locate the two screw holes in the shelf stiffener that are 40” apart. Install two #10 x 3/8” phillips head sheet metal screws partially into the holes, leaving them pro- truding approximately 1/16”. See figure...

Page 77: L O C K I N G

80954lx parts list description qty. 6584x shelf, 24” 2217x shelf, 30” 2219x shelf, 36” 4715x shelf, 42” 1 1546x shelf, 48” 1 3768x shelf, 54” 1544x shelf, 60” 3769x shelf, 66” 2218x shelf, 72” 2 1531x end panel 2 3 1533x end panel, shelf 2 8227x top, 24” 8228x top, 30” 8229x top, 36” 8230x top, 42” ...

Page 78: L O C K I N G

80954lx l o c k i n g c o m p a r t m e n t s ( c o n t . ) technical furniture d-11.

Page 79: O R G A N I Z E R S

P a s s - t h r o u g h o r g a n i z e r s important : it is recommended that the assembly of this product be done on the floor. Assistance may be re- quired. Assembling the organizer 1. Carefully insert the channel fillers into the uprights . Be sure that the holes for mounting brackets are at the...

Page 80

P a s s - t h r o u g h o r g a n i z e r s ( c o n t . ) 2. Install a mounting bracket at each corner of the worksurface with the #10 x 3/4” phillips pan head screws provided. See figure 3 . 3. With two people, carefully lift and place the organizer on the worksurface with the bottom of the upright...

Page 81: O R G A N I Z E R

C o r n e r w o r k s t a t i o n o r g a n i z e r 1. Using the cardboard drill template provided, drill two 1/8” diameter holes approximately 1/2” deep into the two corners of the linx corner workstation as shown in figure 1 . Carefully fold the template along perforations and place the template o...

Page 82

C o r n e r w o r k s t a t i o n o r g a n i z e r ( c o n t . ) 2. Install mounting brackets at each corner of the work- surface with the #10 x 3/4” phillips pan head screws provided. See figure 3 . 3. Install an upright at each corner of the worksurface by fitting the uprights down over the mount...

Page 83

C o r n e r w o r k s t a t i o n o r g a n i z e r ( c o n t . ) 4. Insert one end of a back panel into an upright and and then install two 1/4”-20 x 2-1/2” button head cap screws into the back of the upright. Thread the screws in until their heads touch the upright (snug fit). Do not tighten . See...

Page 84: S H E L F

C o r n e r l a m i n a t e s h e l f caution : the workstation organizer must be securely attached to a worksurface before proceeding with the in- stallation of the corner laminate shelf . The shelf must must be securely attached to the organizer before loading items onto it. Failure to secure the ...

Page 85

C o r n e r l a m i n a t e s h e l f ( c o n t . ) 1. Determine the corner shelf height and remove two 1/4”-20 button head cap screws from each upright at the desired height. Use the 5/32” allen wrench pro- vided. See figure 2 . Save the button head cap screws; they will be re-used in step 2. 2. Fa...

Page 86

C o r n e r l a m i n a t e s h e l f ( c o n t . ) 3. Install one rear support “a” and one rear support “b” on each side of the organizer. See figure 4 . Ensure that each rear support “b” is at the same height as the shelf side brackets. Note : all corner shelves with the exception of the wd06-xx *...

Page 87

C o r n e r l a m i n a t e s h e l f ( c o n t . ) 81571 parts list description qty. 1 2287x shelf side bracket 2 2 2288x rear shelf support “a” 2 3 2289x rear shelf support “b” 2 4 59103 #10ab x 3/4” phillips head thread forming screw 4 2371x 12” shelf, 30” corner workstation organizer 5 2372x 12”...

Page 88

R e c e p t i o n s u r f a c e tools required -5/32” allen wrench (provided) -phillips head screwdriver 1. Using the 5/32” allen wrench, remove the two 1/4”-20 x .50” button head cap screws from the top inner surface of the uprights of each organizer receiving a reception surface . See figure 1 . D...

Page 89: ( C O N T . )

R e c e p t i o n s u r f a c e ( c o n t . ) 85037 parts list description qty. 1 4608x support 2 2 59103 #10ab x .75” phillips head screw 4 5411x reception counter, 15” x 24” 5412x reception counter, 15” x 30” 5413x reception counter, 15” x 36” 5414x reception counter, 15” x 42” 5415x reception cou...

Page 90: S H E L F

O r g a n i z e r o v e r h e a d s h e l f tools required -5/32” allen wrench (provided) -7/16” wrench -plastic mallet note : the shelf is shipped with four shoulder screws installed in the bottom surface. Be careful not to damage other surfaces after unpacking. 1. Remove the top cap from each of t...

Page 91

O r g a n i z e r o v e r h e a d s h e l f ( c o n t . ) 4. Four 3/4” squares of double faced adhesive tape have been provided to attach the bottom edge of the shelf rear panel to the top of the organizer back panel. Attach the four squares of double faced tape , evenly spaced, to the top of the or...

