- DL manuals

- Eaton

- Controller

- S811+N37 series

- User Manual

Eaton S811+N37 series User Manual

Summary of S811+N37 series

Page 1

S811+ soft starter user manual effective november 2012 supersedes july 2012.

Page 2

S811+ soft starter s811+ soft starter mn03900001e—november 2012 i disclaimer of warranties and limitation of liability the information, recommendations, descriptions and safety notations in this document are based on eaton corporation’s (“eaton”) experience and judgment and may not cover all conting...

Page 3

S811+ soft starter s811+ soft starter mn03900001e—november 2012 iii table of contents safety definitions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Viii hazardous high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 4

S811+ soft starter iv s811+ soft starter mn03900001e—november 2012 table of contents, continued functional description power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 control . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5

S811+ soft starter s811+ soft starter mn03900001e—november 2012 v table of contents, continued appendix a—parameters monitoring menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 soft start config menu . . . . . . . . . . . . . . . . . . . . . . ....

Page 6

S811+ soft starter vi s811+ soft starter mn03900001e—november 2012 list of figures eaton s811+ soft starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 installation mounting and dimensions s811+n… . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

S811+ soft starter s811+ soft starter mn03900001e—november 2012 vii list of tables introduction emc conformance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 technical data and specifications environmental specifications . . . . . . . . . . . . ....

Page 8

S811+ soft starter viii s811+ soft starter mn03900001e—november 2012 list of tables, continued appendix a—parameters monitoring menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 soft start config—s811+ …n3s standard . . . . . . . . . . . . . ...

Page 9

S811+ soft starter s811+ soft starter mn03900001e—november 2012 ix safety definitions and symbols warning this symbol indicates high voltage. It calls your attention to items or operations that could be dangerous to you and other persons operating this equipment. Read the message and follow the inst...

Page 10

S811+ soft starter x s811+ soft starter mn03900001e—november 2012 caution if the auto reset mode setting is used, caution must be exercised to assure that any restart occurs in the safe manner. Caution if the auto reset mode setting is used with level sensing, caution must be exercised to assure tha...

Page 11

Introduction s811+ soft starter mn03900001e—november 2012 1 introduction overview the eaton s811+ soft starter from eaton’s electrical business is an electronic, self-contained, panel- or enclosure-mounted motor soft-starting device. It is intended to provide three-phase induction motors with a smoo...

Page 12

Introduction 2 s811+ soft starter mn03900001e—november 2012 standards and certifications ● ul 508 ● csa 22.2-14-1995 ● iec 60947-4-2 ● ccc gb14048 ce conformance emc conformance 1. The 24 vdc power supply must be grounded. 2. Add ferrite, fair-rite #0446176451 to dc control power leads and control i...

Page 13

Technical data and specifications s811+ soft starter mn03900001e—november 2012 3 technical data and specifications environmental environmental specifications physical unit weight and dimensions description specification temperature range operating –40° to 122°f (–40° to 50°c) storage –58° to 158°f (...

Page 14

Technical data and specifications 4 s811+ soft starter mn03900001e—november 2012 short-circuit ratings—component short-circuit ratings—enclosed control (fuses) short-circuit ratings—enclosed control (breaker) frame size fuses circuit breaker voltage sccr rating (a) s811+n… j hfd 600 10 ka s811+r… rk...

Page 15

Technical data and specifications s811+ soft starter mn03900001e—november 2012 5 short-circuit information with iec breakers note: for more details on short-circuit protector selections and enclosure sizing, please refer to the linked spreadsheet on ul’s website at: http://www.Ul.Com/global/document...

Page 16

Receipt/unpacking 6 s811+ soft starter mn03900001e—november 2012 receipt/unpacking general upon receipt of the unit, verify that the catalog number and unit options stated on the shipping container match those stated on the order/purchase form. Inspect the equipment upon delivery. Report any crate o...

Page 17

Installation s811+ soft starter mn03900001e—november 2012 7 installation mounting the s811+ does not require any special tools for mounting operations. To aid with panel layout, refer to the dimension drawings on pages 8–10. Drill holes per mounting hole location as shown. Mounting hardware may util...

