- DL manuals

- Ecco

- Paint Sprayer

- Xtatic HP6000

- Operation And Maintenance Manual

Ecco Xtatic HP6000 Operation And Maintenance Manual

ECCO FINISHING AB,

Box 93, S-532 22 SKARA, Sweden

9836 4057 01

Tel: +46 (0)511-134 45, Fax: +46 (0)511-180 13

2012-07

E-

mail: info@eccofinishing.com • www.eccofinishing.com

EIB12/15-02

0518

II 2 G EEx 0.24 mJ

Operation and Maintenance Manual

ECCO Xtatic

HP6000

This manual contains important information on warnings and cautions. Read the

manual thoroughly before starting to operate this equipment, and follow the

instructions. Always keep the manual handy until such time as the equipment is no

longer being used. If your manual is lost or worn badly, do not hesitate to contact

our agency which is closest to you, or the ECCO Finishing AB, directly, and ask us to

send you a new one.

Air Wrap Airless Electrostatic Spray Gun

Summary of Xtatic HP6000

Page 1

Ecco finishing ab, box 93, s-532 22 skara, sweden 9836 4057 01 tel: +46 (0)511-134 45, fax: +46 (0)511-180 13 2012-07 e- mail: info@eccofinishing.Com • www.Eccofinishing.Com eib12/15-02 0518 ii 2 g eex 0.24 mj operation and maintenance manual ecco xtatic hp6000 this manual contains important informa...

Page 2: Introduction

1 co n tent s 1 2 3 4 5 6 7 8 9 thank you for buying our product, air wrap airless electrostatic spray gun, ecco xtatic hp6000. Before you use the equipment, carefully read this manual and get to know how to use it safely, efficiently and effectively. Especially, fully understand the operating condi...

Page 3: Warning

1 please read and follow all the technical and safety instructions in this manual. Failure to do so may result in personal injury and/or property damage. While all the safety precautions in the manual are very important, you should not consider them to be as cure-all. They are nothing but minimum re...

Page 4: Warning

2 for correct use of the product never use acids, corrosive materials and halogenated hydrocarbon-based solvents for the product covered by this manual. If you have any doubt about the intended use or materials of the product, please consult us. The use of the product under conditions other than spe...

Page 5: Warning

3 > the air wrap airless electrostatic spray gun is equipped with safety devices. Correctly use them. whenever using the gun, check that all of the safety devices correctly function. □ trigger lock the gun trigger can be locked by raising the switch button at the backside of the trigger. whe...

Page 6: Warning

4 danger of the misuse > an excessive pressure, modifications to the parts, the misuse of the paint or solvent or the use of a worn or broken part may lead to damage to the pump, injury from the paint spray or splashes into your eyes or skin and/or serious disasters such as fire and explosion. nev...

Page 7: Warning

5 > this system cannot be used for electrostatic coating with a conductive paint such as water-soluble one. check that the paint and solvent to be used are compatible with the “materials of part of the pump that is in contact with the fluid. ” before using a paint or solvent with the air wrap airl...

Page 8: Warning

6 possibility of fire or explosion > static electricity is generated when the paint runs through the pump or hose. If parts of the coating machine are not appropriately grounded, electrostatic sparks may be generated to ignite the volatile component of a solvent, sprayed paint mist, suspending debri...

Page 9: Warning

7 □ grounding of the paint hose use a securely grounded paint hose. When using an extension paint hose, check that it has been securely grounded. See the section “for safety of the hose” (on page 5). □ grounding of the air wrap airless electrostatic spray gun the air wrap airless electrostatic spr...

Page 10: Note

8 > the solvent used for cleaning shall have a flash point not lower than 38°c and equivalent to or higher than that of the paint to be used. A halogenated hydrocarbon-based solvent may explode if it is brought into contact with an aluminum or plated part in a pressure vessel (e.G. Pump, heater, fil...

Page 11: Specifications

9 air wrap airless electrostatic spray gun model hp6000 maximum voltage to be charged dc -60kv shorting current 80μa fluid pressure normal 2 to 16mpa max. 21mpa wrap air pressure normal 0.2 to 0.5mpa max. 0.6mpa air consumption max. 150l/min (normal) outside dimensions l208 × w55 × h219 (mm) weight...

Page 12: Installation

10 [connecting the controller and paint pump] see the example of system construction on page 29. Before starting operation, be sure to read thoroughly the operation and maintenance manuals for controller and paint pump. ① connecting to the connecting cable correctly connect the air wrap airless elec...

Page 13: Caution

11 firmly connect the cable to the gun with hand. After connecting, lock it using stopper. If the cable is not in right position, do not connect it forcibly but unscrew the nut so as to bring its hexagonal flat into close contact with the stopper for proper connection. Forcible tightening using a to...

Page 14: Warning

12 ④ connecting to the paint hose in order to connect the paint hose, connect the hose joint on the electrostatic spray gun and that at the paint outlet of the paint pump. (connect 3, 5m long and 6, 5m long hoses using an intermediate joint into a 10m long hose.) be sure to check the paint hose for ...

Page 15: Caution

13 ⑥ caution in bundling and handling the connecting cable (1) when bundling the electrostatic spray gun connecting cable and hoses, follow the instructions below, in order not to impair the strength and service life of the connecting cable. ① do not bundle the connecting cable and hoses at points w...

Page 16: Warning

14 [installing and removing the air wrap airless electrostatic spray nozzle] when installing the air wrap airless electrostatic spray nozzle, engage it with the air cap with the notch on the nozzle aligned with the locating pin on the air cap and firmly tighten it to the gun barrel with a retaining ...

