- DL manuals

- Ecco

- Paint Sprayer

- Xtatic LP6000M

- Operation And Maintenance Manual

Ecco Xtatic LP6000M Operation And Maintenance Manual

ECCO FINISHING AB,

Box 93, S-532 22 SKARA, Sweden

9836 4056 01

Tel: +46 (0)511-134 45, Fax: +46 (0)511-180 13

2012-07

E-mail: info@eccofi

nishing.com • www.eccofinishing.com

EIB 12/15-01

0518

II 2 G EEx 0.24 mJ

Operation and Maintenance Manual

ECCO Xtatic

LP6000W

LP6000S

LP6000M

This manual contains important information on warnings and cautions. Read the

manual thoroughly before starting to operate this equipment, and follow the

instructions. Always keep the manual handy until such time as the equipment is no

longer being used. If your manual is lost or worn badly, do not hesitate to contact our

agency which is closest to you, or the ECCO Finishing AB, directly, and ask us to

send you a new one.

Air Electrostatic Spray Gun

Summary of Xtatic LP6000M

Page 1

Ecco finishing ab, box 93, s-532 22 skara, sweden 9836 4056 01 tel: +46 (0)511-134 45, fax: +46 (0)511-180 13 2012-07 e-mail: info@eccofi nishing.Com • www.Eccofinishing.Com eib 12/15-01 0518 ii 2 g eex 0.24 mj operation and maintenance manual ecco xtatic lp6000w lp6000s lp6000m this manual contains...

Page 2: Introduction

1 thank you for your choice of ecco xtatic lp6000 series manual air electrostatic spray gun(s). In order to ensure long and proper use of this equipment under the most optimum conditions, please read all the contents of this manual. You are requested to note and understand all of the indicated speci...

Page 3

2 contents 1. For safety and correct use ··································· 1 2. Outline of the equipment ······································ 3 3. Specifications ···················································· 5 4. Features ·························································· 6 5. Exp...

Page 4: Warning

- 1 - please read and follow all the technical and safety instructions in this manual. Failure to do so may result in personal injury and/or property damage. While all the safety precautions in the manual are very important, you should not consider them to be as cure-all. They are nothing but minimu...

Page 5

- 2 - > equipment covered by this instruction manual are electrostatic hand spray guns, model lp6000w/s/m which are to be used for manual paint spraying in a spray booth equipped with a power exhaust. This equipment is a manually operated spray gun used to apply paint to a grounded object. If there ...

Page 6: Outline Of The Equipment

- 3 - the electrostatic spray guns, lp6000w/sm, are to be used in combination with control unit exc lp and a paint supply system (pump, pressure tank, or circulating system). 1. A typical make up of an air electrostatic spray system: 2 outline of the equipment fig.1 an example of a system compositio...

Page 7

- 4 - 2. Main parts of 3. Names of main parts on material adjusting valve barrel pattern air adjusting valve power cable hook trigger grip paint hose (milky white color) pattern air adjusting valve material adjusting valve material adjusting valve hook barrel grip trigger paint hose (milky white col...

Page 8: Specifications

- 5 - air electrostatic spray gun model lp6000w/s/m maximum voltage to be charged dc -60kv shorting current 80μa fluid pressure normal 0 to 0,3mpa max. 0,62mpa air pressure normal 0.05 to 4mpa max. 0.62mpa air consumption max. 150l/min (normal) outside dimensions l207 × w55 × h219 (mm) weight (excl...

Page 9

- 6 - our distributor or ecco finishing ab..

Page 10: Features

- 7 - 1. Better maneuverability the pattern adjusting valve at left side of gun body allows quick and easy adjustment. Lighter weight and triggering provides less fatigue of workers. 2. High productivity in addition to conventional electrostatic spray nozzles, newly developed flat spray nozzles are ...

Page 11

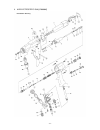

- 8 - 1. Air electrostatic gun [lp6000w] 5 breakdown drawing a b c.

Page 12

- 9 - air electrostatic gun lp6000w no part no. Part name qty note no part no. Part name qty note 1 6004 0330 60 body 1 36 6004 0330 85 e-shaped snap ring 1 2 6004 0330 61 grip end 1 *3 37 0663 9301 00 o-ring 1 3 6004 0330 62 connector 1 *3 38 0663 9302 00 o-ring 1 4 6004 0330 63 hose fitting 1 39 0...

Page 13

- 10 - 2. Air electrostatic gun [lp6000s] breakdown drawing C b a.

Page 14

- 11 - air electrostatic gun lp6000s no. Part № part name qty note no. Part № part name qty note 1 6004 0330 60 body 1 36 6004 0330 85 e-shaped snap ring 1 2 6004 0330 61 grip end 1 *3 37 0663 9301 00 o-ring 1 3 6004 0330 62 connector 1 *3 38 0663 9302 00 o-ring 1 4 6004 0330 63 hose fitting 2 39 06...