Page 18

Installation 8 s811+ soft starter mn03900001e—november 2012 dimensions approximate dimensions in inches (mm) s811+n… s811+r… 6.87 (174.5) 1.97 (50.0) 4x Ø 0.22 (5.5) 7.37 (187.2) 6.45 (163.9) 5.35 (135.9) 5.89 (149.7) 3.32 (84.4) 2.66 (67.6) 5.54 (140.7) 4.38 (111.3) 3.54 (90.0) 4x Ø 0.27 (6.8) 6.64...

Page 19

Installation s811+ soft starter mn03900001e—november 2012 9 approximate dimensions in inches (mm) s811+t… s811+u… 11.77 (299.0) 12.71 (322.9) 6.47 (164.4) 7.65 (194.4) 5.40 (137.3) 5.95 (151.1) 5.91 (150.0) 0.28 (7.1) 6x Ø 2.95 (75.0) 7.16 (181.8) 6x Ø 12.72 (323.1) 11.77 (299.0) 6.09 (154.8) 6.64 (...

Page 20

Installation 10 s811+ soft starter mn03900001e—november 2012 approximate dimensions in inches (mm) s811+v… 6.79 (172.5) 0.236 (6.00) 3.05 (77.5) 9.84 (250.0) 15.63 (397.0) 4x Ø 0.2650 (6.731) 6.50 (165.1) 7.39 (187.8) 11.05 (280.6) 16.57 (420.8).

Page 21

Installation s811+ soft starter mn03900001e—november 2012 11 power wiring using the wiring diagrams in below as guides, connect the line and motor wiring in accordance with appropriate local and national codes. Note: to provide optimum motor protection the line and motor power wiring should be tight...

Page 22

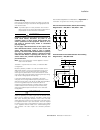

Installation 12 s811+ soft starter mn03900001e—november 2012 selecting inline or inside-the-delta operating configuration the mains wiring configuration is set with the motor wiring config parameter located in the soft start config menu to inline (default) or inside the delta. The motor nameplate fl...

Page 23

Installation s811+ soft starter mn03900001e—november 2012 13 s811+v10… installation requirements 1. Install the device in a minimum enclosure size 30 ft 3 . 2. Two (2) forced air ventilation fans with a minimum 500 ft 3 /min, at a location for “air in”—bottom right or left corner and “air out”—oppos...

Page 24

Installation 14 s811+ soft starter mn03900001e—november 2012 lug installation, s811+n… and s811+r… wire the appropriate line and load conductors to the soft starter in accordance with federal and local codes. Torque fasteners per table on page 12. Lug installation, s811+t…, s811+u…, and s811+v… fram...

Page 25

Installation s811+ soft starter mn03900001e—november 2012 15 control wiring terminal blocks caution only apply 24 vdc to control power terminal block. All control wiring is 22–12 awg (0.33–2.5 mm 2 ). Caution do not apply 120 vac to the control input terminals of the control power terminal block. Ca...

Page 26

Installation 16 s811+ soft starter mn03900001e—november 2012 terminal block control input function options programmable control input functions are available on terminals 1, 2, 3, and 4. Please note that all input signals except the analog input must be 18 vdc or greater (high) and 5 vdc or less (lo...

Page 27

Installation s811+ soft starter mn03900001e—november 2012 17 8–ext trip–control input 24 vdc only (maintained) the s811+ unit may be tripped by an external device. Removal of the 24 vdc signal (maintained) will initiate a fault trip action. Functionality of this feature will remove power from the mo...

Page 28

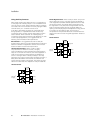

Installation 18 s811+ soft starter mn03900001e—november 2012 using auxiliary contacts often these contacts are used as shown in the illustrations on this page with indicating lamps. In some installations the user may wish to use an electromagnetic relay for indication of the status at a remote locat...

