- DL manuals

- Echo

- Drill

- EDR-2400

- Operator's Manual

Echo EDR-2400 Operator's Manual

Summary of EDR-2400

Page 1

Warning danger read instructions carefully and follow rules for safe operation. Failure to do so could result in serious injury. Operator’s manual engine drill edr-2400

Page 2

2 introduction echo engine drill edr-2400 is a lightweight, high performance, two-stroke engined unit designed for drilling. Do not use this unit for any purpose other than aforementioned. This manual provides the information necessary for operation and maintenance. Specifications, descriptions and ...

Page 3

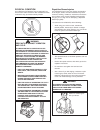

3 symbol form/shape symbol description/application symbol form/shape symbol description/application carefully read the operator’s manual wear eyes, ears and head protection emergency stop petrol and oil mixture decals and symbols hot surface objects danger this symbol accompanied by the word “danger...

Page 4

4 • do all drilling at full throttle speed. Drilling at less at than full speed can damage the clutch by allowing it to slip. Warning use a firm grip with thumbs and fingers encircling the handles. A firm grip will help you keep control of the engine drill. Never operate the engine drill only one ha...

Page 5

5 warning precaution against vibration and cold it is believed that a condition called raynaud’s phenomenon, which affects the fingers of certain individuals may be brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sensations followed by l...

Page 6

6 • when starting to drill, run the engine at full throttle. Warning before drilling, be sure to read and understand the entire operator’s manual to avoid the chance of serious injury. • do not force the drills and only move as quickly as the drills will allow. • stop the engine and disconnect from ...

Page 7

7 description 1. Operator’s manual - included with unit. Read before operation and keep for future reference to learn proper, safe operating techniques. 2. Throttle trigger - device activated by the operator’s finger, for controlling the engine speed. 3. Rear handle - handle located furthest from th...

Page 8

8 assembling • insert the front handle to the machine, and turn clockwise. (tighten the screw firmly) - to operate front handle with right hand, remove right plug then reverse sides when installing handle and plug. Front handle front handle drill bit • loosen the chuck and insert the drill bit (not ...

Page 9

9 on stop throttle trigger handling fuel danger after refuelling, tighten fuel cap firmly and check for leakage. In case of fuel leakage, repair before starting operation since there is a danger of fire. • never smoke or allow flame or sparks near fuel. • always fill the fuel tank outdoors. Never po...

Page 10

10 reverse rotation • this model is equipped with reverse rotation mechanism. • when drilling, set shift lever down to clockwise rotation position. • if bit is locked due to deep penetration during drilling operation, set shift lever up to anticlockwise rotation position and operate reversed for eas...

Page 11

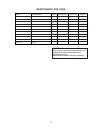

11 important time intervals are maximum. Actual use and your experience will determine the frequency of required maintenance. Record dates of monthly and yearly inspections. Maintenance and care area maintenance page before use monthly yearly air filter clean/replace 13 • fuel filter inspect/clean/r...

Page 12

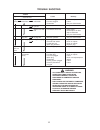

12 trouble shooting engine engine cranks engine does not crank engine runs trouble - hard to start - does not start fuel at carburettor fuel at cylinder spark at end of plug wire spark at plug dies or accelerates poorly no fuel at carburettor no fuel at cylinder silencer wet with fuel no spark at en...

Page 13

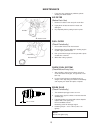

13 maintenance air filter (before each use) 1. Remove air cleaner cover and pull out air filter. 2. Lightly brush off dust or wash it in water and detergent. 3. Dry completely before putting it back in place. Fuel filter fuel tank cap spark plug (check periodically) 1. The standard spark gap is 0.6 ...

Page 14

14 replacement of chuck replacement of chuck should be done in the following manner: 1. Fit 19 mm spanner onto driving axle and keep it fitted. 2. Remove bolt with hexagonal hole fixed in the driving axle. 3. Insert accessory hexagonal bar (part number 895412-20960) into chuck and fix. 4. Fit 10 mm ...

Page 15

15 storage long term storage (over 30 days) warning do not store in an enclosure where fuel fumes may accumulate or reach an open flame or spark. Do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following: ...

Page 16

16 mass : unit without specified drill bit, empty tank kg 4.7 unit with specified drill bit, full tank kg 5.6 volume : fuel tank l 0.45 drill : size mm 32 - 178 chuck capacity mm 13 speed r/min 520 mission : reduction ratio 17.1 (regular side) 18.6 (reverse side) lubrication grease external dimensio...

Page 17

17 memorandum.

Page 18

18 memorandum.

Page 19

19 memorandum.

Page 20

7-2 suehirocho 1-chome, ohme, tokyo 198-8760, japan phone: 81-428-32-6118. Fax: 81-428-32-6145. X750-016 94 0 x750 409-420 0 © 2010 printed in japan 1006a 0099 es.