Page 15

- 12 - 3. Air electrostatic gun [lp6000m] breakdown drawing.

Page 16

- 13 - air electrostatic gun lp6000m no. Part № part name qty note no. Part № part name qty note 1 6004 0330 60 body 1 36 6004 0330 85 e-shaped snap ring 1 2 6004 0330 61 grip end 1 *3 37 0663 9301 00 o-ring 1 3 6004 0330 62 connector 1 *3 38 0663 9302 00 o-ring 1 4 6004 0330 63 hose fitting 2 39 06...

Page 17

- 14 - 4. Flat nozzle flat nozzle Ø1,6 no. Part no. Part name qty note no. Part no. Part name qty note 1 6004 0330 44 60 air cap 1 4 6004 0330 46 stopper ring 1 2 6004 0330 52 paint nozzle ( 1. 6) 1 5 6004 0330 47 charge electrode 1 3 6004 0330 45 retaining nut 1 flat nozzle Ø1,1 no. Part no. Part n...

Page 18: Installation

- 15 - the standard system composition with lp6000w/s/m guns are illustrated on fig. 1 (page 3). 1. Connection of air supply connect air supply hose to air regulator on the control unit. (g 1/4 fitting) 2. Connection of grounding wire securely connect a grounding wire to control unit. Phillips screw...

Page 19: Caution

- 16 - 3. Connection of the power cable to the spray gun after cleaning the metal connector at the end of power cable fixed to gun with clean cloth, connect it securely to output terminal (output) on the control unit. Attach the cable to the gun by tightening it manually. After the attachment, use a...

Page 20: Caution

- 17 - 4. Connection of air hose connect one end of the air hose to the nipple at rear side of the spray gun (next to power cable) and the other end to the air exit on the control unit and tighten (g 1/4 fitting). It is recommended that the spanner of 17mm be used. *the case in which two hoses are u...

Page 21: Caution

- 18 - 6. Cautions when banding l. V. Cable with hoses (1) in order to extend the life of the cable, follow the instructions on the cautions of banding the cable with the hoses. 1) do not band the connection cable at the length shorter than 70cm from the grip portion of the gun. 2) when banding the ...

Page 22: Caution

- 19 - 7. Assembly of nozzle with gun 1) fix and tighten together the nozzle joint and material nozzle. 2) put charging electrode into the material nozzle and fix nozzle joint to extension, tightening it with the spanner (hex. 10). 3) put the air cap in the holding nut and fix them to the barrel and...

Page 23: Safety Control

- 20 - in order to maintain safety of operation and good condition for the equipment, please note the following issues for care not only before and during but after operation. Securely ground the control unit. It is one of the most basic provisions for safety to ground the control unit, as grounding...

Page 24: Warning

- 21 - never use a metal brush to clean nozzles. Nozzles are vital parts of the coating equipment and may be easily damaged by the use of metal brushes, which can cause distorted paint atomization. When cleaning is required, use a bamboo brush provided in the tool kit supplied with the equipment. Al...

Page 25: Checking Before Operation

- 22 - 1. Checking high voltage generator (1) open the air valve and adjust the air pressure on the regulator to 0.3 to 0.4mpa to supply air to the system. Be sure that there is no air leakage from any hose connection. (2) holding gun grip, switch on power to control unit. Green pilot lamp should be...

Page 26: Operation

- 23 - 1. Preparation for operation (1) fill the paint supply system. The viscosity of the paint normally used for this equipment ranges in 9 to 30sec/fc #4, but not limited to viscosity. Consideration must me given to the type of paint and solvent, configuration of the part to be coated, required f...

Page 27: Caution

- 24 - 2. Starting operation (1) switch on the power to control unit. When trigger is pulled, red lamp is illuminated to indicate high voltage is applied at the gun head. High voltage is not generated when switch at gun grip is off. Before switching on the control unit, confirm again that the unit i...

Page 28: Caution

- 25 - (6) wipe off the nozzle and gun body and remove paint and dirt using solvent soaked cloth. To clean a flat spray nozzle, remove its air guide and to clean the round spray nozzle remove its air cap. Whenever coating work is curtailed, close the material adjusting valve on the gun body to preve...

Page 29: Maintenance

- 26 - 1. Spray gun (1) always keep spray gun clean. To clean the spray gun, do not dip the gun body into solvent. Hold it your hand and wash it carefully using a soft brush or cloth and solvent. Replace the gun cover before being heavily contaminated. High voltage is likely to leak through paint at...