Page 29

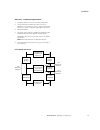

Installation s811+ soft starter mn03900001e—november 2012 19 network control terminal block the network control terminal block provides connections d0, d1, and ground for connection directly to a modbus system. Additional networks may be accommodated by utilizing communications adapters. Typical con...

Page 30

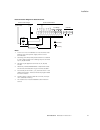

Installation 20 s811+ soft starter mn03900001e—november 2012 basic connection diagram for 2-wire pushbutton notes 1. A minimum wire of 14 awg (2.5 mm 2 ) should be used between the control power supply and the control terminal block. 2. See using an auxiliary relay section below if it is desired to ...

Page 31

Installation s811+ soft starter mn03900001e—november 2012 21 basic connection diagram for network control notes 1. A minimum wire of 14 awg (2.5 mm 2 ) should be used between the control power supply and the control terminal block. 2. See using an auxiliary relay section below if it is desired to us...

Page 32

Installation 22 s811+ soft starter mn03900001e—november 2012 24 vdc control power requirements the s811+ soft starter requires 24 vdc control power. The sealed in and inrush characteristics of the s811+ soft starter are summarized in the table below: control power requirements for applications where...

Page 33

Installation s811+ soft starter mn03900001e—november 2012 23 control wiring application notes caution only apply 24 vdc to the control terminal block. Control wiring is 22–12 awg (0.33–4.0 mm 2 ). Failure to follow this caution may result in damage to the control circuit. 1. Connect 24 vdc supply po...

Page 34

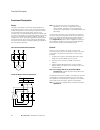

Functional description 24 s811+ soft starter mn03900001e—november 2012 functional description power the s811+ soft starter controls the voltage applied to a three-phase induction motor in order to control the starting torque and provide a smooth starting characteristic. Within the soft starter are t...

Page 35

Functional description s811+ soft starter mn03900001e—november 2012 25 starting/stopping options the following starting options are available in the s811+ soft starter: voltage ramp start this is the most commonly used mode of soft starting. Starting at an initial value set by the initial torque par...

Page 36

Functional description 26 s811+ soft starter mn03900001e—november 2012 current limit start this mode is typically used when it is necessary to limit the maximum current during start-up due to line power limitations or other considerations. During a current limit start the s811+ applies a constant vo...

Page 37

Functional description s811+ soft starter mn03900001e—november 2012 27 control functions network control when the s811+ is in network control and a 24 vdc signal is present at control block terminal “p”, it is ready to respond to motor start control commands issued through the network comms port. Th...

Page 38

Functional description 28 s811+ soft starter mn03900001e—november 2012 level or edge sensing level or edge sensing determines how the soft starter reacts to start control commands after a fault trip has occurred. It is important to be aware if the start command is a momentary or maintained signal. I...

Page 39

Functional description s811+ soft starter mn03900001e—november 2012 29 auto reset reset mode—three (3) modes of resetting fault trips are available: 0–manual—requires pressing reset button on dim, pressing reset button on the face of the s811+, or by providing a signal to an input control terminal c...

Page 40

S811+ operating configuration 30 s811+ soft starter mn03900001e—november 2012 s811+ operating configuration introduction the s811+ has a wide range of operation and protection parameters to enable coordinated motor and load protection. Commonly used parameters are directly accessible through the dig...

Page 41

S811+ operating configuration s811+ soft starter mn03900001e—november 2012 31 ● predefined keys are used to perform critical functions: predefined keys transfer of s811+ configuration parameters the 811+ has the ability to capture (store) configuration parameters to the dim. The configuration parame...

Page 42

S811+ operating configuration 32 s811+ soft starter mn03900001e—november 2012 initial configuration: 1. It is suggested that the s811+ soft starter be configured before applying the line voltage. Before applying the line voltage, apply 24 vdc to the supply connections of the s811+’s control terminal...

Page 43

S811+ operating configuration s811+ soft starter mn03900001e—november 2012 33 operating parameters—soft start configuration—s811+ …p3s premium note 1 has no reference. Note: s811+… units cannot be configured with pump start + inside-the-delta functionality enabled at the same time. Soft start config...