Page 17: Warning

15 there is a possibility of fire or explosion. check that the devices, equipment and floor in the coating workshop and the parts of hangers that are in contact with the product to be coated are free from deposited paint. Especially, remove the paint completely from the parts of hangers in contact ...

Page 18: Operation Procedure

16 ① preparation of paint this system can be used for electrostatic coating with almost all types of synthetic resin paints except some types of paints. It is not necessary to specially prepare a paint by mixing. However, some paints require adjustment using a solvent to improve the electrostatic co...

Page 19: Warning

17 (4) check the coating machine and hose joints for paint leakage. Set the operating pressure to between 2mpa and 16mpa. The maximum operating paint pressure for this gun is 21mpa. Never use it with a paint pressure exceeding 21mpa. Doing so may damage the gun or lead to injury or other accidents f...

Page 20: Caution

18 (2) if you want to suspend the work longer than 24 hours: when using a two-component paint or other paint that cures by chemical action or paint that settles easily, clean the gun with the following procedure after each use. 1. Be sure to turn off the power switch on the controller. 2. Remove the...

Page 21: Warning

19 ② electrostatic spray nozzle (1) keep the electrostatic spray nozzle clean. When cleaning the nozzle, carefully wipe out using a bristle brush or cloth soaked with a small amount of solvent. There is a possibility of electric shock or injury. When cleaning or replacing the nozzle, first turn off ...

Page 22: Warning

20 (1) select a nozzle for the air wrap airless electrostatic spray gun from the table below according to the discharge rate and pattern width (adjustable) determined by the conditions of use. (2) the nozzle is made of cemented carbide, which is very hard but easily chipped and, therefore, shall not...

Page 23: Troubleshooting

21 [electrostatic spray gun] ※ for part names, see pages 30 and 31. Symptom cause countermeasure red lamp on controller lights but electrostatic spray effect is not sufficient. Electric resistance of paint is not appropriate. Adjust the electric resistance of paint to between 10 and 100m Ω-cm at ac5...

Page 24

22 symptom cause countermeasure spray performance is poor. Wrap air does not come out or wrap air pressure is too low. Raise the wrap air pressure. Paint viscosity is too high. Reduce the paint viscosity. Paint pressure is too low. Adjust paint pump to raise the pressure. Air outlet in air cap is cl...

Page 25

23 [electrostatic effect] symptom cause countermeasure electric shock is felt at the moment gun grip is held. Controller is not completely grounded. Check the grounding. Operator is not holding the gun with bare hand. Take off gloves or cut off a portion of palm of each glove so that your bare hand ...

Page 26

24 parts replacement and repairing shall be conducted according to the procedures below. During the procedure, be sure to stop the compressed air supply to the gun, turn off the control unit, remove the paint in the paint circuit and clean the circuit. (the numbers shown below correspond to the numb...

Page 27: Caution

25 (3) when assembling, engage the filter, temporarily lock the nut with the stay, rotate the pipe 37 (6004 0335 87) to eliminate the gap between the filter and the pipe, and tighten the retainer with care not to install the stay in the opposite direction. Then, secure the nut with the stay and inst...

Page 28

26 (3) rotate the rod 11 (6004 0335 78) in the depth counterclockwise using a flat-ended screwdriver while pushing. Push the washer 15 (6004 0330 70) rearward through the trigger window and pull out the rod. This operation requires a flat-ended screwdriver. (4) after removing the plate 39 (6004 0330...

Page 29: Caution

27 (6) when assembling, adjust the entire length from the tip end of the paint needle to the rear end of the rod to 169mm. If it is short, the paint is discharged earlier when the gun is triggered and then sprayed directly after the air spouts out. If it is too large, the paint does not come out whe...

Page 30

28 the ecco xtatic hp6000 air wrap airless electrostatic spray gun takes advantage of both airless and air sprays and wraps the atomized paint with an air flow so as to promote the pulverization and radically vary the spray pattern width. A controller (exc hp), a pump for pressurizing and feeding th...

Page 31

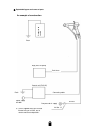

29 ② exploded diagram and names of parts an example of construction ※ the air supplied to the gun must be filtrated using an air filter, etc. To remove moisture and particles. Earth p rod uc t to b e c oa ted earth compressed air supply air filter ※ air hose paint hose connecting cable power supply ...

Page 32

30 ecco xtatic hp6000 exploded diagram.

Page 33

31 ecco xtatic hp6000 air wrap airless electrostatic spray gun no. Part no. Part name qty no. Part no. Part name qty 1 6004 0335 72 body 1 set 34 6004 0330 90 cushion 1 2 6004 0335 73 grip end unit 1 set 35 6004 0330 91 terminal cover 1 3 6004 0330 63 joint 1 36 6803 3079 00 filter 1 4 6004 0335 74 ...

Page 34: Maintenance Log

32 shown below is a maintenance log format of a kind we recommend you to keep. Each time that you conduct a maintenance service, such as replacement of a part, tear-down cleaning, post-failure repair, etc., record the details. In the long run, you will find that such a log is very valuable in keepin...

Page 35: Warranty

33 ecco finishing ab (the “company”) shall provide the original purchaser (the “purchaser”) with warranty service against defects in material or workmanship for a period of one (1) year from the date of purchase of the product, as follows: should you find defects in material or workmanship with reg...

Page 36

Ecco finishing ab, box 93, s-532 22 skara, sweden tel: +46 (0)511-134 45, fax: +46 (0)511-180 13 e- mail: info@eccofinishing.Com • www.Eccofinishing.Com.