Page 30: Caution

- 27 - 3. Paint hose and power cable (1) hose and cable should be kept clean from paint accumulation. (2) use caution not to damage hoses and cables with heavy objects or vehicles. Before any maintenance and/or service work, make sure that the power switch is turned off on the control unit and the a...

Page 31

- 28 - in cases where spray coating is unsatisfactory, the reasons for appearance defects may be complex and can be a combination of several factors. 1. Poor atomization possible causes solution (1) too low atomization air pressure (1) increase pressure. (2) too high paint output (2) decrease output...

Page 32

- 29 - 4. Tried stringy particles from the paint sticking to the nozzle, or pimples on coated surface possible causes solutions (1) too fast evaporating solvent (1) change to slower solvent or adjust with (2) higher viscosity of paint (2) lower the viscosity. 5. Pimples on coated surface possible ca...

Page 33

- 30 - 9. Poor hiding film possible causes solutions (1) insufficient paint output (1) adjust paint output, move gun faster and consider overlapping spray. (2) too low paint viscosity (2) adjust the viscosity. 10. Pinholes on coated surface possible causes solutions (1) contaminated atomizing air (1...

Page 34

- 31 - it is possible that the cause for trouble may be complex and could come from a combination of various problems. In the following descriptions, the numbers in column “ref. ” mean numbers of article and clause in this instruction manual where detailed methods for solutions are explained. For ex...

Page 35

- 32 - 4. Paint leaks from the barrel possible causes solutions ref. (1) defective packing and needle section (1) remove material output adjuster and replace the packing. 13 - 2 (2) insufficient tightening or seating of the guide (2) replace the guide. 13 - 2 5. Paint leaks from the nozzle even afte...

Page 36: Caution

- 33 - 9. Buzzer alarm sounds on the control unit (when no insulation stand is used). Possible causes solutions ref. (1) paint has accumulated on the gun extension. (1) clean the extension. 7 (2) paint has built up on the paint tube. (2) clean the paint tube. 7 (3) water has accumulated in the air p...

Page 37

- 34 - replacement or repair of parts should be done according to the following procedures. Before starting the work, be sure to shut off compressed air to the gun, switch off power to control unit, relieve paint pressure from the fluid passages in the system and clean all paint passages. (numbers i...

Page 38: Caution

- 35 - 2. Replacement of the material needle, material packing, air tappet and air packing (1) remove the hex. Socket screw 46 (03-70310) and pivot 31 (6004 0330 88) remove the trigger 52 (6004 0330 25). The hexagonal bar wrench of 3mm is required for this operation. (2) remove the adapter 22 (6004 ...

Page 39

- 36 - (4) loosen hex. Nut 50 (6004 0330 34), then replace the air seat 18 (6004 0330 83), tappet 14 (6004 0330 69), packing 17 (6004 0330 82), needle set 11(6004 0330 99) and o-ring 37 (0663 9301 00). *for lp6000w, 63, 64 65 and 66 are changed to 62, 63, 64 and 65, respectively. (5) insert a hex wr...

Page 40: Caution

- 37 - 3. Replacement of cascade (1) remove trigger taking the same steps as in 2 –(1). (2)-1 remove the tube 57 (6004 0330 18) connected to the bottom of the barrel. (2)-2 remove hex. Socket screw 61 (6004 0330 38), then remove nut 54 (6004 0330 24) and hose support 55(6004 0330 23). (3) remove fou...

Page 41

- 38 - (5) take out the cascade 7(6004 0330 97) from the barrel. The two o-rings 44(0663 9306 10) should be replaced. (6) care must be taken not to connect the colored wires to their responding terminals on the cascade. The precision philips screwdriver is required for this operation. (7) to assembl...

Page 42: Caution

- 39 - 4. Replacement of o-ring of the adjuster for pattern air (1) remove the adjust. (2) replace the o-ring 38 (0663 9302 00) at the tip of adjuster. Air leaked into the gun is discharged from the dial portion of the adjuster when the o-ring is damaged. If operation is continued without replacing ...

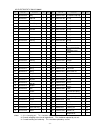

Page 43: Service Record

- 40 - shown below is a maintenance log format of a kind we recommend you to keep. Each time that you conduct a maintenance service, such as replacement of a part, tear-down cleaning, post-failure repair, etc., record the details. In the long run, you will find that such a log is very valuable in ke...

Page 44: Scope Of Warranty

- 41 - ecco finishing ab (the “company”) shall provide the original purchaser (the “purchaser”) with warranty service against defects in material or workmanship for a period of one (1) year from the date of purchase of the product, as follows: should you find defects in material or workmanship with ...

Page 45

Ecco finishing ab, box 93, s-532 22 skara, sweden tel: +46 (0)511-134 45, fax: +46 (0)511-180 13 e- mail: info@eccofinishing.Com • www.Eccofinishing.Com.