Page 92

82247 o r g a n i z e r o v e r h e a d s h e l f ( c o n t . ) parts list description qty. 2967x 24” laminated shelf 2968x 30” laminated shelf 1 2969x 36” laminated shelf 1 2970x 48” laminated shelf 2971x 60” laminated shelf 2971x 72” laminated shelf 2 82248 #12smt x .88 screw 4 3 2973x shelf suppo...

Page 93

T a c k a b l e f a b r i c b a c k p a n e l s tools required -none note : the linx organizer must be fastened to the worksurface. 1. The tackable fabric back panel has magnetic strips which allows it to be installed on the back of a linx organizer. Position the panel on the back of the organizer a...

Page 94

T a c k a b l e f a b r i c b a c k p a n e l s ( c o n t . ) 69376 parts list description qty. W206-xx 16”h x 24”w rear fabric panel w306-xx 16”h x 30”w rear fabric panel w366-xx 16”h x 36”w rear fabric panel w436-xx 16”h x 42”w rear fabric panel w406-xx 16”h x 48”w rear fabric panel w506-xx 16”h x...

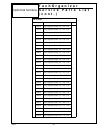

Page 95

69299 parts list description qty. 1479x 16” upright, r.H. 1 1480x 32” upright, r.H. 1 4932x 36” upright, r.H. 1464x 16” upright, l.H. 2 1465x 32” upright, l.H. 1 4931x 36” upright, l.H. 3 1454x cap 2 4 2236x mounting bracket 2 5 59103 #10 x 3/4” phillips pan head screws 4 6 69361 1/4”-20 x 2-1/2” bu...

Page 96

69299 w o r k s t a t i o n o r g a n i z e r s s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture d-29 parts list description qty. 84601 tack panel, 16” high back panels 84602 tack panel, 16” high back panels 84603 tack panel, 16” high back panels 84604 tack panel, 16” high back pane...

Page 97

69299 16” high corner organizer w o r k s t a t i o n o r g a n i z e r s s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture d-30 36” high organizer.

Page 98

69299 w o r k s t a t i o n o r g a n i z e r s s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture d-31 16” high organizer 32” high organizer.

Page 99

69299 36” high corner organizer 32” high corner organizer w o r k s t a t i o n o r g a n i z e r s s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture d-32.

Page 100

69299 36” high pass-through organizer w o r k s t a t i o n o r g a n i z e r s s e r v i c e p a r t s l i s t ( c o n t . ) technical furniture d-33.

Page 101

T e c h o r g a n i z e r tools required -#33 (.113 dia.) drill (jobbers length) -electric drill -phillips head screwdriver -plastic mallet the techorganizer can be installed on linx worksurfaces or appropriate industrial work benches. Linx worksurfaces with full depth uprights are recommended to pr...

Page 102

85030 parts list description qty. 6074x organizer frame, 16” x 24” 6075x organizer frame, 32” x 24” 6076x organizer frame, 36” x 24” 6077x organizer frame, 48” x 24” 6078x organizer frame, 16” x 30” 6079x organizer frame, 32” x 30” 6080x organizer frame, 36” x 30” 6081x organizer frame, 48” x 30” 60...

Page 103: ( C O N T . )

85030 parts list description qty. 6251x cws organizer frame, 16” x 24”- r.H. 6253x cws organizer frame, 32” x 24”- r.H. 6255x cws organizer frame, 36” x 24”- r.H. 6257x cws organizer frame, 48” x 24”- r.H. 6259x cws organizer frame, 16” x 30”-r.H. 6261x cws organizer frame, 32” x 30”- r.H. 6263x cws...

Page 104: ( C O N T . )

85030 parts list description qty. 6250x cws organizer frame, 16” x 24”- l.H. 6252x cws organizer frame, 32” x 24”- l.H. 6254x cws organizer frame, 36” x 24”- l.H. 6256x cws organizer frame, 48” x 24”- l.H. 6258x cws organizer frame, 16” x 30”- l.H. 6260x cws organizer frame, 32” x 30”- l.H. 6262x cw...

Page 105: ( C O N T . )

85030 parts list description qty. 6229x corner post, 16” 8 6230x corner post, 32” 1 6231x corner post, 36” 6232x corner post, 48” 9 6233x cap 1 10 83508 1/4”-20 x 1-5/8” button head cap screw part number techorganizer corner techorganizer t e c h o r g a n i z e r s e r v i c e p a r t s l i s t ( c...

Page 106: C O R N E R

C o r n e r t e c h o r g a n i z e r the corner techorganizer can be installed on linx worksurfaces or appropriate industrial work benches. Linx worksurfaces with full depth uprights are recommended to provide a workstation/organizer with greatest stability. Important safety instructions * the orga...

