- DL manuals

- EBARA

- Water Pump

- EV-A03

- Instruction Manual

EBARA EV-A03 Instruction Manual

Summary of EV-A03

Page 1

Pm10u ebara corporation ev-a series dry vacuum pump applicable type ev-a03 instruction manual.

Page 3

P.3 pm10u ebara corporation handling of manual this instruction manual describes installation, operation, and maintenance about the ev-a series dry vacuum pump. Be sure to read this instruction manual to operate correctly before installing and operating it. In particular, take care about the precaut...

Page 4

P.4 pm10u ebara corporation this instruction manual describes important matters related to pump operation. Keep the manual in an easy-to-see place so that it may be available whenever required. <definitions of term> definitions of term are as follows. Solvent: ipa, organic solvent such as ethanol an...

Page 5

1. Warranties seller warranties each standard product manufactured and sold by it to be free of defects in materials and workmanship for such period of time and under such conditions as are specified herein or as may be specified by seller on the face of its quotation or otherwise reduced to writing...

Page 6

P.6 pm10u ebara corporation application of the vacuum pump * this vacuum pump is intended to get a vacuum source for vacuum exhaust, maintenance of vacuum condition, and a clean usage as a vacuum source for general industry. However, the above is not applicable to the case where using this vacuum pu...

Page 7

P.7 pm10u ebara corporation contents 1. Items related to safety 1.1 safety --------------- 8 1.2 types of warning label -------------- 12 1.3 warning label positions -------------- 13 2. Product confirmation -------------- 14 3. Product overview 3.1 pump body -------------- 15 3.2 electrical equipme...

Page 8

P.8 pm10u ebara corporation 1. Items related to safety 1.1 safety this instruction manual describes the following items related to safety. Read this manual carefully before operating this product. Safety precautions are also described in each related sections. Danger do not use this product for pump...

Page 9

P.9 pm10u ebara corporation caution do not step on the pump, otherwise falling or turnover may be caused. Do not place anything on the pump as it may damage the product. Do not lift the pump by yourself. Lift the pump by hand with two (2) persons. Do not use sling or the like to lift the pump as the...

Page 10

P.10 pm10u ebara corporation confirmation don't pile packed pumps and don't lay each pump on its side in any case; otherwise the damage may be caused to the pumps. Keep space, 100mm or more at front and rear side, 50mm or more at lateral side, to secure good ventilation for cooling. Bad ventilation ...

Page 11

P.11 pm10u ebara corporation confirmation always use gas ballast mechanism (optional) when the pump needs to exhaust solvent gas and water vapor. Air gas ballast mechanism has a built in filter to protect the pump from foreign materials in the atmosphere. When pump is used in dusty environment the f...

Page 12

P.12 pm10u ebara corporation 1.2 types of warning label the following warning labels are attached to the main body of the dry vacuum pump to provoke cautions on use. The warning label positions are shown on the next page. List of warning labels on the dry vacuum pump warning label a warning label b ...

Page 13

P.13 pm10u ebara corporation 1.3 warning label positions warning label c warning label a warning label b warning label d 排気口 吸気口 1ph ac100-120v 50/60hz pe CN1 CN2 warning label b warning label a warning label c warning label d.

Page 14

P.14 pm10u ebara corporation 2. Product confirmation this dry vacuum pump is delivered after it is strictly inspected and packed. When the user receives the package, open it and confirm the following points. * check if its components parts are all included. * check if the pump specifications comply ...

Page 15

P.15 pm10u ebara corporation 3. Product overview pumps basically consist of a pumping mechanism; electrical parts are mounted on the base and covered with package. 3.1 pump body * a pair of hybrid roots rotors synchronously rotates, keeping a given clearance, and transfers the gas from inlet port to...

Page 16

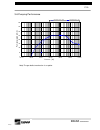

P.16 pm10u ebara corporation 3.4 product specifications specification table ev-a03 model item ev-a03-1 (single phase 100v) ev-a03-2 (single phase 200v) ev-a03-3 (three phase 200v) max. Pumping speed [50/60 hz] 250 l/min 1.0 pa note1) w/ gas ballast off ultimate pressure 10 pa note1) w/ gas ballast o...

Page 17

P.17 pm10u ebara corporation note 1) the gas ballast mechanism is an option. Note 2) n2 supply pressure for n2 gas ballast mechanism note 3) maximum water vapor pumping rate with gas ballast valve fully opened. Note 4) actual value may not be in the range depending on facility. Note 5) this describe...