Page 44

S811+ operating configuration 34 s811+ soft starter mn03900001e—november 2012 operating parameters—soft start configuration—s811+ …v3s premium (690 volt) soft start config menu units minimum inline maximum inline default inline notes access level mtr nameplate fla 2 s811+t18… amps 56 180 56 motor fl...

Page 45

S811+ operating configuration s811+ soft starter mn03900001e—november 2012 35 protection parameters in addition to motor overload protection, the s811+ has many programmable features designed to protect the motor. ● incoming line phase reversal, loss, imbalance, over voltage, and under voltage trips...

Page 46

S811+ operating configuration 36 s811+ soft starter mn03900001e—november 2012 fault trip/fault warning/disable options the s811+ has a comprehensive array of protection parameters. Selected protection parameters have options to be set to a fault trip, fault warning, or disabled. Disabling fault prot...

Page 47

S811+ operating configuration s811+ soft starter mn03900001e—november 2012 37 alarm-no-trip option the alarm-no-trip option is intended for use with applications that have motor run-to-destruction protocols in the application specifications. This feature allows the s811+ to start/run the motor under...

Page 48

S811+ operating configuration 38 s811+ soft starter mn03900001e—november 2012 when the alarm-no-trip option is enabled, mains voltage operating conditions noted in table (2) below are monitored by the s811+. (2) mains voltage operating faults—full scr start (2) s811+ mains voltage operating faults—f...

Page 49

S811+ operating configuration s811+ soft starter mn03900001e—november 2012 39 thermal overload the s811+ soft starter features an electronic motor overload protection feature. It is designed to protect the motor and power wiring against overheating caused by operating at excessive current levels for...

Page 50

S811+ operating configuration 40 s811+ soft starter mn03900001e—november 2012 the table below notes the values of initial torque settings as a percentage of locked rotor current. Initial torque settings the national electrical code requires that all alternating current motors of 1/2 horsepower and h...

Page 51

Troubleshooting s811+ soft starter mn03900001e—november 2012 41 troubleshooting general in this section of the manual, we present a procedure you can follow to diagnose a problem with your s811+. While many potential situations are outlined in this section, it is possible you may run into a problem ...

Page 52

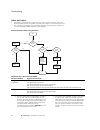

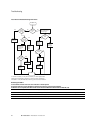

Troubleshooting 42 s811+ soft starter mn03900001e—november 2012 define the problem 1. If the s811+ soft starter fails to respond in any way to a start command., look at the digital interface module of the s811+ soft starter and determine the fault status of the unit. The following troubleshooting fl...

Page 53

Troubleshooting s811+ soft starter mn03900001e—november 2012 43 note: if connected to a network, starting the s811+ from the control input terminal block may isolate problems associated with the network and not with the soft starter. 2. It is often useful in determining the nature of the fault condi...

Page 54

Troubleshooting 44 s811+ soft starter mn03900001e—november 2012 local control troubleshooting flow chart in extreme cases, it may be necessary to reset parameter settings and operating values to restore proper operation. The s811+ may be reset by following the instruction below. Resetting the s811+ ...

Page 55

Accessories s811+ soft starter mn03900001e—november 2012 45 accessories lug kits lug kits—s811+t, u… lug kits—s811+v… optional accessory kits accessory kits communications contact eatoncare for availability of communications adapters. Communications replacement parts replacement parts description pa...

Page 56

Appendix a—parameters 46 s811+ soft starter mn03900001e—november 2012 appendix a—parameters monitoring menu monitoring menu description units access level flt/warn active 0 fault/warn list 0 fault/warn history 0 3Ø line currents amps 0 current as % fla % 0 dc cntrl voltage volts 0 3Ø pole voltages v...

Page 57

Appendix a—parameters s811+ soft starter mn03900001e—november 2012 47 soft start config menu soft start config—s811+ …n3s standard soft start config menu units minimum inline (insidedelta) maximum inline (insidedelta) default inline (insidedelta) notes access level mtr nameplate fla 2 s811+n37… amps...

