- DL manuals

- Eberspächer

- Heater

- Hydronic D4

- Installation Manual

Eberspächer Hydronic D4 Installation Manual

Summary of Hydronic D4

Page 1

Eberspächer marine heater installation guide hydronic d4, hydronic d5 eberspächer (uk) ltd. Headlands business park, salisbury road, ringwood, hants bh24 3pb. Tel: 01425 480151 fax: 01425 480152 www.Eberspacher.Com 22298b © eberspächer (u .K.) ltd. 2007..

Page 2

Introduction 2 1 introduction 3 1 concept of this manual 1 introduction provides initial information and advice on using the content of this manual. 5 fuel system connections and limitations of the fuel system. 2 positioning the heater discusses suitable mounting locations and possibilities. 6 elect...

Page 3

Introduction 2 1 introduction 3 1 special text structure, presentation and picture symbols this manual uses special text structures and picture symbols to emphasise different contents. Please refer to the examples below for the corresponding meanings and associated actions. Special structure and pre...

Page 4

Introduction 4 1 introduction 5 1 – all appropriate precautions must be taken when arranging the heater to minimise the risk of injuries to persons or damage to other property. • fuel supply – the fuel intake connection must not be located in the passenger compartment and must be sealed with a prope...

Page 5

Introduction 4 1 introduction 5 1 • before the heater is installed again in another vehicle, rinse the heater parts carrying water with clear water. • when carrying out electric welding on the vehicle, the plus pole cable at the battery should be disconnected and placed at ground to protect the cont...

Page 6

Positioning the heater 6 positioning the heater 7 1 2 the heater should be installed in a dry and protected position and within the permissible mounting planes as shown in figure 1. Before deciding on the position, be aware that the location of the exhaust hull fitting and length of the exhaust may ...

Page 7

Positioning the heater 6 positioning the heater 7 1 attach the heater mounting bracket to a suitable strong bulkhead. Thin bulkheads may need additional support to give the heater a secure mounting. Care should be taken to avoid securing directly onto cabin bulkheads where the possibility of noise o...

Page 8

Positioning the heater 8 1 water pipework 9 ! Danger! Risk of injuries and burns! It is possible for the coolant and components of the coolant circuit to get very hot. • parts conveying water must be routed and fastened in such a way that they pose no temperature risk to man, animals or material sen...

Page 9

Positioning the heater 8 1 water pipework 9 general guidelines in order to obtain the best performance from the system, restrictions in the water flow should be kept to a minimum. The use of right angle bends and large variations in height should be avoided where possible. Ideally, the hydronic shou...

Page 10

Water pipework 10 water pipework 11 1 3 expansion tank based systems positioning the expansion tank the expansion tank must be positioned above the highest water component in the system and in a location that allows it to be topped up and the level checked periodically. Caution should be taken when ...

Page 11

Water pipework 10 water pipework 11 1 installing fan matrix units eberspächer fan matrix units are available in both non- ducted and ducted versions. Our non-ducted units feature very low power consumption fans that gives their maximum performance when able to allow air to flow with minimal restrict...

Page 12

Water pipework 12 1 exhaust and combustion air system 13 1 the majority of boats will probably have a calorifier already installed, which is usually connected to the engine and/or a mains ac supply. If the existing single coil calorifier is used with the hydronic heater, it is strongly recommended t...

Page 13

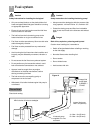

Water pipework 12 1 exhaust and combustion air system 13 1 exhaust the exhaust system included in the kit comprises of an exhaust hull fitting, a flexible insulated exhaust with silencer, securing clamps and exhaust support brackets. Installing the hull fitting the position of the exhaust hull fitti...

Page 14

Exhaust and combustion air system 14 1 fuel system 15 1 ! Danger! Risk of injury and burns! All combustion processes produce high temperature and toxic exhaust fumes. This is the reason why the exhaust system must be installed to these instructions. • do not perform any work on the exhaust system wh...

Page 15

Exhaust and combustion air system 14 1 fuel system 15 1 the fuel system supplied comprises of a fuel standpipe, shut off valve, a quantity of fuel line, connectors and a fuel-metering pump (integral on the hydronic d4 / d5 sc heater models). Figure 11 illustrates a typical installation using a fuel ...

Page 16

Fuel system 16 1 fuel system 17 1 ! Caution! Safety instructions for installing the fuel pipes! • only use a sharp blade to cut the plastic/rubber fuel hoses and pipes. Metal fuel pipes should be cut using an appropriate pipe cutter. • ensure all cuts are free from burrs and the fuel lines are not c...

Page 17

Fuel system 16 1 fuel system 17 1 fuel supply fuel quality for diesel heaters the heater can run on commercially available diesel fuel to din en 590 specification. Fuel for special cases in special cases (above 0°c), the heater can also run on fuel oil el or paraffin. Fuel for low temperatures refin...

Page 18

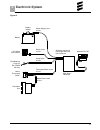

Electrical system 18 1 electrical system 19 1 the electrical system comprises of a heater cable harness and individual looms for the power supply, operating device and the fuel-metering pump (where necessary). Also a fuse box assembly and the operating device you have selected are included. The indi...

Page 19

Electrical system 18 1 electrical system 19 16 battery battery isolator figure 15 p mon tue wed thu fri sat sun power supply loom 2 core switch loom 4 core pump loom 2 core thermostat power loom 2 core matrix power loom 3 core main fuse / relay box hydronic d4 / d5 all looms connect via multi plugs ...

Page 20

Electrical system 20 1 electrical system 21 1 6 figure 16 mwh 2kw model fan matrix control wiring diagram note: this fuse box and loom no. 1 are optional extras. They are only necessary when 2 or more fan matrix are used. Fuse box thermostat fan matrix loom 3 connec...

Page 21

Electrical system 20 1 electrical system 21 16 electrical wiring of fan matrix 3.7kw (optional extra) thermostat thermostat connections 3.7kw matrix 1 - rt 2 - or 4 - br 5 - ge loom 1 locate the matrix thermostat in a convenient area within...

Page 22

Electrical system 22 1 electrical system 23 1 6 figure 18 2kw fan matrix arrangement wiring diagram ...

Page 23

Electrical system 22 1 electrical system 23 16 figure 19 3.7kw fan matrix arrangement wiring diagram ...

Page 24

Commissioning the system 24 warranty information 25 filling the coolant system before filling the coolant system ensure that all pipe and hose connections are secure. Fill the system with an anti-freeze mixture of at least 40% to prevent corrosion and coolant freezing. The anti- freeze mixture conce...

Page 25

Commissioning the system 24 warranty information 25 separate documents concerning warranty accompany the heater. 8.

Page 26

Notes 26 19.

Page 27

Notes 26 1.

Page 28

Eberspächer.