Page 18

P.18 pm10u ebara corporation 3.5 external view cn2 i/ o con n e c to r cn1 p o w e r input co n tr o l pan e mai n swi tch 12 8 38 oi l le ve l gau ge 21 9 210 91 91 (28) 250 227 38 5 inle t nw25 ou tlet nw2 5 gas bal last port 13 0 40 40 17 2×2 × m6 ha n d le 21 24 th ree p h ase 20 0v cn2 i/ o con...

Page 19

P.19 pm10u ebara corporation 3.6 pumping performance 0 50 100 150 200 250 300 350 400 1.0e-01 1.0e+00 1.0e+01 1.0e+02 1.0e+03 1.0e+04 1.0e+05 pressure [pa] gas ballast valve : off gas ballast valve : on pum p in g spe e d [ l /m in ] note) the gas ballast mechanism is an option..

Page 20

P.20 pm10u ebara corporation 4. Installation of the pump the pumping performance of the dry vacuum pump is affected by the opening diameter and length of the inlet / outlet pipe and the performance of the installed peripheral units. Moreover, when corrosive gas is pumped, proper maintenance is requi...

Page 21

P.21 pm10u ebara corporation *please fix the pump with appropriate bracket. (fig.4.1,fig4.2) (the bracket is an option.) * use m8 bolt and nut for pump fixing. The holes for fixed bolts 45 10 385 475 45 10 40 130 40 inlet nw25 outlet nw25 bracket 2×2×φ9 fig.4.1 pump fixation position 25 0 max. 20 ap...

Page 22

P.22 pm10u ebara corporation 4.2 piping 4.2.1 vacuum and outlet piping connect a vacuum pipe and an outlet pipe to the inlet port and the outlet port, respectively. The inlet port of the dry pump is an nw25 quick flange, while the inlet port of this pump is an nw25 quick flange. Perform piping or ma...

Page 23

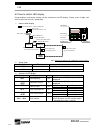

P.23 pm10u ebara corporation 4.3 electric wiring this product is not equipped with earth leakage breaker (elb) and emergency off switch (emo). Follow the local regulations when installing this product. Use adequate earth leakage breaker which corresponds to the specifications below if necessary. ※us...

Page 24

P.24 pm10u ebara corporation 4.3.1 power wiring (connector symbol: cn1, power supply) warning be sure to perform grounding, otherwise an electric shock may be caused by electric leakage. Use the wiring materials that correspond to the pump power. Table 4.2 wiring material type ev-a03-1 ev-a03-2 ev-a...

Page 25

P.25 pm10u ebara corporation a. How to connect wires; single phase 100v type. [ev-a03-1] for pin connections of the power connector, refer to fig.4.3, table 4.3, and table 4.4. Table 4.3 cn1 receptacle pin assign pin no. Phase x l : load y n : neutral (ground side) g grounding fig.4.3 cn1 pump-side ...

Page 26

P.26 pm10u ebara corporation 4.3.2 control wiring (connector symbol: i/o connector cn2) please install the driving connector in the i/o connector (cn2) when it will operate under “direct power input”. To perform remote operation or monitoring, perform wiring to the i/o connector cn2. For pin connect...

Page 27

P.27 pm10u ebara corporation the output signal (pin no. 5-13) is no-voltage relay contact outputs. The contact capacity is ac230v/0.2a and dc30v/0.3a. The output signal (pin no. 6, 7-14) is 1c no-voltage relay contact outputs. The contact capacity is ac230v.0.2a and dc30v/0.3a. Please make the reset...

Page 28

P.28 pm10u ebara corporation 5. Operation panel there are four different modes to run and stop the pump, “direct power input”, “operation by operation- panel”, “operation by external signal” and “operation by the handheld controller”. If “direct power input” is selected, set driving connector, that ...

Page 29

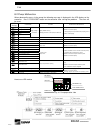

P.29 pm10u ebara corporation table. 5.1 explanation of operation panel. No. Name subject (1) power lamp lights up when power is supplied (2) alarm lamp lights up in red when inverter trips (3) program lamp does not light up (4) run lamp lights up when running (5) monitor lamp(hz) lights up when led ...

Page 30

P.30 pm10u ebara corporation 5.2 how to switch led display pump conditions and control settings can be checked on the led display. Display shows 4 digits and the first letter from the left is group code. 1) how to switch display note)when the pump turns on, led display shows run hour. 2) group code ...

Page 31

P.31 pm10u ebara corporation led display data range example run hour / time *1 0.0 – 9999. 3333. 3,333 hour *2 1000 – 9999 3333 33,330 hour total run hour total electrified hour *3 「100 - 「999 「333 333,000 hour *4 0. – 9999. 3333. 3,333 time error count monitor *5 1000 - 6553 3333 33,330 time.