Page 58

Appendix a—parameters 48 s811+ soft starter mn03900001e—november 2012 soft start config—s811+ …p3s premium note: s811+… units cannot be configured with pump start + inside-the-delta functionality enabled at the same time. Soft start config menu units minimum inline (insidedelta) maximum inline (insi...

Page 59

Appendix a—parameters s811+ soft starter mn03900001e—november 2012 49 soft start config—s811+ …v3s premium (690 volt) soft start config menu units minimum inline maximum inline default inline notes access level mtr nameplate fla 2 s811+t18… amps 56 180 56 motor fla parameter must be set to motor nam...

Page 60

Appendix a—parameters 50 s811+ soft starter mn03900001e—november 2012 protection menu protections menu—all catalog numbers fault code protections menu units minimum maximum default notes 14 overload fault enable 0 2 1 0 = disable 1 = enable 2 = warning * ovld on start 0 1 1 0 = disable 1 = enable * ...

Page 61

Appendix a—parameters s811+ soft starter mn03900001e—november 2012 51 protections menu, continued advanced i/o menu parameter list—advanced i/o setup—all catalog numbers fault code protections menu units minimum maximum default notes 40 3Ø power fault—enable 0 2 0 0 = disable 1 = enable 2 = warning ...

Page 62

Appendix a—parameters 52 s811+ soft starter mn03900001e—november 2012 parameter list—advanced i/o setup—all catalog numbers, continued advanced i/o setup menu units minimum maximum default notes access level relay config entry 0 = terminals 13, 14 0 10 3 0 = no function 1 = fault 2 = fault not 3 = b...

Page 63

Appendix a—parameters s811+ soft starter mn03900001e—november 2012 53 network setup menu network setup network setup minimum maximum default notes access level comm loss action 0 7 0 0 = auto stop 1 = auto run1 2 = unavailable 3 = hold last 4 = unavailable 5 = unavailable 6 = unavailable 7 = all sto...

Page 64

Appendix a—parameters 54 s811+ soft starter mn03900001e—november 2012 lcd dim setup menu lcd dim setup notes 1 digital interface module. 2 0 = disabled (fault) 1 = enabled (no fault). 3 0 = disabled (fault) 1 = enabled (jog). Lcd dim setup units minimum maximum default access level upload settings 2...

Page 65

Appendix b—protection s811+ soft starter mn03900001e—november 2012 55 appendix b—protection thermal overload the s811+ soft starter features an electronic motor overload protection feature. This is intended to protect the motor and power wiring against overheating caused by excessive current for ext...

Page 66

Appendix b—protection 56 s811+ soft starter mn03900001e—november 2012 once the trip level reaches level 3, it will take 144 minutes to go back to level 2, then 96 minutes to get back to level 1. To get from level 3 to a reset thermal overload at level 1, it takes 240 minutes without a trip. A reset ...

Page 67

Appendix b—protection s811+ soft starter mn03900001e—november 2012 57 overload trip curves t ime (seconds) percent fla 10000.0 1000.0 100.0 10.0 1.0 0 class 5 class 20 class 10 class 30 100 200 300 400 500 600 700 800 900 115% class 30 class 10 class 5 class 20

Page 68

Appendix c—ratings, cooling and power losses—inline 58 s811+ soft starter mn03900001e—november 2012 appendix c—ratings, cooling and power losses—inline power ratings standard duty—15 second ramp, 300% current limit at 40°c—inline connection notes 1.0sf = 1.0 service factor. 1.15sf = 1.15 service fac...

Page 69

Appendix c—ratings, cooling and power losses—inline s811+ soft starter mn03900001e—november 2012 59 severe duty—30 second ramp and/or 450% current limit at 50°c—inline connection notes 1.0sf = 1.0 service factor. 1.15sf = 1.15 service factor. Maximum current three-phase motors catalog number kw rati...

