- DL manuals

- EBARA

- Water Pump

- EPD

- Instruction And Operation Manual

EBARA EPD Instruction And Operation Manual

Summary of EPD

Page 1

M o d e l e p d , e p p d instruction and operation manual p r o d r a i n e r s u b m e r s i b l e p u m p s ebara international corporation standard pump division call 1-800-577-8111 for sales and support call 1-800-577-8111 for sales and support.

Page 2: Purchase Date:

Thank you for purchasing this ebara stainless steel sump pump. We hope you are pleased with your purchase and that our pumps will provide you with long service life and exceptional performance. To ensure satisfactory service life, there are several consid- erations regarding proper installation, ope...

Page 3: Epd, Eppd

Epd, eppd important safeguards to reduce risk of injury, always follow these instructions and safety precautions when using this pump and to maintain warranty. Read all instructions prior to installation (save these instructions) installation/operation: • never lift or carry pump by the electrical c...

Page 4: Epd, Eppd

Epd, eppd important safeguards proper lifting: a separate chain or rope should be attached to the handle for normal lifting. Please note that this will help prevent damage due to inadvertent lifting of the pump by the power cord. Rope attached to automatic pump for lifting and installation. Rope att...

Page 5: Contents

Section page general application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 safety information and introduction & specifications . . . . . . . . . . . . . . . . . . 7 materials/tools & installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6: (Cont.)

Safety reasons. You should never touch a sump pump or discharge piping while the pump is connected to electrical power and water is present. The pump should be disconnected from the electrical source before handling in all cases. Discharge piping installation to assure the maximum performance from y...

Page 7: Warning

Basin and cover the basin should not be less than 18 inches in diameter and 24 inches deep. Larger diameters are advisable in instances of increased pump capacity requirements: the basin should be located such that all water flows into the basin due to gravity. Outdoor installations should be at a s...

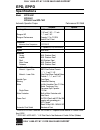

Page 8: Caution

Check the nameplate for your pump’s head (head), discharge volume (capacity), speed (speed), motor voltage and current. Other specifications are noted in the chart below: item no. Model discharge motor motor weight dia. Output phase voltage manual operation inch (hp) eppd-3ms1 32z707u6.3s 1 1 / 4 1/...

Page 9: Materials Needed

• pvc or abs pipe cement (read manufacturer’s instructions carefully) • pvc or abs pipe; – 1 1 / 4 " for eppd-3 & epd-3 – 1 1 / 2 " for epd-5,7,10 & 15 • pvc adapter – 1 1 / 4 " for eppd-3 & epd-3 – 1 1 / 2 " for epd-5, 7, 10 & 15 • in line check valve • sump basin 18” or larger diameter plastic, fi...

Page 10: Warning:

• pumps are 115 v, 60 hz and are grounded to prevent electrical shock. Warning: risk of electric shock—this pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded, grounding-typ...

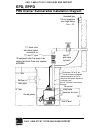

Page 11: General Materials Needed

Refer to the installation illustration on the following page for the following instructions. Be certain sump basin is clean and all power to pump is shut off. If pump fails to operate prop- erly after installation, refer to the troubleshooting checklist on page 12 or contact ebara. General materials...

Page 12: Epd, Eppd

10 1 / 2 " min. 14" min. Bottom of inlet pipe sump pump drill 1/8" relief hole 5" above pump discharge discharge piping can be pvc or abs plastic with proper adapters, or can be galv. Steel shut-off gate valve (optional) turn on level grounded type 115 volt receptacle min. Height above floor – 4 ft....

Page 13: Motor Wiring Diagram

Manual operation type output (three phase) • output 1 / 3 to 1 1 / 2 hp automatic operation type output (single phase) • output 1 / 3 to 3 / 4 hp manual operation type output (single phase) • output 1 / 3 to 3 / 4 hp motor wiring diagram epd, eppd call 1-800-577-8111 for sales and support call 1-800...

Page 14: Warning

Electrical wiring – three phase warning check that the power is locked off and disconnected before working on pump. All electric work should be performed by a qualified electrician and all national and local electrical codes must be observed. Note: use with approved motor control that matches motor ...

Page 15: Specifications

Model eppd-3as1 epd-3as1 epd-5as1 and epd-7as1 automatic operation pumps performance: iso 2548 standard optional discharge size 1 / 3 hp – 1 1 / 4 inch 1 / 2 hp and 3 / 4 hp – 1 1 / 2 inch range of hp 1 / 3 , 1 / 2 , and 3 / 4 hp range of performance capacity 2.7 to 72 gpm head 9.3 to 57 feet limita...