Page 32

P.32 pm10u ebara corporation 6. Operation and stop 6.1 preparations for operation 1) check if electric wiring is properly performed. 2) check if the inlet pipe and the outlet pipe are securely connected. When a valve is installed on the outlet side, open the valve securely before starting the pump. ...

Page 33

P.33 pm10u ebara corporation b. Driving by main power switch on/off start 1) supply power to the pump. 2) turn on the main power switch on the pump. At the time, the pump will be started. (the power lamp, run lamp on the operation panel will come on.) 3) make sure that abnormality (unusual noise and...

Page 34

P.34 pm10u ebara corporation 6.2.3 operation by external signal applicable plug and housing are not standard accessory. Prepare them separately. (please refer to the chart of clause 4.3.2 control wiring in p.28 for details of wiring for the control.) start 1) supply power to the pump. Turn on the ma...

Page 35

P.35 pm10u ebara corporation 6-2-4. Operation by the handheld controller note) the handheld controller is an option. Start 1) supply power to the pump. Turn on the main power switch on the pump. (the power lamp on the operation panel will come on.) 2) press the run/stop switch on the handheld contro...

Page 36

P.36 pm10u ebara corporation 6.3 about the gas ballast mechanism note) the gas ballast mechanism is an option important *condensable gas (water vapor, solvent mixed gas) can be prevented from being condensed inside the pump by making the gas ballast valve "open". Use gas ballast valve whenever you u...

Page 37

P.37 pm10u ebara corporation atmospheric 1/4 tube fitting n2 photo 6.1 gas ballast specifications inlet outlet gas ballast valve photo 6.2 the pump of which gas ballast valve is installed gas ballast valve :close gas ballast valve :open 1/4 tube fitting check valve valve fig 6.1 how to open-and-clos...

Page 38

P.38 pm10u ebara corporation 7. Maintenance 7.1 routine maintenance check pump condition such as power supply, ultimate pressure and back pressure etc. Regularly and verify that the pump is used under normal operating condition. Refer to p.45 (8. Trouble shooting) section for trouble shooting if the...

Page 39

P.39 pm10u ebara corporation 7.2 inlet and outlet piping take the following precautions when performing the piping maintenance. (1) always turn off power supply. (2) dry the piping completely before installation if cleaning performed. Warning pump remains hot during and/or after operation. Avoid dir...

Page 40

P.40 pm10u ebara corporation oil refill is required when the level is below lower limit. Refill the oil following the procedure bellow. (1) stop the pump. Remove the packaging covers. (2) wait until pump internal pressure becomes atmospheric and cool enough. Then remove the filler plug. (3) refill o...

Page 41

P.41 pm10u ebara corporation 7.4 overhaul take the following precautions for a safe operation and prolonged pump life. (1) operate the pump within the range described in the catalog and the instruction manual. (2) perform maintenance as specified on p.40 (7. Maintenance) section. (3) product inspect...

Page 42

P.42 pm10u ebara corporation 7.5 removal of the pump danger turn off the main switch on the pump and disconnect power cable before servicing. Do not supply power before completion of service work. Warning wiring work must be done by qualified workers. Pump remains hot during and/or after operation. ...

Page 43

P.43 pm10u ebara corporation 8. Troubleshooting danger turn off the main switch on the pump and disconnect power cable before servicing. Do not supply power before completion of service work. Warning wiring work must be done by qualified workers. Pump remains hot during and/or after operation. Avoid...

Page 44

P.44 pm10u ebara corporation 8.2 pump malfunction when abnormality occurs in the pump, the following message is displayed in the led display on the controller. Press stop/reset button on the controller after solving the problem. The error will be reset. Led display contents cause corrective measures...

Page 45

P.45 pm10u ebara corporation 9. Scrapping method the pump main body and peripheral units may have been polluted by hazardous substances depending on each applied process. Perform scrapping in compliance with the safety control standards of the nation and each local self- governing body. 10. Precauti...

Page 46

P.46 pm10u ebara corporation return notice sheet date : . . . I. Product to be returned i) model no. Of the product be returned ii) serial no. Of the product to be returned ii. Pollution of the product to be returned i) applied process name ii) pollutant table pollutant name chemical symbol precauti...

Page 47

Global network (eng) usa taiwan ebara technologies incorporated ebara precision machinery taiwan inc. Headquarters/fsc headquarters sacramento (ca) taipei 51 main avenue, sacramento, ca 95838 room 1402 chia hsin bldg.,no.96, secretary. 2, phone:1-916-920-5451 chung shan n. Rd.,taipei taiwan, r.O.C. ...