Page 70

Appendix d—ratings, cooling and power losses—inside-the-delta 60 s811+ soft starter mn03900001e—november 2012 appendix d—ratings, cooling and power losses—inside-the-delta power ratings standard duty—15 second ramp, 300% current limit at 40°c—inside-the-delta connection notes 1.0sf = 1.0 service fac...

Page 71

Appendix d—ratings, cooling and power losses—inside-the-delta s811+ soft starter mn03900001e—november 2012 61 severe duty—30 second ramp and/or 450% current limit at 50°c—inside-the-delta connection notes 1.0sf = 1.0 service factor. 1.15sf = 1.15 service factor. 1 consult factory. Maximum continuous...

Page 72

Appendix d—ratings, cooling and power losses—inside-the-delta 62 s811+ soft starter mn03900001e—november 2012 power losses the following table lists the maximum power loss for each s811+ soft starter when it is operating in bypass at the maximum frame size current. These losses should be used in con...

Page 73

Appendix e—motor/application considerations s811+ soft starter mn03900001e—november 2012 63 appendix e—motor/application considerations squirrel cage motor this is the most common application. The motor is configured with three motor leads available. In this case, wire the motor to the soft starter ...

Page 74

Appendix f—pump control option 64 s811+ soft starter mn03900001e—november 2012 appendix f—pump control option pump control option this option is intended to reduce the potential for water hammer in a centrifugal pump system by utilizing a starting and stopping algorithm developed for pump control. U...

Page 75

Appendix g—modbus register map s811+ soft starter mn03900001e—november 2012 65 appendix g—modbus register map register map parameter data length modbus register number read/write data type description motor control status 1 300 r uint8 bit 0 1 2 3 4 5 6 7 status running1 running2 permissive ramp2 lo...

Page 76

Appendix g—modbus register map 66 s811+ soft starter mn03900001e—november 2012 three-phase rms ac voltage 2 308 r uint16 l1 rms voltage 2 309 r uint16 l2 rms voltage 2 310 r uint16 l3 rms voltage total number of motor starts 4 311 r uint32 # of motor starts 312 r reg311 = lsb1, lsb0 reg312 = msb, ls...

Page 77

Appendix g—modbus register map s811+ soft starter mn03900001e—november 2012 67 fault queue (fault/warning codes are not repeated in the list) 2 318 r uint16 latest fault/warning code 2 319 r uint16 2nd latest fault/warning code 2 320 r uint16 3rd latest fault/warning code 2 321 r uint16 4th latest f...

Page 78

Appendix g—modbus register map 68 s811+ soft starter mn03900001e—november 2012 scaled average three phase currents in amps—pole 2 352 r uint16 scaled average pole current in amps scaled three phase currents in amps—pole 2 353 r uint16 l1 rms pole current in amps 2 354 r uint16 l2 rms pole current in...

Page 79

Appendix g—modbus register map s811+ soft starter mn03900001e—november 2012 69 modbus motor two wire control 1 501 r/w uint8 bit 0 1 2 3 4 5 6 7 description run1—level sense run2—level sense reserved fault reset reserved reserved reserved ramp2 enable network inputs 1 502 r/w uint8 bit 0 1 2 3 4 5 6...

Page 80

Appendix g—modbus register map 70 s811+ soft starter mn03900001e—november 2012 motor start method 1 608 r/w uint8 0 = voltage ramp 1 = current limit 2 = unavailable 3 = pump start (w pump option) percent initial torque 1 609 r/w uint8 0–100% motor start ramp time 2 610 r/w uint16 0.5–180s (in 0.1 se...

Page 81

Appendix g—modbus register map s811+ soft starter mn03900001e—november 2012 71 motor control output configuration s811 output#1 cfg s811 output#2 cfg network output#1 cfg network output#2 cfg 2 2 2 2 633 634 635 636 r/w r/w r/w r/w uint16 uint16 uint16 uint16 0 = no function 1 = faulted 2 = not faul...