Page 16: Specifications

Model eppd-3ms1 epd-3ms1 epd-5 to 15 manual operation pumps performance: iso 2548 standard optional discharge size 1 / 3 hp – 1 1 / 4 inch 1 / 2 hp through 1 1 / 2 hp – 1 1 / 2 inch range of hp 1 / 3 , 1 / 2 , 3 / 4 , 1, and 1 1 / 2 hp range of performance capacity 2.7 to 86 gpm head 9.3 to 61 feet ...

Page 17: Epd, Eppd

Ebara pump no. (serial number) ① model ➁ cap. Usgpm ➂ ➄ head ft ➃ ➅ ➆ phase induction motor ➇ kw ⑨ hp 60 hz ➉ v a pole 2 ins. Class f max. Amb. 122° f motor model name plate 12 item no. Designation: example: epd 3 m s 1 horsepower 3 = 1/3 hp 5 = 1/2 hp 7 = 3/4 hp 10 = 1 hp 15 = 1 1 / 2 hp m – manual...

Page 18: Troubleshooting Checklist

Possible causes • line circuit breaker is off, or fuse is blown or loose. • water level in sump has not reached turn-on level as indicated in installation drawing. • pump cord is not making contact in receptacle. • float is stuck. It should operate freely in basin. • if all of the above are ok, then...

Page 19: Maintenance and Service

Warning: pump warranty becomes void if you remove motor housing, unscrew impeller, or otherwise remove impeller seal. If pump does not operate properly, follow the steps shown under troubleshooting. For any work on pump or switch, always unplug power cord(s). Do not just turn off circuit breaker or ...

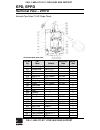

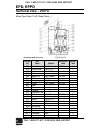

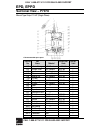

Page 20: Sectional View – Z707U

Sectional view – z707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 012 suction cover noryl g.F. 3 1 021 impeller noryl g.F. 3 1 041 sleeve 304 stainless/ceramic 1 048 impeller nut 304 stainless aisi 304 1 *114 oil...

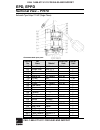

Page 21: Sectional View – Z707U

Sectional view – z707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 012 suction cover noryl g.F. 3 1 021 impeller noryl g.F. 3 1 041 sleeve 304 stainless/ceramic 1 048 impeller nut 304 stainless aisi 304 1 *114 oil...

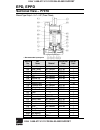

Page 22: Sectional View – P707U

Sectional view – p707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 012 suction cover noryl g.F. 3 1 021 impeller noryl g.F. 3 1 041 sleeve 304 stainless/ceramic 1 048 impeller nut 304 stainless aisi 304 1 *114 oil...

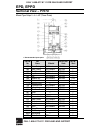

Page 23: Sectional View – P707U

Sectional view – p707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 009 inner casing 304 stainless aisi 304 1 016 seal cover 304 stainless aisi 304 1 021 impeller 304 stainless aisi 304 1 039 key 304 stainless aisi...

Page 24: Sectional View – P707U

Sectional view – p707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 009 inner casing 304 stainless aisi 304 1 016 seal cover 304 stainless aisi 304 1 021 impeller 304 stainless aisi 304 1 039 key 304 stainless aisi...

Page 25: Sectional View – P707U

Sectional view – p707u * recommended spare parts part no. Part astm, aisi no. For no. Name material code 1 unit 007 outer casing 304 stainless aisi 304 1 012 suction cover 304 stainless aisi 304 1 021 impeller 304 stainless aisi 304 1 041 sleeve ceramic/steel 1 048 impeller nut 304 stainless aisi 30...

Page 26: Disassembly and Assembly

Disassembly and assembly epd, eppd 1. Disassembly when disassembling pump, have a piece of cardboard or wooden board ready to place the different parts on as you work. Do not pile parts on top of each other. They should be laid out neatly in rows. The o-ring and gasket can not be used again once the...

Page 27: Warranty

Warranty epd, eppd commercial pump/ products limited warranty ebara international corporation, rock hill, sc (“eic-rh”) warrants to the original purchaser only (“customer”) that the eic-rh commercial pump/product (“pump”) will be free of defects in workmanship and material for a period of twelve (12...

Page 28

Contact your dealer or supplier for more information about other ebara products: call 1-800-577-8111 for sales and support call 1-800-577-8111 for sales and support.