Echo CS-610 Service Data

INTRODUCTION

We are constantly working on technical im-

provement of our products. For this reason,

technical data, equipment and design are

subject to change without notice. All speci-

fications and directions in this SERVICE

DATA are based on the latest product infor-

mation available at the time of publication.

ECHO SERVICE MANUAL Ord. 401-31

(Model : CS-600) contains lots of informa-

tion for servicing this model.

SERVICE DATA

CHAIN SAW

ECHO:

CS-610

STAGE MODEL

(Serial number : 37000001 and after)

CONTENTS

page

1 SERVICE INFORMATION .............................. 2

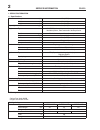

1-1 Specifi cation ............................................... 2

1-2 Technical data ............................................. 3

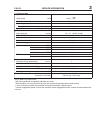

1-3 Torque limits................................................ 4

1-4 Special repairing materials ......................... 5

1-5 Service limits............................................... 6

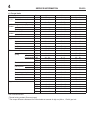

1-6 Special tools ............................................... 7

2 CARBURETTOR ADJUSTMENT PROCEDURE .. 8

2-1 General adjusting rules ............................... 8

2-2 Presetting Idle adjust screw, L mixture needle

and H mixture needle ....................................... 8

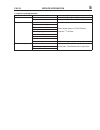

2-3 Adjusting carburettor................................. 10

Reference No.

01-59D-00

I S S U E D : 2 0 1 2 0 1

CS-610

01-59D-00

1

0