Prothatch attachment operator's manual model 99944200563 models used on: srm-2400sb srm-260sb/261sb pas-2400 pas-2601 pas-230/231 pas-260/261 pas-265/266 pas-280 x7702093503 x770001303 10/12 warning users of this equipment risk injury to themselves and others if the unit is used im- properly and/or ...

2 copyright© 2012 by echo, incorporated all rights reserved. T able of c ontents introduction .................................................................... 2 - the operator's manual ........................................... 2 safety .............................................................

P ro t hatch a ttachment o perator ' s m anual 3 warning refer to your pro attachment series or split boom operator's manual for correct engine fueling, starting and stop- ping instructions. Manual safety symbols and important information throughout this manual and on the product itself, you will fi...

4 vibration and cold -- it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sen- sations followed by loss of color and numbn...

P ro t hatch a ttachment o perator ' s m anual 5 danger do not operate this product indoors or in inadequately ventilated areas. Engine exhaust contains poisonous emissions and can cause serious injury or death. Read the manuals • provide all users of this equipment with the operator's manual for in...

6 equipment warning use this attachment with echo approved models only. Serious injury may result from the use of this attachment combined with a non approved echo product. Before operation a complete check of the unit must be performed; • check unit for loose/missing nuts, bolts and screws. Tighten...

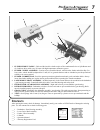

P ro t hatch a ttachment o perator ' s m anual 7 1. Flexible drive cable - cable end fits into drive shaft coupler of pro attachment series or split boom mod- els. Lubricate drive cable every 25 hours with high temperature automotive grease. 2. Fender / wheel assembly - consists of pre-assembled whe...

8 a ssembly a a lower drive shaft assembly to dethatcher gear housing parts required: dethatcher gear housing, lower drive shaft with fender / wheel assembly 1. Place dethatcher gear housing on a flat surface with gear housing shaft mount at 45 ° angle. 2. Remove gear housing shaft alignment screw (...

P ro t hatch a ttachment o perator ' s m anual 9 a b c d 4. Install and seat lower drive shaft end (end with fender/wheel as- sembly into gear housing shaft mount. Make sure grass guide (d) is facing down toward the ground. 5. Rotate and align hole in drive shaft housing with gear housing shaft hole...

10 parts required: pas or srm-sb power head w/shaft & coupling. 1. Set power head/shaft assembly on a level surface. 2. Pull locator pin (a) out, and turn counter-clockwise 1/4 turn to lock-out position. 3. Remove vinyl cap from attachment drive shaft. 4. Remove cardboard spacer, if necessary. 5. Ca...

P ro t hatch a ttachment o perator ' s m anual 11 important do not rotate wheels against tines. Wheels and tines will be dam- aged during operation. If wheel rotation is not sufficient to provide proper wheel height clear- ance then perform these additional steps: 4. Loosen two upper wheel bracket b...

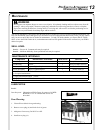

12 dethatching information thatch is a normal buildup of grass and leaf clippings around the base of grass stems. Excessive thatch prevents air, wa- ter and nutrients from reaching the root system, increasing the probability of lawn disease from mold spore and insects. When excessive thatch is remov...

P ro t hatch a ttachment o perator ' s m anual 13 lubrication level 1. Parts required: lithium-based ep00 grease for gearcase; power blendx tm 8 oz. Or lithium base grease for driveshaft gear housing 1. Clean all loose debris from gear housing. 2. Remove screw plug (a) and check level of grease. 3. ...

14 drive shaft (lower) 1. Remove gear housing locator screw (a). 2. Loosen gear housing mounting bolt (b). 3. Pull gear box from drive shaft housing. 4. Pull flexible cable from the drive shaft housing, wipe clean and re-coat with a thin coating [15 ml (1/2 oz.)] of grease 5. Slide the flexible cabl...

P ro t hatch a ttachment o perator ' s m anual 15 tine replacement (outer five (5) rows from open reel end) 1. Hold inner tine mounting bolt from turning with 13 mm wrench inserted through open reel end. 2. Grip plastic sleeve at the base of the tine firmly with vice grip. Re- move tine from bolt tu...

16 s torage 1. Clean dethatcher attachment with a bristle brush and rinse with clear water. Important do not immerse this attachment in water. Water will enter gear housing and damage gears, bearings and seals. 2. Apply thin coating of oil to metal parts to prevent rust. 3. Lubricate lower shaft ass...

P ro t hatch a ttachment o perator ' s m anual 17 notes.

18 notes.

P ro t hatch a ttachment o perator ' s m anual 19 notes.

Echo, incorporated 400 o akwood r oad l ake z urich , il 60047-1564 www . Echo - usa . Com s ervicing i nformation parts / serial number genuine echo parts and echo repower™ parts and assem- blies for your echo products are available only from an authorized echo dealer. When you do need to buy parts...