Page 107: C O R N E R

C o r n e r t e c h o r g a n i z e r ( c o n t . ) 2. With two people, position the techorganizer in the desired location on the back of the worksurface. On a linx worksurface, locate the back of the frame .20” from the back edge of the worksurface. See figure 2 . 3. Using the holes in the frame bo...

Page 108

W h i t e , p e g a n d b i n b o a r d s white board tools required -phillips head screwdriver -flat blade screwdriver -plastic mallet note : white boards, peg boards and bin boards are provided in various widths and heights depending on the size of your techorganizer. The 19” boards can be install...

Page 109: ( C O N T . )

W h i t e , p e g a n d b i n b o a r d s ( c o n t . ) figure 2 white, peg or bin board panel hooks mounting channel rectangular slot #10-24 x 3/4” phillips pan head thread forming 2. Attach the board panel to the mounting channels by inserting the panel hooks into the rectangular slots in the moun...

Page 110: ( C O N T . )

85089 w h i t e , p e g a n d b i n b o a r d s ( c o n t . ) parts list description qty. 85100 white board - 11.64” high x 20.92” wide 85101 white board - 11.64” high x 26.92” wide 85102 white board - 11.64” high x 32.92” wide 84902 white board - 18.64” high x 20.92” wide 84903 white board - 18.64”...

Page 111: ( C O N T . )

85089 w h i t e , p e g a n d b i n b o a r d s ( c o n t . ) parts list description qty. 6197x peg board - 31.64” high x 32.92” wide 2 6198x peg board - 43.64” high x 20.92” wide 1 6199x peg board - 43.64” high x 26.92” wide 6200x peg board - 43.64” high x 32.92” wide 6782x bin board - 11.64” high ...

Page 112: ( C O N T . )

85089 w h i t e , p e g a n d b i n b o a r d s ( c o n t . ) technical furniture e-12.

Page 113

M a r k e r t r a y tools required -none white board white board marker tray bend line marker tray 1. Remove the release liner from the double faced tape on the back of the marker tray . 2. Carefully align the bottom of the tray with the bend line at the bottom of the white board and center it side ...

Page 114

M a r k e r t r a y ( c o n t . ) parts list description qty. 6596x marker tray - 24” 1 6597x marker tray - 30” 1 6598x marker tray - 36” part number 85130 technical furniture e-14.

Page 115

F a b r i c t e c h w a l l tools required -phillips head screwdriver -flat file note : panels are provided in various widths and heights depending on the size of your unit. Important for ease of installation, it is recommended that the fabric tech walls be installed onto the techorganizer frame pri...

Page 116: ( C O N T . )

F a b r i c t e c h w a l l ( c o n t . ) important : for proper tech wall installation, the mounting channels must attach flat against the slotted standards. If a weld joining the two halves of the double standard exceeds a height of approxi- mately .03”(.8mm), it may be necessary to carefully file...

Page 117: ( C O N T . )

F a b r i c t e c h w a l l ( c o n t . ) tech walls may be installed onto the organizer frames that have other components on one side. 1. Attach a single steel mounting channel to the left or right side of each frame section. See figure 1 . 2. Install the tech wall onto the single mounting channel....

Page 118: ( C O N T . )

85082 parts list description qty. 6213x 12.52” x 21.21” fabric panel 6214x 12.52” x 27.21” fabric panel 6215x 12.52” x 33.21” fabric panel 6685x 12.52” x 39.21” fabric panel 6216x 28.52” x 21.21” fabric panel 6217x 28.52” x 27.21” fabric panel 6218x 28.52” x 33.21” fabric panel 6686x 28.52” x 39.21”...

Page 119: ( C O N T . )

85082 f a b r i c t e c h w a l l ( c o n t . ) technical furniture e-19.

Page 120

C o r n e r l a m i n a t e h o o k - o n s h e l v e s 1. Determine the location of the corner laminate hook- on shelf . Position the shelf supports as shown in figure 1 . Insert the hooks on the back of the supports into the slotted standards and push down. To ensure that the hooks are seated, tap...

Page 121: ( C O N T . )

85093 c o r n e r l a m i n a t e h o o k - o n s h e l v e s ( c o n t . ) parts list description qty. 6239x corner shelf 24” x 24”- 12” deep 6240x corner shelf 30” x 30”- 12” deep 6341x corner shelf 36” x 36”- 12” deep 6242x corner shelf 42” x 42”- 12” deep 6243x corner shelf 48” x 48”- 12” deep 6...

Page 122: ( C O N T . )

85093 c o r n e r l a m i n a t e h o o k - o n s h e l v e s ( c o n t . ) technical furniture e-22.

Page 123

Eaton 160 gold star boulevard worcester, ma 01606 united states 800-225-7348 508-852-4300 eaton.Com/compass eaton 1000 eaton boulevard cleveland, oh 44122 united states eaton.Com © 2018 eaton all rights reserved printed in usa publication no. Ib211002en may 2018 follow us on social media to get the ...