Page 82

Appendix g—modbus register map 72 s811+ soft starter mn03900001e—november 2012 motor voltage imbalance fault level 1 657 r/w uint8 1–100% motor voltage imbalance fault duration 2 658 r/w uint16 0.1–60.0 sec (in 0.1 sec) motor under voltage fault enable 1 659 r/w uint8 0 = protection disabled 1 = fau...

Page 83

Appendix g—modbus register map s811+ soft starter mn03900001e—november 2012 73 scr shorted fault enable 1 678 r/w uint8 0 = protection disabled 1 = fault enabled 2 = warning enabled alarm-no-trip enable 1 679 r/w uint8 1 = enable 0 = disable motor control start delay warning enable 1 680 r/w uint8 1...

Page 84

Appendix g—modbus register map 74 s811+ soft starter mn03900001e—november 2012 modbus_production list note that the values must be modbus register address (i.E., register number-1) not register number. 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 1000 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1...

Page 85

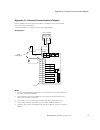

Appendix h—universal communications adapter s811+ soft starter mn03900001e—november 2012 75 appendix h—universal communications adapter external adapters can be connected to the s811+ to enable the unit to be controlled by networks other than modbus. Connect the adapter in accordance with the wiring...

Page 86

Appendix i—troubleshooting guide 76 s811+ soft starter mn03900001e—november 2012 appendix i—troubleshooting guide this guide is intended to provide the information necessary to successfully troubleshoot issues that may occur during the operation of the s611 soft starter. The troubleshooting sequence...

Page 87

Appendix i—troubleshooting guide s811+ soft starter mn03900001e—november 2012 77 general information 24 vdc control power—terminal block connections ● run enable 24 vdc applied to terminal “p”, this 24 vdc input must be maintained continuously during run operation from either the terminal block or a...

Page 88

Appendix i—troubleshooting guide 78 s811+ soft starter mn03900001e—november 2012 ● thermal memory ● this parameter is not the same as thermal overload. ● parameter may be viewed in the monitoring menu. ● at 100% thermal memory the soft starter will stop with a red status led. ● at 99% thermal memory...

Page 89

Appendix i—troubleshooting guide s811+ soft starter mn03900001e—november 2012 79 s811+ fault codes code fault status condition solution na fault warning impending ol trip overload trip is impending. Motor current 120% above fla parameter setting. 1 firmware incompatibility or hardware failure. Fault...

Page 90

Appendix i—troubleshooting guide 80 s811+ soft starter mn03900001e—november 2012 7 phase imbalance fault trip fault warning disable phase imbalance exceeds parameter value. Correct imbalance problem with mains. Increase the current and/or voltage fault imbalance parameters. Disable the fault if the ...

Page 91

Appendix i—troubleshooting guide s811+ soft starter mn03900001e—november 2012 81 14 overload fault fault trip fault warning disable motor operation in excess of 115% or rated fla. Excessive ramp times. Excessive starts per hour. Reduce the motor’s load. Verify the overld trip fla and/or ovrld trip c...

Page 92

Appendix i—troubleshooting guide 82 s811+ soft starter mn03900001e—november 2012 41 motor high power fault trip fault warning disable average power has increased above the high threshold set by user. Inspect application for cause of high power. Increase high power trip threshold notes: rated power =...

Page 93

Appendix i—troubleshooting guide s811+ soft starter mn03900001e—november 2012 83 56 internal comm2 fault fault trip internal communications error. Excessive electrical noise or hardware failure. Try a 24 vdc control voltage power cycle to attempt to clear problem. Contact eatoncare for service. Note...

Page 94

Appendix i—troubleshooting guide 84 s811+ soft starter mn03900001e—november 2012 64 v zero cross lost fault trip mains voltage lost. Phase l1 or l3 lost. Load disconnected restore mains or lost phases. Verify that the load is connected and any disconnect devices are properly engaged. Contact eatonca...

Page 95

Appendix i—troubleshooting guide s811+ soft starter mn03900001e—november 2012 85 notes all mains and control power connections must be completed and voltage applied prior to a start command. Failure to make all connections will result in one or more faults. All isolation and/or reversing contactors ...