E e e e c c c ch h h h 2 2 2 2 o tec. O tec. O tec. O tec. Tm watermakers modular series (belt driven) 200-bms-1 / 400-bms-2 / 500-bml-1 600-bms-3 / 800-bms-4 / 900-bml-2 1200-bml-3 / 1500-bml-4 owners manual pages 2 introduction 3 specifications 4-5 standard system features, options and accessories...

Introduction thank you for choosing an ech 2 o tec. Reverse osmosis watermaker. We trust that you will be completely satisfied with our product. Ech 2 o tec watermakers are manufactured by echo-marine as a result of many years of experience installing, servicing and modifying all brands of watermake...

Specifications (belt driven) rated performance: ech 2 o tec. 200 – bms-1 8 gallons / 30ltr. / hour 400 – bms-2 16 gallons / 60ltr. / hour 500 – bml-1 20 gallons / 76ltr. / hour 600 – bms-3 24 gallons / 90ltr. / hour 800 – bms-4 33 gallons / 126ltr. / hour 900 – bml-2 38 gallons / 143ltr. / hour 1200...

Standard system features 1) 1 pvc sea strainer 2 3/4” barbed hose connectors straight 2) 1 filter housing with 20 micron pre filter cartridge (without boost pump) or 2 filter housings with 5 and 20-micron pre filter cartridges (with boost pump) 1 stainless steel bracket with 8 screws. 1 20micron car...

Available options and accessories if the high-pressure pump is installed less than 1 foot under the waterline or an additional 5-micron pre-filter is added, the installation of an optional boost pump is recommended. Boost pump (3/4” intake hose barb, 5/8” outlet hose barb, 4 feet / 1.2 meter 3/4” wi...

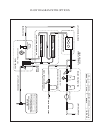

Flow diagram with options control p anel freshw a teroutlet exsisting freshw a tert ank freshw a terint ake sea w a terinlet system modular-series ech ot ec. 2 watermakers da te 31/05/06 rev . 3.1 dr wn ms boost pump freshw a terflushfil ter fil ter strainer fil ter pump fil ter 5 µ 20 µ psi psi flo...

Installation instructions (belt driven) high pressure pump to minimize vibration, it is best to build brackets on the motor itself, similar to alternator brackets. Use cardboard to construct a pattern first before making these brackets. The high-pressure pump has a maximum rpm of 1750. The recommend...

Control panel mount the control panel in an easily accessible location as close as possible to the membrane housing(s). Sea strainer mount the sea strainer with the provided 3/4" npt nylon nipple directly to the intake of the 20micron pre-filter housing. If an optional boost pump is required (refer ...

Run one of the high-pressure hoses from the output of the hp pump (o ring sealed fitting) to the o ring sealed fitting at the end of the membrane that is marked in. A minimum hose length of 3 feet/1m is required for pulsation dampening. The hose can be coiled where needed. Run the second high-pressu...

Installation instruction (options) boost pump install the boost pump with the motor up or sideways in a dry location below the water line, in between the sea strainer and the pre-filter(s). The intake is at the center of the pump. Avoid elbows/90 degree fittings in your plumbing. The complete pump h...

System operation instructions the reverse osmosis membrane contains a preservative solution to prevent microbiological growth. If ingested, may cause irritation of the gastro-intestinal tract, colic, diarrhea, or other similar symptoms. Therefore, discard all the product water for at least thirty mi...

Fresh water flush procedure caution: the fresh water pressure should not exceed the range of the low pressure gauge/s. The installation of a pressure reducer may be necessary. If you don’t use your watermaker for the next three days, you will need to flush your system with fresh water or infuse a bi...

Membrane cleaning procedure the echo tec. Watermaker must be chemically cleaned when the product water output drops by 15% of the specified amount. The frequency of this occurring will vary greatly depending upon feed water. Fouling of the membrane will naturally occur during normal usage of the ech...

Maintenance timetable the following maintenance timetable is an estimate of the time intervals at which maintenance may be required only. This schedule must be adjusted to the regularity of usage, the condition of the intake water, the length of time the system is exposed to seawater and the total r...

Membrane changing procedure pressure vessel end plug changing procedure 1) remove the product port (if installed) and the high pressure fitting. 2) remove the two/three m6 bolts. 3) remove the two/tree locking plates (locks) 4) remove the backing plate 5) pull the end plug with the aid of a hand tig...

High pressure pump system troubleshooting guide malfunction cause remedy the pressure and/or the product amount drops broken valve spring belt slippage (bml series) fouled inlet strainer fouled pre-filter(s) cavitation (noisy operation) air in system replace spring tighten or replace belt clean stra...

High pressure pump repair instruction series ep-12-34 / ep-14-34 / ep-17-34 disassembly sequence of the front end of the ech 2 o tec. High-pressure pump. Refer to the pump diagram. 1) remove the three discharge valve plugs and the three inlet valve plugs (32), with a 22 mm socket wrench. Inspect the...

5) should you find it necessary to service the plunger assembly (16), you can do so by removing the tension screw (16d). Inspect all parts and replace as necessary. Note: in order to drive the pump from the side opposite the present shaft extension, simply remove the valve casing from the crankcase ...

Ech 2 o tec. Watermaker limited warranty echo marine ltd. For a period of thirty-six (36) months from the date of shipment that the echo tec. Watermaker will perform according to specifications. The triplex plunger high-pressure pump and the high pressure vessel/s are guaranteed for life to the orig...

The echo tec. Membrane element is guaranteed to be cleanable for a minimum of one year from date of shipment, provided that cleaning instructions are adhered to and foulant is acid soluble metal hydroxides and calcium carbonates or alkaline soluble organic, inorganic substances and microbiological s...